Fine-Tuning GDI Engine for Performance in Varying Climates

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

GDI Engine Climate Adaptation Background and Objectives

Gasoline Direct Injection (GDI) technology has evolved significantly since its commercial introduction in the late 1990s, revolutionizing internal combustion engine efficiency and performance. This evolution has been driven by increasingly stringent emissions regulations, consumer demand for fuel economy, and the automotive industry's push toward more sustainable transportation solutions. GDI engines represent a critical bridge technology in the transition from traditional combustion engines to fully electrified powertrains, offering substantial improvements in fuel efficiency while reducing carbon emissions.

The fundamental principle of GDI technology involves injecting fuel directly into the combustion chamber rather than the intake port, allowing for precise control over the fuel-air mixture and combustion timing. However, this precision is highly susceptible to environmental factors, particularly temperature and humidity variations, which can significantly impact performance, emissions, and reliability across different climate conditions.

Recent research indicates that GDI engines experience performance variations of up to 15% when operating in extreme temperature conditions compared to moderate climates. Cold-start emissions can increase by 30-40% in sub-zero temperatures, while hot climate operation often leads to increased knock tendency and reduced volumetric efficiency. These climate-dependent performance variations present significant challenges for global automotive manufacturers seeking to maintain consistent engine performance across diverse markets.

The primary objective of this technical research is to develop adaptive calibration strategies and hardware modifications that enable GDI engines to maintain optimal performance, efficiency, and emissions compliance across varying climatic conditions. Specifically, we aim to identify technological solutions that can dynamically adjust fuel injection parameters, ignition timing, and air management strategies in response to ambient temperature, humidity, and altitude variations.

Secondary objectives include quantifying the relationship between climate variables and GDI engine performance metrics, developing predictive models for climate-adaptive engine control strategies, and evaluating the cost-benefit ratio of implementing climate-adaptive technologies in production vehicles. The research will also explore the integration of machine learning algorithms to enable continuous optimization of engine parameters based on real-time environmental data.

The technological trajectory suggests that next-generation GDI systems will increasingly incorporate advanced sensors, predictive algorithms, and variable hardware components to address climate adaptation challenges. Industry forecasts indicate that by 2025, over 70% of new internal combustion engines will feature some form of climate-adaptive technology, highlighting the strategic importance of this research area for maintaining competitiveness in the global automotive market.

The fundamental principle of GDI technology involves injecting fuel directly into the combustion chamber rather than the intake port, allowing for precise control over the fuel-air mixture and combustion timing. However, this precision is highly susceptible to environmental factors, particularly temperature and humidity variations, which can significantly impact performance, emissions, and reliability across different climate conditions.

Recent research indicates that GDI engines experience performance variations of up to 15% when operating in extreme temperature conditions compared to moderate climates. Cold-start emissions can increase by 30-40% in sub-zero temperatures, while hot climate operation often leads to increased knock tendency and reduced volumetric efficiency. These climate-dependent performance variations present significant challenges for global automotive manufacturers seeking to maintain consistent engine performance across diverse markets.

The primary objective of this technical research is to develop adaptive calibration strategies and hardware modifications that enable GDI engines to maintain optimal performance, efficiency, and emissions compliance across varying climatic conditions. Specifically, we aim to identify technological solutions that can dynamically adjust fuel injection parameters, ignition timing, and air management strategies in response to ambient temperature, humidity, and altitude variations.

Secondary objectives include quantifying the relationship between climate variables and GDI engine performance metrics, developing predictive models for climate-adaptive engine control strategies, and evaluating the cost-benefit ratio of implementing climate-adaptive technologies in production vehicles. The research will also explore the integration of machine learning algorithms to enable continuous optimization of engine parameters based on real-time environmental data.

The technological trajectory suggests that next-generation GDI systems will increasingly incorporate advanced sensors, predictive algorithms, and variable hardware components to address climate adaptation challenges. Industry forecasts indicate that by 2025, over 70% of new internal combustion engines will feature some form of climate-adaptive technology, highlighting the strategic importance of this research area for maintaining competitiveness in the global automotive market.

