Gate valve improvements for consistent THW flows in aerospace cooling systems

AUG 20, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Aerospace Cooling Gate Valve Evolution and Objectives

Gate valves have played a crucial role in aerospace cooling systems since the early days of aviation. The evolution of these valves has been closely tied to the advancement of aircraft technology and the increasing demands for more efficient and reliable cooling systems. Initially, simple mechanical gate valves were used to control the flow of coolant in early aircraft engines. However, as aircraft became more sophisticated and flew at higher altitudes and speeds, the need for more precise and responsive cooling systems grew.

In the 1950s and 1960s, the introduction of jet engines and supersonic flight posed new challenges for cooling systems. This led to the development of more advanced gate valves that could withstand higher pressures and temperatures. The focus shifted towards materials that could maintain their integrity under extreme conditions, such as high-performance alloys and ceramics.

The advent of fly-by-wire systems in the 1970s and 1980s brought about a revolution in aircraft control, including cooling system management. This period saw the integration of electronic controls into gate valves, allowing for more precise and automated regulation of coolant flow. The objective was to achieve optimal engine performance while maintaining safe operating temperatures across various flight conditions.

As aerospace technology continued to advance, the goals for gate valve improvements became more refined. Key objectives included reducing weight without compromising strength, enhancing reliability to minimize maintenance requirements, and improving response times to sudden changes in cooling demands. The industry also began to focus on developing valves that could provide consistent THW (Temperature, Humidity, and Water) flows, recognizing the critical role these factors play in overall system efficiency.

In recent years, the push for more fuel-efficient and environmentally friendly aircraft has further driven innovation in gate valve technology. Current objectives include developing smart valves with integrated sensors and predictive maintenance capabilities, as well as exploring new materials and designs that can further optimize coolant flow and heat transfer efficiency.

Looking ahead, the aerospace industry aims to achieve even greater precision in THW flow control, with gate valves that can adapt in real-time to changing flight conditions and engine performance parameters. There is also a growing interest in developing valves that can operate effectively with alternative coolants, as the industry explores more sustainable cooling solutions. The ultimate goal is to create gate valves that contribute to safer, more efficient, and more environmentally friendly aerospace cooling systems.

In the 1950s and 1960s, the introduction of jet engines and supersonic flight posed new challenges for cooling systems. This led to the development of more advanced gate valves that could withstand higher pressures and temperatures. The focus shifted towards materials that could maintain their integrity under extreme conditions, such as high-performance alloys and ceramics.

The advent of fly-by-wire systems in the 1970s and 1980s brought about a revolution in aircraft control, including cooling system management. This period saw the integration of electronic controls into gate valves, allowing for more precise and automated regulation of coolant flow. The objective was to achieve optimal engine performance while maintaining safe operating temperatures across various flight conditions.

As aerospace technology continued to advance, the goals for gate valve improvements became more refined. Key objectives included reducing weight without compromising strength, enhancing reliability to minimize maintenance requirements, and improving response times to sudden changes in cooling demands. The industry also began to focus on developing valves that could provide consistent THW (Temperature, Humidity, and Water) flows, recognizing the critical role these factors play in overall system efficiency.

In recent years, the push for more fuel-efficient and environmentally friendly aircraft has further driven innovation in gate valve technology. Current objectives include developing smart valves with integrated sensors and predictive maintenance capabilities, as well as exploring new materials and designs that can further optimize coolant flow and heat transfer efficiency.

Looking ahead, the aerospace industry aims to achieve even greater precision in THW flow control, with gate valves that can adapt in real-time to changing flight conditions and engine performance parameters. There is also a growing interest in developing valves that can operate effectively with alternative coolants, as the industry explores more sustainable cooling solutions. The ultimate goal is to create gate valves that contribute to safer, more efficient, and more environmentally friendly aerospace cooling systems.

THW Flow Consistency Market Analysis

The market for THW (Thermal Working Fluid) flow consistency in aerospace cooling systems has been experiencing significant growth due to the increasing demand for more efficient and reliable thermal management solutions in aircraft and spacecraft. As aerospace technologies advance, the need for precise temperature control and heat dissipation becomes paramount, driving the market for improved gate valve systems that can ensure consistent THW flows.

