Gate Valve Innovations in Pyrolysis Applications.

SEP 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Pyrolysis Gate Valve Technology Background and Objectives

Pyrolysis technology has evolved significantly over the past several decades, transforming from basic thermal decomposition processes to sophisticated systems capable of converting various feedstocks into valuable products. Gate valves, as critical components in these systems, have undergone parallel development to meet the increasingly demanding requirements of modern pyrolysis applications. The historical trajectory shows a shift from simple mechanical valves to advanced engineered solutions capable of withstanding extreme temperatures, corrosive environments, and high-pressure conditions characteristic of pyrolysis operations.

The pyrolysis process typically involves temperatures ranging from 400°C to 900°C, creating challenging operating conditions for valve technologies. Traditional gate valve designs have proven inadequate in these environments, experiencing issues such as thermal expansion, seal degradation, and material failure. This has driven continuous innovation in valve design, materials science, and operational mechanisms to enhance performance reliability and longevity.

Current technological objectives in pyrolysis gate valve development focus on several key areas. First, improving thermal resistance capabilities to maintain structural integrity and operational functionality at extreme temperatures. Second, enhancing sealing technologies to prevent leakage of potentially hazardous pyrolysis gases and liquids. Third, developing materials resistant to the corrosive byproducts commonly generated during pyrolysis processes, including acids, tars, and various reactive compounds.

Another significant objective is the integration of smart technologies into gate valve systems, enabling real-time monitoring, predictive maintenance, and remote operation capabilities. This trend aligns with broader Industry 4.0 initiatives and responds to the increasing complexity of pyrolysis systems in both research and commercial applications.

The evolution of pyrolysis applications themselves has also driven gate valve innovation. As pyrolysis expands beyond traditional waste management into specialized applications such as biomass conversion, plastic recycling, and sustainable fuel production, valve technologies must adapt to diverse feedstock characteristics and process requirements. Each application presents unique challenges regarding temperature profiles, pressure conditions, and chemical environments.

Looking forward, the technological trajectory points toward multifunctional gate valves specifically engineered for pyrolysis systems. These next-generation valves aim to combine robust mechanical performance with advanced materials and intelligent control systems. The ultimate goal is to develop gate valve technologies that not only withstand the harsh conditions of pyrolysis but also contribute to process optimization, safety enhancement, and operational efficiency across the expanding range of pyrolysis applications.

The pyrolysis process typically involves temperatures ranging from 400°C to 900°C, creating challenging operating conditions for valve technologies. Traditional gate valve designs have proven inadequate in these environments, experiencing issues such as thermal expansion, seal degradation, and material failure. This has driven continuous innovation in valve design, materials science, and operational mechanisms to enhance performance reliability and longevity.

Current technological objectives in pyrolysis gate valve development focus on several key areas. First, improving thermal resistance capabilities to maintain structural integrity and operational functionality at extreme temperatures. Second, enhancing sealing technologies to prevent leakage of potentially hazardous pyrolysis gases and liquids. Third, developing materials resistant to the corrosive byproducts commonly generated during pyrolysis processes, including acids, tars, and various reactive compounds.

Another significant objective is the integration of smart technologies into gate valve systems, enabling real-time monitoring, predictive maintenance, and remote operation capabilities. This trend aligns with broader Industry 4.0 initiatives and responds to the increasing complexity of pyrolysis systems in both research and commercial applications.

The evolution of pyrolysis applications themselves has also driven gate valve innovation. As pyrolysis expands beyond traditional waste management into specialized applications such as biomass conversion, plastic recycling, and sustainable fuel production, valve technologies must adapt to diverse feedstock characteristics and process requirements. Each application presents unique challenges regarding temperature profiles, pressure conditions, and chemical environments.

