Exploring Tungsten Carbide's Industrial Applications

Tungsten Carbide Evolution and Objectives

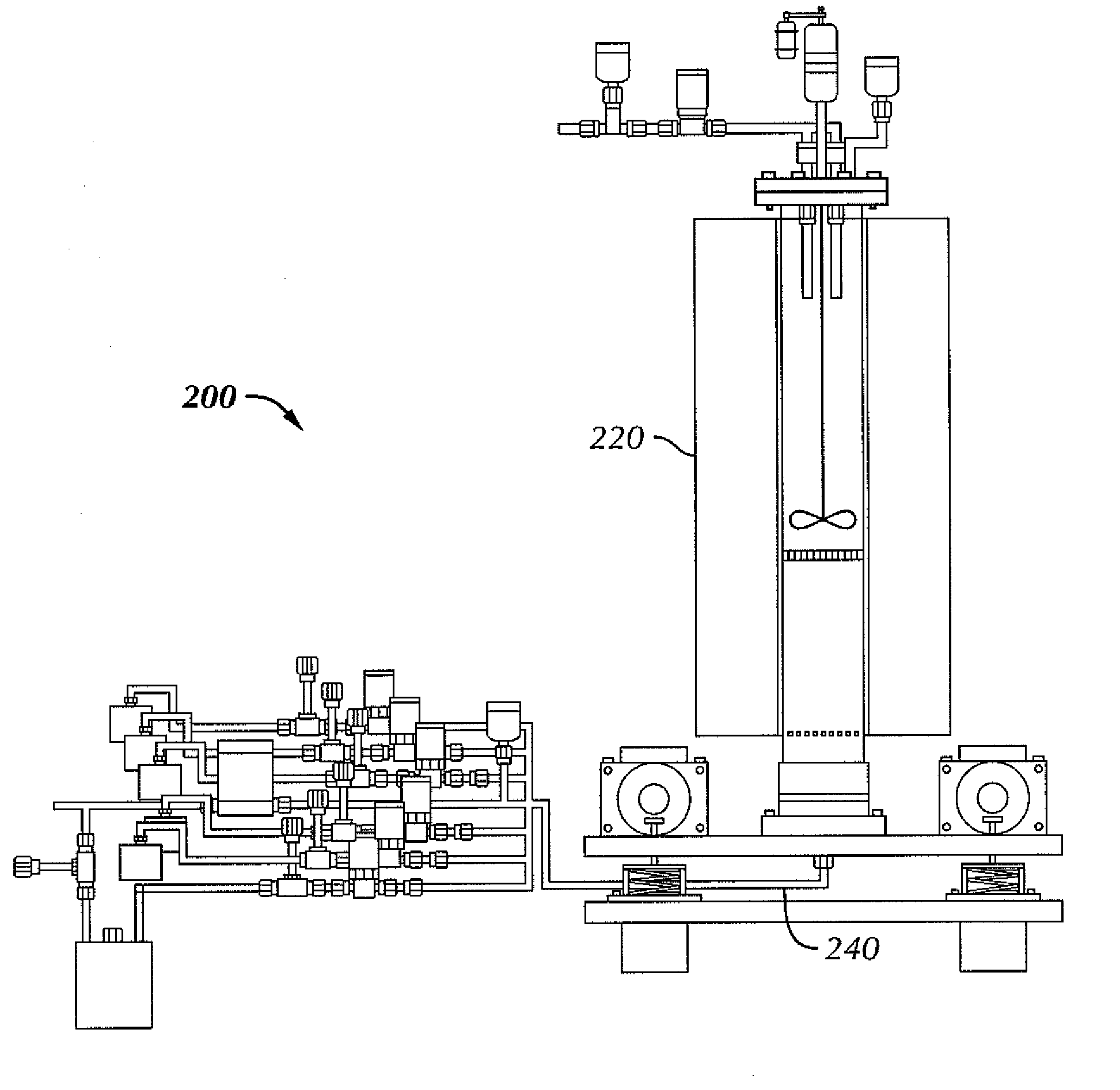

Tungsten carbide, a composite material consisting of tungsten and carbon atoms, has undergone significant evolution since its discovery in the early 20th century. Initially developed as a more durable alternative to diamond in industrial cutting tools, tungsten carbide has since found widespread applications across various industries due to its exceptional hardness, wear resistance, and thermal stability.

