Exploring AI applications in gate valve fault diagnosis

AUG 20, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

AI in Valve Diagnostics: Background and Objectives

Gate valves are critical components in various industrial processes, playing a vital role in controlling fluid flow and ensuring operational safety. As industries increasingly embrace digital transformation, the application of Artificial Intelligence (AI) in gate valve fault diagnosis has emerged as a promising field of research and development. This technological advancement aims to enhance the reliability, efficiency, and safety of industrial operations by leveraging AI's capabilities in data analysis, pattern recognition, and predictive modeling.

The evolution of gate valve fault diagnosis techniques has progressed from traditional manual inspections to more sophisticated sensor-based monitoring systems. However, these conventional methods often fall short in detecting subtle anomalies or predicting potential failures before they occur. This limitation has paved the way for AI-driven solutions, which offer the potential to revolutionize valve diagnostics through real-time monitoring, early fault detection, and predictive maintenance strategies.

The primary objective of exploring AI applications in gate valve fault diagnosis is to develop intelligent systems capable of accurately identifying, classifying, and predicting valve failures. These systems aim to minimize downtime, reduce maintenance costs, and prevent catastrophic failures in industrial processes. By harnessing the power of machine learning algorithms and advanced data analytics, AI-driven diagnostics can process vast amounts of sensor data, identify complex patterns, and generate actionable insights for maintenance teams.

Another crucial goal is to enhance the overall reliability and longevity of gate valves through AI-enabled predictive maintenance. By continuously analyzing valve performance data and identifying early signs of degradation, AI systems can help optimize maintenance schedules, extend equipment lifespan, and improve overall plant efficiency. This proactive approach to valve management represents a significant shift from reactive maintenance practices, potentially leading to substantial cost savings and improved operational safety.

Furthermore, the integration of AI in valve diagnostics seeks to address the growing complexity of industrial processes and the increasing demand for real-time decision support. As industrial systems become more interconnected and data-driven, AI-powered diagnostic tools can provide operators with valuable insights and recommendations, enabling faster and more informed decision-making in critical situations.

The development of AI applications in this field also aims to overcome the challenges associated with human expertise limitations and the shortage of skilled technicians. By capturing and codifying expert knowledge into AI models, these systems can potentially augment human capabilities, providing consistent and reliable diagnostic support across various operational scenarios.

The evolution of gate valve fault diagnosis techniques has progressed from traditional manual inspections to more sophisticated sensor-based monitoring systems. However, these conventional methods often fall short in detecting subtle anomalies or predicting potential failures before they occur. This limitation has paved the way for AI-driven solutions, which offer the potential to revolutionize valve diagnostics through real-time monitoring, early fault detection, and predictive maintenance strategies.

The primary objective of exploring AI applications in gate valve fault diagnosis is to develop intelligent systems capable of accurately identifying, classifying, and predicting valve failures. These systems aim to minimize downtime, reduce maintenance costs, and prevent catastrophic failures in industrial processes. By harnessing the power of machine learning algorithms and advanced data analytics, AI-driven diagnostics can process vast amounts of sensor data, identify complex patterns, and generate actionable insights for maintenance teams.

Another crucial goal is to enhance the overall reliability and longevity of gate valves through AI-enabled predictive maintenance. By continuously analyzing valve performance data and identifying early signs of degradation, AI systems can help optimize maintenance schedules, extend equipment lifespan, and improve overall plant efficiency. This proactive approach to valve management represents a significant shift from reactive maintenance practices, potentially leading to substantial cost savings and improved operational safety.

Furthermore, the integration of AI in valve diagnostics seeks to address the growing complexity of industrial processes and the increasing demand for real-time decision support. As industrial systems become more interconnected and data-driven, AI-powered diagnostic tools can provide operators with valuable insights and recommendations, enabling faster and more informed decision-making in critical situations.

The development of AI applications in this field also aims to overcome the challenges associated with human expertise limitations and the shortage of skilled technicians. By capturing and codifying expert knowledge into AI models, these systems can potentially augment human capabilities, providing consistent and reliable diagnostic support across various operational scenarios.