Looking forward, the technological trajectory points toward multifunctional gate valves specifically engineered for pyrolysis systems. These next-generation valves aim to combine robust mechanical performance with advanced materials and intelligent control systems. The ultimate goal is to develop gate valve technologies that not only withstand the harsh conditions of pyrolysis but also contribute to process optimization, safety enhancement, and operational efficiency across the expanding range of pyrolysis applications.

Market Demand Analysis for Advanced Pyrolysis Valves

The global market for advanced pyrolysis valves is experiencing significant growth, driven by the expanding adoption of pyrolysis technologies across various industrial sectors. Current market analysis indicates strong demand particularly in waste-to-energy applications, where pyrolysis offers an environmentally sustainable solution for converting plastic waste into valuable fuels and chemicals. This segment alone is projected to grow substantially as governments worldwide implement stricter waste management regulations and circular economy initiatives.

The petrochemical industry represents another major demand driver, where pyrolysis processes are essential for cracking hydrocarbons into smaller molecules. As refineries and chemical plants seek to optimize efficiency and reduce downtime, the need for high-performance gate valves capable of withstanding extreme pyrolysis conditions has intensified. Industry reports suggest that maintenance and replacement costs associated with valve failures in pyrolysis units represent a significant operational expense, creating a compelling value proposition for advanced valve solutions.

Biomass pyrolysis applications are emerging as a rapidly expanding market segment, particularly in regions with abundant agricultural waste. The conversion of biomass to bio-oil through pyrolysis requires specialized valves that can handle the corrosive compounds and particulate matter inherent in these feedstocks. Market research indicates growing investment in biomass pyrolysis facilities across North America, Europe, and parts of Asia, creating new opportunities for valve manufacturers.

Geographically, the demand for advanced pyrolysis valves shows distinct regional patterns. North America and Europe lead in terms of technology adoption, driven by stringent environmental regulations and mature industrial infrastructure. However, the Asia-Pacific region, particularly China and India, is witnessing the fastest growth rate due to rapid industrialization and increasing focus on sustainable waste management solutions.

Customer requirements are evolving toward valves with enhanced durability under extreme temperature cycling, improved resistance to coking and fouling, and capabilities for handling abrasive char particles. End-users increasingly demand valves with longer service intervals, predictive maintenance capabilities, and lower total cost of ownership. This shift is creating premium market segments for technologically advanced solutions that can demonstrate superior performance metrics in challenging pyrolysis environments.

Market forecasts suggest that the specialized valve segment for pyrolysis applications will outpace the growth of the general industrial valve market by a significant margin over the next five years. This trend is further reinforced by the increasing scale of pyrolysis installations and the growing technical sophistication of these facilities, which require more specialized components capable of ensuring operational reliability and safety.

The petrochemical industry represents another major demand driver, where pyrolysis processes are essential for cracking hydrocarbons into smaller molecules. As refineries and chemical plants seek to optimize efficiency and reduce downtime, the need for high-performance gate valves capable of withstanding extreme pyrolysis conditions has intensified. Industry reports suggest that maintenance and replacement costs associated with valve failures in pyrolysis units represent a significant operational expense, creating a compelling value proposition for advanced valve solutions.

Biomass pyrolysis applications are emerging as a rapidly expanding market segment, particularly in regions with abundant agricultural waste. The conversion of biomass to bio-oil through pyrolysis requires specialized valves that can handle the corrosive compounds and particulate matter inherent in these feedstocks. Market research indicates growing investment in biomass pyrolysis facilities across North America, Europe, and parts of Asia, creating new opportunities for valve manufacturers.

Geographically, the demand for advanced pyrolysis valves shows distinct regional patterns. North America and Europe lead in terms of technology adoption, driven by stringent environmental regulations and mature industrial infrastructure. However, the Asia-Pacific region, particularly China and India, is witnessing the fastest growth rate due to rapid industrialization and increasing focus on sustainable waste management solutions.

