Gas Welding Procedures for Modular Construction Systems

AUG 7, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Gas Welding Evolution and Objectives

Gas welding has been a cornerstone of construction and manufacturing for over a century, evolving significantly since its inception in the late 1800s. The technology's journey began with the discovery of acetylene in 1836, leading to the development of the first practical oxyacetylene welding torch in 1903. This innovation revolutionized metal joining processes, offering a portable and versatile solution for various industries.

In the context of modular construction systems, gas welding has played a crucial role in enabling the prefabrication and on-site assembly of building components. The technology's ability to provide high-quality joints with minimal equipment has made it particularly valuable in this field. As modular construction gained popularity in the mid-20th century, gas welding procedures were adapted to meet the specific needs of this innovative building approach.

The evolution of gas welding in modular construction has been driven by several key objectives. Foremost among these is the need for increased efficiency and speed in the assembly process. Gas welding techniques have been refined to allow for rapid joining of modular components, reducing on-site construction time and labor costs. Additionally, there has been a continuous push for improved weld quality and consistency, essential for ensuring the structural integrity and longevity of modular buildings.

Another significant objective in the development of gas welding procedures for modular construction has been the enhancement of portability and versatility. As modular construction often involves work in diverse environments, from factory floors to construction sites, welding equipment and techniques have been adapted to function effectively in various conditions. This has led to the creation of more compact and mobile welding setups, as well as the development of specialized gas mixtures and nozzle designs optimized for modular construction applications.

Safety and environmental considerations have also shaped the evolution of gas welding in this field. Efforts have been made to reduce fume emissions, improve flame control, and enhance operator safety through the development of advanced regulators and safety systems. Furthermore, the industry has sought to optimize gas consumption and reduce waste, aligning with broader sustainability goals in construction.

Looking ahead, the objectives for gas welding in modular construction systems continue to evolve. There is a growing focus on integrating smart technologies and automation to further improve precision and efficiency. Research is ongoing into new gas mixtures and welding techniques that could offer superior joint properties while minimizing heat-affected zones, a critical factor in maintaining the dimensional stability of modular components. Additionally, there is an increasing emphasis on developing procedures that are compatible with a wider range of materials, including advanced alloys and composites used in modern modular construction.

In the context of modular construction systems, gas welding has played a crucial role in enabling the prefabrication and on-site assembly of building components. The technology's ability to provide high-quality joints with minimal equipment has made it particularly valuable in this field. As modular construction gained popularity in the mid-20th century, gas welding procedures were adapted to meet the specific needs of this innovative building approach.

The evolution of gas welding in modular construction has been driven by several key objectives. Foremost among these is the need for increased efficiency and speed in the assembly process. Gas welding techniques have been refined to allow for rapid joining of modular components, reducing on-site construction time and labor costs. Additionally, there has been a continuous push for improved weld quality and consistency, essential for ensuring the structural integrity and longevity of modular buildings.

Another significant objective in the development of gas welding procedures for modular construction has been the enhancement of portability and versatility. As modular construction often involves work in diverse environments, from factory floors to construction sites, welding equipment and techniques have been adapted to function effectively in various conditions. This has led to the creation of more compact and mobile welding setups, as well as the development of specialized gas mixtures and nozzle designs optimized for modular construction applications.

Safety and environmental considerations have also shaped the evolution of gas welding in this field. Efforts have been made to reduce fume emissions, improve flame control, and enhance operator safety through the development of advanced regulators and safety systems. Furthermore, the industry has sought to optimize gas consumption and reduce waste, aligning with broader sustainability goals in construction.

Looking ahead, the objectives for gas welding in modular construction systems continue to evolve. There is a growing focus on integrating smart technologies and automation to further improve precision and efficiency. Research is ongoing into new gas mixtures and welding techniques that could offer superior joint properties while minimizing heat-affected zones, a critical factor in maintaining the dimensional stability of modular components. Additionally, there is an increasing emphasis on developing procedures that are compatible with a wider range of materials, including advanced alloys and composites used in modern modular construction.

Modular Construction Market Analysis

The modular construction market has experienced significant growth in recent years, driven by increasing demand for cost-effective, efficient, and sustainable building solutions. This market segment is characterized by the prefabrication of building components in controlled factory environments, which are then transported and assembled on-site. The global modular construction market was valued at approximately $112 billion in 2021 and is projected to reach $191 billion by 2026, growing at a compound annual growth rate (CAGR) of 6.9%.