The global aerospace thermal management market, which includes THW flow control systems, is projected to reach a substantial value in the coming years. This growth is primarily attributed to the rising production of commercial and military aircraft, as well as the increasing focus on space exploration missions. The demand for more advanced cooling systems is particularly strong in regions with a robust aerospace industry, such as North America, Europe, and Asia-Pacific.

One of the key drivers for the THW flow consistency market is the growing emphasis on fuel efficiency and environmental sustainability in the aerospace sector. Improved thermal management systems, including those with enhanced gate valves, contribute to overall aircraft efficiency by optimizing engine performance and reducing fuel consumption. This aligns with the industry's goals to reduce carbon emissions and operating costs.

The market is also influenced by the increasing complexity of aircraft systems and the integration of more electronic components, which generate additional heat. This trend necessitates more sophisticated cooling solutions, further boosting the demand for advanced gate valve technologies that can maintain consistent THW flows under varying operational conditions.

In the space exploration segment, the market for THW flow consistency solutions is driven by the need for highly reliable and long-lasting thermal management systems. Spacecraft operating in extreme environments require precise temperature control to protect sensitive equipment and ensure mission success. This has led to increased investment in research and development of advanced gate valve technologies for space applications.

The competitive landscape of the THW flow consistency market is characterized by a mix of established aerospace component manufacturers and specialized thermal management solution providers. Key players are focusing on developing innovative gate valve designs that offer improved precision, durability, and performance in aerospace cooling systems. Collaborations between aerospace companies and thermal management specialists are becoming more common, fostering technological advancements in this field.

Looking ahead, the market for THW flow consistency solutions in aerospace cooling systems is expected to continue its growth trajectory. Emerging technologies such as electric and hybrid-electric propulsion systems in aircraft will likely create new opportunities for advanced thermal management solutions, including improved gate valve systems. Additionally, the increasing adoption of additive manufacturing techniques in aerospace component production may lead to novel gate valve designs that further enhance THW flow consistency.

The global aerospace thermal management market, which includes THW flow control systems, is projected to reach a substantial value in the coming years. This growth is primarily attributed to the rising production of commercial and military aircraft, as well as the increasing focus on space exploration missions. The demand for more advanced cooling systems is particularly strong in regions with a robust aerospace industry, such as North America, Europe, and Asia-Pacific.

One of the key drivers for the THW flow consistency market is the growing emphasis on fuel efficiency and environmental sustainability in the aerospace sector. Improved thermal management systems, including those with enhanced gate valves, contribute to overall aircraft efficiency by optimizing engine performance and reducing fuel consumption. This aligns with the industry's goals to reduce carbon emissions and operating costs.

The market is also influenced by the increasing complexity of aircraft systems and the integration of more electronic components, which generate additional heat. This trend necessitates more sophisticated cooling solutions, further boosting the demand for advanced gate valve technologies that can maintain consistent THW flows under varying operational conditions.

In the space exploration segment, the market for THW flow consistency solutions is driven by the need for highly reliable and long-lasting thermal management systems. Spacecraft operating in extreme environments require precise temperature control to protect sensitive equipment and ensure mission success. This has led to increased investment in research and development of advanced gate valve technologies for space applications.

The competitive landscape of the THW flow consistency market is characterized by a mix of established aerospace component manufacturers and specialized thermal management solution providers. Key players are focusing on developing innovative gate valve designs that offer improved precision, durability, and performance in aerospace cooling systems. Collaborations between aerospace companies and thermal management specialists are becoming more common, fostering technological advancements in this field.

Looking ahead, the market for THW flow consistency solutions in aerospace cooling systems is expected to continue its growth trajectory. Emerging technologies such as electric and hybrid-electric propulsion systems in aircraft will likely create new opportunities for advanced thermal management solutions, including improved gate valve systems. Additionally, the increasing adoption of additive manufacturing techniques in aerospace component production may lead to novel gate valve designs that further enhance THW flow consistency.

Gate Valve Challenges in Aerospace Cooling

Gate valves play a critical role in aerospace cooling systems, regulating the flow of thermal working fluids (THW) to maintain optimal temperature control. However, these valves face several challenges in ensuring consistent and reliable performance under the extreme conditions encountered in aerospace applications.

