Gas Welding in Large-Scale Module Construction Systems

AUG 7, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Gas Welding Evolution and Objectives

Gas welding has been a cornerstone in construction and manufacturing for over a century, evolving significantly since its inception in the late 1800s. In the context of large-scale module construction systems, gas welding has undergone substantial transformations to meet the increasing demands of efficiency, precision, and scalability.

The evolution of gas welding in modular construction began with simple oxy-fuel welding techniques, primarily used for joining metal components. As the scale and complexity of modular construction increased, so did the need for more advanced welding technologies. The introduction of automated and robotic gas welding systems marked a significant milestone, enabling faster and more consistent welds across large modules.

In recent years, the integration of computer-controlled systems and sensors has further enhanced the capabilities of gas welding in modular construction. These advancements have led to improved weld quality, reduced material waste, and increased productivity, all crucial factors in large-scale projects.

The primary objective of gas welding in large-scale module construction systems is to achieve high-quality, structurally sound joints while maximizing efficiency and minimizing costs. This involves developing welding techniques that can accommodate the unique challenges posed by modular construction, such as the need for precise alignment and the ability to weld in various positions.

Another key goal is to enhance the portability and flexibility of gas welding equipment, allowing for on-site welding of large modules. This is particularly important in industries such as shipbuilding, aerospace, and large-scale infrastructure projects, where modules may need to be assembled or modified at the final location.

Improving safety and environmental sustainability is also a critical objective in the evolution of gas welding for modular construction. This includes developing cleaner burning fuel mixtures, implementing more effective fume extraction systems, and designing ergonomic welding equipment to reduce operator fatigue and injury risks.

Looking ahead, the future objectives for gas welding in large-scale module construction systems include further automation and integration with digital technologies. This may involve the use of artificial intelligence for weld path optimization, real-time quality control through advanced sensors, and the implementation of augmented reality systems to assist welders in complex operations.

In conclusion, the evolution of gas welding in large-scale module construction systems reflects a continuous drive towards greater efficiency, precision, and adaptability. As the industry moves forward, the focus will remain on developing innovative solutions that can meet the ever-growing demands of modern construction and manufacturing processes.

The evolution of gas welding in modular construction began with simple oxy-fuel welding techniques, primarily used for joining metal components. As the scale and complexity of modular construction increased, so did the need for more advanced welding technologies. The introduction of automated and robotic gas welding systems marked a significant milestone, enabling faster and more consistent welds across large modules.

In recent years, the integration of computer-controlled systems and sensors has further enhanced the capabilities of gas welding in modular construction. These advancements have led to improved weld quality, reduced material waste, and increased productivity, all crucial factors in large-scale projects.

The primary objective of gas welding in large-scale module construction systems is to achieve high-quality, structurally sound joints while maximizing efficiency and minimizing costs. This involves developing welding techniques that can accommodate the unique challenges posed by modular construction, such as the need for precise alignment and the ability to weld in various positions.

Another key goal is to enhance the portability and flexibility of gas welding equipment, allowing for on-site welding of large modules. This is particularly important in industries such as shipbuilding, aerospace, and large-scale infrastructure projects, where modules may need to be assembled or modified at the final location.

Improving safety and environmental sustainability is also a critical objective in the evolution of gas welding for modular construction. This includes developing cleaner burning fuel mixtures, implementing more effective fume extraction systems, and designing ergonomic welding equipment to reduce operator fatigue and injury risks.

Looking ahead, the future objectives for gas welding in large-scale module construction systems include further automation and integration with digital technologies. This may involve the use of artificial intelligence for weld path optimization, real-time quality control through advanced sensors, and the implementation of augmented reality systems to assist welders in complex operations.

In conclusion, the evolution of gas welding in large-scale module construction systems reflects a continuous drive towards greater efficiency, precision, and adaptability. As the industry moves forward, the focus will remain on developing innovative solutions that can meet the ever-growing demands of modern construction and manufacturing processes.

Market Analysis for Module Construction

The modular construction market has experienced significant growth in recent years, driven by the increasing demand for efficient and cost-effective building solutions. This trend is particularly evident in large-scale construction projects, where gas welding plays a crucial role in module assembly and integration.

The global modular construction market was valued at approximately $112 billion in 2021 and is projected to reach $191 billion by 2027, growing at a CAGR of 7.8% during the forecast period. This growth is attributed to several factors, including the need for faster construction timelines, reduced on-site labor requirements, and improved quality control in prefabricated environments.

