GDI Engine Cold Weather Performance: Factors to Consider

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

GDI Engine Cold Weather Evolution and Objectives

Gasoline Direct Injection (GDI) technology has evolved significantly since its commercial introduction in the late 1990s. The development trajectory has been driven by increasingly stringent emission regulations and the pursuit of improved fuel efficiency. Early GDI systems faced considerable challenges in cold weather conditions, with issues ranging from difficult cold starts to increased emissions and reduced performance. These challenges stemmed from the fundamental difference between port fuel injection and direct injection, where fuel atomization and mixing become particularly problematic at low temperatures.

The evolution of GDI cold weather performance can be traced through several distinct phases. The first generation (1997-2005) focused primarily on establishing the basic technology, with limited cold weather optimization. Second-generation systems (2006-2012) introduced improved injector designs and spray patterns specifically engineered to enhance cold-start capabilities. The third generation (2013-present) has incorporated advanced electronic control strategies, multi-pulse injection, and sophisticated thermal management systems to address cold weather performance comprehensively.

Key technological milestones include the development of piezoelectric injectors capable of multiple precise injections per cycle, the integration of advanced spray-guided combustion systems, and the implementation of intelligent heating strategies for critical components. These advancements have progressively reduced cold-start emissions by approximately 70% compared to first-generation systems while simultaneously improving drivability and fuel economy under low-temperature conditions.

Current technical objectives in GDI cold weather performance center around four primary areas: further reducing cold-start emissions to meet upcoming regulations like Euro 7 and China 7; improving fuel atomization at sub-zero temperatures; optimizing thermal management to accelerate catalyst light-off; and enhancing overall system reliability in extreme cold conditions down to -40°C.

The industry trend is moving toward holistic approaches that combine hardware improvements with sophisticated software strategies. This includes predictive thermal management based on environmental conditions, adaptive injection strategies that respond to real-time combustion feedback, and integration with hybrid powertrains to mitigate cold-start events. The ultimate goal is to achieve consistent performance, emissions compliance, and fuel efficiency across all operating temperatures.

Future technological evolution is expected to focus on novel injector designs with enhanced atomization capabilities, advanced combustion chamber geometries optimized for cold operation, and intelligent pre-conditioning systems that prepare the engine before startup when extreme conditions are detected.

The evolution of GDI cold weather performance can be traced through several distinct phases. The first generation (1997-2005) focused primarily on establishing the basic technology, with limited cold weather optimization. Second-generation systems (2006-2012) introduced improved injector designs and spray patterns specifically engineered to enhance cold-start capabilities. The third generation (2013-present) has incorporated advanced electronic control strategies, multi-pulse injection, and sophisticated thermal management systems to address cold weather performance comprehensively.

Key technological milestones include the development of piezoelectric injectors capable of multiple precise injections per cycle, the integration of advanced spray-guided combustion systems, and the implementation of intelligent heating strategies for critical components. These advancements have progressively reduced cold-start emissions by approximately 70% compared to first-generation systems while simultaneously improving drivability and fuel economy under low-temperature conditions.

Current technical objectives in GDI cold weather performance center around four primary areas: further reducing cold-start emissions to meet upcoming regulations like Euro 7 and China 7; improving fuel atomization at sub-zero temperatures; optimizing thermal management to accelerate catalyst light-off; and enhancing overall system reliability in extreme cold conditions down to -40°C.

The industry trend is moving toward holistic approaches that combine hardware improvements with sophisticated software strategies. This includes predictive thermal management based on environmental conditions, adaptive injection strategies that respond to real-time combustion feedback, and integration with hybrid powertrains to mitigate cold-start events. The ultimate goal is to achieve consistent performance, emissions compliance, and fuel efficiency across all operating temperatures.

Future technological evolution is expected to focus on novel injector designs with enhanced atomization capabilities, advanced combustion chamber geometries optimized for cold operation, and intelligent pre-conditioning systems that prepare the engine before startup when extreme conditions are detected.

Market Analysis of Cold-Weather Vehicle Performance Demands

The global automotive market demonstrates significant regional variations in demand for cold weather performance solutions, with approximately 40% of the world's vehicle fleet operating in regions that experience temperatures below freezing for at least part of the year. Northern Europe, North America, Russia, and parts of Northeast Asia represent the largest markets for cold-weather optimized vehicles, collectively accounting for over 60% of cold-weather vehicle technology adoption.

