Exploring The Multifunctionality Of Tungsten Alloys

Tungsten Alloy Evolution

Tungsten alloys have undergone significant evolution since their initial development in the early 20th century. The timeline of tungsten alloy development can be divided into several key phases, each marked by notable advancements in composition, processing techniques, and applications.

In the 1930s, the first tungsten heavy alloys were developed, primarily consisting of tungsten, nickel, and copper. These alloys were initially used in military applications due to their high density and strength. The 1940s and 1950s saw further refinement of these alloys, with improvements in sintering processes leading to enhanced mechanical properties.

The 1960s and 1970s marked a period of diversification in tungsten alloy compositions. Researchers began experimenting with various alloying elements such as iron, cobalt, and molybdenum to tailor the properties for specific applications. This era also saw the development of more sophisticated powder metallurgy techniques, enabling better control over microstructure and properties.

During the 1980s and 1990s, there was a significant focus on optimizing the processing parameters of tungsten alloys. Advanced sintering techniques, such as liquid phase sintering and hot isostatic pressing, were introduced, leading to improved densification and mechanical properties. This period also saw the emergence of nanostructured tungsten alloys, offering enhanced strength and ductility.

The turn of the millennium brought about a renewed interest in tungsten alloys for nuclear applications, particularly in fusion reactor components. Research efforts focused on developing radiation-resistant tungsten alloys, capable of withstanding extreme conditions in fusion environments. Simultaneously, the automotive and aerospace industries began exploring tungsten alloys for their high-temperature capabilities and wear resistance.

In recent years, the evolution of tungsten alloys has been driven by the demand for multifunctional materials. Researchers have been exploring novel compositions and processing routes to create tungsten alloys with unique combinations of properties, such as high strength, thermal stability, and radiation shielding capabilities. The development of tungsten-based composites, incorporating ceramic reinforcements or other refractory metals, has opened up new possibilities for tailoring material properties.

The latest trends in tungsten alloy evolution include the exploration of additive manufacturing techniques for producing complex tungsten alloy components, as well as the development of self-healing tungsten alloys for extreme environment applications. These advancements are paving the way for the next generation of tungsten alloys, capable of meeting the increasingly demanding requirements of various high-tech industries.

Market Demand Analysis

The market demand for tungsten alloys has been steadily growing due to their unique combination of properties, including high density, excellent mechanical strength, and superior thermal and electrical conductivity. These characteristics make tungsten alloys increasingly valuable across various industries, driving a robust and expanding market.

In the defense sector, tungsten alloys are crucial for manufacturing armor-piercing ammunition, kinetic energy penetrators, and radiation shielding components. The ongoing global focus on military modernization and defense capabilities has led to a sustained demand for these materials. Additionally, the aerospace industry relies heavily on tungsten alloys for their heat-resistant properties in jet engine components and rocket nozzles, contributing to the market's growth as space exploration and commercial aviation sectors continue to expand.

The automotive industry represents another significant market for tungsten alloys. With the increasing emphasis on vehicle weight reduction and improved fuel efficiency, tungsten alloys are being utilized in various applications such as balance weights, vibration dampers, and high-performance engine components. The growing electric vehicle market also presents new opportunities for tungsten alloys in battery technologies and power electronics.

In the medical field, tungsten alloys find applications in radiation shielding for diagnostic imaging equipment and radiotherapy devices. The global increase in cancer incidence and the subsequent rise in demand for advanced medical imaging and treatment technologies are driving the need for tungsten alloys in this sector.

The electronics industry is another key driver of market demand for tungsten alloys. Their use in heat sinks, electrical contacts, and interconnects is essential for the development of more efficient and compact electronic devices. As the Internet of Things (IoT) and 5G technologies continue to evolve, the demand for tungsten alloys in this sector is expected to grow significantly.