The evolution of tungsten carbide can be traced through several key milestones. In the 1920s, the first commercial production of tungsten carbide began, primarily for use in cutting tools and wear-resistant components. The 1930s and 1940s saw advancements in sintering techniques, leading to improved material properties and expanded applications. By the 1950s and 1960s, tungsten carbide had become a staple in the mining and oil drilling industries, revolutionizing tool performance and longevity.

In recent decades, the focus has shifted towards developing more refined grades of tungsten carbide with tailored properties for specific applications. This has led to the creation of ultra-fine grain structures, gradient materials, and composite formulations that combine tungsten carbide with other materials to enhance specific characteristics.

The primary objective in exploring tungsten carbide's industrial applications is to leverage its unique properties to address challenges in various sectors. These properties include its high hardness (second only to diamond), excellent wear resistance, high compressive strength, and good thermal conductivity. By harnessing these attributes, researchers and engineers aim to develop innovative solutions that can improve efficiency, durability, and performance across a wide range of industrial processes.

Key objectives in the ongoing exploration of tungsten carbide applications include:

1. Enhancing tool life and cutting performance in machining operations, particularly for hard-to-machine materials.

2. Improving wear resistance in mining and earthmoving equipment to reduce downtime and maintenance costs.

3. Developing advanced coatings and surface treatments to extend the lifespan of critical components in aerospace and automotive industries.

4. Exploring new applications in emerging technologies, such as additive manufacturing and nanotechnology.

5. Optimizing tungsten carbide formulations to reduce reliance on rare earth elements while maintaining or improving performance.

As industrial demands continue to evolve, the exploration of tungsten carbide's applications remains a dynamic field. Researchers are constantly pushing the boundaries of material science to unlock new possibilities and overcome existing limitations. The ongoing objectives in this field are driven by the need for materials that can withstand increasingly harsh operating conditions, improve energy efficiency, and contribute to sustainable manufacturing practices.

Industrial Demand Analysis

The industrial demand for tungsten carbide has been steadily growing across various sectors due to its exceptional properties, including high hardness, wear resistance, and thermal stability. In the manufacturing industry, tungsten carbide tools and components are extensively used in metal cutting, drilling, and machining operations. The automotive sector relies on tungsten carbide for producing wear-resistant parts, such as valve seats and fuel injection nozzles, contributing to improved engine performance and longevity.