In the context of large-scale module construction systems, gas welding remains a critical component of the manufacturing process. The market for gas welding equipment and consumables specific to modular construction is estimated to account for about 15% of the overall modular construction market value.

Key market drivers for gas welding in module construction include the increasing adoption of steel-framed modules, which require precise and robust welding techniques. The automotive and aerospace industries' shift towards modular manufacturing has also influenced the construction sector, leading to greater demand for advanced welding technologies.

Geographically, Asia-Pacific dominates the market for modular construction and associated gas welding technologies, accounting for approximately 40% of the global market share. This is primarily due to rapid urbanization, government initiatives promoting prefabrication, and the presence of major manufacturing hubs in countries like China, Japan, and South Korea.

North America and Europe follow closely, with market shares of around 30% and 20% respectively. These regions are witnessing increased adoption of modular construction in commercial, healthcare, and educational sectors, driving the demand for specialized gas welding solutions.

The market landscape is characterized by a mix of established players and innovative startups. Major companies in the gas welding segment for modular construction include Lincoln Electric, ESAB, and Fronius International. These firms are investing heavily in research and development to improve welding efficiency, automation, and integration with digital technologies.

Emerging trends in the market include the development of eco-friendly welding gases, advanced robotic welding systems for module assembly, and the integration of IoT and AI for real-time quality control and predictive maintenance. These innovations are expected to further drive market growth and improve the overall efficiency of large-scale module construction systems.

The global modular construction market was valued at approximately $112 billion in 2021 and is projected to reach $191 billion by 2027, growing at a CAGR of 7.8% during the forecast period. This growth is attributed to several factors, including the need for faster construction timelines, reduced on-site labor requirements, and improved quality control in prefabricated environments.

In the context of large-scale module construction systems, gas welding remains a critical component of the manufacturing process. The market for gas welding equipment and consumables specific to modular construction is estimated to account for about 15% of the overall modular construction market value.

Key market drivers for gas welding in module construction include the increasing adoption of steel-framed modules, which require precise and robust welding techniques. The automotive and aerospace industries' shift towards modular manufacturing has also influenced the construction sector, leading to greater demand for advanced welding technologies.

Geographically, Asia-Pacific dominates the market for modular construction and associated gas welding technologies, accounting for approximately 40% of the global market share. This is primarily due to rapid urbanization, government initiatives promoting prefabrication, and the presence of major manufacturing hubs in countries like China, Japan, and South Korea.

North America and Europe follow closely, with market shares of around 30% and 20% respectively. These regions are witnessing increased adoption of modular construction in commercial, healthcare, and educational sectors, driving the demand for specialized gas welding solutions.

The market landscape is characterized by a mix of established players and innovative startups. Major companies in the gas welding segment for modular construction include Lincoln Electric, ESAB, and Fronius International. These firms are investing heavily in research and development to improve welding efficiency, automation, and integration with digital technologies.

Emerging trends in the market include the development of eco-friendly welding gases, advanced robotic welding systems for module assembly, and the integration of IoT and AI for real-time quality control and predictive maintenance. These innovations are expected to further drive market growth and improve the overall efficiency of large-scale module construction systems.

Gas Welding Challenges in Large Modules

Gas welding in large-scale module construction systems presents several significant challenges that impact the efficiency, quality, and safety of the welding process. One of the primary issues is the difficulty in maintaining consistent weld quality across extensive surfaces. The sheer size of large modules often leads to variations in heat distribution, which can result in uneven penetration and potential weak points in the welded joints.

Another major challenge is the accessibility of welding locations within large modules. Complex structures may have confined spaces or hard-to-reach areas that make it difficult for welders to maintain proper positioning and technique. This can lead to suboptimal welds and increased risk of defects, potentially compromising the structural integrity of the module.

The control of welding parameters becomes increasingly complex in large-scale applications. Factors such as gas flow rates, torch angles, and travel speeds must be carefully managed over extended periods and across diverse surfaces. Maintaining consistency in these parameters throughout the welding process is crucial for ensuring uniform weld quality but becomes more challenging as the scale of the module increases.

Environmental factors also play a significant role in gas welding challenges for large modules. Wind and temperature variations can affect the shielding gas coverage, potentially leading to contamination of the weld pool and reduced weld quality. In outdoor construction settings, these environmental variables are often unpredictable and difficult to control, adding another layer of complexity to the welding process.