The energy sector, particularly in oil and gas exploration, utilizes tungsten alloys for their wear-resistant properties in drilling equipment. As global energy demands rise and exploration activities expand into more challenging environments, the need for durable tungsten alloy components is likely to increase.

Market analysts project a compound annual growth rate (CAGR) for the tungsten alloy market in the mid-single digits over the next five years. This growth is attributed to the expanding applications across various industries and the ongoing research into new tungsten alloy compositions with enhanced properties. However, factors such as the limited availability of tungsten resources and environmental concerns related to mining and processing may pose challenges to market growth.

Technical Challenges

Despite the numerous advantages of tungsten alloys, several technical challenges persist in their development and application. One of the primary obstacles is the high melting point of tungsten, which makes processing and shaping these alloys extremely difficult. Traditional manufacturing methods often struggle to achieve the desired precision and complexity in tungsten alloy components, limiting their potential applications.

Another significant challenge lies in the brittleness of tungsten alloys, particularly at lower temperatures. This inherent property restricts their use in certain applications where impact resistance or ductility is crucial. Researchers are actively seeking ways to improve the low-temperature toughness of these alloys without compromising their high-temperature strength.

The density of tungsten alloys, while beneficial in some applications, poses challenges in others. In aerospace and automotive industries, where weight reduction is a priority, the high density of tungsten alloys can be a limiting factor. Balancing the trade-off between density and performance remains a key area of focus for materials scientists.

Corrosion resistance is another area of concern, especially in harsh environments. While tungsten alloys generally exhibit good corrosion resistance, certain aggressive media can still cause degradation. Developing alloy compositions and surface treatments that enhance corrosion resistance without compromising other properties is an ongoing challenge.

The multifunctionality of tungsten alloys also presents unique challenges in terms of optimizing properties for diverse applications. Achieving the right balance of strength, ductility, thermal conductivity, and radiation shielding properties often requires complex alloying strategies and precise control of microstructure.

Environmental and health concerns associated with tungsten alloy production and use pose additional challenges. The potential toxicity of some tungsten compounds and the environmental impact of mining and processing tungsten ores necessitate the development of more sustainable and eco-friendly production methods.

Lastly, the cost of tungsten alloys remains a significant barrier to their widespread adoption in various industries. The scarcity of tungsten resources and the complex processing requirements contribute to the high cost of these materials. Finding ways to reduce production costs while maintaining or improving performance characteristics is a critical challenge facing researchers and manufacturers in this field.

Current Alloy Solutions

01 Composition and structure of tungsten alloys

Tungsten alloys are developed with specific compositions and structures to enhance their multifunctionality. These alloys often incorporate elements like nickel, iron, or copper to improve properties such as strength, ductility, and corrosion resistance. The microstructure of these alloys can be tailored through various processing techniques to achieve desired characteristics for different applications.- Composition and structure of tungsten alloys: Tungsten alloys are developed with specific compositions and structures to enhance their multifunctionality. These alloys often incorporate elements like nickel, iron, or copper to improve properties such as strength, ductility, and corrosion resistance. The microstructure of these alloys can be tailored through various processing techniques to achieve desired characteristics for different applications.

- Thermal and electrical properties of tungsten alloys: Tungsten alloys are engineered to exhibit superior thermal and electrical properties, making them suitable for use in high-temperature environments and electrical applications. These alloys can maintain their strength and stability at elevated temperatures, while also offering excellent thermal and electrical conductivity. This combination of properties makes them valuable in industries such as aerospace, electronics, and energy production.

- Radiation shielding applications of tungsten alloys: Tungsten alloys are utilized for their exceptional radiation shielding capabilities. Their high density and atomic number make them effective in attenuating various types of radiation, including gamma rays and neutrons. These alloys are employed in medical equipment, nuclear power plants, and space exploration, where protection from ionizing radiation is crucial.