Several factors contribute to the expanding market demand for modular construction systems. Urbanization and population growth have led to a surge in housing and infrastructure needs, particularly in developing countries. The construction industry's labor shortage and rising labor costs have also pushed developers and contractors to seek more efficient building methods. Additionally, the growing emphasis on sustainability and environmental consciousness has increased interest in modular construction, as it typically results in reduced waste and lower carbon emissions compared to traditional construction methods.

The modular construction market can be segmented by type, including permanent and relocatable modules. Permanent modular construction has gained traction in various sectors, such as residential, commercial, healthcare, and education. The residential segment, in particular, has shown strong growth due to the increasing demand for affordable housing and the rise of micro-living concepts in urban areas. Commercial applications, including office buildings and hotels, have also embraced modular construction for its speed and cost-effectiveness.

Geographically, North America and Europe currently dominate the modular construction market, with Asia-Pacific expected to witness the fastest growth in the coming years. The United States, in particular, has seen a surge in modular construction adoption, driven by the need for rapid deployment of healthcare facilities during the COVID-19 pandemic and the ongoing housing shortage in many urban areas.

Key market trends include the integration of advanced technologies such as Building Information Modeling (BIM), 3D printing, and robotics in the modular construction process. These technologies enhance precision, reduce errors, and further improve efficiency. Additionally, there is a growing focus on developing more sustainable and energy-efficient modular units, incorporating green building materials and smart home technologies.

Despite the positive outlook, the modular construction market faces challenges such as transportation limitations, negative perceptions about quality and customization, and the need for significant upfront investment in manufacturing facilities. However, ongoing innovations in design, materials, and manufacturing processes are addressing these concerns and paving the way for wider adoption of modular construction systems across various sectors.

Several factors contribute to the expanding market demand for modular construction systems. Urbanization and population growth have led to a surge in housing and infrastructure needs, particularly in developing countries. The construction industry's labor shortage and rising labor costs have also pushed developers and contractors to seek more efficient building methods. Additionally, the growing emphasis on sustainability and environmental consciousness has increased interest in modular construction, as it typically results in reduced waste and lower carbon emissions compared to traditional construction methods.

The modular construction market can be segmented by type, including permanent and relocatable modules. Permanent modular construction has gained traction in various sectors, such as residential, commercial, healthcare, and education. The residential segment, in particular, has shown strong growth due to the increasing demand for affordable housing and the rise of micro-living concepts in urban areas. Commercial applications, including office buildings and hotels, have also embraced modular construction for its speed and cost-effectiveness.

Geographically, North America and Europe currently dominate the modular construction market, with Asia-Pacific expected to witness the fastest growth in the coming years. The United States, in particular, has seen a surge in modular construction adoption, driven by the need for rapid deployment of healthcare facilities during the COVID-19 pandemic and the ongoing housing shortage in many urban areas.

Key market trends include the integration of advanced technologies such as Building Information Modeling (BIM), 3D printing, and robotics in the modular construction process. These technologies enhance precision, reduce errors, and further improve efficiency. Additionally, there is a growing focus on developing more sustainable and energy-efficient modular units, incorporating green building materials and smart home technologies.

Despite the positive outlook, the modular construction market faces challenges such as transportation limitations, negative perceptions about quality and customization, and the need for significant upfront investment in manufacturing facilities. However, ongoing innovations in design, materials, and manufacturing processes are addressing these concerns and paving the way for wider adoption of modular construction systems across various sectors.

Gas Welding Challenges in Modular Systems

Gas welding in modular construction systems presents several unique challenges that require careful consideration and innovative solutions. One of the primary difficulties lies in the precise alignment and positioning of modular components during the welding process. The inherent nature of modular construction, with its pre-fabricated units, demands exceptional accuracy to ensure seamless integration and structural integrity.

The confined spaces within modular units pose another significant challenge for gas welding procedures. Welders often find themselves working in tight, enclosed areas with limited ventilation, which can lead to the accumulation of hazardous fumes and gases. This not only creates potential health risks for the workers but also affects the quality of the welds due to reduced visibility and maneuverability.

Temperature control and heat distribution present additional complexities in modular construction welding. The diverse materials used in modular systems, including various metals and composite materials, have different thermal properties and expansion rates. Maintaining consistent heat application across these materials while preventing warping or distortion is a delicate balancing act that requires advanced techniques and equipment.

The transportation and handling of modular units before and after welding introduce further challenges. Welds must be robust enough to withstand the stresses of transportation, lifting, and installation without compromising their integrity. This necessitates the development of specialized welding procedures that can produce joints capable of enduring dynamic loads and environmental factors.