Customer requirements are evolving toward valves with enhanced durability under extreme temperature cycling, improved resistance to coking and fouling, and capabilities for handling abrasive char particles. End-users increasingly demand valves with longer service intervals, predictive maintenance capabilities, and lower total cost of ownership. This shift is creating premium market segments for technologically advanced solutions that can demonstrate superior performance metrics in challenging pyrolysis environments.

Market forecasts suggest that the specialized valve segment for pyrolysis applications will outpace the growth of the general industrial valve market by a significant margin over the next five years. This trend is further reinforced by the increasing scale of pyrolysis installations and the growing technical sophistication of these facilities, which require more specialized components capable of ensuring operational reliability and safety.

Current Challenges in High-Temperature Valve Technology

Gate valve technology in high-temperature pyrolysis applications faces significant challenges that limit operational efficiency and reliability. The extreme thermal conditions, often exceeding 800°C in pyrolysis processes, create material integrity issues as conventional valve materials experience accelerated degradation, thermal expansion, and potential warping. These conditions compromise sealing capabilities and lead to increased maintenance frequency and operational downtime.

Corrosion resistance presents another critical challenge, as pyrolysis environments contain highly corrosive compounds including tars, acids, and various reactive hydrocarbons. Current valve technologies struggle to maintain structural integrity when exposed to these substances at elevated temperatures, resulting in premature component failure and potential process contamination.

Sealing effectiveness remains problematic under fluctuating temperature conditions. Traditional sealing materials deteriorate rapidly in pyrolysis environments, creating leakage pathways that compromise process efficiency and safety. The industry has yet to develop sealing solutions that maintain consistent performance across the wide temperature ranges experienced during startup, operation, and shutdown phases.

Operational control precision is increasingly demanded by modern pyrolysis systems, yet current high-temperature valve technologies offer limited modulation capabilities. The thermal expansion characteristics of valve components often result in inconsistent positioning and reduced control accuracy, particularly problematic in processes requiring precise flow regulation.

Maintenance challenges compound these issues, as high-temperature valves in pyrolysis applications typically require frequent servicing. The complex designs necessary for thermal resistance often result in components that are difficult to access and replace, extending maintenance periods and increasing operational costs.

Energy efficiency concerns have emerged as another limitation, with current valve designs exhibiting significant thermal losses. These losses not only represent wasted energy but can create localized cooling that promotes fouling and coking within the valve assembly, further degrading performance over time.

Safety considerations remain paramount, as valve failures in high-temperature pyrolysis applications can lead to catastrophic outcomes. Current technologies often lack robust fail-safe mechanisms that can reliably operate under extreme thermal conditions, creating potential vulnerabilities in critical safety systems.

Cost-effectiveness presents the final major challenge, as specialized high-temperature valves require expensive alloys and complex manufacturing processes. The industry continues to search for more economical solutions that do not compromise on performance or reliability, particularly as pyrolysis technologies expand into new applications and markets.

Corrosion resistance presents another critical challenge, as pyrolysis environments contain highly corrosive compounds including tars, acids, and various reactive hydrocarbons. Current valve technologies struggle to maintain structural integrity when exposed to these substances at elevated temperatures, resulting in premature component failure and potential process contamination.

Sealing effectiveness remains problematic under fluctuating temperature conditions. Traditional sealing materials deteriorate rapidly in pyrolysis environments, creating leakage pathways that compromise process efficiency and safety. The industry has yet to develop sealing solutions that maintain consistent performance across the wide temperature ranges experienced during startup, operation, and shutdown phases.

Operational control precision is increasingly demanded by modern pyrolysis systems, yet current high-temperature valve technologies offer limited modulation capabilities. The thermal expansion characteristics of valve components often result in inconsistent positioning and reduced control accuracy, particularly problematic in processes requiring precise flow regulation.

Maintenance challenges compound these issues, as high-temperature valves in pyrolysis applications typically require frequent servicing. The complex designs necessary for thermal resistance often result in components that are difficult to access and replace, extending maintenance periods and increasing operational costs.