- Mechanical properties and wear resistance of tungsten alloys: Tungsten alloys are designed to possess exceptional mechanical properties and wear resistance. These alloys exhibit high hardness, tensile strength, and toughness, making them suitable for applications requiring durability and longevity. Their wear-resistant nature makes them ideal for use in cutting tools, mining equipment, and military applications.

- Advanced manufacturing techniques for tungsten alloys: Innovative manufacturing techniques are employed to produce tungsten alloys with enhanced multifunctionality. These methods include powder metallurgy, additive manufacturing, and advanced sintering processes. Such techniques allow for precise control over the alloy's composition, microstructure, and properties, enabling the production of complex shapes and tailored characteristics for specific applications.

02 Thermal and electrical properties of tungsten alloys

Tungsten alloys are engineered to exhibit superior thermal and electrical properties, making them suitable for applications in electronics, energy, and aerospace industries. These alloys can maintain their properties at high temperatures and offer excellent thermal conductivity and electrical resistance. The combination of these properties allows for the creation of multifunctional components that can withstand extreme conditions.Expand Specific Solutions03 Mechanical properties and wear resistance

The multifunctionality of tungsten alloys extends to their exceptional mechanical properties and wear resistance. These alloys are designed to have high hardness, tensile strength, and impact resistance. The combination of these properties makes them ideal for use in cutting tools, mining equipment, and military applications where durability and longevity are crucial.Expand Specific Solutions04 Radiation shielding capabilities

Tungsten alloys are utilized for their excellent radiation shielding properties, making them valuable in medical, nuclear, and space industries. These alloys can effectively attenuate various types of radiation, including X-rays and gamma rays, while maintaining structural integrity. This multifunctional aspect allows for the creation of compact and efficient shielding solutions.Expand Specific Solutions05 Surface treatments and coatings for enhanced functionality

Various surface treatments and coatings are applied to tungsten alloys to further enhance their multifunctionality. These treatments can improve corrosion resistance, reduce friction, increase hardness, or add specific properties like biocompatibility. Advanced coating techniques allow for the creation of multifunctional surfaces that can adapt to different environments or operating conditions.Expand Specific Solutions

Key Industry Players

The exploration of tungsten alloys' multifunctionality is in a mature development stage, with a growing market driven by diverse industrial applications. The global tungsten alloy market is projected to reach significant size due to increasing demand in aerospace, automotive, and electronics sectors. Technologically, the field is advancing rapidly, with companies like Central South University, Toyota Central R&D Labs, and Toshiba Corp. leading research efforts. These entities are focusing on enhancing tungsten alloys' properties for specific applications, such as improved thermal management and radiation shielding. The involvement of major players like General Electric Company and Siemens Corp. indicates the technology's strategic importance across various industries, suggesting a competitive landscape with ongoing innovation and market expansion.

Central South University

Toshiba Materials Co., Ltd.

Core Innovations

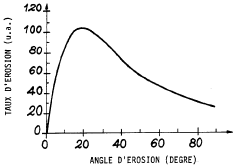

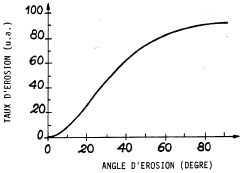

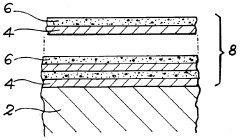

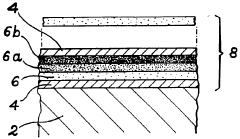

- A multilayer material comprising alternated ductile layers of metallic tungsten or tungsten alloy and hard layers of carbon or nitrogen solid solutions in tungsten, deposited using cathodic sputtering or evaporation at low temperatures, ensuring stability and resistance to erosion and abrasion across various particle sizes and angles.