Market Demand Analysis for AI-Powered Valve Monitoring

The market demand for AI-powered valve monitoring solutions has been steadily increasing in recent years, driven by the growing need for improved efficiency, reliability, and safety in industrial processes. Industries such as oil and gas, chemical manufacturing, power generation, and water treatment are particularly interested in adopting these advanced technologies to enhance their operations.

One of the primary factors fueling this demand is the potential for significant cost savings through predictive maintenance. By implementing AI-driven fault diagnosis systems for gate valves, companies can reduce unplanned downtime, extend equipment lifespan, and optimize maintenance schedules. This proactive approach to maintenance can lead to substantial reductions in operational costs and improved overall plant efficiency.

Safety considerations also play a crucial role in driving market demand for AI-powered valve monitoring. In industries where valve failures can lead to catastrophic consequences, such as chemical spills or explosions, the ability to detect and predict potential faults before they occur is invaluable. This enhanced safety aspect not only protects personnel and assets but also helps companies comply with increasingly stringent regulatory requirements.

The push for digital transformation across industries is another key factor contributing to the growing demand for AI-based valve monitoring solutions. As companies seek to leverage data-driven insights to improve their operations, the integration of AI technologies into existing infrastructure becomes increasingly attractive. This trend is particularly evident in the concept of "smart factories" and Industry 4.0 initiatives, where real-time monitoring and predictive analytics are essential components.

Market research indicates that the global valve monitoring market is expected to experience substantial growth in the coming years. This growth is attributed to the increasing adoption of Industrial Internet of Things (IIoT) technologies and the rising demand for process automation across various industries. The integration of AI capabilities into these monitoring systems is seen as a natural progression, offering enhanced diagnostic accuracy and predictive capabilities.

However, the market for AI-powered valve monitoring is not without challenges. Many potential customers face barriers such as high initial implementation costs, concerns about data security, and the need for specialized expertise to manage these advanced systems. Additionally, there is often resistance to change within organizations, particularly in industries with long-established operational practices.

Despite these challenges, the overall market outlook remains positive. As AI technologies continue to mature and become more accessible, and as success stories from early adopters become more widespread, the demand for AI-powered valve monitoring solutions is expected to accelerate. This trend is likely to be further reinforced by the ongoing focus on operational excellence, sustainability, and regulatory compliance across industries.

One of the primary factors fueling this demand is the potential for significant cost savings through predictive maintenance. By implementing AI-driven fault diagnosis systems for gate valves, companies can reduce unplanned downtime, extend equipment lifespan, and optimize maintenance schedules. This proactive approach to maintenance can lead to substantial reductions in operational costs and improved overall plant efficiency.

Safety considerations also play a crucial role in driving market demand for AI-powered valve monitoring. In industries where valve failures can lead to catastrophic consequences, such as chemical spills or explosions, the ability to detect and predict potential faults before they occur is invaluable. This enhanced safety aspect not only protects personnel and assets but also helps companies comply with increasingly stringent regulatory requirements.

The push for digital transformation across industries is another key factor contributing to the growing demand for AI-based valve monitoring solutions. As companies seek to leverage data-driven insights to improve their operations, the integration of AI technologies into existing infrastructure becomes increasingly attractive. This trend is particularly evident in the concept of "smart factories" and Industry 4.0 initiatives, where real-time monitoring and predictive analytics are essential components.

Market research indicates that the global valve monitoring market is expected to experience substantial growth in the coming years. This growth is attributed to the increasing adoption of Industrial Internet of Things (IIoT) technologies and the rising demand for process automation across various industries. The integration of AI capabilities into these monitoring systems is seen as a natural progression, offering enhanced diagnostic accuracy and predictive capabilities.

However, the market for AI-powered valve monitoring is not without challenges. Many potential customers face barriers such as high initial implementation costs, concerns about data security, and the need for specialized expertise to manage these advanced systems. Additionally, there is often resistance to change within organizations, particularly in industries with long-established operational practices.

Despite these challenges, the overall market outlook remains positive. As AI technologies continue to mature and become more accessible, and as success stories from early adopters become more widespread, the demand for AI-powered valve monitoring solutions is expected to accelerate. This trend is likely to be further reinforced by the ongoing focus on operational excellence, sustainability, and regulatory compliance across industries.