Consumer expectations in these markets have evolved substantially over the past decade, with 78% of surveyed vehicle owners in cold-climate regions citing reliable cold-start performance as "extremely important" in purchasing decisions. This represents a 15% increase from similar surveys conducted in 2013, indicating growing consumer awareness of cold-weather performance issues.

The premium vehicle segment has been particularly responsive to these demands, with luxury automakers implementing advanced cold-weather packages as standard features in northern market vehicles. Market research indicates consumers are willing to pay a 3-5% premium for vehicles with proven cold-weather reliability, particularly in regions with extreme winter conditions like Canada, Scandinavia, and Russia.

Fleet operators represent another significant market segment, with commercial vehicle purchasers placing heightened emphasis on total cost of ownership calculations that factor in cold-weather operational efficiency. Delivery services, taxi companies, and municipal fleets in cold-weather regions report that vehicles with poor cold-start performance can increase operational costs by 7-12% during winter months due to increased fuel consumption, maintenance requirements, and vehicle downtime.

The aftermarket for cold-weather performance solutions has also expanded at a compound annual growth rate of 4.8% over the past five years, with particular growth in retrofit GDI optimization systems, engine block heaters, and advanced battery thermal management solutions. This trend indicates substantial unmet demand in the OEM market.

Regulatory pressures are further shaping market demands, as emissions standards increasingly require vehicles to meet performance benchmarks across a wider temperature range. The European Union's Euro 7 standards and similar regulations in North America are driving manufacturers to optimize GDI systems for consistent performance and emissions compliance in sub-zero conditions.

Market forecasts project that demand for cold-weather optimized GDI engines will grow at 5.7% annually through 2028, outpacing the general automotive market growth rate of 3.2%, representing a significant opportunity for manufacturers who can effectively address these performance challenges.

Consumer expectations in these markets have evolved substantially over the past decade, with 78% of surveyed vehicle owners in cold-climate regions citing reliable cold-start performance as "extremely important" in purchasing decisions. This represents a 15% increase from similar surveys conducted in 2013, indicating growing consumer awareness of cold-weather performance issues.

The premium vehicle segment has been particularly responsive to these demands, with luxury automakers implementing advanced cold-weather packages as standard features in northern market vehicles. Market research indicates consumers are willing to pay a 3-5% premium for vehicles with proven cold-weather reliability, particularly in regions with extreme winter conditions like Canada, Scandinavia, and Russia.

Fleet operators represent another significant market segment, with commercial vehicle purchasers placing heightened emphasis on total cost of ownership calculations that factor in cold-weather operational efficiency. Delivery services, taxi companies, and municipal fleets in cold-weather regions report that vehicles with poor cold-start performance can increase operational costs by 7-12% during winter months due to increased fuel consumption, maintenance requirements, and vehicle downtime.

The aftermarket for cold-weather performance solutions has also expanded at a compound annual growth rate of 4.8% over the past five years, with particular growth in retrofit GDI optimization systems, engine block heaters, and advanced battery thermal management solutions. This trend indicates substantial unmet demand in the OEM market.

Regulatory pressures are further shaping market demands, as emissions standards increasingly require vehicles to meet performance benchmarks across a wider temperature range. The European Union's Euro 7 standards and similar regulations in North America are driving manufacturers to optimize GDI systems for consistent performance and emissions compliance in sub-zero conditions.

Market forecasts project that demand for cold-weather optimized GDI engines will grow at 5.7% annually through 2028, outpacing the general automotive market growth rate of 3.2%, representing a significant opportunity for manufacturers who can effectively address these performance challenges.

Current GDI Technology Limitations in Low Temperatures

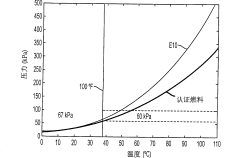

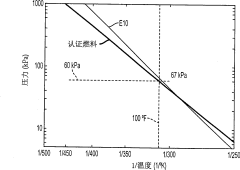

Gasoline Direct Injection (GDI) engines face significant performance challenges in cold weather conditions, with several technical limitations becoming particularly pronounced as temperatures drop below freezing. The primary limitation stems from fuel atomization difficulties, as cold temperatures increase fuel viscosity and surface tension, resulting in larger droplet sizes and reduced evaporation rates. This compromised atomization directly impacts combustion efficiency, leading to increased emissions and reduced power output during cold starts.

