GaN HEMT Implementation In Industrial Motor Drives

SEP 8, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

GaN HEMT Evolution and Implementation Goals

Gallium Nitride (GaN) High Electron Mobility Transistors (HEMTs) have emerged as revolutionary power semiconductor devices, transforming the landscape of industrial motor drives over the past decade. The evolution of GaN HEMT technology began in the early 1990s with fundamental research into wide bandgap semiconductors, but significant commercial implementation only materialized in the 2010s when manufacturing processes matured sufficiently for industrial applications.

The technological trajectory of GaN HEMTs has been characterized by continuous improvements in power density, switching frequency capabilities, and thermal performance. Early iterations faced challenges with reliability and cost-effectiveness, limiting their industrial adoption. However, recent advancements have addressed these limitations, enabling GaN HEMTs to operate at higher voltages (600V-1200V) and temperatures (up to 250°C) while maintaining exceptional efficiency.

Current implementation goals for GaN HEMTs in industrial motor drives center around several key objectives. Primary among these is achieving higher power conversion efficiency, with targets exceeding 99% in next-generation designs. This represents a significant improvement over traditional silicon-based solutions that typically plateau at 96-97% efficiency. The resulting reduction in energy consumption directly translates to operational cost savings and reduced environmental impact.

Another critical implementation goal involves increasing power density to enable more compact motor drive designs. GaN HEMTs' ability to switch at frequencies 5-10 times higher than silicon IGBTs allows for smaller passive components, potentially reducing overall drive volume by 30-50%. This miniaturization trend aligns with industry demands for space-efficient solutions in robotics, electric vehicles, and factory automation.

Reliability enhancement represents a third pivotal goal, with research focused on extending device lifetime under harsh industrial conditions. Current efforts target mean time between failures (MTBF) exceeding 100,000 hours while maintaining performance stability across wide temperature ranges and under repetitive stress conditions. This reliability imperative is particularly relevant for mission-critical applications where downtime carries substantial financial implications.

Cost reduction remains an ongoing objective, with industry roadmaps aiming to achieve price parity with silicon alternatives by 2025-2027. This goal necessitates innovations in substrate materials, epitaxial growth techniques, and high-volume manufacturing processes. Recent progress in 8-inch GaN-on-Si wafer technology represents a significant step toward this economic target.

The ultimate implementation goal extends beyond component-level improvements to system-level optimization. This includes developing specialized gate drivers, optimized thermal management solutions, and EMI mitigation techniques specifically tailored for high-frequency GaN operation in motor drive applications. Such holistic approaches are essential to fully capitalize on GaN HEMT's inherent advantages and overcome integration challenges in real-world industrial environments.

The technological trajectory of GaN HEMTs has been characterized by continuous improvements in power density, switching frequency capabilities, and thermal performance. Early iterations faced challenges with reliability and cost-effectiveness, limiting their industrial adoption. However, recent advancements have addressed these limitations, enabling GaN HEMTs to operate at higher voltages (600V-1200V) and temperatures (up to 250°C) while maintaining exceptional efficiency.

Current implementation goals for GaN HEMTs in industrial motor drives center around several key objectives. Primary among these is achieving higher power conversion efficiency, with targets exceeding 99% in next-generation designs. This represents a significant improvement over traditional silicon-based solutions that typically plateau at 96-97% efficiency. The resulting reduction in energy consumption directly translates to operational cost savings and reduced environmental impact.

Another critical implementation goal involves increasing power density to enable more compact motor drive designs. GaN HEMTs' ability to switch at frequencies 5-10 times higher than silicon IGBTs allows for smaller passive components, potentially reducing overall drive volume by 30-50%. This miniaturization trend aligns with industry demands for space-efficient solutions in robotics, electric vehicles, and factory automation.

Reliability enhancement represents a third pivotal goal, with research focused on extending device lifetime under harsh industrial conditions. Current efforts target mean time between failures (MTBF) exceeding 100,000 hours while maintaining performance stability across wide temperature ranges and under repetitive stress conditions. This reliability imperative is particularly relevant for mission-critical applications where downtime carries substantial financial implications.