Market Analysis for Climate-Optimized GDI Engines

The global market for climate-optimized Gasoline Direct Injection (GDI) engines is experiencing significant growth, driven by increasingly stringent emission regulations and consumer demand for fuel-efficient vehicles that perform consistently across diverse climate conditions. Current market valuations indicate that the GDI engine segment represents approximately 45% of the global automotive engine market, with projections showing continued expansion at a compound annual growth rate of 6.8% through 2028.

Regional market analysis reveals distinct patterns in demand for climate-optimized GDI systems. North American and European markets prioritize cold-weather performance optimization, particularly addressing cold-start emissions and fuel atomization challenges in sub-zero temperatures. Conversely, markets in Southeast Asia, Middle East, and parts of Latin America demonstrate stronger demand for heat-resistant components and cooling system enhancements to maintain optimal performance in high-temperature environments.

Consumer research indicates a growing awareness of climate-related vehicle performance issues, with 67% of new vehicle buyers in premium segments considering all-weather performance capabilities as "important" or "very important" in their purchasing decisions. This trend is particularly pronounced in regions with extreme seasonal variations, such as Canada, Northern Europe, and mountainous regions globally.

The commercial vehicle sector represents an emerging opportunity for climate-optimized GDI technology, with fleet operators increasingly focused on total cost of ownership calculations that factor in climate-related performance degradation. Market surveys indicate that fleet managers are willing to pay a 5-7% premium for engines with demonstrated performance stability across varying climate conditions.

Competitive landscape analysis shows that Japanese and German manufacturers currently lead in climate-optimized GDI technology patents, with significant investments in thermal management systems and advanced materials science. Chinese manufacturers are rapidly closing this gap through aggressive R&D investments and strategic partnerships with technology providers.

Market forecasts suggest that the highest growth potential exists in "climate-transition" technologies—solutions that enable GDI engines to rapidly adapt to sudden temperature changes without performance degradation. This segment is projected to grow at twice the rate of the broader GDI market over the next five years, driven by increasing climate volatility in many regions and consumer expectations for consistent vehicle performance regardless of environmental conditions.

The aftermarket for climate optimization components represents another significant opportunity, currently valued at approximately 3.2 billion USD annually with double-digit growth projections as older GDI-equipped vehicles require upgrades to maintain performance in changing climate conditions.

Regional market analysis reveals distinct patterns in demand for climate-optimized GDI systems. North American and European markets prioritize cold-weather performance optimization, particularly addressing cold-start emissions and fuel atomization challenges in sub-zero temperatures. Conversely, markets in Southeast Asia, Middle East, and parts of Latin America demonstrate stronger demand for heat-resistant components and cooling system enhancements to maintain optimal performance in high-temperature environments.

Consumer research indicates a growing awareness of climate-related vehicle performance issues, with 67% of new vehicle buyers in premium segments considering all-weather performance capabilities as "important" or "very important" in their purchasing decisions. This trend is particularly pronounced in regions with extreme seasonal variations, such as Canada, Northern Europe, and mountainous regions globally.

The commercial vehicle sector represents an emerging opportunity for climate-optimized GDI technology, with fleet operators increasingly focused on total cost of ownership calculations that factor in climate-related performance degradation. Market surveys indicate that fleet managers are willing to pay a 5-7% premium for engines with demonstrated performance stability across varying climate conditions.

Competitive landscape analysis shows that Japanese and German manufacturers currently lead in climate-optimized GDI technology patents, with significant investments in thermal management systems and advanced materials science. Chinese manufacturers are rapidly closing this gap through aggressive R&D investments and strategic partnerships with technology providers.

Market forecasts suggest that the highest growth potential exists in "climate-transition" technologies—solutions that enable GDI engines to rapidly adapt to sudden temperature changes without performance degradation. This segment is projected to grow at twice the rate of the broader GDI market over the next five years, driven by increasing climate volatility in many regions and consumer expectations for consistent vehicle performance regardless of environmental conditions.

