GDI Engine Fuel Pressure Regulation for Consistency

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

GDI Fuel Pressure Technology Background and Objectives

Gasoline Direct Injection (GDI) technology has evolved significantly since its commercial introduction in the late 1990s, revolutionizing internal combustion engine efficiency and performance. The fundamental principle of GDI involves injecting fuel directly into the combustion chamber rather than the intake port, allowing for precise control over fuel delivery timing and quantity. This direct approach enables higher compression ratios, improved fuel atomization, and more efficient combustion compared to traditional port fuel injection systems.

The evolution of GDI technology has been driven by increasingly stringent emissions regulations worldwide and consumer demand for improved fuel economy without sacrificing performance. Early GDI systems operated at relatively low pressures of 50-100 bar, while modern systems commonly function at 200-350 bar, with advanced systems pushing beyond 400 bar. This pressure escalation represents a critical technological trend that directly impacts engine performance, emissions control, and reliability.

Fuel pressure regulation in GDI systems presents unique challenges compared to conventional fuel injection technologies. The system must maintain consistent high pressure across varying engine loads, speeds, and environmental conditions while responding rapidly to transient demands. Pressure fluctuations as small as 5-10 bar can significantly impact fuel atomization quality, air-fuel mixture homogeneity, and consequently combustion stability and emissions formation.