Cost reduction remains an ongoing objective, with industry roadmaps aiming to achieve price parity with silicon alternatives by 2025-2027. This goal necessitates innovations in substrate materials, epitaxial growth techniques, and high-volume manufacturing processes. Recent progress in 8-inch GaN-on-Si wafer technology represents a significant step toward this economic target.

The ultimate implementation goal extends beyond component-level improvements to system-level optimization. This includes developing specialized gate drivers, optimized thermal management solutions, and EMI mitigation techniques specifically tailored for high-frequency GaN operation in motor drive applications. Such holistic approaches are essential to fully capitalize on GaN HEMT's inherent advantages and overcome integration challenges in real-world industrial environments.

Market Demand for GaN-based Motor Drive Solutions

The global market for industrial motor drives is experiencing a significant shift towards more efficient and compact solutions, with Gallium Nitride (GaN) High Electron Mobility Transistor (HEMT) technology emerging as a promising alternative to traditional silicon-based power devices. Current market analysis indicates that the industrial motor drive sector, valued at approximately $16 billion in 2022, is projected to grow at a compound annual growth rate (CAGR) of 5.8% through 2028, with energy-efficient solutions being a primary driver.

The demand for GaN-based motor drive solutions is being fueled by several key market factors. Industrial automation continues to expand across manufacturing sectors, requiring more precise motor control and higher efficiency drives. This trend is particularly evident in industries such as automotive manufacturing, food processing, and pharmaceutical production, where precision motion control directly impacts product quality and operational costs.

Energy efficiency regulations and sustainability initiatives worldwide are creating substantial market pull for more efficient motor drive technologies. The European Union's Ecodesign Directive, China's Energy Efficiency Top Runner program, and similar policies in North America are establishing increasingly stringent efficiency standards for industrial motors and drives. GaN HEMT technology, with its potential to reduce power losses by 40-50% compared to silicon IGBTs, presents a compelling solution to meet these regulatory requirements.

The miniaturization trend in industrial equipment is another significant market driver. Manufacturing facilities are increasingly space-constrained, particularly in high-cost urban areas, creating demand for smaller motor drive solutions. GaN-based drives, which can operate at higher switching frequencies, enable smaller passive components and heat sinks, potentially reducing overall drive volume by up to 60% compared to silicon-based alternatives.

Total cost of ownership considerations are shifting purchasing decisions toward higher-efficiency solutions despite higher initial costs. Market research indicates that industrial customers are increasingly willing to pay a 15-25% premium for motor drives that offer demonstrable energy savings and reliability improvements over conventional options. This shift in purchasing behavior is creating a viable market entry point for GaN technology despite its current cost premium.

Specific industry verticals showing the strongest demand include HVAC systems, where variable frequency drives are essential for energy optimization; electric vehicle charging infrastructure, which benefits from GaN's high power density; and renewable energy systems, where efficient power conversion is critical. These sectors collectively represent over 40% of the potential market for GaN-based motor drive solutions.

Regional analysis shows that Asia-Pacific currently leads in adoption potential, driven by China's manufacturing sector and Japan's focus on industrial automation. North America and Europe follow closely, with particular interest in GaN solutions for upgrading aging industrial infrastructure to meet new efficiency standards.

The demand for GaN-based motor drive solutions is being fueled by several key market factors. Industrial automation continues to expand across manufacturing sectors, requiring more precise motor control and higher efficiency drives. This trend is particularly evident in industries such as automotive manufacturing, food processing, and pharmaceutical production, where precision motion control directly impacts product quality and operational costs.

Energy efficiency regulations and sustainability initiatives worldwide are creating substantial market pull for more efficient motor drive technologies. The European Union's Ecodesign Directive, China's Energy Efficiency Top Runner program, and similar policies in North America are establishing increasingly stringent efficiency standards for industrial motors and drives. GaN HEMT technology, with its potential to reduce power losses by 40-50% compared to silicon IGBTs, presents a compelling solution to meet these regulatory requirements.