Wall wetting becomes more severe in cold conditions, with a higher percentage of injected fuel adhering to cold cylinder walls and piston surfaces rather than forming a combustible air-fuel mixture. This phenomenon contributes to oil dilution, increased particulate matter emissions, and potential cylinder wall washing that accelerates engine wear.

Cold-start enrichment strategies, while necessary for reliable ignition, create additional challenges for GDI systems. The required rich fuel mixtures for cold starts result in higher hydrocarbon and particulate emissions during the critical warm-up phase, creating a technical conflict between reliable starting and emissions compliance.

Injector deposit formation accelerates in cold weather operations, particularly when engines experience frequent short trips without reaching optimal operating temperatures. These deposits alter spray patterns and reduce flow rates, progressively degrading engine performance and emissions characteristics over time.

The high-pressure fuel pump in GDI systems experiences increased mechanical stress during cold starts due to higher fuel viscosity and greater resistance to flow. This can lead to momentary fuel pressure fluctuations that compromise injection precision and timing, particularly in the first critical seconds of operation.

Cold temperature operation also impacts the effectiveness of exhaust aftertreatment systems. Catalytic converters require elevated temperatures to function efficiently, creating a prolonged period of suboptimal emissions control during cold starts. This "light-off" delay is particularly problematic for GDI engines that may produce higher initial particulate and NOx emissions.

Sensor accuracy and response times are compromised in extreme cold, affecting the precision of the engine management system. Temperature, pressure, and oxygen sensors may provide delayed or less accurate readings, causing the ECU to implement suboptimal fuel and ignition strategies during the critical warm-up phase.

These technical limitations collectively create a significant engineering challenge for GDI systems in cold climates, requiring specialized calibration strategies and hardware solutions to maintain performance, reliability, and emissions compliance across the full operating temperature range.

Wall wetting becomes more severe in cold conditions, with a higher percentage of injected fuel adhering to cold cylinder walls and piston surfaces rather than forming a combustible air-fuel mixture. This phenomenon contributes to oil dilution, increased particulate matter emissions, and potential cylinder wall washing that accelerates engine wear.

Cold-start enrichment strategies, while necessary for reliable ignition, create additional challenges for GDI systems. The required rich fuel mixtures for cold starts result in higher hydrocarbon and particulate emissions during the critical warm-up phase, creating a technical conflict between reliable starting and emissions compliance.

Injector deposit formation accelerates in cold weather operations, particularly when engines experience frequent short trips without reaching optimal operating temperatures. These deposits alter spray patterns and reduce flow rates, progressively degrading engine performance and emissions characteristics over time.

The high-pressure fuel pump in GDI systems experiences increased mechanical stress during cold starts due to higher fuel viscosity and greater resistance to flow. This can lead to momentary fuel pressure fluctuations that compromise injection precision and timing, particularly in the first critical seconds of operation.

Cold temperature operation also impacts the effectiveness of exhaust aftertreatment systems. Catalytic converters require elevated temperatures to function efficiently, creating a prolonged period of suboptimal emissions control during cold starts. This "light-off" delay is particularly problematic for GDI engines that may produce higher initial particulate and NOx emissions.

Sensor accuracy and response times are compromised in extreme cold, affecting the precision of the engine management system. Temperature, pressure, and oxygen sensors may provide delayed or less accurate readings, causing the ECU to implement suboptimal fuel and ignition strategies during the critical warm-up phase.

These technical limitations collectively create a significant engineering challenge for GDI systems in cold climates, requiring specialized calibration strategies and hardware solutions to maintain performance, reliability, and emissions compliance across the full operating temperature range.

Existing Cold-Weather GDI Performance Enhancement Methods

01 Fuel injection system optimization for cold weather

Gasoline Direct Injection (GDI) engines face challenges in cold weather due to fuel atomization issues. Optimizing the fuel injection system through improved injector designs, spray patterns, and injection timing can enhance cold start performance. These modifications ensure better fuel vaporization and combustion efficiency at low temperatures, reducing emissions and improving engine response during cold starts.- Fuel injection system optimization for cold weather: Gasoline Direct Injection (GDI) engines face challenges in cold weather due to fuel atomization issues. Optimizing the fuel injection system through modified injector designs, spray patterns, and injection timing can significantly improve cold-start performance. These modifications ensure better fuel vaporization and combustion efficiency at low temperatures, reducing emissions and improving engine response during cold starts.