Quality control and inspection of welds in modular systems present unique difficulties due to the limited access to certain areas once the modules are assembled. Ensuring comprehensive weld quality throughout the structure requires innovative inspection methods and potentially the integration of advanced monitoring technologies during the welding process.

The variability in environmental conditions at different construction sites adds another layer of complexity to gas welding procedures in modular construction. Welders must adapt their techniques to account for factors such as humidity, temperature, and wind, which can significantly impact weld quality and gas flow dynamics.

Lastly, the need for rapid assembly and the pressure to meet tight construction schedules often conflict with the time required for proper welding and cooling processes. Balancing speed with quality in gas welding procedures remains a persistent challenge in the modular construction industry, driving the need for more efficient welding technologies and methodologies.

The confined spaces within modular units pose another significant challenge for gas welding procedures. Welders often find themselves working in tight, enclosed areas with limited ventilation, which can lead to the accumulation of hazardous fumes and gases. This not only creates potential health risks for the workers but also affects the quality of the welds due to reduced visibility and maneuverability.

Temperature control and heat distribution present additional complexities in modular construction welding. The diverse materials used in modular systems, including various metals and composite materials, have different thermal properties and expansion rates. Maintaining consistent heat application across these materials while preventing warping or distortion is a delicate balancing act that requires advanced techniques and equipment.

The transportation and handling of modular units before and after welding introduce further challenges. Welds must be robust enough to withstand the stresses of transportation, lifting, and installation without compromising their integrity. This necessitates the development of specialized welding procedures that can produce joints capable of enduring dynamic loads and environmental factors.

Quality control and inspection of welds in modular systems present unique difficulties due to the limited access to certain areas once the modules are assembled. Ensuring comprehensive weld quality throughout the structure requires innovative inspection methods and potentially the integration of advanced monitoring technologies during the welding process.

The variability in environmental conditions at different construction sites adds another layer of complexity to gas welding procedures in modular construction. Welders must adapt their techniques to account for factors such as humidity, temperature, and wind, which can significantly impact weld quality and gas flow dynamics.

Lastly, the need for rapid assembly and the pressure to meet tight construction schedules often conflict with the time required for proper welding and cooling processes. Balancing speed with quality in gas welding procedures remains a persistent challenge in the modular construction industry, driving the need for more efficient welding technologies and methodologies.

Current Gas Welding Techniques for Modules

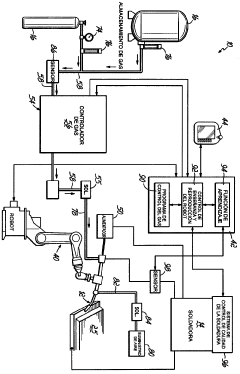

01 Welding equipment and setup

Gas welding procedures involve specific equipment setup and preparation. This includes selecting appropriate welding torches, regulators, and hoses, as well as properly adjusting gas pressures and flame characteristics. Proper setup ensures optimal welding performance and safety.- Welding equipment and setup: Gas welding procedures involve specific equipment setup and preparation. This includes selecting appropriate gas cylinders, regulators, hoses, and torches. Proper assembly and connection of these components are crucial for safe and effective welding operations. The setup also involves adjusting gas pressures and flame characteristics to achieve optimal welding conditions.

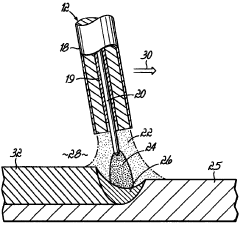

- Gas mixture and flame control: The selection and control of gas mixtures are essential in gas welding procedures. Different combinations of gases, such as acetylene and oxygen, are used to achieve specific flame characteristics. Proper adjustment of the gas ratio and flame type (neutral, oxidizing, or reducing) is crucial for different welding applications and materials. Flame control techniques are employed to maintain consistent heat input and weld quality.

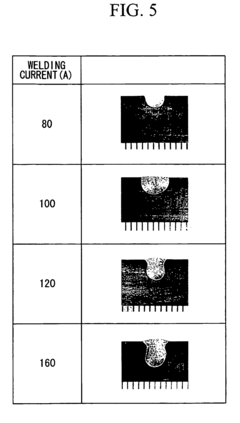

- Welding techniques and joint preparation: Gas welding procedures involve various techniques for different joint types and materials. This includes proper joint preparation, such as cleaning and beveling of edges. Welding techniques like forehand and backhand welding, as well as specific movements of the torch and filler rod, are employed to achieve desired weld characteristics. Proper heat input control and puddle manipulation are crucial for creating strong and defect-free welds.