The miniaturization trend in industrial equipment is another significant market driver. Manufacturing facilities are increasingly space-constrained, particularly in high-cost urban areas, creating demand for smaller motor drive solutions. GaN-based drives, which can operate at higher switching frequencies, enable smaller passive components and heat sinks, potentially reducing overall drive volume by up to 60% compared to silicon-based alternatives.

Total cost of ownership considerations are shifting purchasing decisions toward higher-efficiency solutions despite higher initial costs. Market research indicates that industrial customers are increasingly willing to pay a 15-25% premium for motor drives that offer demonstrable energy savings and reliability improvements over conventional options. This shift in purchasing behavior is creating a viable market entry point for GaN technology despite its current cost premium.

Specific industry verticals showing the strongest demand include HVAC systems, where variable frequency drives are essential for energy optimization; electric vehicle charging infrastructure, which benefits from GaN's high power density; and renewable energy systems, where efficient power conversion is critical. These sectors collectively represent over 40% of the potential market for GaN-based motor drive solutions.

Regional analysis shows that Asia-Pacific currently leads in adoption potential, driven by China's manufacturing sector and Japan's focus on industrial automation. North America and Europe follow closely, with particular interest in GaN solutions for upgrading aging industrial infrastructure to meet new efficiency standards.

GaN HEMT Technology Status and Challenges

Gallium Nitride High Electron Mobility Transistors (GaN HEMTs) have emerged as a revolutionary technology in power electronics, offering significant advantages over traditional silicon-based devices. Currently, GaN HEMT technology has reached commercial maturity for applications below 650V, with several manufacturers offering reliable products. The wide bandgap properties of GaN enable higher breakdown voltages, faster switching speeds, and lower on-resistance compared to silicon MOSFETs, making them particularly attractive for industrial motor drive applications.

Despite these advancements, GaN HEMT technology faces several critical challenges that limit its widespread adoption in industrial motor drives. Thermal management remains a significant concern due to the high power density and concentrated heat generation in these devices. The thermal conductivity of GaN substrates is lower than that of silicon carbide, necessitating innovative cooling solutions for high-power applications typical in industrial environments.

Reliability issues continue to pose challenges, particularly in high-temperature and high-voltage switching conditions common in industrial motor drives. Current collapse phenomena and dynamic on-resistance increase under high-voltage stress can degrade performance over time. Additionally, gate reliability concerns, including threshold voltage shifts and gate leakage, require further improvement for the extended operational lifetimes expected in industrial applications.

Manufacturing scalability presents another significant hurdle. While GaN-on-Si technology has made considerable progress in reducing costs, the production of large-diameter wafers with consistent quality remains challenging. Defect densities in GaN epitaxial layers grown on silicon substrates are still higher than ideal, affecting device yield and reliability in high-power applications.

From a geographical perspective, GaN HEMT technology development shows distinct regional characteristics. Japan and the United States lead in fundamental research and intellectual property, while Taiwan and China have made significant investments in manufacturing infrastructure. European research institutions have focused on reliability enhancement and application-specific optimizations for industrial systems.

The integration of GaN HEMTs into motor drive systems introduces additional challenges related to gate driver design and electromagnetic interference (EMI) management. The ultra-fast switching capabilities of GaN devices (sub-10ns) require specialized gate drivers with precise timing control and robust protection features. Furthermore, the rapid voltage transitions can generate significant EMI, necessitating careful circuit layout and filtering techniques.

Cost remains a significant barrier to widespread adoption in cost-sensitive industrial applications. While the performance benefits of GaN HEMTs are well-established, the price premium over silicon alternatives still limits penetration in many industrial motor drive segments where initial cost often outweighs lifetime efficiency gains in purchasing decisions.

Despite these advancements, GaN HEMT technology faces several critical challenges that limit its widespread adoption in industrial motor drives. Thermal management remains a significant concern due to the high power density and concentrated heat generation in these devices. The thermal conductivity of GaN substrates is lower than that of silicon carbide, necessitating innovative cooling solutions for high-power applications typical in industrial environments.