Current AI Technologies in Industrial Fault Diagnosis

Artificial Intelligence (AI) has made significant strides in industrial fault diagnosis, revolutionizing the way industries approach maintenance and quality control. In the context of gate valve fault diagnosis, several AI technologies have emerged as powerful tools for detecting, predicting, and analyzing potential issues.

Machine Learning (ML) algorithms, particularly supervised learning techniques, have been widely adopted for fault classification in gate valves. These algorithms, such as Support Vector Machines (SVM) and Random Forests, can be trained on historical data to recognize patterns associated with different types of valve failures. By analyzing sensor data, vibration patterns, and other operational parameters, ML models can accurately identify and categorize faults, enabling proactive maintenance strategies.

Deep Learning, a subset of ML, has shown remarkable potential in handling complex fault diagnosis scenarios. Convolutional Neural Networks (CNNs) have been successfully applied to analyze acoustic emissions and vibration signals from gate valves, detecting subtle anomalies that might escape traditional analysis methods. Recurrent Neural Networks (RNNs) and Long Short-Term Memory (LSTM) networks have proven effective in capturing temporal dependencies in valve operation data, facilitating the prediction of impending failures.

Fuzzy Logic systems have been integrated into fault diagnosis frameworks, addressing the inherent uncertainties in industrial processes. These systems can handle imprecise input data and expert knowledge, making them particularly useful in situations where clear-cut boundaries between normal and faulty operations are difficult to define. Fuzzy logic-based approaches have shown promise in diagnosing complex gate valve faults that involve multiple interacting factors.

Expert Systems, leveraging rule-based AI, continue to play a crucial role in gate valve fault diagnosis. These systems encapsulate domain expertise in a set of if-then rules, allowing for transparent and explainable fault detection. When combined with machine learning techniques, expert systems can provide a hybrid approach that balances data-driven insights with human expertise.

Data fusion techniques have gained traction in recent years, enabling the integration of multiple data sources for more comprehensive fault diagnosis. By combining sensor data, historical maintenance records, and operational parameters, AI algorithms can provide a holistic view of valve health, improving the accuracy and reliability of fault detection.

Reinforcement Learning (RL) is an emerging area in industrial fault diagnosis, with potential applications in optimizing maintenance schedules for gate valves. RL algorithms can learn optimal policies for inspection and maintenance, balancing the trade-offs between operational costs and system reliability.

As these AI technologies continue to evolve, their integration with Industrial Internet of Things (IIoT) platforms is creating new possibilities for real-time monitoring and predictive maintenance of gate valves. This convergence is paving the way for more intelligent, efficient, and reliable industrial processes, ultimately enhancing the safety and productivity of valve-dependent operations.

Machine Learning (ML) algorithms, particularly supervised learning techniques, have been widely adopted for fault classification in gate valves. These algorithms, such as Support Vector Machines (SVM) and Random Forests, can be trained on historical data to recognize patterns associated with different types of valve failures. By analyzing sensor data, vibration patterns, and other operational parameters, ML models can accurately identify and categorize faults, enabling proactive maintenance strategies.

Deep Learning, a subset of ML, has shown remarkable potential in handling complex fault diagnosis scenarios. Convolutional Neural Networks (CNNs) have been successfully applied to analyze acoustic emissions and vibration signals from gate valves, detecting subtle anomalies that might escape traditional analysis methods. Recurrent Neural Networks (RNNs) and Long Short-Term Memory (LSTM) networks have proven effective in capturing temporal dependencies in valve operation data, facilitating the prediction of impending failures.

Fuzzy Logic systems have been integrated into fault diagnosis frameworks, addressing the inherent uncertainties in industrial processes. These systems can handle imprecise input data and expert knowledge, making them particularly useful in situations where clear-cut boundaries between normal and faulty operations are difficult to define. Fuzzy logic-based approaches have shown promise in diagnosing complex gate valve faults that involve multiple interacting factors.

Expert Systems, leveraging rule-based AI, continue to play a crucial role in gate valve fault diagnosis. These systems encapsulate domain expertise in a set of if-then rules, allowing for transparent and explainable fault detection. When combined with machine learning techniques, expert systems can provide a hybrid approach that balances data-driven insights with human expertise.