Energy efficiency concerns have emerged as another limitation, with current valve designs exhibiting significant thermal losses. These losses not only represent wasted energy but can create localized cooling that promotes fouling and coking within the valve assembly, further degrading performance over time.

Safety considerations remain paramount, as valve failures in high-temperature pyrolysis applications can lead to catastrophic outcomes. Current technologies often lack robust fail-safe mechanisms that can reliably operate under extreme thermal conditions, creating potential vulnerabilities in critical safety systems.

Cost-effectiveness presents the final major challenge, as specialized high-temperature valves require expensive alloys and complex manufacturing processes. The industry continues to search for more economical solutions that do not compromise on performance or reliability, particularly as pyrolysis technologies expand into new applications and markets.

State-of-the-Art Gate Valve Solutions for Pyrolysis

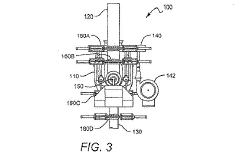

01 Gate valve structural designs

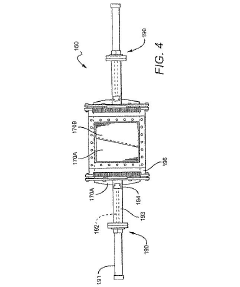

Various structural designs of gate valves that improve functionality and performance. These designs include different gate configurations, sealing mechanisms, and body structures that enhance the valve's operation in various applications. The structural innovations focus on improving flow control, reducing wear, and increasing the valve's lifespan under different operating conditions.- Gate valve structural designs: Various structural designs of gate valves that improve functionality and performance. These designs include different gate configurations, sealing mechanisms, and body structures that enhance the valve's operation in various applications. The structural innovations focus on improving flow control, reducing wear, and increasing the valve's operational lifespan.

- Sealing mechanisms for gate valves: Advanced sealing technologies specifically designed for gate valves to prevent leakage under various operating conditions. These sealing mechanisms include innovative seat designs, specialized sealing materials, and pressure-responsive elements that maintain seal integrity even under high pressure or temperature fluctuations. The sealing solutions address common issues such as wear, corrosion, and thermal expansion.

- Actuation systems for gate valves: Various actuation systems designed for operating gate valves, including manual, pneumatic, hydraulic, and electric actuators. These systems provide different methods for controlling the opening and closing of gate valves, offering solutions for remote operation, automated control, and integration with broader control systems. The actuation technologies focus on precision, reliability, and adaptability to different operational environments.

- Gate valve materials and manufacturing: Innovative materials and manufacturing techniques used in gate valve production to enhance durability, resistance to corrosion, and performance under extreme conditions. These innovations include the use of specialized alloys, composite materials, and advanced coating technologies. The manufacturing methods focus on improving precision, reducing production costs, and enhancing the quality and consistency of gate valve components.

- Specialized gate valves for specific applications: Gate valves designed for specific industrial applications such as oil and gas, water treatment, chemical processing, and high-pressure systems. These specialized designs incorporate features tailored to the unique requirements of each application, including resistance to specific chemicals, ability to handle abrasive media, and compliance with industry-specific standards and regulations. The specialized valves address the particular challenges and operational parameters of their intended use environments.

02 Sealing mechanisms for gate valves

Advanced sealing technologies specifically designed for gate valves to prevent leakage under high pressure or temperature conditions. These sealing mechanisms include innovative seat designs, specialized materials, and unique configurations that maintain tight seals during operation. The sealing solutions address common issues such as wear, corrosion, and thermal expansion that can compromise valve integrity.Expand Specific Solutions03 Actuation systems for gate valves

Various actuation systems designed for operating gate valves, including manual, pneumatic, hydraulic, and electric actuators. These systems provide different methods for controlling the opening and closing of gate valves in various industrial applications. The actuation technologies focus on improving control precision, operational efficiency, and reliability while accommodating different installation environments and operational requirements.Expand Specific Solutions04 Gate valve materials and manufacturing