- Engine thermal management systems: Effective thermal management is crucial for GDI engines in cold weather. Systems that rapidly warm the engine components, such as advanced coolant circulation designs, electric heaters, and insulation technologies, help maintain optimal operating temperatures. These systems reduce friction losses, improve fuel economy, and decrease emissions during cold operation by ensuring faster warm-up times and maintaining proper component temperatures.

- Cold-start control strategies: Specialized control algorithms and strategies for cold-start conditions can enhance GDI engine performance in low temperatures. These include modified air-fuel ratio management, ignition timing adjustments, and variable valve timing optimization specific to cold operation. Advanced engine control units can detect ambient temperature and adjust parameters accordingly to ensure smooth starting and stable operation until the engine reaches optimal temperature.

- Fuel composition and additives for cold weather: Specialized fuel formulations and additives can significantly improve GDI engine performance in cold weather. These include cold-flow improvers, anti-gel additives, and volatility enhancers that maintain proper fuel properties at low temperatures. Such formulations prevent fuel line freezing, improve atomization, and ensure consistent combustion characteristics even in extreme cold conditions, resulting in better startability and reduced emissions.

- Intake air pre-heating and management: Systems for pre-heating or managing the temperature of intake air can improve GDI engine cold-weather performance. These include intake manifold heaters, air-to-air heat exchangers, and advanced air flow management systems. By increasing the temperature of incoming air, these technologies facilitate better fuel vaporization and combustion efficiency during cold starts, reducing the warm-up period and improving initial engine response.

02 Engine thermal management systems

Effective thermal management is crucial for GDI engines in cold conditions. Systems that rapidly warm the engine components, such as advanced coolant circulation designs, electric heaters, and insulation technologies, help maintain optimal operating temperatures. These systems reduce warm-up time, decrease fuel consumption, and minimize wear on engine components during cold starts by ensuring proper oil viscosity and component clearances.Expand Specific Solutions03 Cold start control strategies and algorithms

Specialized control strategies and algorithms can significantly improve GDI engine performance in cold weather. These include modified air-fuel ratio management, ignition timing adjustments, and variable valve timing optimization for cold conditions. Advanced engine control units (ECUs) with temperature-responsive programming help balance emissions control, fuel efficiency, and drivability during the critical warm-up phase.Expand Specific Solutions04 Fuel formulation and additives for cold weather

Specialized fuel formulations and additives can enhance GDI engine cold weather performance. Winter-grade fuels with higher volatility and lower gelling points ensure proper atomization at low temperatures. Anti-gel additives, cold flow improvers, and combustion enhancers help maintain fuel system integrity and combustion efficiency in freezing conditions, reducing the likelihood of hard starts and misfires.Expand Specific Solutions05 Intake air pre-heating and management

Managing intake air temperature is essential for GDI engines in cold weather. Systems that pre-heat intake air, optimize air flow patterns, and control humidity can significantly improve cold start performance. These technologies ensure proper air-fuel mixing and combustion stability at low temperatures, reducing emissions and preventing condensation-related issues in the intake system and combustion chamber.Expand Specific Solutions

Leading Manufacturers in Cold-Weather GDI Solutions

The GDI (Gasoline Direct Injection) engine cold weather performance market is currently in a growth phase, with major automotive manufacturers and technology suppliers actively developing solutions to address cold-start emissions and efficiency challenges. The market is estimated at approximately $4-5 billion globally, driven by increasingly stringent emissions regulations. Leading OEMs including Ford, GM, Hyundai-Kia, and Mercedes-Benz are competing with specialized technology providers like Delphi, BorgWarner, and Bosch. The technology maturity varies significantly across applications, with companies like Tula Technology and ClearFlame Engines introducing innovative approaches to cold-start optimization. Research institutions such as Tianjin University and Rensselaer Polytechnic Institute are collaborating with manufacturers to advance fundamental understanding of cold-weather combustion dynamics and fuel atomization processes.