Reliability issues continue to pose challenges, particularly in high-temperature and high-voltage switching conditions common in industrial motor drives. Current collapse phenomena and dynamic on-resistance increase under high-voltage stress can degrade performance over time. Additionally, gate reliability concerns, including threshold voltage shifts and gate leakage, require further improvement for the extended operational lifetimes expected in industrial applications.

Manufacturing scalability presents another significant hurdle. While GaN-on-Si technology has made considerable progress in reducing costs, the production of large-diameter wafers with consistent quality remains challenging. Defect densities in GaN epitaxial layers grown on silicon substrates are still higher than ideal, affecting device yield and reliability in high-power applications.

From a geographical perspective, GaN HEMT technology development shows distinct regional characteristics. Japan and the United States lead in fundamental research and intellectual property, while Taiwan and China have made significant investments in manufacturing infrastructure. European research institutions have focused on reliability enhancement and application-specific optimizations for industrial systems.

The integration of GaN HEMTs into motor drive systems introduces additional challenges related to gate driver design and electromagnetic interference (EMI) management. The ultra-fast switching capabilities of GaN devices (sub-10ns) require specialized gate drivers with precise timing control and robust protection features. Furthermore, the rapid voltage transitions can generate significant EMI, necessitating careful circuit layout and filtering techniques.

Cost remains a significant barrier to widespread adoption in cost-sensitive industrial applications. While the performance benefits of GaN HEMTs are well-established, the price premium over silicon alternatives still limits penetration in many industrial motor drive segments where initial cost often outweighs lifetime efficiency gains in purchasing decisions.

Current GaN HEMT Solutions for Motor Drives

01 GaN HEMT device structures and fabrication methods

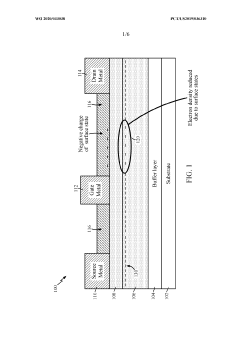

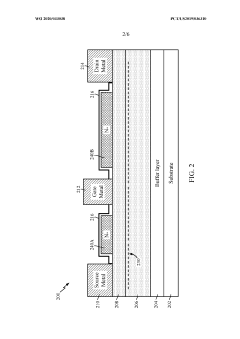

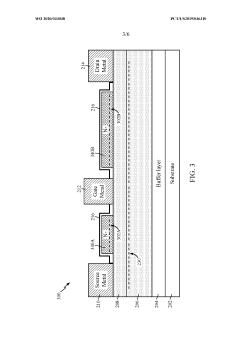

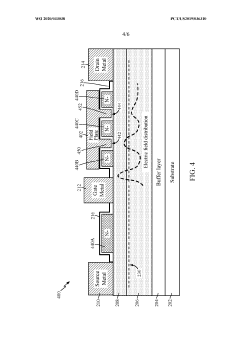

Gallium Nitride High Electron Mobility Transistors (GaN HEMTs) have specific device structures that enhance their performance. These structures include specialized gate configurations, buffer layers, and channel designs that improve electron mobility and power handling capabilities. Various fabrication methods are employed to create these structures, including epitaxial growth techniques and advanced lithography processes that optimize the two-dimensional electron gas (2DEG) formation at the heterojunction interface.- GaN HEMT device structure and fabrication: Gallium Nitride High Electron Mobility Transistors (GaN HEMTs) have specific device structures that enhance their performance. These structures typically include multiple layers such as buffer layers, channel layers, barrier layers, and cap layers. The fabrication processes involve epitaxial growth techniques, gate formation, and contact metallization. Various structural innovations aim to improve electron mobility, reduce leakage current, and enhance overall device performance.

- Power applications and efficiency improvements: GaN HEMTs are widely used in power electronics applications due to their high breakdown voltage, low on-resistance, and high-frequency operation capabilities. Innovations in this area focus on improving power efficiency, thermal management, and reliability under high-voltage and high-current conditions. These improvements enable GaN HEMTs to outperform silicon-based devices in power conversion applications, including power supplies, inverters, and motor drives.