The management of thermal stress and distortion is particularly challenging in large-scale welding applications. As heat is applied during welding, it can cause the metal to expand and contract, leading to warping or misalignment of components. In large modules, these effects are amplified and can result in significant structural issues if not properly addressed through careful planning and execution of the welding sequence.

Productivity and efficiency concerns are also prominent in gas welding of large modules. The time required to complete extensive welding operations can be substantial, impacting project timelines and costs. Balancing the need for thorough, high-quality welds with the pressure to meet production schedules is an ongoing challenge for welders and project managers alike.

Lastly, safety considerations are paramount when dealing with gas welding in large-scale environments. The presence of flammable gases, potential for gas leaks, and the need for proper ventilation in enclosed spaces within modules all contribute to increased safety risks. Ensuring compliance with safety regulations while maintaining productivity adds another layer of complexity to the welding process in large module construction.

Another major challenge is the accessibility of welding locations within large modules. Complex structures may have confined spaces or hard-to-reach areas that make it difficult for welders to maintain proper positioning and technique. This can lead to suboptimal welds and increased risk of defects, potentially compromising the structural integrity of the module.

The control of welding parameters becomes increasingly complex in large-scale applications. Factors such as gas flow rates, torch angles, and travel speeds must be carefully managed over extended periods and across diverse surfaces. Maintaining consistency in these parameters throughout the welding process is crucial for ensuring uniform weld quality but becomes more challenging as the scale of the module increases.

Environmental factors also play a significant role in gas welding challenges for large modules. Wind and temperature variations can affect the shielding gas coverage, potentially leading to contamination of the weld pool and reduced weld quality. In outdoor construction settings, these environmental variables are often unpredictable and difficult to control, adding another layer of complexity to the welding process.

The management of thermal stress and distortion is particularly challenging in large-scale welding applications. As heat is applied during welding, it can cause the metal to expand and contract, leading to warping or misalignment of components. In large modules, these effects are amplified and can result in significant structural issues if not properly addressed through careful planning and execution of the welding sequence.

Productivity and efficiency concerns are also prominent in gas welding of large modules. The time required to complete extensive welding operations can be substantial, impacting project timelines and costs. Balancing the need for thorough, high-quality welds with the pressure to meet production schedules is an ongoing challenge for welders and project managers alike.

Lastly, safety considerations are paramount when dealing with gas welding in large-scale environments. The presence of flammable gases, potential for gas leaks, and the need for proper ventilation in enclosed spaces within modules all contribute to increased safety risks. Ensuring compliance with safety regulations while maintaining productivity adds another layer of complexity to the welding process in large module construction.

Current Gas Welding Techniques

01 Welding equipment and techniques

Gas welding involves specialized equipment and techniques for joining metals using heat generated by combustion of gases. This includes torches, regulators, and specific methods for controlling flame and heat distribution.- Welding equipment and techniques: Gas welding involves specialized equipment and techniques for joining metals using heat generated by combustion of gases. This includes torches, regulators, and various gas mixtures to achieve optimal welding results for different materials and applications.

- Safety measures in gas welding: Safety is crucial in gas welding operations. This includes proper handling of gas cylinders, use of personal protective equipment, and implementation of safety protocols to prevent accidents and ensure worker protection during welding processes.

- Automation and robotics in gas welding: Advancements in automation and robotics have been applied to gas welding processes. This includes the development of automated welding systems, robotic welders, and computer-controlled welding equipment to improve precision, efficiency, and consistency in welding operations.

- Gas mixture optimization: Research focuses on optimizing gas mixtures used in welding to enhance weld quality, reduce defects, and improve overall welding performance. This involves studying the effects of different gas compositions on various materials and welding conditions.

- Innovations in welding torch design: Continuous improvements in welding torch design aim to enhance control, ergonomics, and efficiency. This includes developing new nozzle designs, improving gas flow dynamics, and incorporating advanced materials for better heat resistance and longevity.