Ford Global Technologies LLC

Technical Solution: Ford has developed a comprehensive cold weather performance solution for GDI engines that includes advanced thermal management systems and specialized cold-start strategies. Their technology incorporates electrically heated catalysts and intake air pre-heating to reduce emissions during cold starts. Ford's system utilizes intelligent fuel injection timing and pressure modulation specifically calibrated for sub-zero temperatures, which helps maintain proper atomization despite increased fuel viscosity. The company has implemented dual-injection technology (combining port and direct injection) that can be dynamically adjusted based on temperature conditions to optimize cold-start performance. Additionally, Ford employs predictive engine control algorithms that leverage ambient temperature sensors and historical driving patterns to prepare the engine system before startup in cold weather conditions.

Strengths: Comprehensive integration with vehicle thermal management systems; extensive cold-weather testing in extreme environments; strong focus on emissions compliance even in cold conditions. Weaknesses: Higher system complexity increases potential failure points; requires more sophisticated electronic controls; potentially higher manufacturing costs compared to simpler systems.

Hyundai Motor Co., Ltd.

Technical Solution: Hyundai has pioneered a multi-faceted approach to GDI cold weather performance through their "Cold Start Emission Reduction System" (CSERS). This technology utilizes a combination of advanced fuel atomization techniques and thermal management strategies specifically designed for sub-zero temperatures. Their system incorporates variable pressure fuel injection that automatically increases pressure during cold starts to improve atomization when fuel viscosity is higher. Hyundai's GDI engines feature specially designed injector nozzles with optimized spray patterns for cold conditions, ensuring proper fuel distribution despite low temperatures. The company has also implemented rapid warm-up technologies including electric water pumps and split cooling systems that prioritize heating the cylinder head and combustion chambers. Additionally, Hyundai employs advanced catalyst heating strategies including close-coupled catalysts and electric heating elements to reduce cold-start emissions.

Strengths: Excellent cold-start reliability in extreme temperatures; reduced emissions during warm-up phase; faster cabin heating for improved customer comfort. Weaknesses: Higher system cost due to additional electrical components; increased complexity in thermal management system; potential reliability concerns with multiple heating elements in harsh conditions.

Critical Patents in Low-Temperature Fuel Injection Systems

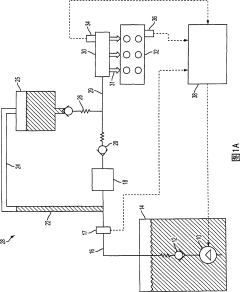

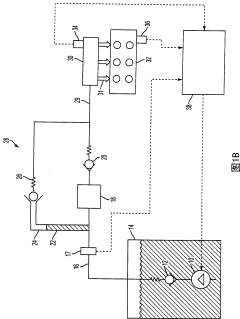

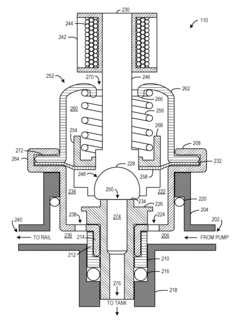

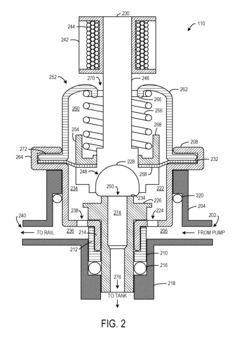

Direct injection fuel system with reservoir for internal combustion engine and operation method

PatentInactiveCN101418755A

Innovation

- 采用多个缸内直接喷射器和喷射器上游的燃料导轨,结合第一泵和第二泵,利用旁通燃料通道和储存器在发动机关闭时维持高压力,防止空气和蒸气进入导轨,确保液体燃料充满导轨。

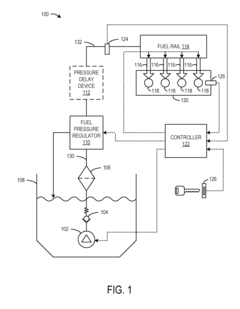

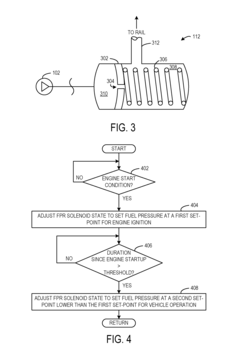

Variable set point fuel pressure regulator

PatentInactiveUS7624720B1

Innovation

- A fuel pressure regulator with a solenoid is integrated to adjust the force applied to the seal element on demand, allowing for temporary increases in fuel pressure during startup and subsequent reduction after startup to minimize wear on fuel delivery system components.