One of the primary challenges is the wide range of operating temperatures that gate valves must withstand. Aerospace cooling systems can experience temperature fluctuations from cryogenic levels to several hundred degrees Celsius. This thermal cycling puts significant stress on valve components, potentially leading to material fatigue, thermal expansion issues, and seal degradation.

Pressure variations pose another significant challenge. Gate valves in aerospace cooling systems must maintain tight seals and precise control under both high-pressure and vacuum conditions. The rapid pressure changes during ascent and descent can cause valve malfunction or leakage if not properly designed and manufactured.

Corrosion resistance is a critical factor, as gate valves are exposed to various coolants and potentially corrosive fluids. The materials used in valve construction must be carefully selected to withstand chemical attack while maintaining structural integrity and performance over extended periods.

Weight and size constraints in aerospace applications present additional challenges. Gate valves must be compact and lightweight without compromising functionality or durability. This necessitates innovative designs and advanced materials to achieve the required performance within strict space and weight limitations.

Reliability and longevity are paramount in aerospace systems. Gate valves must operate flawlessly for thousands of cycles under extreme conditions with minimal maintenance. Achieving this level of reliability requires advanced engineering, precise manufacturing, and rigorous testing protocols.

The challenge of precise flow control is particularly acute in aerospace cooling systems. Gate valves must provide accurate and repeatable flow regulation to maintain optimal thermal management. This requires advanced actuation systems and sophisticated control algorithms to respond quickly to changing cooling demands.

Vibration and shock resistance are essential considerations, as aerospace vehicles experience significant mechanical stresses during launch, flight, and landing. Gate valves must maintain their integrity and functionality under these dynamic conditions, necessitating robust designs and vibration-dampening features.

Addressing these challenges requires a multidisciplinary approach, combining materials science, fluid dynamics, thermal engineering, and advanced manufacturing techniques. Ongoing research and development efforts focus on improving gate valve designs, exploring new materials, and enhancing control systems to meet the evolving demands of aerospace cooling applications.

One of the primary challenges is the wide range of operating temperatures that gate valves must withstand. Aerospace cooling systems can experience temperature fluctuations from cryogenic levels to several hundred degrees Celsius. This thermal cycling puts significant stress on valve components, potentially leading to material fatigue, thermal expansion issues, and seal degradation.

Pressure variations pose another significant challenge. Gate valves in aerospace cooling systems must maintain tight seals and precise control under both high-pressure and vacuum conditions. The rapid pressure changes during ascent and descent can cause valve malfunction or leakage if not properly designed and manufactured.

Corrosion resistance is a critical factor, as gate valves are exposed to various coolants and potentially corrosive fluids. The materials used in valve construction must be carefully selected to withstand chemical attack while maintaining structural integrity and performance over extended periods.

Weight and size constraints in aerospace applications present additional challenges. Gate valves must be compact and lightweight without compromising functionality or durability. This necessitates innovative designs and advanced materials to achieve the required performance within strict space and weight limitations.

Reliability and longevity are paramount in aerospace systems. Gate valves must operate flawlessly for thousands of cycles under extreme conditions with minimal maintenance. Achieving this level of reliability requires advanced engineering, precise manufacturing, and rigorous testing protocols.

The challenge of precise flow control is particularly acute in aerospace cooling systems. Gate valves must provide accurate and repeatable flow regulation to maintain optimal thermal management. This requires advanced actuation systems and sophisticated control algorithms to respond quickly to changing cooling demands.

Vibration and shock resistance are essential considerations, as aerospace vehicles experience significant mechanical stresses during launch, flight, and landing. Gate valves must maintain their integrity and functionality under these dynamic conditions, necessitating robust designs and vibration-dampening features.

Addressing these challenges requires a multidisciplinary approach, combining materials science, fluid dynamics, thermal engineering, and advanced manufacturing techniques. Ongoing research and development efforts focus on improving gate valve designs, exploring new materials, and enhancing control systems to meet the evolving demands of aerospace cooling applications.