- RF and microwave applications: GaN HEMTs excel in radio frequency (RF) and microwave applications due to their high electron mobility and power density. Designs in this category focus on optimizing frequency response, linearity, and power output for communications systems, radar, and wireless infrastructure. Specific innovations include improved impedance matching networks, harmonic suppression techniques, and specialized layouts for high-frequency performance.

- Reliability and thermal management solutions: Ensuring long-term reliability and effective thermal management are critical challenges for GaN HEMT technology. Innovations in this area include novel heat dissipation structures, passivation techniques to prevent degradation, and design modifications to reduce hot electron effects and current collapse phenomena. These solutions aim to extend device lifetime and maintain stable performance under various operating conditions.

- Integration and packaging technologies: Advanced integration and packaging technologies for GaN HEMTs focus on combining these devices with other components and implementing them in practical systems. This includes heterogeneous integration with silicon-based circuits, novel packaging approaches to maximize thermal performance, and module-level designs that optimize the overall system performance. These innovations enable GaN HEMTs to be effectively utilized in compact, high-performance electronic systems.

02 Power electronics applications of GaN HEMTs

GaN HEMTs are widely used in power electronics applications due to their high breakdown voltage, low on-resistance, and excellent thermal conductivity. These transistors enable more efficient power conversion in applications such as power supplies, motor drives, and renewable energy systems. The wide bandgap properties of GaN allow these devices to operate at higher frequencies and temperatures compared to silicon-based alternatives, resulting in smaller, more efficient power electronic systems.Expand Specific Solutions03 RF and microwave applications of GaN HEMTs

GaN HEMTs excel in radio frequency (RF) and microwave applications due to their high electron mobility and saturation velocity. These properties enable high-frequency operation with superior power density and efficiency compared to other semiconductor technologies. GaN HEMTs are used in wireless communication infrastructure, radar systems, and satellite communications where high power, high frequency, and reliability are critical requirements.Expand Specific Solutions04 Reliability and thermal management of GaN HEMTs

Reliability and thermal management are crucial aspects of GaN HEMT technology. Various techniques are employed to address challenges such as current collapse, gate leakage, and thermal degradation. These include passivation layers, field plates, and specialized heat dissipation structures. Advanced packaging solutions and thermal interface materials are also developed to manage the high power density of these devices and ensure long-term operational stability under extreme conditions.Expand Specific Solutions05 Novel materials and integration technologies for GaN HEMTs

Research in GaN HEMT technology focuses on novel materials and integration approaches to enhance performance. This includes the development of new barrier layers, substrates, and gate dielectrics to improve device characteristics. Integration technologies such as monolithic integration with other semiconductor technologies, heterogeneous integration on silicon platforms, and advanced packaging techniques are being explored to enable new applications and improve overall system performance.Expand Specific Solutions

Key Players in GaN HEMT and Industrial Drive Market

GaN HEMT technology in industrial motor drives is currently in the early growth phase, with a rapidly expanding market expected to reach significant scale due to increasing demand for high-efficiency power electronics. The technology offers superior switching performance and power density compared to silicon-based solutions, though it remains in the transition from research to widespread commercial adoption. Leading players include established semiconductor manufacturers like Wolfspeed, Infineon Technologies, and Texas Instruments who are developing commercial GaN power devices, alongside research-focused entities such as Xidian University and Peking University advancing fundamental technologies. Companies like Nexperia and Power Integrations are focusing on application-specific implementations, while TSMC and UMC provide critical manufacturing capabilities, creating a competitive ecosystem that spans research institutions and commercial enterprises across the value chain.

Wolfspeed, Inc.

Technical Solution: Wolfspeed has pioneered GaN HEMT technology for industrial motor drives with their silicon carbide (SiC) and gallium nitride (GaN) power solutions. Their implementation focuses on high-frequency operation (>100 kHz) that enables smaller passive components and higher power density. Wolfspeed's GaN HEMT devices feature low on-resistance (RDS(on)) of less than 70 mΩ and fast switching capabilities with rise/fall times under 10ns. Their motor drive solutions incorporate advanced gate driver designs with robust protection features to manage the fast switching transients inherent in GaN technology. Wolfspeed has demonstrated motor drive efficiency improvements of 2-3% compared to silicon-based solutions, which translates to significant energy savings in industrial applications. Their GaN HEMT devices operate at 650V rating with low output capacitance (Coss) enabling reduced switching losses and higher frequency operation in motor drive inverters.