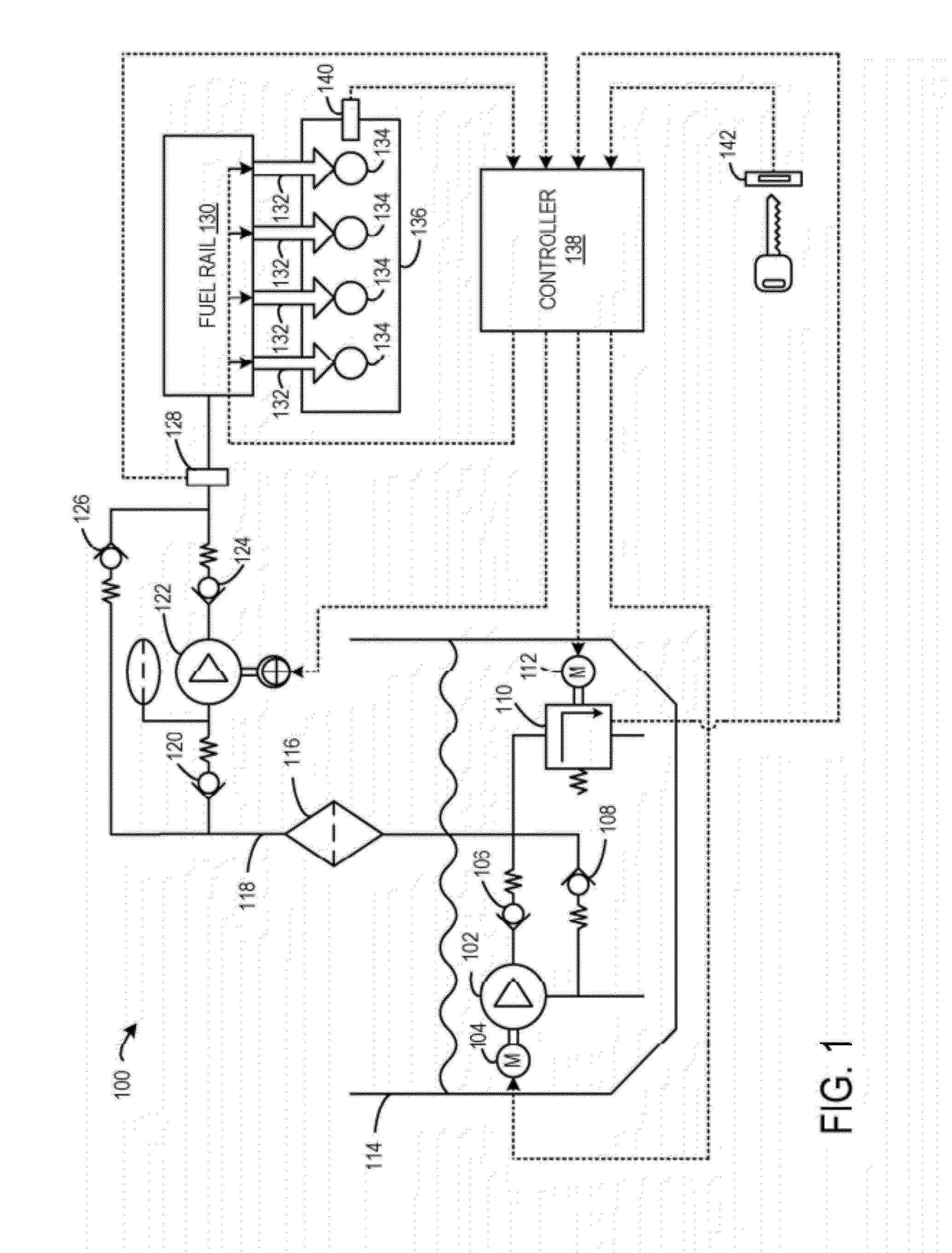

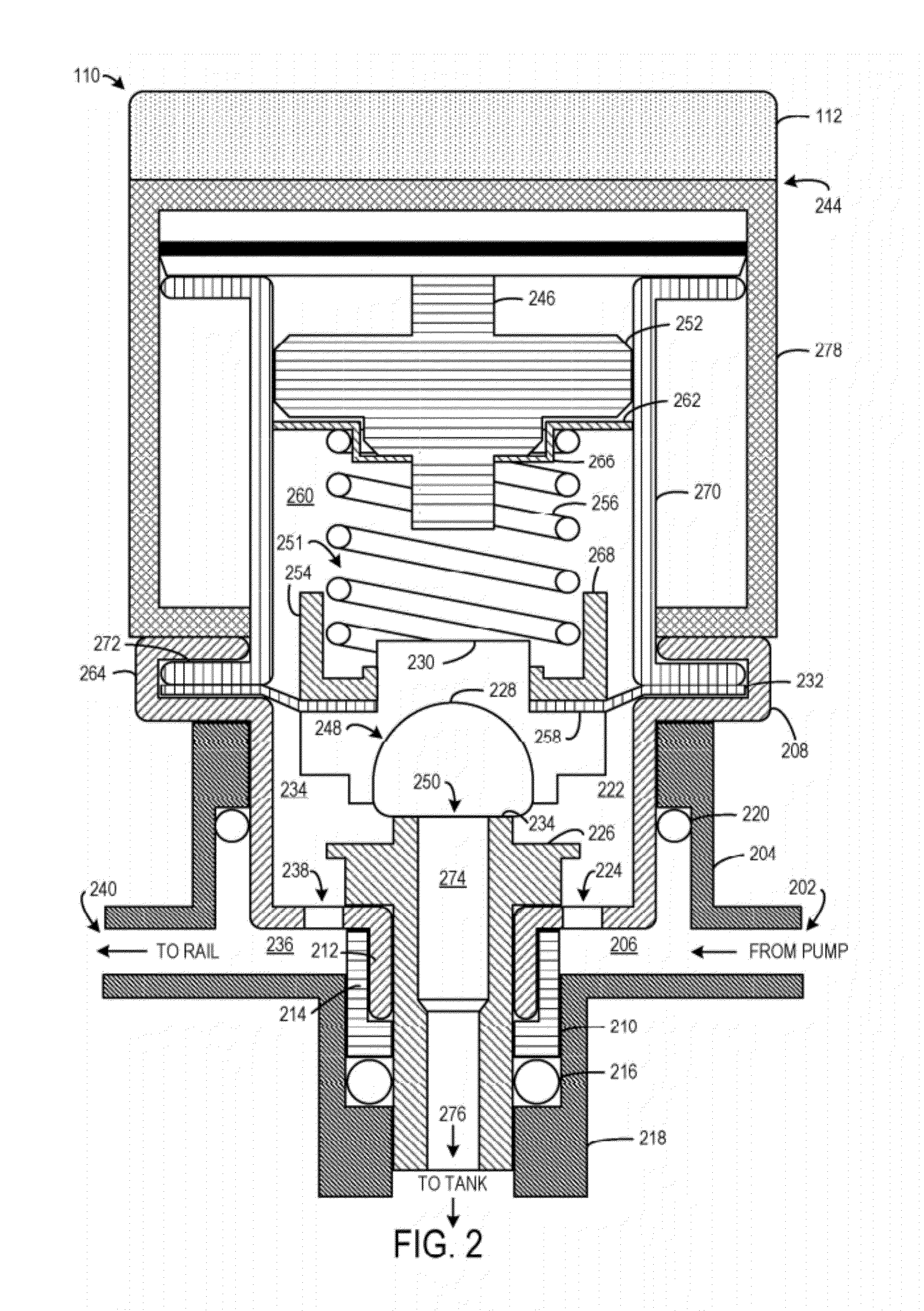

Current GDI pressure regulation typically employs a two-stage approach: a low-pressure fuel pump delivers fuel from the tank to a high-pressure pump driven by the engine camshaft. This high-pressure pump then supplies the fuel rail and injectors. Pressure regulation occurs through mechanical pressure regulators, electronic pressure control valves, or a combination of both. However, these systems often struggle to maintain absolute consistency across all operating conditions.