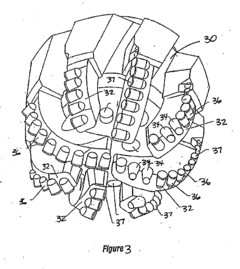

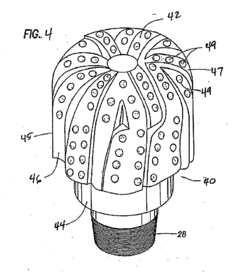

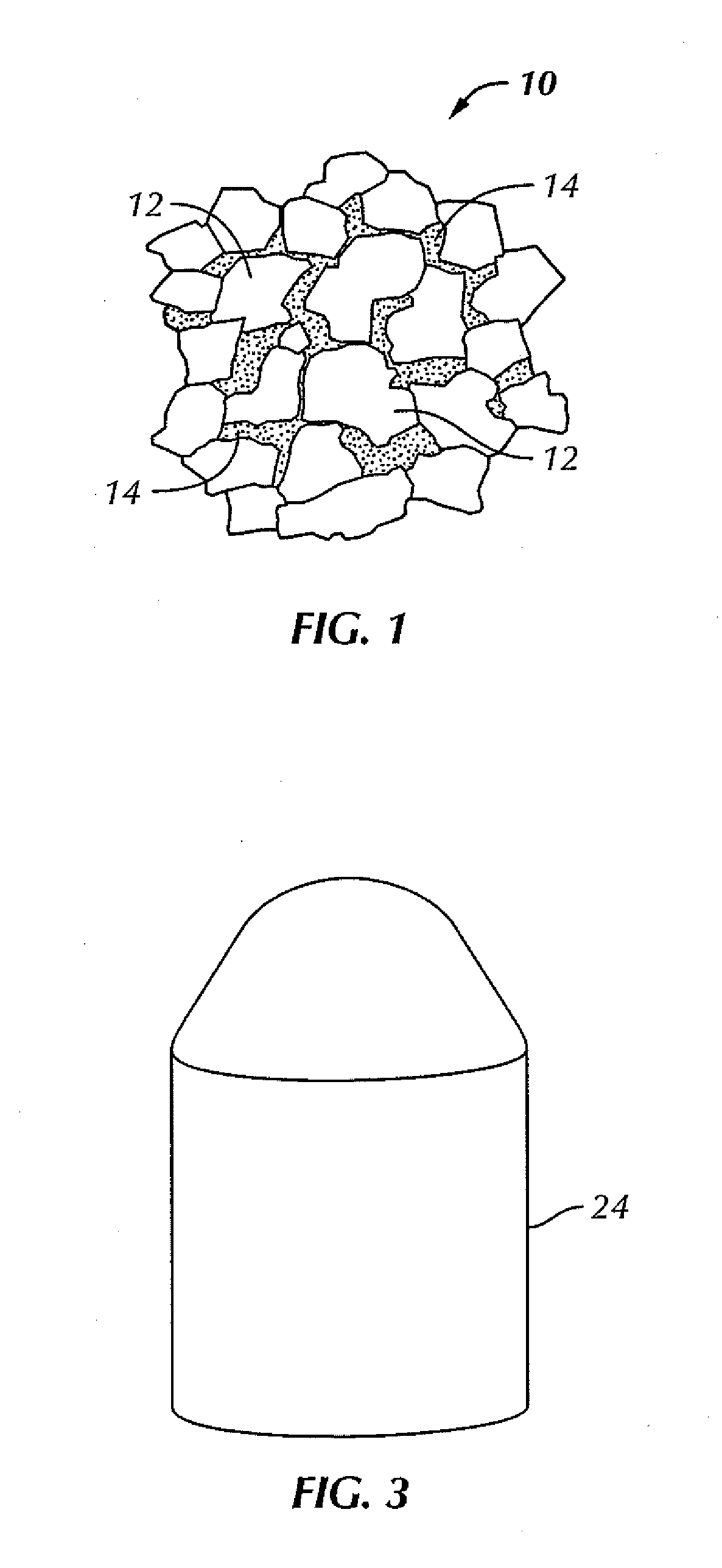

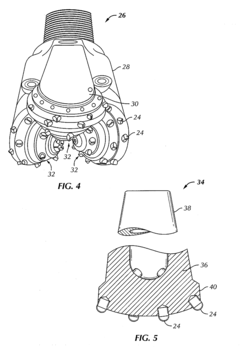

The mining and construction industries have shown a significant increase in demand for tungsten carbide-tipped tools and equipment. These tools offer superior durability and efficiency in drilling, excavation, and rock crushing operations, leading to reduced downtime and increased productivity. The oil and gas sector also utilizes tungsten carbide in drill bits, valves, and other components exposed to harsh environments, where resistance to corrosion and abrasion is crucial.

In the aerospace industry, tungsten carbide finds applications in turbine engine components and landing gear systems, where its high-temperature strength and wear resistance are invaluable. The electronics industry employs tungsten carbide in the production of circuit board drills and other precision tools used in manufacturing electronic components.