Strengths: Industry-leading GaN material quality with vertical integration from substrate to device manufacturing; exceptional thermal performance allowing higher power density; proven reliability with robust short-circuit capability. Weaknesses: Higher cost compared to silicon solutions; requires more sophisticated gate drive circuits; limited availability of complementary components optimized for GaN's switching speeds.

STMicroelectronics International NV

Technical Solution: STMicroelectronics has developed a comprehensive GaN HEMT solution for industrial motor drives based on their PowerGaN technology. Their implementation features 650V normally-off GaN HEMTs with RDS(on) values below 50mΩ, specifically optimized for high-frequency motor drive applications. ST's approach integrates specialized gate drivers with their GaN devices that provide precise timing control and robust protection features essential for industrial reliability. Their motor drive reference designs demonstrate switching frequencies up to 300 kHz, enabling smaller filter components and higher power density exceeding 3 kW/L. ST's implementation includes advanced thermal management techniques with specialized packaging achieving thermal resistance below 0.6°C/W. Their GaN-based motor drives incorporate sophisticated control algorithms that leverage the fast switching capabilities to improve motor efficiency and dynamic response. ST has also developed EMI mitigation techniques specific to GaN implementations in industrial environments, addressing one of the key challenges in high-frequency motor drive applications.

Strengths: Vertical integration from semiconductor manufacturing to system solutions; robust reliability testing and qualification for industrial environments; comprehensive development ecosystem including software tools and reference designs. Weaknesses: Relatively newer to GaN technology compared to some specialized competitors; higher system complexity requiring careful design; premium pricing compared to silicon-based solutions.

Core Patents and Innovations in GaN HEMT Technology

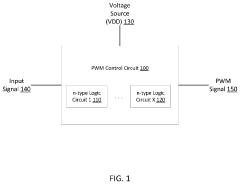

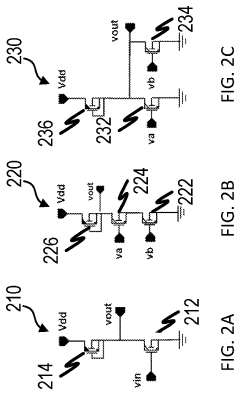

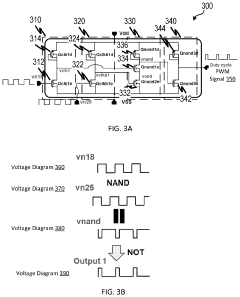

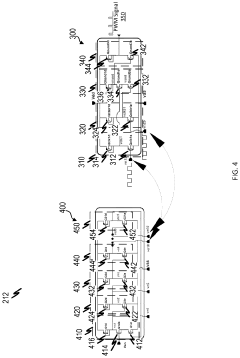

Pulse Width Control Apparatus and Method

PatentActiveUS20230396238A1

Innovation

- Implementing logic circuitry using only n-type HEMTs to generate PWM signals with minimal to no power loss, utilizing a combination of enhancement mode (E-HEMTs) and depletion mode (D-HEMTs) in series to control duty cycles without the need for additional components like sawtooth generators, level shifters, or comparators.

Gallium nitride high electron mobility transistor with ledges and field plates

PatentWO2020033038A1

Innovation

- Incorporating n-doped protuberances, or ledges, between the gate and source/drain electrodes, and optionally using field plates, to reduce surface states and increase channel electron density, thereby enhancing breakdown voltage and switching efficiency.

Thermal Management Strategies for GaN HEMT Drives

Thermal management represents a critical challenge in the implementation of Gallium Nitride High Electron Mobility Transistor (GaN HEMT) technology for industrial motor drives. As these devices operate at higher switching frequencies and power densities than traditional silicon-based solutions, they generate significant thermal loads that must be effectively managed to ensure reliability and performance.