02 Gas mixture optimization

Optimizing gas mixtures for welding is crucial for achieving high-quality welds. This involves selecting appropriate ratios of fuel gases and oxygen to create ideal flame characteristics for different materials and applications.Expand Specific Solutions03 Safety measures and equipment

Safety is paramount in gas welding operations. This includes the use of protective gear, proper ventilation systems, and safety protocols to prevent accidents and protect welders from harmful fumes and radiation.Expand Specific Solutions04 Automated gas welding systems

Advancements in automation have led to the development of robotic gas welding systems. These systems improve precision, consistency, and efficiency in welding processes, particularly for large-scale or repetitive welding tasks.Expand Specific Solutions05 Specialized gas welding applications

Gas welding techniques are adapted for specialized applications such as underwater welding, repair of specific materials, or welding in challenging environments. These applications require modified equipment and procedures to ensure effective and safe welding operations.Expand Specific Solutions

Key Players in Module Construction

The gas welding market in large-scale module construction systems is in a mature stage, with established players dominating the industry. The market size is substantial, driven by ongoing infrastructure projects and industrial development worldwide. Technologically, the field is well-developed, with companies like Illinois Tool Works Inc. and Lincoln Global, Inc. leading innovation. These firms, along with others such as Applied Materials, Inc. and Siemens AG, have advanced welding technologies that cater to the specific needs of large-scale module construction. The competitive landscape is characterized by a mix of global conglomerates and specialized welding equipment manufacturers, each leveraging their strengths in technology, distribution networks, and customer relationships to maintain market share.

Illinois Tool Works Inc.

Technical Solution: Illinois Tool Works (ITW) has developed advanced gas welding systems for large-scale module construction. Their technology focuses on precision control of gas flow and mixture, ensuring optimal welding performance in various environmental conditions. ITW's system incorporates real-time monitoring and adjustment capabilities, allowing for consistent weld quality across large modules. The company has also introduced a proprietary nozzle design that enhances gas distribution, resulting in improved weld penetration and strength[1]. Additionally, ITW has implemented automated welding processes that can be integrated into modular construction workflows, significantly reducing manual labor and increasing efficiency[3].

Strengths: Precision control, real-time monitoring, and automated processes enhance efficiency and quality. Weaknesses: May require significant initial investment and specialized training for operators.

Lincoln Global, Inc.

Technical Solution: Lincoln Global has pioneered a hybrid gas welding system specifically designed for large-scale module construction. This innovative approach combines traditional gas welding techniques with advanced electronic controls and data analytics. The system utilizes a proprietary gas mixture that optimizes heat input and reduces spatter, resulting in cleaner and stronger welds[2]. Lincoln's technology also incorporates adaptive power management, which automatically adjusts gas flow and pressure based on the specific requirements of different module components. Furthermore, the company has developed a modular torch design that allows for quick interchange of components, reducing downtime during large-scale projects[4].

Strengths: Hybrid technology offers versatility and improved weld quality. Adaptive systems enhance efficiency. Weaknesses: Complexity of the system may require specialized maintenance and support.

Innovative Gas Welding Patents

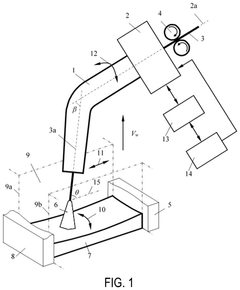

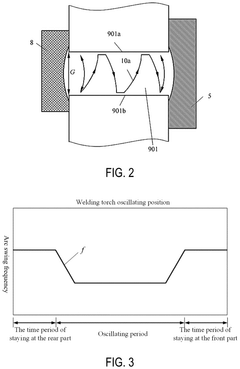

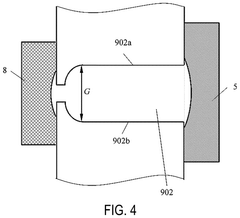

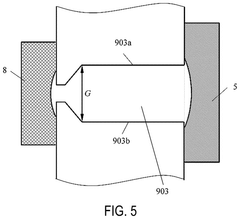

Rapid electro-gas welding method with swing arc, and welding torch therewith and application thereof

PatentPendingUS20250187097A1

Innovation

- A swing arc rapid electro-gas welding method with a variable arc swing angle and frequency, utilizing a welding torch with a large-angle bent conductive rod mechanism and an arc swing mechanism, which enables the arc to perform circular-arc-shaped swings and linear oscillations along the plate thickness direction.

Method for welding large-sized constructions from aluminum alloys

PatentActivePL422255A1

Innovation

- The use of a membrane module with a microstructure for cooling, allowing for precise control of cooling gas flow and heat transfer.