- Safety measures and precautions: Gas welding procedures require strict adherence to safety protocols. This includes proper ventilation, use of personal protective equipment (PPE), and fire prevention measures. Regular inspection and maintenance of equipment, proper storage of gas cylinders, and implementation of safety interlocks are essential. Training and certification of welders in safe gas welding practices are also crucial aspects of the procedure.

- Quality control and inspection: Gas welding procedures incorporate quality control measures to ensure weld integrity. This includes visual inspection of welds, non-destructive testing methods, and destructive testing when required. Proper documentation of welding parameters, procedures, and inspection results is maintained. Continuous monitoring and adjustment of welding parameters during the process help maintain consistent weld quality.

02 Gas mixture and flame control

The selection and control of gas mixtures are crucial in gas welding procedures. Different ratios of fuel gas and oxygen produce various flame types, each suitable for specific welding applications. Proper flame adjustment and maintenance are essential for achieving high-quality welds.Expand Specific Solutions03 Welding techniques and joint preparation

Gas welding procedures encompass various techniques for different joint types and materials. This includes proper joint preparation, filler material selection, and welding motions. Mastering these techniques is essential for producing strong, defect-free welds across a range of applications.Expand Specific Solutions04 Safety measures and protective equipment

Gas welding procedures require strict adherence to safety protocols. This includes using appropriate personal protective equipment, ensuring proper ventilation, and implementing fire prevention measures. Safety considerations are paramount in gas welding operations to prevent accidents and injuries.Expand Specific Solutions05 Quality control and inspection

Gas welding procedures involve various quality control measures and inspection techniques. This includes visual inspection, non-destructive testing methods, and adherence to welding standards. Proper quality control ensures the integrity and reliability of gas-welded joints in various applications.Expand Specific Solutions

Key Modular Construction Welding Players

The gas welding procedures for modular construction systems market is in a growth phase, driven by increasing demand for efficient and cost-effective construction methods. The market size is expanding as more industries adopt modular construction techniques. Technologically, the field is advancing rapidly, with companies like Siemens AG, Lincoln Global, Inc., and Illinois Tool Works Inc. leading innovation in welding technologies. These firms are developing automated and precision welding solutions specifically tailored for modular construction, improving efficiency and quality. Universities like Worcester Polytechnic Institute and the University of Warwick are contributing to research and development, further accelerating technological maturity in this sector.

Lincoln Global, Inc.

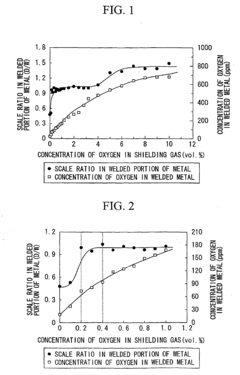

Technical Solution: Lincoln Global has developed advanced gas welding procedures for modular construction systems, focusing on precision and efficiency. Their approach integrates automated welding systems with specialized gas mixtures to optimize weld quality and speed. The company's technology includes adaptive gas flow control, which adjusts gas composition in real-time based on welding parameters and environmental conditions[1]. This system is particularly effective for large-scale modular construction projects, where consistency and speed are crucial. Lincoln Global has also introduced a proprietary shielding gas blend that reduces spatter and improves weld bead appearance, especially beneficial in visible joints of modular structures[2].

Strengths: High precision, improved efficiency, and adaptability to various modular construction needs. Weaknesses: Potentially higher initial equipment costs and the need for specialized training for operators.

Illinois Tool Works Inc.

Technical Solution: Illinois Tool Works (ITW) has pioneered innovative gas welding solutions for modular construction, emphasizing portability and versatility. Their system incorporates lightweight, portable gas welding equipment designed specifically for on-site assembly of modular units. ITW's technology features a patented gas mixing system that allows for precise control of flame characteristics, enabling welders to easily switch between different types of welds required in modular construction[3]. The company has also developed a range of specialized welding tips and nozzles optimized for common joint configurations in modular systems, improving both speed and quality of welds[4].

Strengths: Highly portable, versatile for various welding needs in modular construction. Weaknesses: May not be as suitable for large-scale, high-volume production environments.

Innovative Gas Welding Patents for Modularity

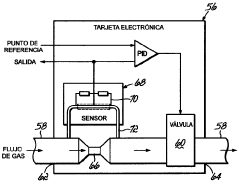

Gas systems and methods of welding.