The aftermarket for climate optimization components represents another significant opportunity, currently valued at approximately 3.2 billion USD annually with double-digit growth projections as older GDI-equipped vehicles require upgrades to maintain performance in changing climate conditions.

Technical Challenges in GDI Performance Across Temperature Ranges

Gasoline Direct Injection (GDI) engines face significant performance challenges across varying temperature ranges, which directly impact their efficiency, emissions, and reliability. At low temperatures, fuel atomization becomes problematic as the increased viscosity of gasoline reduces spray penetration and droplet breakup, leading to incomplete combustion and higher emissions. Cold-start conditions particularly exacerbate these issues, with studies showing up to 40% reduction in combustion efficiency at temperatures below -10°C.

Conversely, high ambient temperatures introduce different challenges. Fuel volatility increases, potentially causing vapor lock in fuel lines and reducing the volumetric efficiency of the engine. The reduced air density at higher temperatures also affects the air-fuel mixture, requiring precise adjustments to injection timing and duration to maintain optimal combustion parameters.

The injector performance itself varies significantly across temperature ranges. Research indicates that injector flow rates can vary by up to 15% between -30°C and 80°C, necessitating sophisticated compensation algorithms. The piezoelectric or solenoid actuators in modern GDI injectors exhibit temperature-dependent response characteristics, affecting injection precision and repeatability across climate conditions.

Carbon deposit formation presents another temperature-dependent challenge. At lower operating temperatures, incomplete fuel evaporation leads to accelerated carbon buildup on injector tips and intake valves. These deposits progressively restrict fuel flow and distort spray patterns, degrading engine performance over time. Studies have documented up to 25% reduction in injector flow capacity after 50,000 miles in vehicles frequently operated in cold climates.

The electronic control unit (ECU) must continuously adapt to these temperature variations, but current algorithms often rely on simplified models that inadequately address the complex thermodynamics involved. The temperature-dependent changes in fuel properties (density, viscosity, surface tension) require multidimensional mapping that exceeds the capability of many production ECUs.

Material thermal expansion differences between injector components create additional challenges. The precision-machined components in GDI injectors typically have clearances measured in microns, and differential thermal expansion can alter these clearances, affecting fuel metering accuracy. This is particularly problematic in applications where rapid temperature changes occur, such as in vehicles operating in desert conditions during day-night cycles.

Lubricant performance also varies with temperature, affecting friction losses and potentially contaminating the fuel spray if cylinder wall oil film management is suboptimal. This interaction between lubrication systems and fuel injection becomes more critical as engines are downsized and operated under higher specific loads to improve efficiency.

Conversely, high ambient temperatures introduce different challenges. Fuel volatility increases, potentially causing vapor lock in fuel lines and reducing the volumetric efficiency of the engine. The reduced air density at higher temperatures also affects the air-fuel mixture, requiring precise adjustments to injection timing and duration to maintain optimal combustion parameters.

The injector performance itself varies significantly across temperature ranges. Research indicates that injector flow rates can vary by up to 15% between -30°C and 80°C, necessitating sophisticated compensation algorithms. The piezoelectric or solenoid actuators in modern GDI injectors exhibit temperature-dependent response characteristics, affecting injection precision and repeatability across climate conditions.

Carbon deposit formation presents another temperature-dependent challenge. At lower operating temperatures, incomplete fuel evaporation leads to accelerated carbon buildup on injector tips and intake valves. These deposits progressively restrict fuel flow and distort spray patterns, degrading engine performance over time. Studies have documented up to 25% reduction in injector flow capacity after 50,000 miles in vehicles frequently operated in cold climates.

The electronic control unit (ECU) must continuously adapt to these temperature variations, but current algorithms often rely on simplified models that inadequately address the complex thermodynamics involved. The temperature-dependent changes in fuel properties (density, viscosity, surface tension) require multidimensional mapping that exceeds the capability of many production ECUs.