Innovative materials and manufacturing techniques used in gate valve production to enhance durability, corrosion resistance, and performance under extreme conditions. These innovations include advanced metal alloys, composite materials, and specialized coatings that extend valve life and improve functionality. The manufacturing methods focus on precision, quality control, and cost-effectiveness while meeting industry standards and specifications.Expand Specific Solutions05 Gate valve applications in specialized industries

Specialized gate valve designs adapted for specific industrial applications such as oil and gas, chemical processing, water treatment, and power generation. These valves feature modifications that address the unique challenges of each industry, including extreme temperatures, corrosive media, high pressures, or sanitary requirements. The specialized designs incorporate industry-specific features while maintaining the fundamental gate valve operating principles.Expand Specific Solutions

Leading Manufacturers and Competitive Landscape

The gate valve innovation landscape in pyrolysis applications is currently in a growth phase, with an expanding market driven by increasing demand for efficient thermal decomposition processes. The market size is projected to grow significantly as industries adopt pyrolysis for waste-to-energy and chemical production applications. Technologically, the field shows varying maturity levels, with established players like Fisher Controls International and NOV Inc. offering proven valve solutions, while companies such as Applied Materials and Tokyo Electron are advancing high-temperature and corrosion-resistant designs. Emerging players like Luoyang Jianguang Special Equipment and Dalian Kangwei Technology are introducing innovations specifically tailored to pyrolysis conditions, focusing on improved sealing mechanisms and materials that withstand the harsh operating environments characteristic of pyrolysis processes.

Equinor Energy AS

Technical Solution: Equinor has developed advanced gate valve systems specifically designed for pyrolysis applications in their bio-oil production facilities. Their innovation focuses on high-temperature resistant gate valves that can withstand the extreme conditions of biomass pyrolysis processes (400-600°C). The company's proprietary valve design incorporates ceramic-coated valve gates and specialized sealing technology that prevents leakage of pyrolysis vapors and bio-oils. Equinor's gate valves feature remote monitoring capabilities that track valve performance and predict maintenance needs through integrated sensors that measure temperature, pressure, and flow rates. This technology has been implemented in their renewable energy division where they convert forestry residues and agricultural waste into bio-crude through pyrolysis processes. The valves are designed with self-cleaning mechanisms to prevent coking and fouling from pyrolysis byproducts, significantly extending operational lifespans in these harsh environments.

Strengths: Exceptional resistance to high temperatures and corrosive pyrolysis byproducts; advanced predictive maintenance capabilities reduce downtime; self-cleaning mechanisms extend operational life. Weaknesses: Higher initial cost compared to conventional valves; requires specialized training for maintenance personnel; limited track record in extremely large-scale operations.

Fisher Controls International LLC

Technical Solution: Fisher Controls has pioneered the development of specialized gate valves for pyrolysis applications with their Fisher™ PyroSeal series. These valves are engineered with proprietary alloys that resist the carbon deposition and corrosion typical in pyrolysis environments where temperatures can exceed 800°C. The company's innovation includes a dual-sealing system that maintains integrity even when handling abrasive char particles and condensable pyrolysis vapors. Their gate valves incorporate a patented stem design that minimizes leakage paths and provides precise control over flow rates critical for optimizing pyrolysis reaction conditions. Fisher's digital valve controllers enable real-time monitoring and adjustment of valve positions, allowing for automated responses to process variations. The PyroSeal valves feature specialized thermal isolation sections that protect actuators and electronic components from the extreme heat of pyrolysis reactors, significantly extending component life and reducing maintenance requirements. These innovations have been successfully deployed in both fast and slow pyrolysis systems across petrochemical and biomass conversion facilities.

Strengths: Industry-leading temperature resistance; digital integration capabilities allow for precise process control; proven reliability in commercial pyrolysis operations with documented 40% reduction in maintenance costs. Weaknesses: Premium pricing positions these valves at the higher end of the market; complex design requires specialized servicing; heavier than conventional alternatives which may impact installation requirements.