- Achieving high cooling rates (100°C/s - 400°C/s) through the combination of microstructure design and controlled gas flow.

- Optimized cooling gas microstructure diameter (40-60 micrometers) and flow velocities (40-50 m/s) for effective heat transfer in large-sized aluminum alloy constructions.

Safety Regulations in Gas Welding

Safety regulations in gas welding for large-scale module construction systems are critical to ensure the well-being of workers and the integrity of the construction process. These regulations are typically established by national and international safety organizations, such as the Occupational Safety and Health Administration (OSHA) in the United States and the European Agency for Safety and Health at Work (EU-OSHA) in Europe.

One of the primary safety concerns in gas welding is the management of compressed gases. Regulations often mandate proper storage, handling, and transportation of gas cylinders. This includes securing cylinders in an upright position, using appropriate valve protection caps, and storing them in well-ventilated areas away from heat sources and flammable materials.

Personal protective equipment (PPE) is another crucial aspect of safety regulations. Welders are required to wear appropriate protective gear, including flame-resistant clothing, safety glasses or goggles, welding helmets with proper shade lenses, and leather gloves. Additionally, respiratory protection may be necessary when working in confined spaces or with certain materials that produce hazardous fumes.

Fire prevention measures are also a key component of safety regulations. This includes maintaining a fire watch during and after welding operations, having appropriate fire extinguishing equipment readily available, and implementing hot work permit systems to ensure proper precautions are taken before welding begins.

Ventilation requirements are specified to control exposure to welding fumes and gases. Regulations often mandate the use of local exhaust ventilation systems or general ventilation to maintain safe air quality in the work area. Regular air monitoring may also be required to ensure compliance with exposure limits for various contaminants.

Electrical safety is another important consideration, particularly when using electric arc welding equipment in conjunction with gas welding. Regulations typically require proper grounding of equipment, regular inspection and maintenance of electrical components, and the use of appropriate circuit protection devices.

Training and certification requirements for welders are often specified in safety regulations. This ensures that workers have the necessary skills and knowledge to perform welding tasks safely and effectively. Regular refresher training and updates on new safety procedures may also be mandated.

Specific regulations may apply to the use of gas welding in large-scale module construction systems. These could include requirements for fall protection when working at heights, confined space entry procedures, and coordination of welding activities with other construction operations to minimize risks.

Regular inspection and maintenance of welding equipment is typically required by safety regulations. This includes checking for gas leaks, ensuring proper functioning of regulators and valves, and verifying the integrity of hoses and connections.

One of the primary safety concerns in gas welding is the management of compressed gases. Regulations often mandate proper storage, handling, and transportation of gas cylinders. This includes securing cylinders in an upright position, using appropriate valve protection caps, and storing them in well-ventilated areas away from heat sources and flammable materials.

Personal protective equipment (PPE) is another crucial aspect of safety regulations. Welders are required to wear appropriate protective gear, including flame-resistant clothing, safety glasses or goggles, welding helmets with proper shade lenses, and leather gloves. Additionally, respiratory protection may be necessary when working in confined spaces or with certain materials that produce hazardous fumes.

Fire prevention measures are also a key component of safety regulations. This includes maintaining a fire watch during and after welding operations, having appropriate fire extinguishing equipment readily available, and implementing hot work permit systems to ensure proper precautions are taken before welding begins.

Ventilation requirements are specified to control exposure to welding fumes and gases. Regulations often mandate the use of local exhaust ventilation systems or general ventilation to maintain safe air quality in the work area. Regular air monitoring may also be required to ensure compliance with exposure limits for various contaminants.

Electrical safety is another important consideration, particularly when using electric arc welding equipment in conjunction with gas welding. Regulations typically require proper grounding of equipment, regular inspection and maintenance of electrical components, and the use of appropriate circuit protection devices.

Training and certification requirements for welders are often specified in safety regulations. This ensures that workers have the necessary skills and knowledge to perform welding tasks safely and effectively. Regular refresher training and updates on new safety procedures may also be mandated.

Specific regulations may apply to the use of gas welding in large-scale module construction systems. These could include requirements for fall protection when working at heights, confined space entry procedures, and coordination of welding activities with other construction operations to minimize risks.

Regular inspection and maintenance of welding equipment is typically required by safety regulations. This includes checking for gas leaks, ensuring proper functioning of regulators and valves, and verifying the integrity of hoses and connections.