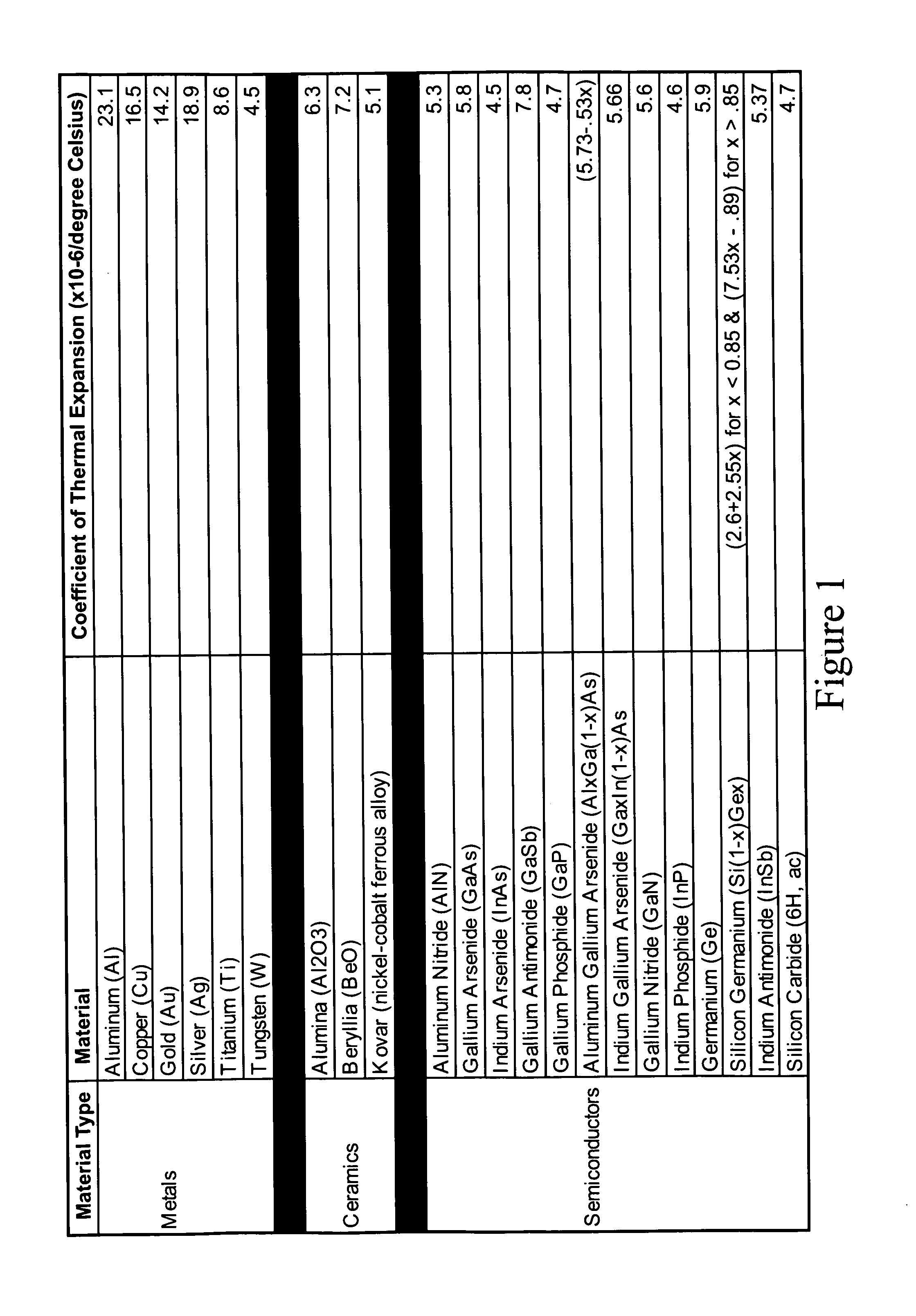

- A Titanium-Tungsten alloy with adjustable CTE is developed, allowing the alloy's properties to be tailored to match those of semiconductor and ceramic materials, providing excellent electrical and thermal conductivities, and enabling direct bonding without intermediate layers to reduce thermal stresses and improve reliability.