Key Patents and Technical Breakthroughs in Valve Design

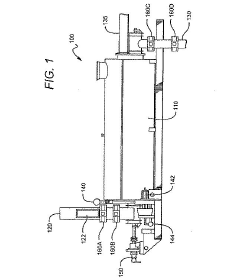

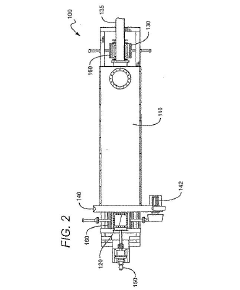

Gate valve

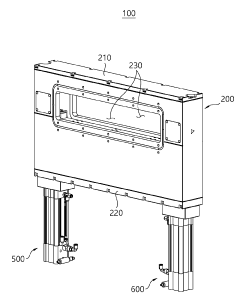

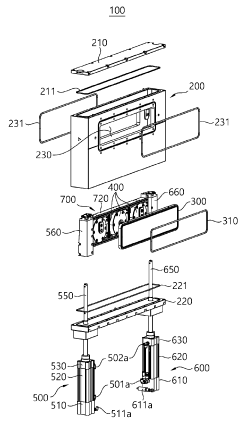

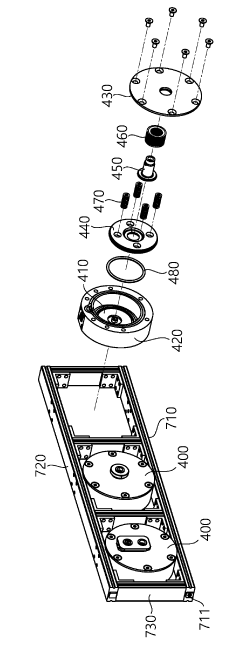

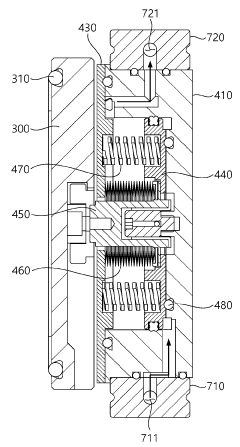

PatentInactiveKR1020190060512A

Innovation

- A gate valve design that eliminates the need for a block-shaped metal plate by incorporating a pressure supply and discharge system through a cylinder tube, using a bellows and elastic bodies to drive the gate, and elevating cylinders to support the gate, reducing overall thickness and improving vacuum exhaust efficiency.

Pyrolysis waste treatment system with double knife gate valve

PatentInactiveJP2009521310A

Innovation

- Implementing a pyrolysis waste treatment system with dual knife gate valves featuring movable blades that cooperate to cut and restrict waste material, minimizing clogging and maintaining a controlled environment by limiting gas presence.

Material Science Advancements for Extreme Conditions

The extreme conditions present in pyrolysis applications pose significant challenges for gate valve materials, necessitating continuous advancements in material science. Traditional metal alloys often fail prematurely when exposed to the harsh combination of high temperatures (500-1000°C), corrosive gases, and abrasive particulates characteristic of pyrolysis environments.

Recent developments in ceramic-metal composites (cermets) have shown promising results for gate valve components. Silicon carbide (SiC) and silicon nitride (Si3N4) ceramics, when integrated with specialized metal matrices, demonstrate exceptional thermal stability and wear resistance while maintaining structural integrity under rapid temperature fluctuations. These materials exhibit thermal expansion coefficients that minimize warping and sealing issues common in conventional valve designs.

Superalloys based on nickel and cobalt have undergone significant refinement specifically for pyrolysis applications. The latest generations incorporate precise amounts of refractory elements such as molybdenum, tungsten, and rhenium, creating microstructures that resist creep deformation at elevated temperatures. Advanced precipitation hardening techniques have improved their performance in the carbon-rich atmospheres typical of pyrolysis processes.