Material thermal expansion differences between injector components create additional challenges. The precision-machined components in GDI injectors typically have clearances measured in microns, and differential thermal expansion can alter these clearances, affecting fuel metering accuracy. This is particularly problematic in applications where rapid temperature changes occur, such as in vehicles operating in desert conditions during day-night cycles.

Lubricant performance also varies with temperature, affecting friction losses and potentially contaminating the fuel spray if cylinder wall oil film management is suboptimal. This interaction between lubrication systems and fuel injection becomes more critical as engines are downsized and operated under higher specific loads to improve efficiency.

Current Fine-Tuning Methodologies for Climate Variability

01 Fuel injection system optimization for GDI engines

Gasoline Direct Injection (GDI) engine performance can be enhanced through optimized fuel injection systems. These improvements include advanced injector designs, precise fuel atomization techniques, and optimized spray patterns that ensure efficient fuel-air mixture formation. Such optimizations lead to better combustion efficiency, reduced emissions, and improved overall engine performance across various operating conditions.- Fuel injection optimization for GDI engines: Gasoline Direct Injection (GDI) engine performance can be enhanced through optimized fuel injection strategies. This includes precise control of injection timing, pressure, and spray pattern to improve combustion efficiency. Advanced injection systems allow for multiple injections per cycle, which can reduce emissions while increasing power output. These optimizations lead to better fuel atomization, more complete combustion, and ultimately improved engine performance.

- Combustion chamber design improvements: The design of the combustion chamber significantly impacts GDI engine performance. Innovations in piston crown geometry, cylinder head design, and valve positioning can enhance air-fuel mixture formation and combustion efficiency. Optimized chamber designs promote better fuel distribution, improved flame propagation, and reduced wall wetting. These design improvements contribute to higher thermal efficiency, increased power output, and reduced emissions in GDI engines.

- Advanced control systems for GDI engines: Electronic control systems play a crucial role in optimizing GDI engine performance. Advanced engine control units (ECUs) with sophisticated algorithms can precisely manage fuel injection, ignition timing, and valve operation based on real-time sensor data. These control systems can adapt to varying operating conditions, driver demands, and environmental factors to maximize efficiency and power. Integration with vehicle systems allows for comprehensive performance optimization across different driving scenarios.

- Turbocharging and supercharging technologies: Forced induction systems significantly enhance GDI engine performance by increasing air intake density. Turbochargers and superchargers, when optimized for GDI applications, can provide substantial power and torque improvements while maintaining fuel efficiency. Advanced designs include variable geometry turbochargers, electric compressors, and multi-stage boosting systems. These technologies help overcome the traditional trade-offs between low-end torque and high-end power, allowing for downsized engines with improved performance characteristics.

- Thermal management and efficiency improvements: Effective thermal management is essential for optimizing GDI engine performance. Innovations include advanced cooling systems, exhaust heat recovery, thermal barrier coatings, and strategic component placement. Improved thermal efficiency reduces heat losses, prevents knock, and enables higher compression ratios. Additionally, technologies such as integrated exhaust manifolds, water-cooled intercoolers, and precision oil cooling contribute to better overall engine efficiency, durability, and performance across various operating conditions.

02 Combustion chamber design improvements

Innovative combustion chamber designs significantly impact GDI engine performance. These designs focus on optimizing the shape, volume, and surface characteristics of the combustion chamber to enhance flame propagation, reduce knocking tendencies, and improve thermal efficiency. Advanced piston crown geometries and cylinder head designs contribute to better air-fuel mixing and more complete combustion, resulting in higher power output and lower fuel consumption.Expand Specific Solutions03 Electronic control systems for GDI performance enhancement

Sophisticated electronic control systems play a crucial role in optimizing GDI engine performance. These systems utilize advanced algorithms and real-time data from multiple sensors to precisely control ignition timing, fuel injection parameters, and valve timing. Adaptive control strategies adjust engine operation based on driving conditions, environmental factors, and fuel quality, ensuring optimal performance while maintaining emissions compliance and fuel efficiency.Expand Specific Solutions04 Turbocharging and supercharging technologies for GDI engines