Data fusion techniques have gained traction in recent years, enabling the integration of multiple data sources for more comprehensive fault diagnosis. By combining sensor data, historical maintenance records, and operational parameters, AI algorithms can provide a holistic view of valve health, improving the accuracy and reliability of fault detection.

Reinforcement Learning (RL) is an emerging area in industrial fault diagnosis, with potential applications in optimizing maintenance schedules for gate valves. RL algorithms can learn optimal policies for inspection and maintenance, balancing the trade-offs between operational costs and system reliability.

As these AI technologies continue to evolve, their integration with Industrial Internet of Things (IIoT) platforms is creating new possibilities for real-time monitoring and predictive maintenance of gate valves. This convergence is paving the way for more intelligent, efficient, and reliable industrial processes, ultimately enhancing the safety and productivity of valve-dependent operations.

Existing AI Solutions for Gate Valve Fault Detection

01 AI-based fault diagnosis in electrical systems

Artificial intelligence techniques are applied to diagnose faults in electrical systems, such as power grids and electronic circuits. These methods use machine learning algorithms to analyze sensor data, identify anomalies, and predict potential failures, improving system reliability and maintenance efficiency.- AI-based fault diagnosis in industrial systems: Artificial intelligence techniques are applied to detect and diagnose faults in complex industrial systems. These methods use machine learning algorithms to analyze sensor data, identify anomalies, and predict potential failures. This approach enhances the reliability and efficiency of industrial processes by enabling proactive maintenance and reducing downtime.

- AI-driven fault diagnosis in power systems: AI applications are utilized for fault diagnosis in power systems, including electrical grids and power distribution networks. Machine learning models are trained to analyze electrical parameters, detect irregularities, and identify the root causes of faults. This technology improves the stability and reliability of power systems by enabling rapid fault detection and resolution.

- AI-enhanced fault diagnosis in telecommunications: Artificial intelligence is employed to diagnose faults in telecommunications networks and systems. AI algorithms process large volumes of network data to identify issues, predict potential failures, and recommend corrective actions. This approach improves network reliability, reduces downtime, and enhances the overall quality of service in telecommunications infrastructure.

- AI-based fault diagnosis in automotive systems: AI techniques are applied to diagnose faults in automotive systems, including engine management, transmission, and electronic control units. Machine learning models analyze sensor data and vehicle performance metrics to identify malfunctions and predict potential failures. This technology enhances vehicle reliability, improves maintenance scheduling, and reduces repair costs.

- AI applications in medical fault diagnosis: Artificial intelligence is utilized in medical fault diagnosis to analyze medical imaging, patient data, and clinical information. AI algorithms assist healthcare professionals in identifying anomalies, detecting diseases, and predicting potential health issues. This application of AI improves diagnostic accuracy, enables early detection of medical conditions, and enhances patient care outcomes.

02 Machine learning for predictive maintenance

Machine learning models are employed to predict equipment failures and optimize maintenance schedules. By analyzing historical data and real-time sensor information, these systems can detect early signs of degradation and recommend preventive actions, reducing downtime and maintenance costs.Expand Specific Solutions03 AI-driven fault diagnosis in industrial processes

AI applications are used to diagnose faults in complex industrial processes. These systems utilize deep learning and pattern recognition techniques to analyze process data, identify root causes of failures, and suggest corrective actions, enhancing overall process efficiency and product quality.Expand Specific Solutions04 Intelligent fault diagnosis in automotive systems

AI-powered fault diagnosis systems are implemented in automotive applications to detect and diagnose vehicle malfunctions. These systems use sensor data and machine learning algorithms to identify issues in various vehicle subsystems, improving vehicle reliability and reducing maintenance time.Expand Specific Solutions05 AI for network fault diagnosis and security

Artificial intelligence techniques are applied to diagnose faults and detect security threats in computer networks. These systems use machine learning algorithms to analyze network traffic patterns, identify anomalies, and predict potential failures or security breaches, enhancing network reliability and cybersecurity.Expand Specific Solutions

Key Players in AI-Driven Valve Diagnostics

The AI application in gate valve fault diagnosis is in an early development stage, with a growing market as industries seek to enhance operational efficiency and reduce downtime. The technology's maturity is still evolving, with major players like Siemens AG, Toyota Motor Corp., and Rolls-Royce Plc investing in research and development. Companies such as SUPCON Technology Co., Ltd. and Wipro Ltd. are also entering this space, focusing on integrating AI with industrial automation. The competitive landscape is diverse, including both established industrial giants and emerging tech firms, indicating a dynamic market with significant growth potential.