Environmental Impact Assessment

Gas welding in large-scale module construction systems has significant environmental implications that require careful assessment. The process involves the combustion of fuel gases, typically acetylene or propane, which releases various pollutants into the atmosphere. These emissions primarily consist of carbon dioxide, carbon monoxide, nitrogen oxides, and particulate matter. The extent of environmental impact depends on factors such as the scale of the construction project, the duration of welding operations, and the specific welding techniques employed.

Air quality is a primary concern in the environmental impact assessment of gas welding. The release of greenhouse gases contributes to global warming, while other pollutants can lead to localized air pollution. This is particularly significant in urban areas or regions with existing air quality issues. The potential for smog formation and reduced visibility must be considered, especially in large-scale construction projects where welding activities are extensive and prolonged.

Water pollution is another aspect that requires evaluation. Welding operations can produce metal fumes and particulates that may settle on nearby water bodies or be washed into water systems through rainfall. This can lead to contamination of surface water and potentially affect aquatic ecosystems. Additionally, the storage and handling of welding gases and associated chemicals pose risks of spills or leaks, which could impact soil and groundwater quality.

Noise pollution is an often-overlooked environmental impact of gas welding. The process generates significant noise levels, which can be disruptive to local communities and wildlife. In large-scale module construction, the cumulative effect of multiple welding operations can create substantial noise pollution, necessitating mitigation measures to protect both workers and the surrounding environment.

Energy consumption is a critical factor in the environmental assessment. Gas welding requires substantial amounts of fuel, contributing to resource depletion and increased carbon footprint. The transportation and storage of welding gases also add to the overall energy consumption and environmental impact of the construction process.

Waste generation is another environmental concern. Welding operations produce various types of waste, including spent welding rods, slag, and contaminated personal protective equipment. Proper disposal and recycling of these materials are essential to minimize environmental impact and comply with waste management regulations.

The assessment should also consider the potential for accidental fires or explosions due to the use of flammable gases. Such incidents can have severe environmental consequences, including air and water pollution, as well as damage to surrounding ecosystems.

To mitigate these environmental impacts, the assessment should recommend best practices and technologies. These may include the use of more efficient welding equipment, implementation of proper ventilation systems, adoption of low-emission welding techniques, and stringent safety protocols. Additionally, the assessment should propose monitoring and reporting mechanisms to ensure ongoing environmental compliance throughout the construction process.

Air quality is a primary concern in the environmental impact assessment of gas welding. The release of greenhouse gases contributes to global warming, while other pollutants can lead to localized air pollution. This is particularly significant in urban areas or regions with existing air quality issues. The potential for smog formation and reduced visibility must be considered, especially in large-scale construction projects where welding activities are extensive and prolonged.

Water pollution is another aspect that requires evaluation. Welding operations can produce metal fumes and particulates that may settle on nearby water bodies or be washed into water systems through rainfall. This can lead to contamination of surface water and potentially affect aquatic ecosystems. Additionally, the storage and handling of welding gases and associated chemicals pose risks of spills or leaks, which could impact soil and groundwater quality.

Noise pollution is an often-overlooked environmental impact of gas welding. The process generates significant noise levels, which can be disruptive to local communities and wildlife. In large-scale module construction, the cumulative effect of multiple welding operations can create substantial noise pollution, necessitating mitigation measures to protect both workers and the surrounding environment.

Energy consumption is a critical factor in the environmental assessment. Gas welding requires substantial amounts of fuel, contributing to resource depletion and increased carbon footprint. The transportation and storage of welding gases also add to the overall energy consumption and environmental impact of the construction process.

Waste generation is another environmental concern. Welding operations produce various types of waste, including spent welding rods, slag, and contaminated personal protective equipment. Proper disposal and recycling of these materials are essential to minimize environmental impact and comply with waste management regulations.

The assessment should also consider the potential for accidental fires or explosions due to the use of flammable gases. Such incidents can have severe environmental consequences, including air and water pollution, as well as damage to surrounding ecosystems.

To mitigate these environmental impacts, the assessment should recommend best practices and technologies. These may include the use of more efficient welding equipment, implementation of proper ventilation systems, adoption of low-emission welding techniques, and stringent safety protocols. Additionally, the assessment should propose monitoring and reporting mechanisms to ensure ongoing environmental compliance throughout the construction process.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!