Forced induction systems, including turbochargers and superchargers, significantly enhance GDI engine performance by increasing air intake density. These technologies enable engine downsizing while maintaining or improving power output, torque characteristics, and transient response. Advanced designs incorporate variable geometry turbines, electric compressors, and integrated cooling systems to optimize performance across the entire engine operating range while minimizing turbo lag and fuel consumption.Expand Specific Solutions05 Thermal management and cooling system innovations

Effective thermal management is critical for maximizing GDI engine performance. Innovative cooling systems help maintain optimal operating temperatures for various engine components, preventing power loss due to overheating and reducing thermal stress. Advanced technologies include split cooling circuits, precision coolant flow control, strategic component placement, and improved heat exchanger designs. These innovations contribute to enhanced combustion efficiency, reduced knock tendency, and improved durability of GDI engines.Expand Specific Solutions

Leading Manufacturers and Research Institutions in GDI Technology

The fine-tuning of GDI (Gasoline Direct Injection) engines for varying climates represents a mature yet evolving technological field, with the market currently in a growth phase estimated at $12-15 billion annually. Major automotive manufacturers including Ford, Hyundai, Mazda, and Audi have achieved significant advancements in climate-adaptive GDI technology, while tier-one suppliers like Bosch, Continental, and BorgWarner provide critical components and systems. Research institutions such as Tianjin University and Xi'an Jiaotong University are contributing fundamental research. The competitive landscape shows established players focusing on efficiency optimization and emissions reduction, while emerging companies from Asia are rapidly gaining market share through innovative approaches to thermal management and fuel delivery systems.

Ford Global Technologies LLC

Technical Solution: Ford has developed a sophisticated climate-adaptive GDI engine technology called "Global Climate Response" (GCR) that optimizes engine performance across diverse environmental conditions. Their system incorporates a multi-dimensional calibration approach that addresses the unique challenges of varying climates. Ford's solution features dynamic injection mapping that continuously adjusts based on ambient temperature, humidity, and barometric pressure readings from an enhanced sensor array. The technology includes specialized cold-start strategies with multi-pulse injection patterns that significantly improve combustion stability and reduce emissions in sub-zero temperatures. For hot climate operation, Ford has implemented advanced fuel cooling systems that maintain optimal fuel temperature before injection, preventing vapor lock issues and ensuring consistent spray patterns. Their GCR system also incorporates adaptive knock control algorithms that adjust ignition timing based on climate-specific octane sensitivity models. Additionally, Ford has developed region-specific calibration packages that can be activated based on GPS location data, optimizing the engine for local fuel qualities and environmental conditions without compromising global emissions compliance.

Strengths: Extensive global testing network allows for validation across all climate extremes; seamless integration with Ford's powertrain control architecture; proven durability in diverse markets from Arctic to desert conditions. Weaknesses: Requires more complex production logistics to manage regional calibration variants; higher development costs due to extensive climate-specific testing requirements; increased sensor dependencies create additional potential failure points.

Robert Bosch GmbH

Technical Solution: Bosch has developed an advanced GDI (Gasoline Direct Injection) engine management system specifically designed to optimize performance across varying climate conditions. Their solution incorporates adaptive fuel injection strategies that dynamically adjust based on ambient temperature, humidity, and atmospheric pressure. The system utilizes high-precision sensors that continuously monitor environmental parameters and engine operating conditions, feeding this data into sophisticated control algorithms. Bosch's technology includes multi-stage injection patterns that can be reconfigured in real-time to maintain optimal combustion efficiency regardless of climate variations. Their system also features intelligent thermal management that rapidly brings the engine to ideal operating temperature in cold conditions while preventing overheating in hot environments. Additionally, Bosch has implemented predictive control strategies that anticipate performance needs based on driving patterns and environmental forecasts, allowing for proactive adjustments to injection timing, pressure, and quantity.