Current Gate Valve Solutions for THW Flow

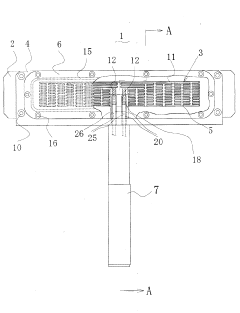

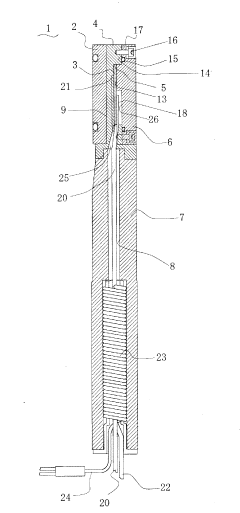

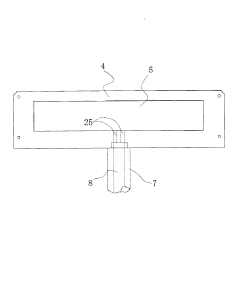

01 Gate valve design for improved flow control

Gate valves are designed with specific features to enhance flow control in THW (Through-Hardened Wall) systems. These designs may include optimized gate shapes, sealing mechanisms, and actuation systems to ensure precise regulation of fluid flow while maintaining durability in high-pressure environments.- Gate valve design for improved flow control: Gate valves are designed with specific features to enhance flow control in THW (Through-Hardened Wall) systems. These designs may include optimized gate shapes, sealing mechanisms, and actuation systems to ensure precise regulation of fluid flow while maintaining durability in high-pressure environments.

- Materials selection for THW gate valves: The choice of materials for gate valves in THW applications is crucial for ensuring longevity and performance. Specialized alloys and coatings are employed to withstand high temperatures, pressures, and potentially corrosive fluids, while maintaining smooth operation and minimal wear over time.

- Sealing mechanisms for THW gate valves: Advanced sealing technologies are incorporated into gate valves for THW systems to prevent leakage and ensure reliable operation. These may include innovative gasket designs, metal-to-metal seals, or composite materials that can withstand extreme conditions while maintaining a tight seal throughout the valve's operational life.

- Actuation systems for THW gate valves: Efficient and reliable actuation systems are crucial for THW gate valves to ensure smooth operation and precise control. These may include hydraulic, pneumatic, or electric actuators designed to provide the necessary force and responsiveness required in high-pressure THW applications.

- Monitoring and control systems for THW gate valves: Integration of advanced monitoring and control systems in THW gate valves allows for real-time performance tracking, predictive maintenance, and remote operation. These systems may include sensors, data analytics, and communication interfaces to optimize valve operation and enhance overall system efficiency.

02 Materials selection for THW gate valves

The choice of materials for gate valves in THW applications is crucial for performance and longevity. Specialized alloys and coatings are used to withstand high temperatures, pressures, and corrosive environments typically encountered in THW systems, ensuring reliable operation and extended service life.Expand Specific Solutions03 Sealing mechanisms for THW gate valves

Advanced sealing technologies are employed in THW gate valves to prevent leakage and ensure tight shut-off. These may include innovative seat designs, multiple sealing surfaces, and self-adjusting mechanisms that maintain seal integrity under varying pressure and temperature conditions.Expand Specific Solutions04 Actuation systems for THW gate valves

THW gate valves incorporate specialized actuation systems designed for reliable operation in demanding conditions. These may include hydraulic, pneumatic, or electric actuators with fail-safe features, position indicators, and remote control capabilities to ensure precise and responsive valve operation.Expand Specific Solutions05 Maintenance and monitoring of THW gate valves

To ensure optimal performance and longevity of THW gate valves, advanced maintenance and monitoring systems are implemented. These may include in-situ diagnostics, predictive maintenance algorithms, and non-invasive inspection techniques to detect potential issues before they lead to valve failure or system downtime.Expand Specific Solutions

Key Aerospace Cooling System Manufacturers

The gate valve improvements for consistent THW flows in aerospace cooling systems represent a niche but critical technological challenge in the aerospace industry. The market is in a mature stage, with established players like Pratt & Whitney Canada, Rolls-Royce, and Honeywell International Technologies leading the field. The market size is relatively small but significant, given the high-value nature of aerospace components. Technological maturity varies, with companies like Safran Aircraft Engines and United Technologies pushing for innovations in valve design and flow control. Emerging players such as ArianeGroup and Aerojet Rocketdyne are also contributing to advancements, indicating a competitive landscape with ongoing R&D efforts to improve efficiency and reliability in aerospace cooling systems.