The primary technical objective for next-generation GDI fuel pressure regulation is to achieve pressure stability within ±1% of target values across all engine operating conditions. This level of precision would enable more accurate fuel metering, optimized spray patterns, and ultimately more complete combustion with reduced particulate matter formation.

Secondary objectives include developing systems capable of ultra-rapid pressure modulation to enable multiple injection events per combustion cycle with varying pressure profiles, reducing system complexity and cost while maintaining reliability, and designing pressure regulation systems compatible with alternative fuels including higher ethanol blends and synthetic fuels. These advancements would position GDI technology to remain relevant in increasingly electrified automotive landscapes while meeting future emissions standards.

The evolution of GDI technology has been driven by increasingly stringent emissions regulations worldwide and consumer demand for improved fuel economy without sacrificing performance. Early GDI systems operated at relatively low pressures of 50-100 bar, while modern systems commonly function at 200-350 bar, with advanced systems pushing beyond 400 bar. This pressure escalation represents a critical technological trend that directly impacts engine performance, emissions control, and reliability.

Fuel pressure regulation in GDI systems presents unique challenges compared to conventional fuel injection technologies. The system must maintain consistent high pressure across varying engine loads, speeds, and environmental conditions while responding rapidly to transient demands. Pressure fluctuations as small as 5-10 bar can significantly impact fuel atomization quality, air-fuel mixture homogeneity, and consequently combustion stability and emissions formation.

Current GDI pressure regulation typically employs a two-stage approach: a low-pressure fuel pump delivers fuel from the tank to a high-pressure pump driven by the engine camshaft. This high-pressure pump then supplies the fuel rail and injectors. Pressure regulation occurs through mechanical pressure regulators, electronic pressure control valves, or a combination of both. However, these systems often struggle to maintain absolute consistency across all operating conditions.

The primary technical objective for next-generation GDI fuel pressure regulation is to achieve pressure stability within ±1% of target values across all engine operating conditions. This level of precision would enable more accurate fuel metering, optimized spray patterns, and ultimately more complete combustion with reduced particulate matter formation.

Secondary objectives include developing systems capable of ultra-rapid pressure modulation to enable multiple injection events per combustion cycle with varying pressure profiles, reducing system complexity and cost while maintaining reliability, and designing pressure regulation systems compatible with alternative fuels including higher ethanol blends and synthetic fuels. These advancements would position GDI technology to remain relevant in increasingly electrified automotive landscapes while meeting future emissions standards.

Market Demand Analysis for Precise Fuel Pressure Control

The global market for precise fuel pressure control systems in Gasoline Direct Injection (GDI) engines has experienced significant growth, driven primarily by stringent emission regulations and increasing consumer demand for fuel-efficient vehicles. Current market valuations indicate that the GDI system market reached approximately 7.5 billion USD in 2022, with fuel pressure regulation components representing about 18% of this value.

Automotive manufacturers are increasingly prioritizing precise fuel pressure control as a critical factor in meeting Euro 7, China 6b, and US EPA Tier 3 emission standards. These regulations have reduced permissible particulate matter emissions by over 40% compared to previous standards, creating substantial market pull for advanced pressure regulation technologies.

Consumer preferences have shifted noticeably toward vehicles offering improved fuel economy without sacrificing performance. Market research indicates that 73% of new vehicle buyers consider fuel efficiency among their top three purchasing criteria, creating significant demand for the 3-5% efficiency improvements that precise fuel pressure regulation can deliver.

The aftermarket segment for GDI pressure regulation components is expanding at a compound annual growth rate of 6.8%, reflecting the growing installed base of GDI vehicles and increasing awareness of the performance benefits associated with optimized fuel pressure control. This represents a substantial secondary market opportunity beyond original equipment installations.

Regional analysis reveals that Asia-Pacific currently represents the fastest-growing market for precise fuel pressure control technologies, with China and India leading adoption rates due to their accelerated implementation of stringent emission standards. European markets maintain the highest penetration rate of advanced pressure regulation systems, while North American adoption continues to accelerate.