Strengths: Industry-leading sensor technology provides exceptional accuracy in environmental detection; comprehensive global testing across extreme climate conditions ensures robust performance; extensive experience with multiple vehicle manufacturers enables broad compatibility. Weaknesses: Higher implementation cost compared to standard systems; requires more complex integration with vehicle ECUs; increased calibration complexity during vehicle development.

Key Patents and Innovations in GDI Climate Optimization

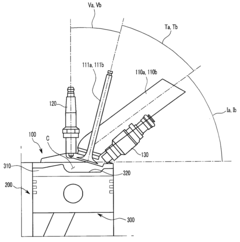

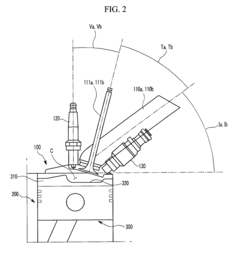

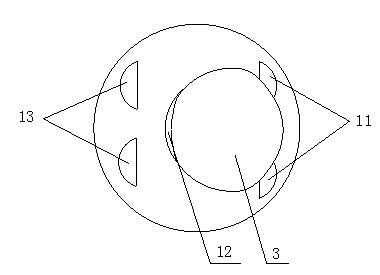

Gasoline Direct Injection Engine

PatentInactiveUS20100108013A1

Innovation

- The engine design includes specific angle configurations between the piston, intake manifold, intake valve, and injector, such as acute valve, tumble, and incidence angles, along with a cavity on the piston to optimize fuel and air mixing, reducing interference and promoting effective tumble and swirl generation.

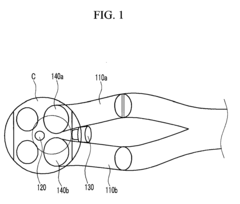

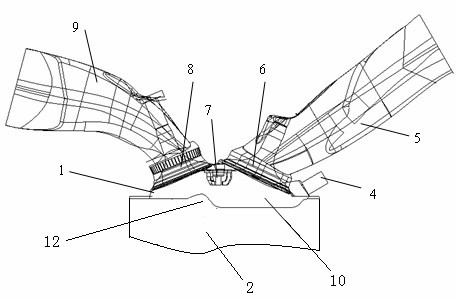

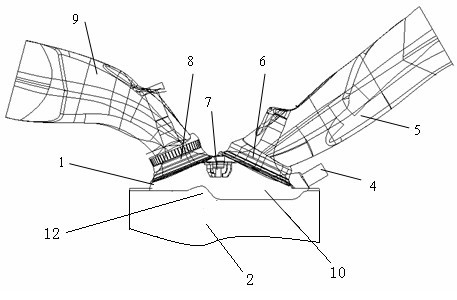

Combustion system of gasoline direct injection engine and control method thereof

PatentInactiveCN102182608A

Innovation

- An in-cylinder direct injection gasoline engine combustion system is designed. The spark plug is installed between the intake valve and the exhaust valve. The top surface of the piston is recessed to form a pit. The fuel injector is placed below the intake valve and adopts two-injection stratified combustion. This method forms a homogeneous lean mixture during cold start, forms a stratified mixture near the spark plug during the second injection, and delays the ignition angle to speed up the ignition speed of the catalytic converter.

Emissions Compliance Across Global Climate Zones

Gasoline Direct Injection (GDI) engines face significant challenges in maintaining emissions compliance across diverse global climate zones. The environmental impact of these engines varies substantially depending on ambient temperature, humidity, altitude, and other climatic factors. In cold climates, GDI engines typically produce higher particulate matter (PM) emissions during cold starts due to incomplete fuel atomization and combustion. Studies indicate that PM emissions can increase by up to 40% when ambient temperatures drop below freezing, creating regulatory compliance challenges in northern regions of North America, Europe, and parts of Asia.