Honeywell International Technologies Ltd.

Technical Solution: Honeywell has developed an innovative gate valve system for aerospace cooling applications, focusing on precision control and reliability. Their solution features a microprocessor-controlled actuator that provides sub-millimeter positioning accuracy, ensuring exact flow control for THW systems [1]. The valve incorporates a self-cleaning mechanism that uses high-frequency vibrations to prevent debris accumulation and maintain consistent performance over time [3]. Honeywell's design also includes a fail-safe mode that automatically adjusts the valve to a predetermined position in case of power or control system failure, ensuring continued operation of critical cooling systems [5]. The company has implemented advanced sealing technologies, including nano-coated surfaces, to minimize leakage and extend the valve's operational life in harsh aerospace environments [7].

Strengths: High-precision control, self-cleaning mechanism, fail-safe operation, and advanced sealing technologies. Weaknesses: Potential for increased complexity due to microprocessor control, and higher initial cost compared to traditional valve systems.

Rolls-Royce Plc

Technical Solution: Rolls-Royce has engineered a cutting-edge gate valve system for aerospace cooling applications, focusing on reliability and efficiency. Their solution incorporates a unique dual-gate design that allows for redundancy and improved flow control [2]. The valve utilizes advanced computational fluid dynamics (CFD) modeling to optimize internal geometry, reducing pressure drop and ensuring consistent THW flows across various operating conditions [4]. Rolls-Royce has also implemented a smart sensor network within the valve assembly, providing real-time monitoring of valve position, flow rates, and system health [6]. This data is integrated into the aircraft's overall health monitoring system, enabling predictive maintenance and reducing downtime. The valve body is constructed using additive manufacturing techniques, allowing for complex internal channels that enhance cooling efficiency [8].

Strengths: Redundant dual-gate design, CFD-optimized flow paths, integrated health monitoring, and advanced manufacturing techniques. Weaknesses: Complexity of the system may lead to higher maintenance requirements and potential reliability issues if not properly managed.

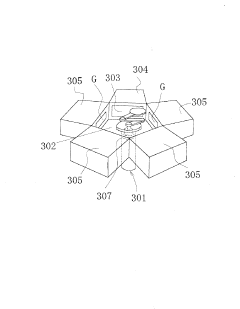

Innovative Gate Valve Designs for Aerospace

Gate valve

PatentInactiveJP2009204137A

Innovation

- A gate valve design with a detachable heater system isolated from the vacuum processing chamber, using a planar heater with increased watt density and atmospheric communication through the valve rod, allowing for efficient heat transfer and replacement of the heater without generating particles.

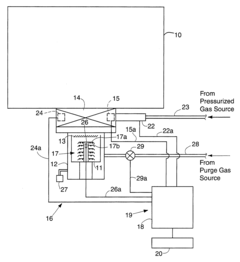

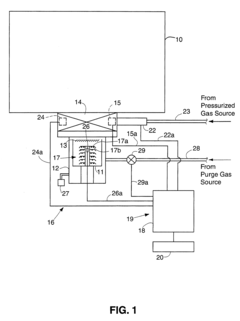

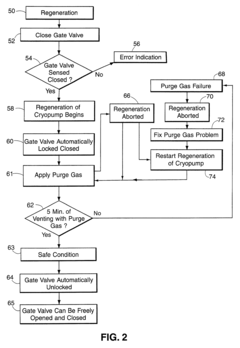

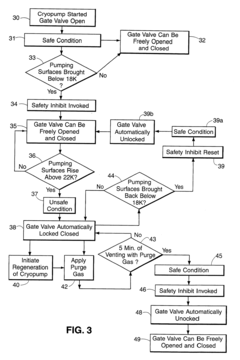

Cryopump with gate valve control

PatentInactiveUS6327863B1

Innovation

- A cryopump system with an integrated electronic controller that automatically determines safe or unsafe conditions based on operational modes and sensed parameters, locking the gate valve closed during unsafe conditions, such as the presence of combustible gases, and unlocking it only when safe conditions are met, ensuring the gate valve remains closed until hydrogen gas is purged or temperatures return to safe levels.