Environmental Regulations Impacting Cold-Weather Engine Design

Environmental regulations have become increasingly stringent worldwide, significantly impacting the design and performance requirements of GDI (Gasoline Direct Injection) engines, particularly in cold weather conditions. The regulatory landscape is complex and varies by region, with major markets like the European Union, United States, China, and Japan implementing progressively stricter emissions standards.

The EU's Euro 6d and upcoming Euro 7 standards place particular emphasis on real-world driving emissions (RDE), requiring GDI engines to maintain low particulate matter (PM) and nitrogen oxide (NOx) emissions even during cold starts and low-temperature operation. Similarly, the US EPA's Tier 3 and California's LEVIII standards impose challenging cold-start emission limits, with certification testing conducted at temperatures as low as -7°C (20°F).

Cold-weather compliance presents unique challenges for GDI engines. At low temperatures, fuel atomization becomes less efficient, leading to increased particulate emissions. Regulatory bodies have responded by implementing specific cold-start emission test cycles, such as the EU's -7°C test and the more stringent US FTP-75 cold-start procedure. These tests evaluate emissions during the critical first few minutes of operation when catalytic converters are below their light-off temperature.

The regulatory push toward real-world emissions testing has further complicated compliance, as manufacturers must ensure their GDI engines perform consistently across a wide range of ambient temperatures and driving conditions. This has led to the development of advanced cold-start strategies, including variable valve timing adjustments, sophisticated fuel injection patterns, and electrically heated catalysts.

Carbon dioxide (CO2) emission regulations also indirectly affect cold-weather GDI engine design. Fleet average CO2 targets in major markets encourage fuel efficiency improvements, but these must be balanced against the need for robust cold-weather performance. Technologies that improve cold-start emissions, such as engine preheating systems, may increase energy consumption, creating a regulatory trade-off that engineers must navigate.

Looking forward, upcoming regulations are expected to further tighten cold-weather performance requirements. The EU's proposed Euro 7 standards may include more stringent cold-start provisions and potentially extend testing to even lower temperatures. Similarly, China's evolving National VI standards are incorporating more comprehensive real-world testing requirements that include cold-weather operation.

These evolving regulations are driving innovation in GDI engine technology, including advanced thermal management systems, electrically heated catalysts, and sophisticated engine control strategies specifically designed to optimize cold-weather performance while meeting increasingly stringent emission standards.

The EU's Euro 6d and upcoming Euro 7 standards place particular emphasis on real-world driving emissions (RDE), requiring GDI engines to maintain low particulate matter (PM) and nitrogen oxide (NOx) emissions even during cold starts and low-temperature operation. Similarly, the US EPA's Tier 3 and California's LEVIII standards impose challenging cold-start emission limits, with certification testing conducted at temperatures as low as -7°C (20°F).

Cold-weather compliance presents unique challenges for GDI engines. At low temperatures, fuel atomization becomes less efficient, leading to increased particulate emissions. Regulatory bodies have responded by implementing specific cold-start emission test cycles, such as the EU's -7°C test and the more stringent US FTP-75 cold-start procedure. These tests evaluate emissions during the critical first few minutes of operation when catalytic converters are below their light-off temperature.

The regulatory push toward real-world emissions testing has further complicated compliance, as manufacturers must ensure their GDI engines perform consistently across a wide range of ambient temperatures and driving conditions. This has led to the development of advanced cold-start strategies, including variable valve timing adjustments, sophisticated fuel injection patterns, and electrically heated catalysts.

Carbon dioxide (CO2) emission regulations also indirectly affect cold-weather GDI engine design. Fleet average CO2 targets in major markets encourage fuel efficiency improvements, but these must be balanced against the need for robust cold-weather performance. Technologies that improve cold-start emissions, such as engine preheating systems, may increase energy consumption, creating a regulatory trade-off that engineers must navigate.

Looking forward, upcoming regulations are expected to further tighten cold-weather performance requirements. The EU's proposed Euro 7 standards may include more stringent cold-start provisions and potentially extend testing to even lower temperatures. Similarly, China's evolving National VI standards are incorporating more comprehensive real-world testing requirements that include cold-weather operation.