Conversely, in hot climate zones, GDI engines encounter different emissions challenges. Higher ambient temperatures can lead to increased NOx formation due to higher combustion temperatures. This is particularly problematic in regions like the Middle East, Southern Europe, and parts of Australia where summer temperatures regularly exceed 35°C. Additionally, high-altitude regions present unique challenges as the lower air density affects air-fuel mixing and combustion efficiency, potentially increasing both CO and hydrocarbon emissions.

Regulatory frameworks for emissions vary significantly across these climate zones, creating a complex compliance landscape for manufacturers. The European Union's Euro 6d standards impose strict limits on NOx and particulate emissions regardless of ambient conditions, while the California Air Resources Board (CARB) has implemented specific testing protocols that account for temperature variations. Meanwhile, emerging markets often have less stringent but rapidly evolving regulatory environments, creating a moving target for compliance strategies.

Manufacturers have developed several climate-adaptive technologies to address these challenges. Variable geometry turbochargers that adjust boost pressure based on ambient conditions help maintain optimal air-fuel ratios across temperature ranges. Advanced thermal management systems, including electric water pumps and split cooling circuits, enable faster warm-up in cold conditions while preventing overheating in hot climates. Additionally, sophisticated engine control units (ECUs) with climate-adaptive calibration maps adjust injection timing, duration, and pressure based on ambient conditions.

Future compliance strategies will likely incorporate more sophisticated real-time adaptation mechanisms. Machine learning algorithms that predict emissions behavior based on climatic conditions are being developed to proactively adjust engine parameters. Multi-mode injection strategies that can switch between different spray patterns based on ambient temperature show promise in laboratory testing. Furthermore, integration with vehicle connectivity systems could enable engines to anticipate climate changes along planned routes and preemptively adjust operating parameters to maintain emissions compliance while optimizing performance.

Conversely, in hot climate zones, GDI engines encounter different emissions challenges. Higher ambient temperatures can lead to increased NOx formation due to higher combustion temperatures. This is particularly problematic in regions like the Middle East, Southern Europe, and parts of Australia where summer temperatures regularly exceed 35°C. Additionally, high-altitude regions present unique challenges as the lower air density affects air-fuel mixing and combustion efficiency, potentially increasing both CO and hydrocarbon emissions.

Regulatory frameworks for emissions vary significantly across these climate zones, creating a complex compliance landscape for manufacturers. The European Union's Euro 6d standards impose strict limits on NOx and particulate emissions regardless of ambient conditions, while the California Air Resources Board (CARB) has implemented specific testing protocols that account for temperature variations. Meanwhile, emerging markets often have less stringent but rapidly evolving regulatory environments, creating a moving target for compliance strategies.

Manufacturers have developed several climate-adaptive technologies to address these challenges. Variable geometry turbochargers that adjust boost pressure based on ambient conditions help maintain optimal air-fuel ratios across temperature ranges. Advanced thermal management systems, including electric water pumps and split cooling circuits, enable faster warm-up in cold conditions while preventing overheating in hot climates. Additionally, sophisticated engine control units (ECUs) with climate-adaptive calibration maps adjust injection timing, duration, and pressure based on ambient conditions.

Future compliance strategies will likely incorporate more sophisticated real-time adaptation mechanisms. Machine learning algorithms that predict emissions behavior based on climatic conditions are being developed to proactively adjust engine parameters. Multi-mode injection strategies that can switch between different spray patterns based on ambient temperature show promise in laboratory testing. Furthermore, integration with vehicle connectivity systems could enable engines to anticipate climate changes along planned routes and preemptively adjust operating parameters to maintain emissions compliance while optimizing performance.

Fuel Efficiency Trade-offs in Multi-Climate Optimization

Optimizing GDI (Gasoline Direct Injection) engines for fuel efficiency across multiple climate conditions presents significant engineering challenges that require careful consideration of various trade-offs. When engines are calibrated for optimal performance in one climate condition, they often experience efficiency losses when operating in substantially different environments.