Aerospace Cooling System Standards

Aerospace cooling system standards play a crucial role in ensuring the safety, reliability, and performance of aircraft thermal management systems. These standards encompass a wide range of requirements, specifications, and guidelines that govern the design, manufacturing, installation, and maintenance of cooling systems used in aerospace applications.

The primary objective of these standards is to establish a consistent framework for the development and implementation of cooling systems that can effectively regulate temperature and manage heat dissipation in various aircraft components. This is particularly important in modern aircraft, where advanced electronics, propulsion systems, and other heat-generating equipment require efficient cooling to maintain optimal performance and prevent overheating-related failures.

Aerospace cooling system standards typically address several key areas, including material selection, component design, system integration, performance testing, and quality control measures. These standards often specify the acceptable materials for use in cooling system components, taking into account factors such as thermal conductivity, corrosion resistance, and weight considerations. They also provide guidelines for the design of heat exchangers, pumps, valves, and other critical components to ensure they meet the stringent requirements of aerospace applications.

Furthermore, these standards outline the necessary testing procedures and performance criteria that cooling systems must meet before being approved for use in aircraft. This includes thermal performance tests, pressure tests, vibration tests, and environmental tests to simulate various operating conditions and ensure the system's reliability under different scenarios.

Compliance with aerospace cooling system standards is mandatory for manufacturers and suppliers in the aviation industry. Regulatory bodies such as the Federal Aviation Administration (FAA) in the United States and the European Union Aviation Safety Agency (EASA) in Europe enforce these standards to maintain the highest levels of safety and reliability in aircraft operations.

As aerospace technology continues to advance, cooling system standards are regularly updated to address new challenges and incorporate emerging technologies. This ongoing evolution ensures that aerospace cooling systems remain at the forefront of innovation while maintaining the highest levels of safety and performance in the aviation industry.

The primary objective of these standards is to establish a consistent framework for the development and implementation of cooling systems that can effectively regulate temperature and manage heat dissipation in various aircraft components. This is particularly important in modern aircraft, where advanced electronics, propulsion systems, and other heat-generating equipment require efficient cooling to maintain optimal performance and prevent overheating-related failures.

Aerospace cooling system standards typically address several key areas, including material selection, component design, system integration, performance testing, and quality control measures. These standards often specify the acceptable materials for use in cooling system components, taking into account factors such as thermal conductivity, corrosion resistance, and weight considerations. They also provide guidelines for the design of heat exchangers, pumps, valves, and other critical components to ensure they meet the stringent requirements of aerospace applications.

Furthermore, these standards outline the necessary testing procedures and performance criteria that cooling systems must meet before being approved for use in aircraft. This includes thermal performance tests, pressure tests, vibration tests, and environmental tests to simulate various operating conditions and ensure the system's reliability under different scenarios.

Compliance with aerospace cooling system standards is mandatory for manufacturers and suppliers in the aviation industry. Regulatory bodies such as the Federal Aviation Administration (FAA) in the United States and the European Union Aviation Safety Agency (EASA) in Europe enforce these standards to maintain the highest levels of safety and reliability in aircraft operations.

As aerospace technology continues to advance, cooling system standards are regularly updated to address new challenges and incorporate emerging technologies. This ongoing evolution ensures that aerospace cooling systems remain at the forefront of innovation while maintaining the highest levels of safety and performance in the aviation industry.

Material Advancements for Gate Valves

Material advancements for gate valves in aerospace cooling systems have been pivotal in addressing the challenges of consistent THW (Thermal Heat Working) flows. Recent developments in metallurgy and composite materials have led to significant improvements in valve performance, durability, and efficiency.

High-performance alloys, such as nickel-based superalloys and titanium alloys, have emerged as preferred materials for gate valve components. These alloys offer exceptional strength-to-weight ratios, corrosion resistance, and thermal stability, crucial for aerospace applications. Nickel-based superalloys, like Inconel 718 and Waspaloy, exhibit excellent mechanical properties at elevated temperatures, making them ideal for valve bodies and gates exposed to extreme thermal conditions.