The global tungsten carbide market size was valued at approximately $16.5 billion in 2020 and is projected to reach $25.3 billion by 2027, growing at a CAGR of 6.3% during the forecast period. This growth is primarily driven by the increasing demand from end-use industries such as automotive, aerospace, and mining.

Regionally, Asia-Pacific dominates the tungsten carbide market, accounting for over 40% of the global share. This is attributed to the rapid industrialization and growth of manufacturing sectors in countries like China, Japan, and South Korea. North America and Europe follow, with significant demand coming from advanced manufacturing and automotive industries.

The market is also witnessing a shift towards the development of nano-grain tungsten carbide, which offers enhanced properties and performance. This trend is expected to open up new applications and drive further growth in the coming years. Additionally, the increasing focus on sustainable manufacturing practices is leading to the development of recycling technologies for tungsten carbide, addressing concerns about the scarcity of raw materials and environmental impact.

Technical Challenges in Tungsten Carbide Production

The production of tungsten carbide presents several significant technical challenges that manufacturers must overcome to ensure high-quality, consistent output. One of the primary difficulties lies in the precise control of particle size and distribution during the powder metallurgy process. Achieving uniform particle size is crucial for the final product's performance, as it directly impacts the material's hardness, toughness, and wear resistance.

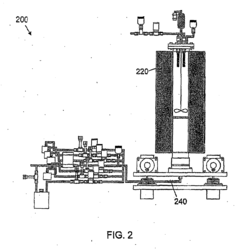

Another major challenge is the high-temperature sintering process required to consolidate tungsten carbide powders. The sintering temperature typically ranges from 1350°C to 1650°C, which demands specialized equipment and careful process control. Maintaining an inert atmosphere during sintering is essential to prevent oxidation and preserve the material's properties. Even slight variations in temperature or atmosphere can lead to defects in the final product, such as porosity or uneven grain growth.

The addition of cobalt as a binder material introduces further complexities. Achieving the optimal balance between tungsten carbide and cobalt is critical for the material's performance. Too little cobalt can result in a brittle product, while too much can compromise hardness. Ensuring uniform distribution of cobalt throughout the tungsten carbide matrix is a technical challenge that requires precise mixing and processing techniques.

Contamination control is another significant issue in tungsten carbide production. Even minute amounts of impurities can significantly affect the material's properties. Manufacturers must implement stringent quality control measures throughout the production process, from raw material selection to final product inspection, to minimize contamination risks.

The machining and shaping of tungsten carbide components pose additional challenges due to the material's extreme hardness. Traditional machining methods are often ineffective, necessitating the use of advanced techniques such as electrical discharge machining (EDM) or diamond grinding. These processes require specialized equipment and expertise, adding to the complexity and cost of production.

Recycling and waste management in tungsten carbide production also present technical hurdles. The recovery of tungsten from scrap and used components is essential for sustainability and cost-effectiveness. However, the recycling process is complex and energy-intensive, requiring advanced separation and purification techniques to maintain the quality of recycled materials.

Addressing these technical challenges requires ongoing research and development efforts. Innovations in powder metallurgy techniques, sintering processes, and quality control methods are continually being pursued to improve the efficiency and reliability of tungsten carbide production. As industrial applications for tungsten carbide continue to expand, overcoming these challenges becomes increasingly critical for meeting the growing demand for high-performance materials in various sectors.

Current Tungsten Carbide Applications

01 Synthesis and production methods of tungsten carbide

Various methods for synthesizing and producing tungsten carbide are described, including carbothermal reduction, direct carburization, and chemical vapor deposition. These processes involve precise control of temperature, pressure, and reactant ratios to achieve desired properties and microstructures of the final product.- Composition and manufacturing of tungsten carbide: Tungsten carbide is a composite material made from tungsten and carbon. Various methods are used to manufacture tungsten carbide, including powder metallurgy techniques. The composition and manufacturing process can be optimized to achieve desired properties such as hardness, wear resistance, and toughness.