Surface engineering breakthroughs have revolutionized gate valve durability through multi-layer coating systems. Thermal barrier coatings (TBCs) utilizing yttria-stabilized zirconia (YSZ) provide thermal insulation, while underlying MCrAlY bond coats offer oxidation protection. The newest developments include self-healing ceramic coatings that can repair microcracks through phase transformation mechanisms triggered by operational stresses.

Computational materials science has accelerated the development cycle through predictive modeling of material behavior under pyrolysis conditions. Machine learning algorithms now analyze performance data from operational environments to optimize material compositions for specific pyrolysis applications, whether biomass, plastic waste, or tire pyrolysis systems.

Nanomaterial incorporation represents the cutting edge of valve material science. Graphene-reinforced composites and carbon nanotube structures provide unprecedented strength-to-weight ratios while enhancing thermal conductivity properties. These nanomaterials, when properly dispersed within metal or ceramic matrices, create gate valve components with superior resistance to thermal shock and chemical attack.

The integration of in-situ monitoring capabilities through embedded sensors in advanced materials enables real-time assessment of material degradation, allowing predictive maintenance before catastrophic failure occurs. This smart materials approach represents a paradigm shift in how gate valves are managed in extreme pyrolysis environments.

Recent developments in ceramic-metal composites (cermets) have shown promising results for gate valve components. Silicon carbide (SiC) and silicon nitride (Si3N4) ceramics, when integrated with specialized metal matrices, demonstrate exceptional thermal stability and wear resistance while maintaining structural integrity under rapid temperature fluctuations. These materials exhibit thermal expansion coefficients that minimize warping and sealing issues common in conventional valve designs.

Superalloys based on nickel and cobalt have undergone significant refinement specifically for pyrolysis applications. The latest generations incorporate precise amounts of refractory elements such as molybdenum, tungsten, and rhenium, creating microstructures that resist creep deformation at elevated temperatures. Advanced precipitation hardening techniques have improved their performance in the carbon-rich atmospheres typical of pyrolysis processes.

Surface engineering breakthroughs have revolutionized gate valve durability through multi-layer coating systems. Thermal barrier coatings (TBCs) utilizing yttria-stabilized zirconia (YSZ) provide thermal insulation, while underlying MCrAlY bond coats offer oxidation protection. The newest developments include self-healing ceramic coatings that can repair microcracks through phase transformation mechanisms triggered by operational stresses.

Computational materials science has accelerated the development cycle through predictive modeling of material behavior under pyrolysis conditions. Machine learning algorithms now analyze performance data from operational environments to optimize material compositions for specific pyrolysis applications, whether biomass, plastic waste, or tire pyrolysis systems.

Nanomaterial incorporation represents the cutting edge of valve material science. Graphene-reinforced composites and carbon nanotube structures provide unprecedented strength-to-weight ratios while enhancing thermal conductivity properties. These nanomaterials, when properly dispersed within metal or ceramic matrices, create gate valve components with superior resistance to thermal shock and chemical attack.

The integration of in-situ monitoring capabilities through embedded sensors in advanced materials enables real-time assessment of material degradation, allowing predictive maintenance before catastrophic failure occurs. This smart materials approach represents a paradigm shift in how gate valves are managed in extreme pyrolysis environments.

Environmental and Safety Considerations in Valve Design

The environmental impact of industrial processes has become a critical consideration in modern engineering design, particularly in high-temperature applications like pyrolysis. Gate valve innovations for pyrolysis systems must address not only operational efficiency but also stringent environmental and safety standards that continue to evolve globally.

Emissions control represents a primary environmental concern in valve design for pyrolysis applications. Modern gate valves incorporate advanced sealing technologies that minimize fugitive emissions of volatile organic compounds (VOCs) and hazardous air pollutants. Triple-barrier sealing systems and low-emission packing materials such as graphite-based composites have demonstrated reduction in leakage rates by up to 95% compared to conventional designs, meeting stringent EPA Method 21 and ISO 15848 standards for fugitive emissions.