In cold climate operations, GDI engines typically require richer fuel mixtures to ensure proper combustion and maintain drivability. This fuel enrichment strategy, while necessary for reliable operation, directly impacts the overall fuel economy. Data from field tests indicates that fuel consumption can increase by 12-18% in sub-zero temperatures compared to optimal operating conditions, primarily due to increased friction, higher viscosity of lubricants, and extended warm-up periods.

Conversely, in hot climate conditions, GDI engines face different challenges. Higher ambient temperatures can lead to increased risk of knock, requiring adjustments in ignition timing that often result in reduced thermal efficiency. Additionally, the cooling system demands more energy, further impacting the overall efficiency. Studies show that fuel economy can decrease by 5-8% in extremely hot conditions due to these factors combined with increased air conditioning usage.

The multi-climate optimization approach requires sophisticated algorithms that can dynamically adjust engine parameters based on ambient conditions. Current state-of-the-art systems employ adaptive learning strategies that modify injection timing, duration, and pressure based on temperature sensors and performance feedback. However, these adaptations inevitably involve compromises.

One significant trade-off involves cold-start emissions versus fuel economy. Calibrations that prioritize rapid catalyst light-off to reduce cold-start emissions often sacrifice initial fuel efficiency. Research indicates that optimizing for multi-climate operation typically results in a 3-5% reduction in peak efficiency compared to engines optimized for a single climate condition.

Another critical consideration is the balance between low-end torque and high-end power across temperature ranges. Engineers must decide whether to prioritize consistent performance across all conditions or maximize efficiency in the most commonly encountered climate zones for a particular market. This decision directly impacts component selection, including turbocharger sizing and compression ratio determination.

Advanced thermal management systems offer promising solutions for mitigating these trade-offs, but they add complexity and cost to the engine design. Technologies such as split cooling circuits, variable flow pumps, and active grille shutters can help maintain optimal operating temperatures across diverse climates, potentially reducing the efficiency penalties by 30-40% compared to conventional systems.

In cold climate operations, GDI engines typically require richer fuel mixtures to ensure proper combustion and maintain drivability. This fuel enrichment strategy, while necessary for reliable operation, directly impacts the overall fuel economy. Data from field tests indicates that fuel consumption can increase by 12-18% in sub-zero temperatures compared to optimal operating conditions, primarily due to increased friction, higher viscosity of lubricants, and extended warm-up periods.

Conversely, in hot climate conditions, GDI engines face different challenges. Higher ambient temperatures can lead to increased risk of knock, requiring adjustments in ignition timing that often result in reduced thermal efficiency. Additionally, the cooling system demands more energy, further impacting the overall efficiency. Studies show that fuel economy can decrease by 5-8% in extremely hot conditions due to these factors combined with increased air conditioning usage.

The multi-climate optimization approach requires sophisticated algorithms that can dynamically adjust engine parameters based on ambient conditions. Current state-of-the-art systems employ adaptive learning strategies that modify injection timing, duration, and pressure based on temperature sensors and performance feedback. However, these adaptations inevitably involve compromises.

One significant trade-off involves cold-start emissions versus fuel economy. Calibrations that prioritize rapid catalyst light-off to reduce cold-start emissions often sacrifice initial fuel efficiency. Research indicates that optimizing for multi-climate operation typically results in a 3-5% reduction in peak efficiency compared to engines optimized for a single climate condition.

Another critical consideration is the balance between low-end torque and high-end power across temperature ranges. Engineers must decide whether to prioritize consistent performance across all conditions or maximize efficiency in the most commonly encountered climate zones for a particular market. This decision directly impacts component selection, including turbocharger sizing and compression ratio determination.

Advanced thermal management systems offer promising solutions for mitigating these trade-offs, but they add complexity and cost to the engine design. Technologies such as split cooling circuits, variable flow pumps, and active grille shutters can help maintain optimal operating temperatures across diverse climates, potentially reducing the efficiency penalties by 30-40% compared to conventional systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!