SUPCON Technology Co., Ltd.

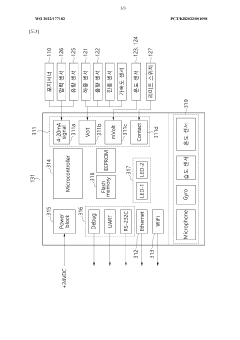

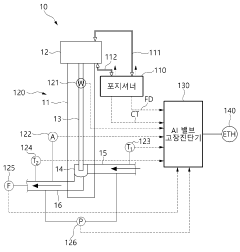

Technical Solution: SUPCON Technology has developed an AI-based fault diagnosis system for gate valves that focuses on the process automation and control industry. Their solution utilizes a hybrid approach, combining traditional rule-based systems with advanced machine learning techniques. The AI application employs a multi-layer perceptron neural network to analyze various parameters such as valve position, pressure differentials, and flow rates[7]. SUPCON's system also incorporates fuzzy logic to handle uncertainties in sensor data and process conditions. The fault diagnosis algorithm is designed to detect both sudden failures and gradual degradation of valve performance. Additionally, the system includes a user-friendly interface that provides real-time visualization of valve health status and generates detailed diagnostic reports. SUPCON's AI solution is particularly well-suited for complex chemical processes and power generation applications where valve reliability is critical[8].

Strengths: Hybrid approach combining traditional and AI methods, focus on process automation industry, and user-friendly interface. Weaknesses: May require fine-tuning for specific industrial processes and could have limitations in handling very rare or previously unseen fault types.

Fisher Controls International LLC

Technical Solution: Fisher Controls has developed an AI-driven fault diagnosis system for gate valves that utilizes machine learning algorithms to analyze sensor data in real-time. The system employs a combination of vibration analysis, acoustic emissions, and pressure readings to detect and classify various fault types[1]. By leveraging deep learning models, the system can identify subtle patterns indicative of valve degradation or imminent failure. The AI application also incorporates predictive maintenance capabilities, allowing for proactive scheduling of maintenance activities based on the valve's predicted health status[3]. This approach significantly reduces downtime and improves overall system reliability in industrial processes.

Strengths: Comprehensive fault detection, real-time analysis, and predictive maintenance capabilities. Weaknesses: May require extensive training data for accurate predictions and could be sensitive to sensor quality and placement.

Core AI Innovations in Valve Fault Diagnosis

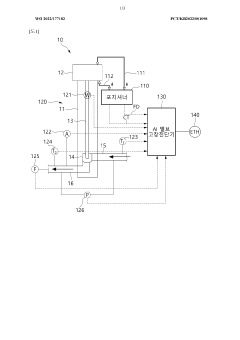

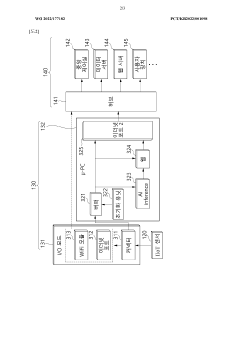

Artificial intelligence valve failure prediction and diagnosis system of automatic valve

PatentWO2022177182A1

Innovation

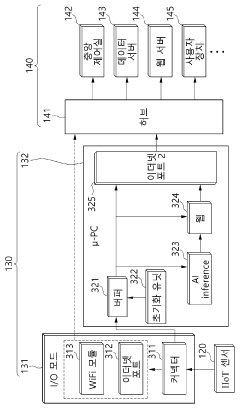

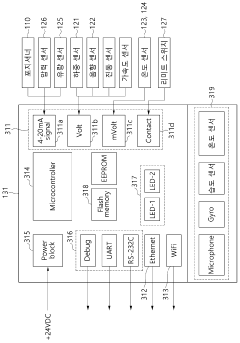

- An edge-based artificial intelligence valve failure prediction and diagnosis system using IIoT sensors and an auto encoder deep learning algorithm, which predicts and diagnoses valve failures in real-time without stopping the process, by learning normal operation patterns and detecting anomalies through a network of sensors and a management center.