The thermal conductivity limitations of GaN substrates present a fundamental challenge, with thermal resistance values typically ranging from 15-30°C/W depending on device packaging. This creates thermal bottlenecks that can lead to junction temperatures exceeding safe operating limits, particularly during high-load conditions common in industrial motor applications.

Current thermal management strategies employ multi-layered approaches combining both passive and active cooling techniques. Advanced packaging solutions utilizing direct bonded copper (DBC) substrates and sintered silver die-attach materials have demonstrated up to 40% improvement in thermal resistance compared to traditional solder-based approaches. These materials provide superior thermal pathways from the GaN die to external heat dissipation structures.

Heat spreading techniques have evolved significantly, with integrated heat spreaders constructed from materials such as copper-molybdenum composites and diamond-copper composites showing promising results. These advanced materials offer thermal conductivity values exceeding 500 W/mK, substantially outperforming conventional aluminum heat sinks limited to approximately 200 W/mK.

Active cooling solutions including forced air convection and liquid cooling systems have been optimized specifically for GaN HEMT applications. Recent developments in microchannel liquid cooling placed directly beneath GaN devices have demonstrated the ability to maintain junction temperatures below 125°C even at power densities exceeding 1 kW/cm².

Thermal interface materials (TIMs) play a crucial role in the thermal management stack. Novel graphene and boron nitride-enhanced thermal greases and phase-change materials have reduced thermal boundary resistance by up to 35% compared to conventional silicone-based compounds, with thermal conductivity values reaching 8-12 W/mK.

Dynamic thermal management through intelligent control algorithms represents an emerging approach. These systems continuously monitor device temperatures and adaptively adjust switching frequencies and gate drive parameters to optimize the performance-thermal tradeoff. Implementation of such systems in industrial motor drives has demonstrated the ability to increase effective power throughput by 15-25% while maintaining safe operating temperatures.

The thermal conductivity limitations of GaN substrates present a fundamental challenge, with thermal resistance values typically ranging from 15-30°C/W depending on device packaging. This creates thermal bottlenecks that can lead to junction temperatures exceeding safe operating limits, particularly during high-load conditions common in industrial motor applications.

Current thermal management strategies employ multi-layered approaches combining both passive and active cooling techniques. Advanced packaging solutions utilizing direct bonded copper (DBC) substrates and sintered silver die-attach materials have demonstrated up to 40% improvement in thermal resistance compared to traditional solder-based approaches. These materials provide superior thermal pathways from the GaN die to external heat dissipation structures.

Heat spreading techniques have evolved significantly, with integrated heat spreaders constructed from materials such as copper-molybdenum composites and diamond-copper composites showing promising results. These advanced materials offer thermal conductivity values exceeding 500 W/mK, substantially outperforming conventional aluminum heat sinks limited to approximately 200 W/mK.

Active cooling solutions including forced air convection and liquid cooling systems have been optimized specifically for GaN HEMT applications. Recent developments in microchannel liquid cooling placed directly beneath GaN devices have demonstrated the ability to maintain junction temperatures below 125°C even at power densities exceeding 1 kW/cm².

Thermal interface materials (TIMs) play a crucial role in the thermal management stack. Novel graphene and boron nitride-enhanced thermal greases and phase-change materials have reduced thermal boundary resistance by up to 35% compared to conventional silicone-based compounds, with thermal conductivity values reaching 8-12 W/mK.

Dynamic thermal management through intelligent control algorithms represents an emerging approach. These systems continuously monitor device temperatures and adaptively adjust switching frequencies and gate drive parameters to optimize the performance-thermal tradeoff. Implementation of such systems in industrial motor drives has demonstrated the ability to increase effective power throughput by 15-25% while maintaining safe operating temperatures.

Reliability and Lifetime Assessment of GaN-based Systems

The reliability and lifetime assessment of GaN-based systems represents a critical consideration for industrial motor drive applications. GaN HEMTs offer superior performance characteristics compared to silicon alternatives, but their long-term reliability under harsh industrial conditions requires comprehensive evaluation. Current reliability testing methodologies focus on accelerated stress tests including high-temperature reverse bias (HTRB), high-temperature gate bias (HTGB), and temperature-humidity-bias (THB) tests to simulate extreme operating conditions.