PatentPendingMX2017000382A

Innovation

- A gas supply system with a shielding gas controller that adjusts the flow rate of shielding gas based on predetermined minimum set points, sensor feedback, and weld quality monitoring to optimize gas usage and maintain consistent weld quality.

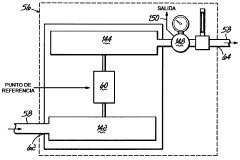

Welding method using a shielding gas comprising bewtween 0.2 % and 10 % of an oxidative gas, the rest being helium

PatentInactiveEP1752249B1

Innovation

- A welding method using a shielding gas comprising 0.2% or more by volume of an oxidative gas, such as oxygen, mixed with helium, which suppresses the dragging force in the molten pool and enhances inward convection, allowing for deeper penetration and a higher D/W ratio, thereby improving weld quality and reducing the number of passes required.

Safety Standards in Modular Gas Welding

Safety standards in modular gas welding are of paramount importance in ensuring the well-being of workers and the integrity of modular construction systems. These standards encompass a wide range of protocols and guidelines designed to mitigate risks associated with gas welding processes in prefabricated construction environments.

One of the primary safety considerations in modular gas welding is the proper handling and storage of compressed gases. Strict regulations govern the transportation, storage, and usage of flammable gases such as acetylene and oxygen. Welding areas must be well-ventilated to prevent the accumulation of potentially explosive gas mixtures. Additionally, gas cylinders must be secured in an upright position and equipped with appropriate pressure regulators and safety valves.

Personal protective equipment (PPE) plays a crucial role in safeguarding welders from various hazards. Standard PPE for gas welding includes flame-resistant clothing, welding helmets with appropriate shade lenses, safety glasses, and leather gloves. Respiratory protection may also be necessary when working in confined spaces or with materials that produce toxic fumes.

Fire prevention measures are essential in modular gas welding operations. Welding areas must be clear of flammable materials, and fire extinguishers should be readily accessible. Hot work permits are often required, and fire watches may be necessary during and after welding operations to monitor for potential fire outbreaks.

Electrical safety is another critical aspect of gas welding safety standards. Proper grounding of equipment and workpieces is essential to prevent electric shock and minimize the risk of fire caused by stray currents. Regular inspection and maintenance of welding equipment, including hoses, regulators, and torches, are mandatory to ensure safe operation.

Training and certification requirements for welders working in modular construction are typically more stringent than those in traditional construction. Welders must be proficient in the specific techniques required for modular assembly and demonstrate a thorough understanding of safety protocols. Many jurisdictions require welders to obtain specialized certifications for working in modular construction environments.

Environmental considerations are increasingly important in modular gas welding safety standards. Proper ventilation and fume extraction systems are necessary to protect workers and comply with air quality regulations. Additionally, waste management protocols must be in place to handle hazardous materials and byproducts generated during the welding process.

Regular safety audits and inspections are integral to maintaining high safety standards in modular gas welding operations. These assessments help identify potential hazards, ensure compliance with regulations, and promote continuous improvement in safety practices. Documentation of safety procedures, incident reports, and corrective actions is essential for regulatory compliance and risk management.

One of the primary safety considerations in modular gas welding is the proper handling and storage of compressed gases. Strict regulations govern the transportation, storage, and usage of flammable gases such as acetylene and oxygen. Welding areas must be well-ventilated to prevent the accumulation of potentially explosive gas mixtures. Additionally, gas cylinders must be secured in an upright position and equipped with appropriate pressure regulators and safety valves.

Personal protective equipment (PPE) plays a crucial role in safeguarding welders from various hazards. Standard PPE for gas welding includes flame-resistant clothing, welding helmets with appropriate shade lenses, safety glasses, and leather gloves. Respiratory protection may also be necessary when working in confined spaces or with materials that produce toxic fumes.

Fire prevention measures are essential in modular gas welding operations. Welding areas must be clear of flammable materials, and fire extinguishers should be readily accessible. Hot work permits are often required, and fire watches may be necessary during and after welding operations to monitor for potential fire outbreaks.

Electrical safety is another critical aspect of gas welding safety standards. Proper grounding of equipment and workpieces is essential to prevent electric shock and minimize the risk of fire caused by stray currents. Regular inspection and maintenance of welding equipment, including hoses, regulators, and torches, are mandatory to ensure safe operation.

Training and certification requirements for welders working in modular construction are typically more stringent than those in traditional construction. Welders must be proficient in the specific techniques required for modular assembly and demonstrate a thorough understanding of safety protocols. Many jurisdictions require welders to obtain specialized certifications for working in modular construction environments.