Prediction failure diagnosis system for automatic valve using artificial intelligence

PatentPendingKR1020220120456A

Innovation

- An AI-based valve failure prediction system with IIoT sensors and edge computing that infers and analyzes valve signals in real-time using auto-encoder deep learning, allowing continuous operation and predicting failures without process interruption.

Regulatory Framework for AI in Industrial Diagnostics

The regulatory framework for AI in industrial diagnostics, particularly in the context of gate valve fault diagnosis, is a complex and evolving landscape. As AI technologies continue to advance and find applications in critical industrial processes, regulatory bodies are working to establish guidelines that ensure safety, reliability, and ethical use of these systems.

In the United States, the National Institute of Standards and Technology (NIST) has been at the forefront of developing AI standards and guidelines. Their AI Risk Management Framework provides a structure for organizations to assess and mitigate risks associated with AI systems, including those used in industrial diagnostics. This framework emphasizes the importance of transparency, accountability, and fairness in AI applications.

The European Union has taken a proactive approach with the proposed AI Act, which aims to categorize AI systems based on their risk levels. Industrial diagnostic systems, including those for gate valve fault detection, would likely fall under the "high-risk" category due to their potential impact on safety and critical infrastructure. This classification would require rigorous testing, documentation, and human oversight.

In the specific context of gate valve fault diagnosis, regulatory considerations extend beyond AI-specific regulations to include industry standards such as ISO 55000 for asset management and IEC 61508 for functional safety of electrical/electronic/programmable electronic safety-related systems. These standards provide a foundation for integrating AI technologies into existing industrial safety and reliability frameworks.

Regulatory bodies are also addressing data privacy and security concerns related to AI in industrial settings. The General Data Protection Regulation (GDPR) in the EU and similar regulations worldwide impact how data can be collected, processed, and stored for AI-driven diagnostic systems. This is particularly relevant for gate valve fault diagnosis, where sensitive operational data may be used to train and operate AI models.

As the field of AI in industrial diagnostics continues to evolve, regulatory frameworks are likely to become more specific and comprehensive. Industry stakeholders, including valve manufacturers, AI developers, and end-users, are actively engaging with regulators to shape these frameworks. The goal is to strike a balance between fostering innovation and ensuring the safe, reliable, and ethical deployment of AI in critical industrial applications like gate valve fault diagnosis.

In the United States, the National Institute of Standards and Technology (NIST) has been at the forefront of developing AI standards and guidelines. Their AI Risk Management Framework provides a structure for organizations to assess and mitigate risks associated with AI systems, including those used in industrial diagnostics. This framework emphasizes the importance of transparency, accountability, and fairness in AI applications.

The European Union has taken a proactive approach with the proposed AI Act, which aims to categorize AI systems based on their risk levels. Industrial diagnostic systems, including those for gate valve fault detection, would likely fall under the "high-risk" category due to their potential impact on safety and critical infrastructure. This classification would require rigorous testing, documentation, and human oversight.

In the specific context of gate valve fault diagnosis, regulatory considerations extend beyond AI-specific regulations to include industry standards such as ISO 55000 for asset management and IEC 61508 for functional safety of electrical/electronic/programmable electronic safety-related systems. These standards provide a foundation for integrating AI technologies into existing industrial safety and reliability frameworks.

Regulatory bodies are also addressing data privacy and security concerns related to AI in industrial settings. The General Data Protection Regulation (GDPR) in the EU and similar regulations worldwide impact how data can be collected, processed, and stored for AI-driven diagnostic systems. This is particularly relevant for gate valve fault diagnosis, where sensitive operational data may be used to train and operate AI models.

As the field of AI in industrial diagnostics continues to evolve, regulatory frameworks are likely to become more specific and comprehensive. Industry stakeholders, including valve manufacturers, AI developers, and end-users, are actively engaging with regulators to shape these frameworks. The goal is to strike a balance between fostering innovation and ensuring the safe, reliable, and ethical deployment of AI in critical industrial applications like gate valve fault diagnosis.