- Tungsten carbide in cutting tools and wear-resistant applications: Tungsten carbide is widely used in cutting tools and wear-resistant applications due to its exceptional hardness and durability. It is often used as a coating or as the main material in tools for machining, mining, and other industrial applications where high wear resistance is required.

- Tungsten carbide coatings and surface treatments: Various methods are employed to apply tungsten carbide coatings or surface treatments to enhance the wear resistance and performance of tools and components. These techniques may include chemical vapor deposition, physical vapor deposition, or thermal spraying processes.

- Nanostructured tungsten carbide materials: Research and development efforts focus on creating nanostructured tungsten carbide materials to improve properties such as hardness, toughness, and wear resistance. These materials may have applications in advanced cutting tools, aerospace components, and other high-performance applications.

- Recycling and recovery of tungsten carbide: Methods for recycling and recovering tungsten carbide from used tools and scrap materials are being developed to reduce waste and conserve resources. These processes may involve chemical treatments, thermal processes, or mechanical separation techniques to extract and reuse the valuable tungsten carbide material.

02 Tungsten carbide composites and coatings

Tungsten carbide is often used in composites and coatings to enhance wear resistance and hardness. These materials can be applied through various techniques such as thermal spraying, physical vapor deposition, or sintering. The composition and processing parameters are optimized to achieve specific mechanical and tribological properties.Expand Specific Solutions03 Nanostructured tungsten carbide materials

Research focuses on developing nanostructured tungsten carbide materials with enhanced properties. These materials exhibit improved hardness, toughness, and wear resistance compared to conventional tungsten carbide. Various synthesis methods and post-processing techniques are employed to control grain size and distribution.Expand Specific Solutions04 Applications in cutting tools and wear-resistant components

Tungsten carbide is widely used in cutting tools and wear-resistant components due to its exceptional hardness and durability. The material is often combined with cobalt or other binders to create cemented carbides. Specific compositions and manufacturing processes are tailored for various applications in machining, mining, and oil and gas industries.Expand Specific Solutions05 Recycling and recovery of tungsten carbide

Methods for recycling and recovering tungsten carbide from used tools and scrap materials are developed to address sustainability concerns and reduce reliance on primary raw materials. These processes involve chemical or electrochemical treatments to separate tungsten carbide from binder materials and other contaminants.Expand Specific Solutions

Key Manufacturers and Competitors

The industrial applications of tungsten carbide are in a mature stage, with a global market size expected to reach $26.3 billion by 2027. The technology's maturity is evident in its widespread use across various sectors, including mining, construction, and manufacturing. Key players like Kennametal, Inc., Sandvik Intellectual Property AB, and Sumitomo Electric Industries Ltd. are driving innovation in this field. These companies, along with others such as Seco Tools AB and Mitsubishi Materials Corp., are focusing on developing advanced tungsten carbide composites and coatings to enhance performance and durability. The competitive landscape is characterized by ongoing research and development efforts, with universities like Central South University and Zhejiang University of Technology contributing to technological advancements in tungsten carbide applications.

Seco Tools AB

Kennametal, Inc.

Innovative Tungsten Carbide Properties

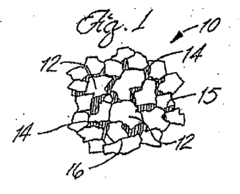

- A composite body is developed with a ductile phase, dispersed carbide particles, and integrated nanotubes, which enhances strength, toughness, and wear resistance by using nanotubes such as carbon nanotubes with ultra-thin coatings to improve dispersion and interfacial adhesion within the metal matrix.

- The application of an ultra-thin, conformal coating on hard phase particles using atomic layer deposition (ALD) to enhance the uniform distribution of hard particles within a ductile binder, improving fracture toughness and thermal stability by reducing binder pooling and altering the microstructure.

Environmental Impact Assessment

The environmental impact of tungsten carbide production and use is a critical consideration in its industrial applications. The mining and processing of tungsten ore, primarily wolframite and scheelite, can lead to significant environmental disturbances. Open-pit mining, often employed for tungsten extraction, results in landscape alterations, habitat destruction, and potential soil erosion. The subsequent ore processing stages, including crushing, grinding, and chemical treatment, generate substantial amounts of waste rock and tailings, which may contain heavy metals and other contaminants.