Titanium alloys, particularly Ti-6Al-4V, have gained traction due to their low density, high strength, and resistance to fatigue. These properties contribute to weight reduction in aerospace systems while maintaining structural integrity. The use of titanium alloys in gate valve stems and actuators has resulted in improved response times and reduced wear, enhancing overall system reliability.

Advanced ceramic materials, such as silicon carbide and alumina, have been introduced for valve seats and seals. These ceramics offer superior hardness, wear resistance, and chemical inertness compared to traditional metallic counterparts. The implementation of ceramic components has led to extended valve life cycles and reduced maintenance requirements, particularly in applications involving corrosive or abrasive fluids.

Composite materials, including carbon fiber reinforced polymers (CFRP) and ceramic matrix composites (CMCs), have found applications in valve housings and external components. These materials provide excellent strength-to-weight ratios and thermal insulation properties, contributing to overall system efficiency and weight reduction.

Surface engineering techniques, such as thermal spraying and physical vapor deposition (PVD), have been employed to enhance the tribological properties of valve components. Coatings like chromium nitride and diamond-like carbon (DLC) have been applied to valve gates and seats, reducing friction and improving wear resistance. These surface treatments have resulted in smoother valve operation and increased reliability in maintaining consistent THW flows.

The integration of smart materials, such as shape memory alloys (SMAs) and piezoelectric materials, has opened new possibilities for active flow control and self-diagnostic capabilities in gate valves. SMAs, like Nitinol, have been utilized in actuator designs, enabling more precise and responsive valve control. Piezoelectric sensors embedded in valve components allow for real-time monitoring of valve performance and early detection of potential issues.

These material advancements have collectively contributed to the development of gate valves capable of maintaining consistent THW flows in aerospace cooling systems. The improved thermal stability, wear resistance, and reduced weight of these advanced materials have resulted in more reliable and efficient cooling systems, crucial for the demanding requirements of modern aerospace applications.

High-performance alloys, such as nickel-based superalloys and titanium alloys, have emerged as preferred materials for gate valve components. These alloys offer exceptional strength-to-weight ratios, corrosion resistance, and thermal stability, crucial for aerospace applications. Nickel-based superalloys, like Inconel 718 and Waspaloy, exhibit excellent mechanical properties at elevated temperatures, making them ideal for valve bodies and gates exposed to extreme thermal conditions.

Titanium alloys, particularly Ti-6Al-4V, have gained traction due to their low density, high strength, and resistance to fatigue. These properties contribute to weight reduction in aerospace systems while maintaining structural integrity. The use of titanium alloys in gate valve stems and actuators has resulted in improved response times and reduced wear, enhancing overall system reliability.

Advanced ceramic materials, such as silicon carbide and alumina, have been introduced for valve seats and seals. These ceramics offer superior hardness, wear resistance, and chemical inertness compared to traditional metallic counterparts. The implementation of ceramic components has led to extended valve life cycles and reduced maintenance requirements, particularly in applications involving corrosive or abrasive fluids.

Composite materials, including carbon fiber reinforced polymers (CFRP) and ceramic matrix composites (CMCs), have found applications in valve housings and external components. These materials provide excellent strength-to-weight ratios and thermal insulation properties, contributing to overall system efficiency and weight reduction.

Surface engineering techniques, such as thermal spraying and physical vapor deposition (PVD), have been employed to enhance the tribological properties of valve components. Coatings like chromium nitride and diamond-like carbon (DLC) have been applied to valve gates and seats, reducing friction and improving wear resistance. These surface treatments have resulted in smoother valve operation and increased reliability in maintaining consistent THW flows.

The integration of smart materials, such as shape memory alloys (SMAs) and piezoelectric materials, has opened new possibilities for active flow control and self-diagnostic capabilities in gate valves. SMAs, like Nitinol, have been utilized in actuator designs, enabling more precise and responsive valve control. Piezoelectric sensors embedded in valve components allow for real-time monitoring of valve performance and early detection of potential issues.

These material advancements have collectively contributed to the development of gate valves capable of maintaining consistent THW flows in aerospace cooling systems. The improved thermal stability, wear resistance, and reduced weight of these advanced materials have resulted in more reliable and efficient cooling systems, crucial for the demanding requirements of modern aerospace applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!