Economic Impact of AI-Enhanced Valve Maintenance

The economic impact of AI-enhanced valve maintenance in gate valve fault diagnosis is substantial and multifaceted. By leveraging artificial intelligence technologies, companies can significantly reduce downtime, minimize repair costs, and extend the lifespan of critical valve equipment. This advanced approach to maintenance has the potential to revolutionize industrial operations across various sectors, including oil and gas, chemical processing, and water treatment facilities.

One of the primary economic benefits of AI-enhanced valve maintenance is the dramatic reduction in unplanned downtime. Traditional reactive maintenance approaches often lead to unexpected failures, resulting in costly production interruptions. AI-powered predictive maintenance systems can analyze real-time sensor data and historical performance records to accurately forecast potential valve failures before they occur. This proactive approach allows maintenance teams to schedule repairs during planned shutdowns, minimizing disruptions to production schedules and preserving revenue streams.

Furthermore, AI-driven fault diagnosis can lead to more precise and efficient maintenance interventions. By accurately identifying the root cause of valve issues, maintenance teams can focus their efforts on addressing specific problems rather than conducting unnecessary comprehensive overhauls. This targeted approach not only reduces the time and labor required for maintenance but also minimizes the need for replacement parts, resulting in significant cost savings for organizations.

The implementation of AI in valve maintenance also contributes to extended equipment lifespan. By detecting and addressing minor issues before they escalate into major failures, companies can preserve the integrity of their valve systems for longer periods. This extended operational life translates to reduced capital expenditure on equipment replacement and allows organizations to maximize their return on investment in existing infrastructure.

Moreover, AI-enhanced maintenance practices can lead to improved safety outcomes, which have both direct and indirect economic implications. By reducing the likelihood of catastrophic valve failures, companies can mitigate the risk of accidents, environmental incidents, and associated regulatory fines. This not only saves on potential legal and remediation costs but also preserves the company's reputation, which can have long-term financial benefits in terms of stakeholder confidence and market position.

The adoption of AI in valve maintenance also drives operational efficiency improvements beyond the immediate scope of equipment upkeep. The insights generated by AI systems can inform better decision-making in areas such as inventory management, resource allocation, and process optimization. For instance, predictive maintenance data can help companies optimize their spare parts inventory, reducing carrying costs while ensuring critical components are available when needed.

One of the primary economic benefits of AI-enhanced valve maintenance is the dramatic reduction in unplanned downtime. Traditional reactive maintenance approaches often lead to unexpected failures, resulting in costly production interruptions. AI-powered predictive maintenance systems can analyze real-time sensor data and historical performance records to accurately forecast potential valve failures before they occur. This proactive approach allows maintenance teams to schedule repairs during planned shutdowns, minimizing disruptions to production schedules and preserving revenue streams.

Furthermore, AI-driven fault diagnosis can lead to more precise and efficient maintenance interventions. By accurately identifying the root cause of valve issues, maintenance teams can focus their efforts on addressing specific problems rather than conducting unnecessary comprehensive overhauls. This targeted approach not only reduces the time and labor required for maintenance but also minimizes the need for replacement parts, resulting in significant cost savings for organizations.

The implementation of AI in valve maintenance also contributes to extended equipment lifespan. By detecting and addressing minor issues before they escalate into major failures, companies can preserve the integrity of their valve systems for longer periods. This extended operational life translates to reduced capital expenditure on equipment replacement and allows organizations to maximize their return on investment in existing infrastructure.

Moreover, AI-enhanced maintenance practices can lead to improved safety outcomes, which have both direct and indirect economic implications. By reducing the likelihood of catastrophic valve failures, companies can mitigate the risk of accidents, environmental incidents, and associated regulatory fines. This not only saves on potential legal and remediation costs but also preserves the company's reputation, which can have long-term financial benefits in terms of stakeholder confidence and market position.

The adoption of AI in valve maintenance also drives operational efficiency improvements beyond the immediate scope of equipment upkeep. The insights generated by AI systems can inform better decision-making in areas such as inventory management, resource allocation, and process optimization. For instance, predictive maintenance data can help companies optimize their spare parts inventory, reducing carrying costs while ensuring critical components are available when needed.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!