Environmental considerations are increasingly important in modular gas welding safety standards. Proper ventilation and fume extraction systems are necessary to protect workers and comply with air quality regulations. Additionally, waste management protocols must be in place to handle hazardous materials and byproducts generated during the welding process.

Regular safety audits and inspections are integral to maintaining high safety standards in modular gas welding operations. These assessments help identify potential hazards, ensure compliance with regulations, and promote continuous improvement in safety practices. Documentation of safety procedures, incident reports, and corrective actions is essential for regulatory compliance and risk management.

Environmental Impact of Gas Welding in Construction

Gas welding in modular construction systems has significant environmental implications that warrant careful consideration. The process involves the combustion of fuel gases, typically acetylene or propane, which releases various pollutants into the atmosphere. These emissions include carbon dioxide (CO2), carbon monoxide (CO), nitrogen oxides (NOx), and particulate matter. The release of these greenhouse gases contributes to global warming and climate change, while other pollutants can have localized impacts on air quality and human health.

The energy-intensive nature of gas welding also raises concerns about resource consumption. The production and transportation of fuel gases require substantial energy inputs, further increasing the carbon footprint of the construction process. Additionally, the inefficiencies inherent in gas welding, such as heat loss and incomplete combustion, exacerbate these environmental impacts.

Water pollution is another potential consequence of gas welding in construction. Runoff from welding sites can contain heavy metals and other contaminants, which may infiltrate groundwater or surface water bodies if not properly managed. This can have detrimental effects on aquatic ecosystems and potentially contaminate drinking water sources.

Noise pollution is a less obvious but still significant environmental impact of gas welding. The high-decibel levels produced during welding operations can disturb local wildlife and affect the quality of life for nearby residents. This is particularly relevant in urban construction projects where noise regulations are often more stringent.

Waste generation is also a concern in gas welding processes. Spent welding rods, slag, and other byproducts contribute to construction waste streams. Proper disposal and recycling of these materials are essential to minimize landfill usage and reduce the overall environmental footprint of modular construction projects.

However, it's important to note that gas welding in modular construction systems can offer some environmental benefits when compared to traditional on-site construction methods. The controlled factory environment in which many modular components are welded allows for more efficient use of materials and energy, potentially reducing waste and emissions. Furthermore, the reduced on-site construction time associated with modular systems can lead to lower overall environmental impacts at the construction site.

To mitigate the environmental impacts of gas welding in modular construction, several strategies can be employed. These include the use of more efficient welding equipment, implementation of proper ventilation systems, adoption of cleaner fuel gases, and the integration of renewable energy sources in the manufacturing process. Additionally, ongoing research into alternative joining technologies and materials may provide more environmentally friendly options for future modular construction projects.

The energy-intensive nature of gas welding also raises concerns about resource consumption. The production and transportation of fuel gases require substantial energy inputs, further increasing the carbon footprint of the construction process. Additionally, the inefficiencies inherent in gas welding, such as heat loss and incomplete combustion, exacerbate these environmental impacts.

Water pollution is another potential consequence of gas welding in construction. Runoff from welding sites can contain heavy metals and other contaminants, which may infiltrate groundwater or surface water bodies if not properly managed. This can have detrimental effects on aquatic ecosystems and potentially contaminate drinking water sources.

Noise pollution is a less obvious but still significant environmental impact of gas welding. The high-decibel levels produced during welding operations can disturb local wildlife and affect the quality of life for nearby residents. This is particularly relevant in urban construction projects where noise regulations are often more stringent.

Waste generation is also a concern in gas welding processes. Spent welding rods, slag, and other byproducts contribute to construction waste streams. Proper disposal and recycling of these materials are essential to minimize landfill usage and reduce the overall environmental footprint of modular construction projects.

However, it's important to note that gas welding in modular construction systems can offer some environmental benefits when compared to traditional on-site construction methods. The controlled factory environment in which many modular components are welded allows for more efficient use of materials and energy, potentially reducing waste and emissions. Furthermore, the reduced on-site construction time associated with modular systems can lead to lower overall environmental impacts at the construction site.

To mitigate the environmental impacts of gas welding in modular construction, several strategies can be employed. These include the use of more efficient welding equipment, implementation of proper ventilation systems, adoption of cleaner fuel gases, and the integration of renewable energy sources in the manufacturing process. Additionally, ongoing research into alternative joining technologies and materials may provide more environmentally friendly options for future modular construction projects.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!