Environmental Impact

The environmental impact of tungsten alloys is a critical consideration in their production, use, and disposal. These alloys, known for their high density and strength, have diverse applications across industries, but their environmental footprint requires careful examination.

The mining and processing of tungsten ores can lead to significant environmental disturbances. Open-pit mining, often used for tungsten extraction, can result in habitat destruction, soil erosion, and water pollution. The energy-intensive nature of tungsten processing contributes to greenhouse gas emissions, further exacerbating climate change concerns.

During the manufacturing of tungsten alloys, various chemical processes are employed, potentially releasing harmful substances into the environment. These may include heavy metals, acids, and other toxic compounds. Proper waste management and treatment systems are essential to mitigate these risks and prevent contamination of soil and water resources.

The use phase of tungsten alloys generally has a lower environmental impact compared to production. However, certain applications, such as in military ammunition, can lead to soil and water contamination when these materials are dispersed in the environment. The long-term effects of tungsten accumulation in ecosystems are still being studied, with potential implications for wildlife and human health.

End-of-life management of tungsten alloy products presents both challenges and opportunities. Recycling of tungsten alloys is technically feasible and can significantly reduce the need for primary raw material extraction. However, the complex composition of some alloys can make recycling processes more difficult and energy-intensive.

Efforts to improve the environmental performance of tungsten alloys are ongoing. Research into more sustainable mining practices, cleaner production processes, and improved recycling technologies is crucial. Additionally, the development of alternative materials with similar properties but lower environmental impact is an area of active investigation.

Regulatory frameworks play a vital role in managing the environmental impact of tungsten alloys. Stricter environmental standards and waste management regulations are being implemented in many countries, pushing the industry towards more sustainable practices. Life cycle assessments are increasingly used to evaluate the overall environmental impact of tungsten alloy products, from raw material extraction to disposal.

Regulatory Landscape

The regulatory landscape surrounding tungsten alloys is complex and multifaceted, reflecting the diverse applications and potential impacts of these materials. Tungsten alloys are subject to various regulations due to their use in critical industries such as aerospace, defense, and medical technology. These regulations primarily focus on safety, environmental protection, and strategic resource management.

In the United States, the Environmental Protection Agency (EPA) regulates the use and disposal of tungsten alloys under the Toxic Substances Control Act (TSCA). The agency monitors potential environmental and health impacts, particularly concerning the release of tungsten particles into soil and water systems. Additionally, the Occupational Safety and Health Administration (OSHA) sets guidelines for worker exposure to tungsten dust in manufacturing environments.

Internationally, the European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation applies to tungsten alloys, requiring manufacturers and importers to assess and manage the risks associated with these materials. This includes providing safety information and ensuring proper handling throughout the supply chain.

The defense sector faces particularly stringent regulations regarding tungsten alloys. In many countries, including the United States, these materials are classified as strategic resources, subject to export controls and trade restrictions. The International Traffic in Arms Regulations (ITAR) in the U.S. governs the export of defense-related articles and services, including certain tungsten alloy products.

In the medical field, tungsten alloys used in medical devices must comply with regulations set by agencies such as the U.S. Food and Drug Administration (FDA) and the European Medicines Agency (EMA). These regulations focus on biocompatibility, durability, and safety for patient use.

The nuclear industry also heavily regulates the use of tungsten alloys due to their radiation shielding properties. Regulatory bodies such as the Nuclear Regulatory Commission (NRC) in the U.S. and equivalent agencies in other countries oversee the use of these materials in nuclear facilities.

As research into the multifunctionality of tungsten alloys progresses, regulatory frameworks are likely to evolve. Emerging applications in areas such as energy storage, advanced manufacturing, and nanotechnology may necessitate new or updated regulations. Policymakers and industry stakeholders must collaborate to ensure that regulatory measures keep pace with technological advancements while maintaining safety and environmental standards.