Material selection for valve components plays a crucial role in both environmental sustainability and operational safety. Recent innovations have focused on replacing traditional chrome-molybdenum alloys with more environmentally benign alternatives that maintain high-temperature resistance. Nickel-based superalloys with reduced heavy metal content offer comparable performance while minimizing environmental impact during manufacturing and end-of-life disposal phases.

Fire safety considerations have driven significant innovations in gate valve design for pyrolysis applications. API 607 and API 6FA compliant fire-safe designs incorporate secondary metal-to-metal seating surfaces that maintain operational integrity even when primary soft seals are compromised by extreme heat. Thermal expansion compensation mechanisms prevent valve seizure during rapid temperature fluctuations, a common safety hazard in pyrolysis operations.

Noise reduction technologies represent another important environmental consideration. Flow-induced vibration and noise can create workplace hazards and environmental disturbances in surrounding communities. Advanced computational fluid dynamics modeling has enabled the development of anti-cavitation trim designs that reduce noise levels by up to 30 decibels while maintaining flow efficiency.

Emergency shutdown capabilities have been enhanced through fail-safe actuation systems that respond to environmental anomalies. Smart valve technologies incorporating temperature, pressure, and emissions sensors can trigger automatic closure when environmental parameters exceed safe thresholds, preventing catastrophic releases of pyrolysis byproducts into the environment.

Lifecycle assessment methodologies are increasingly applied to valve design, evaluating environmental impact from raw material extraction through manufacturing, operation, and eventual decommissioning. This cradle-to-grave approach has led to innovations in recyclable component design and modular construction that facilitate maintenance while reducing waste generation throughout the valve's operational life.

Emissions control represents a primary environmental concern in valve design for pyrolysis applications. Modern gate valves incorporate advanced sealing technologies that minimize fugitive emissions of volatile organic compounds (VOCs) and hazardous air pollutants. Triple-barrier sealing systems and low-emission packing materials such as graphite-based composites have demonstrated reduction in leakage rates by up to 95% compared to conventional designs, meeting stringent EPA Method 21 and ISO 15848 standards for fugitive emissions.

Material selection for valve components plays a crucial role in both environmental sustainability and operational safety. Recent innovations have focused on replacing traditional chrome-molybdenum alloys with more environmentally benign alternatives that maintain high-temperature resistance. Nickel-based superalloys with reduced heavy metal content offer comparable performance while minimizing environmental impact during manufacturing and end-of-life disposal phases.

Fire safety considerations have driven significant innovations in gate valve design for pyrolysis applications. API 607 and API 6FA compliant fire-safe designs incorporate secondary metal-to-metal seating surfaces that maintain operational integrity even when primary soft seals are compromised by extreme heat. Thermal expansion compensation mechanisms prevent valve seizure during rapid temperature fluctuations, a common safety hazard in pyrolysis operations.

Noise reduction technologies represent another important environmental consideration. Flow-induced vibration and noise can create workplace hazards and environmental disturbances in surrounding communities. Advanced computational fluid dynamics modeling has enabled the development of anti-cavitation trim designs that reduce noise levels by up to 30 decibels while maintaining flow efficiency.

Emergency shutdown capabilities have been enhanced through fail-safe actuation systems that respond to environmental anomalies. Smart valve technologies incorporating temperature, pressure, and emissions sensors can trigger automatic closure when environmental parameters exceed safe thresholds, preventing catastrophic releases of pyrolysis byproducts into the environment.

Lifecycle assessment methodologies are increasingly applied to valve design, evaluating environmental impact from raw material extraction through manufacturing, operation, and eventual decommissioning. This cradle-to-grave approach has led to innovations in recyclable component design and modular construction that facilitate maintenance while reducing waste generation throughout the valve's operational life.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!