Water pollution is a major concern in tungsten carbide production. The beneficiation process, which separates tungsten from other minerals, often involves the use of chemicals that can contaminate local water sources if not properly managed. Acid mine drainage, a common issue in metal mining, can occur when sulfide minerals in exposed rock react with air and water, leading to the formation of acidic runoff that can harm aquatic ecosystems and contaminate groundwater.

Air quality is another environmental aspect affected by tungsten carbide production. The sintering process, where tungsten carbide powder is heated to form solid components, releases particulate matter and potentially harmful gases into the atmosphere. These emissions can contribute to local air pollution and may have broader implications for climate change if not adequately controlled.

The energy-intensive nature of tungsten carbide production also contributes to its environmental footprint. The high temperatures required for sintering and the energy needed for mining and processing operations result in significant greenhouse gas emissions, primarily carbon dioxide. This aspect of production aligns tungsten carbide with other energy-intensive materials in terms of climate impact.

Recycling and waste management present both challenges and opportunities in mitigating the environmental impact of tungsten carbide. While tungsten carbide is highly recyclable, the collection and processing of used components require efficient systems to maximize recovery rates. Proper disposal of non-recyclable waste and by-products is crucial to prevent soil and water contamination.

In industrial applications, the durability and longevity of tungsten carbide products contribute positively to their environmental profile. The extended lifespan of tungsten carbide tools and components reduces the frequency of replacement, potentially lowering the overall environmental impact compared to less durable alternatives. However, the hardness of tungsten carbide can make it challenging to machine or reshape, which may limit its reusability in some contexts.

As environmental regulations become more stringent globally, the tungsten carbide industry faces increasing pressure to adopt cleaner production methods and improve waste management practices. Innovations in ore extraction techniques, more efficient processing technologies, and the development of closed-loop recycling systems are areas of focus for reducing the environmental footprint of tungsten carbide throughout its lifecycle.

Supply Chain and Raw Material Considerations

The supply chain for tungsten carbide production is complex and globally distributed, involving multiple stages from raw material extraction to final product manufacturing. Tungsten, the primary raw material, is primarily sourced from China, which accounts for over 80% of global production. Other significant producers include Vietnam, Russia, and Bolivia. The concentration of tungsten resources in a few countries introduces potential supply risks and geopolitical considerations for industries relying on tungsten carbide.

The extraction of tungsten ore, typically wolframite or scheelite, is followed by a series of processing steps to produce tungsten carbide powder. This includes ore concentration, conversion to ammonium paratungstate (APT), reduction to tungsten metal powder, and finally, carburization to form tungsten carbide. Each stage requires specialized equipment and expertise, creating a relatively small number of suppliers capable of producing high-quality tungsten carbide powder.

Carbon, the other key raw material in tungsten carbide production, is typically sourced from high-purity carbon black or graphite. While carbon is more widely available than tungsten, the specific grades required for tungsten carbide production may still face supply constraints.

The global nature of the tungsten carbide supply chain introduces challenges in terms of transportation, inventory management, and quality control. Fluctuations in raw material prices, particularly tungsten, can significantly impact the cost of tungsten carbide products. This volatility necessitates careful supply chain management and potentially long-term contracts to ensure stable supply and pricing.

Environmental and sustainability considerations are increasingly important in the tungsten carbide supply chain. Mining and processing of tungsten ore can have significant environmental impacts, leading to growing interest in recycling and recovery of tungsten from scrap materials. This circular economy approach not only addresses environmental concerns but also helps mitigate supply risks associated with primary raw material sources.

As industrial applications for tungsten carbide continue to expand, ensuring a stable and sustainable supply chain becomes crucial. This may involve diversifying raw material sources, investing in recycling technologies, and developing alternative materials for specific applications where tungsten carbide substitution is feasible.