Field data collected from early GaN HEMT implementations in motor drives indicates promising reliability metrics, with failure rates comparable to established silicon technologies after accounting for infant mortality failures. The primary degradation mechanisms observed include time-dependent dielectric breakdown (TDDB), hot electron effects, and dynamic RDS(on) increase under switching conditions. These phenomena are particularly relevant in motor drive applications where devices experience frequent switching events and temperature fluctuations.

Lifetime prediction models have evolved significantly, incorporating physics-of-failure approaches that consider the unique degradation mechanisms of GaN devices. Monte Carlo simulations combined with Weibull distribution analysis suggest that properly designed GaN HEMT motor drives can achieve operational lifetimes exceeding 15 years under typical industrial conditions. However, these projections require validation through continued field testing and data collection.

Mission profile-based reliability assessment has emerged as a best practice, where actual operating conditions of motor drives—including load profiles, switching frequencies, and ambient temperature variations—are incorporated into lifetime models. This approach provides more accurate predictions than traditional constant-stress testing methodologies.

Packaging reliability represents another crucial aspect, with die-attach integrity and wire bond reliability often becoming limiting factors before the GaN device itself degrades. Advanced packaging solutions utilizing silver sintering and copper clip bonding have demonstrated superior thermal cycling performance compared to traditional soldering techniques.

Manufacturers have established comprehensive qualification procedures aligned with JEDEC standards but adapted for GaN-specific failure modes. Leading suppliers now offer reliability data demonstrating less than 10 FIT (failures in time) rates at typical motor drive operating conditions, supporting the technology's readiness for widespread industrial adoption.

Ongoing research focuses on developing in-situ monitoring techniques to detect early signs of degradation, enabling predictive maintenance strategies for GaN-based motor drive systems. These approaches include monitoring shifts in threshold voltage, dynamic RDS(on), and thermal resistance as indicators of device health, potentially extending practical system lifetimes through condition-based maintenance protocols.

Field data collected from early GaN HEMT implementations in motor drives indicates promising reliability metrics, with failure rates comparable to established silicon technologies after accounting for infant mortality failures. The primary degradation mechanisms observed include time-dependent dielectric breakdown (TDDB), hot electron effects, and dynamic RDS(on) increase under switching conditions. These phenomena are particularly relevant in motor drive applications where devices experience frequent switching events and temperature fluctuations.

Lifetime prediction models have evolved significantly, incorporating physics-of-failure approaches that consider the unique degradation mechanisms of GaN devices. Monte Carlo simulations combined with Weibull distribution analysis suggest that properly designed GaN HEMT motor drives can achieve operational lifetimes exceeding 15 years under typical industrial conditions. However, these projections require validation through continued field testing and data collection.

Mission profile-based reliability assessment has emerged as a best practice, where actual operating conditions of motor drives—including load profiles, switching frequencies, and ambient temperature variations—are incorporated into lifetime models. This approach provides more accurate predictions than traditional constant-stress testing methodologies.

Packaging reliability represents another crucial aspect, with die-attach integrity and wire bond reliability often becoming limiting factors before the GaN device itself degrades. Advanced packaging solutions utilizing silver sintering and copper clip bonding have demonstrated superior thermal cycling performance compared to traditional soldering techniques.

Manufacturers have established comprehensive qualification procedures aligned with JEDEC standards but adapted for GaN-specific failure modes. Leading suppliers now offer reliability data demonstrating less than 10 FIT (failures in time) rates at typical motor drive operating conditions, supporting the technology's readiness for widespread industrial adoption.

Ongoing research focuses on developing in-situ monitoring techniques to detect early signs of degradation, enabling predictive maintenance strategies for GaN-based motor drive systems. These approaches include monitoring shifts in threshold voltage, dynamic RDS(on), and thermal resistance as indicators of device health, potentially extending practical system lifetimes through condition-based maintenance protocols.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!