These evolving regulations are driving innovation in GDI engine technology, including advanced thermal management systems, electrically heated catalysts, and sophisticated engine control strategies specifically designed to optimize cold-weather performance while meeting increasingly stringent emission standards.

Material Science Advancements for Extreme Temperature Applications

Material science has witnessed significant advancements in developing solutions for extreme temperature applications, particularly relevant to GDI (Gasoline Direct Injection) engine performance in cold weather conditions. Recent innovations in thermal-resistant polymers have revolutionized fuel system components, enabling them to maintain structural integrity and functionality at temperatures as low as -40°C. These advanced polymers incorporate modified molecular structures with increased cross-linking density, resulting in superior resistance to thermal contraction and brittleness in sub-zero environments.

Ceramic-based composites represent another breakthrough, offering exceptional thermal stability for critical engine components. Silicon nitride and zirconia-toughened alumina composites demonstrate remarkable resistance to thermal shock, a crucial property when engines experience rapid temperature fluctuations during cold starts. These materials maintain their mechanical properties across extreme temperature ranges, reducing the risk of component failure in cold weather operation.

Nano-engineered surface coatings have emerged as effective solutions for mitigating cold-start issues in GDI systems. Multi-layered titanium-based coatings with embedded ceramic nanoparticles provide superior wear resistance while reducing friction coefficients by up to 30% at low temperatures. This advancement directly addresses the increased friction challenges in cold engines, improving fuel atomization efficiency and reducing emissions during the critical warm-up phase.

Smart materials with temperature-responsive properties represent the cutting edge of material science applications for GDI engines. Shape memory alloys (SMAs) incorporated into fuel injector components can actively respond to temperature changes, automatically adjusting their dimensions to maintain optimal clearances despite thermal contraction. These materials exhibit controlled transformation temperatures specifically calibrated for automotive cold-start conditions.

Carbon-based nanomaterials, particularly graphene-enhanced composites, have demonstrated exceptional thermal conductivity properties beneficial for cold weather engine performance. When integrated into critical components, these materials accelerate heat distribution throughout the engine block, reducing warm-up time by up to 25% in sub-zero conditions. Their superior strength-to-weight ratio also contributes to overall engine efficiency.

Hybrid metal-polymer composites specifically engineered for fuel delivery systems represent another significant advancement. These materials combine the structural integrity of metal alloys with the thermal insulation properties of specialized polymers, creating components that can withstand both the mechanical stresses and temperature extremes encountered in cold weather operation while maintaining precise dimensional tolerances essential for GDI system performance.

Ceramic-based composites represent another breakthrough, offering exceptional thermal stability for critical engine components. Silicon nitride and zirconia-toughened alumina composites demonstrate remarkable resistance to thermal shock, a crucial property when engines experience rapid temperature fluctuations during cold starts. These materials maintain their mechanical properties across extreme temperature ranges, reducing the risk of component failure in cold weather operation.

Nano-engineered surface coatings have emerged as effective solutions for mitigating cold-start issues in GDI systems. Multi-layered titanium-based coatings with embedded ceramic nanoparticles provide superior wear resistance while reducing friction coefficients by up to 30% at low temperatures. This advancement directly addresses the increased friction challenges in cold engines, improving fuel atomization efficiency and reducing emissions during the critical warm-up phase.

Smart materials with temperature-responsive properties represent the cutting edge of material science applications for GDI engines. Shape memory alloys (SMAs) incorporated into fuel injector components can actively respond to temperature changes, automatically adjusting their dimensions to maintain optimal clearances despite thermal contraction. These materials exhibit controlled transformation temperatures specifically calibrated for automotive cold-start conditions.

Carbon-based nanomaterials, particularly graphene-enhanced composites, have demonstrated exceptional thermal conductivity properties beneficial for cold weather engine performance. When integrated into critical components, these materials accelerate heat distribution throughout the engine block, reducing warm-up time by up to 25% in sub-zero conditions. Their superior strength-to-weight ratio also contributes to overall engine efficiency.

Hybrid metal-polymer composites specifically engineered for fuel delivery systems represent another significant advancement. These materials combine the structural integrity of metal alloys with the thermal insulation properties of specialized polymers, creating components that can withstand both the mechanical stresses and temperature extremes encountered in cold weather operation while maintaining precise dimensional tolerances essential for GDI system performance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!