Industry forecasts project that the market for high-precision fuel pressure regulation systems will grow at approximately 9.2% annually through 2028, outpacing the broader automotive components sector. This growth trajectory is supported by the increasing electrification of vehicle systems, which requires more sophisticated pressure control to optimize engine performance during hybrid operation modes.

Commercial vehicle applications represent an emerging market segment, with medium and heavy-duty truck manufacturers beginning to adopt GDI technologies to meet their own emissions challenges. This segment is projected to expand at 11.3% annually, albeit from a smaller base, as commercial fleet operators seek to reduce operating costs through improved fuel efficiency.

Automotive manufacturers are increasingly prioritizing precise fuel pressure control as a critical factor in meeting Euro 7, China 6b, and US EPA Tier 3 emission standards. These regulations have reduced permissible particulate matter emissions by over 40% compared to previous standards, creating substantial market pull for advanced pressure regulation technologies.

Consumer preferences have shifted noticeably toward vehicles offering improved fuel economy without sacrificing performance. Market research indicates that 73% of new vehicle buyers consider fuel efficiency among their top three purchasing criteria, creating significant demand for the 3-5% efficiency improvements that precise fuel pressure regulation can deliver.

The aftermarket segment for GDI pressure regulation components is expanding at a compound annual growth rate of 6.8%, reflecting the growing installed base of GDI vehicles and increasing awareness of the performance benefits associated with optimized fuel pressure control. This represents a substantial secondary market opportunity beyond original equipment installations.

Regional analysis reveals that Asia-Pacific currently represents the fastest-growing market for precise fuel pressure control technologies, with China and India leading adoption rates due to their accelerated implementation of stringent emission standards. European markets maintain the highest penetration rate of advanced pressure regulation systems, while North American adoption continues to accelerate.

Industry forecasts project that the market for high-precision fuel pressure regulation systems will grow at approximately 9.2% annually through 2028, outpacing the broader automotive components sector. This growth trajectory is supported by the increasing electrification of vehicle systems, which requires more sophisticated pressure control to optimize engine performance during hybrid operation modes.

Commercial vehicle applications represent an emerging market segment, with medium and heavy-duty truck manufacturers beginning to adopt GDI technologies to meet their own emissions challenges. This segment is projected to expand at 11.3% annually, albeit from a smaller base, as commercial fleet operators seek to reduce operating costs through improved fuel efficiency.

Current GDI Pressure Regulation Challenges

Gasoline Direct Injection (GDI) systems face significant challenges in maintaining consistent fuel pressure regulation, which directly impacts engine performance, emissions, and durability. Current GDI systems typically operate at pressures ranging from 50 to 200 bar, substantially higher than traditional port fuel injection systems. This high-pressure environment creates unique regulatory challenges that manufacturers continue to address with varying degrees of success.

The primary challenge in GDI pressure regulation stems from the need to maintain precise fuel pressure across diverse operating conditions. Engine load variations, ambient temperature fluctuations, and altitude changes all demand dynamic pressure adjustments. Current high-pressure fuel pumps often struggle to provide consistent pressure during rapid transient conditions, resulting in momentary pressure drops or spikes that compromise combustion efficiency.

Fuel pressure pulsation represents another significant obstacle in GDI systems. The mechanical operation of high-pressure pumps introduces pressure waves into the fuel rail, causing cycle-to-cycle variations in injection quantity. These pulsations become particularly problematic at low engine speeds and during idle conditions, where they can lead to combustion instability and increased emissions.

Temperature-related challenges further complicate pressure regulation. Cold-start conditions require different pressure profiles compared to fully warmed engine operation. Current systems often employ simplified compensation strategies that fail to account for the complex relationship between fuel temperature, viscosity, and atomization characteristics, resulting in suboptimal combustion during warm-up phases.

Durability concerns also plague existing pressure regulation systems. High-pressure components experience accelerated wear, with pressure regulators and pump components showing significant degradation after extended operation. This deterioration gradually alters pressure regulation characteristics, leading to performance drift over the vehicle's lifetime that is difficult to compensate for through existing control algorithms.

Manufacturing tolerances introduce additional variability in pressure regulation. Component-to-component variations in regulators, pumps, and injectors create inconsistencies across production vehicles. Current calibration approaches typically target average performance, leaving individual vehicles potentially operating outside optimal pressure ranges.

Control system limitations further exacerbate these challenges. Most production GDI systems utilize open-loop pressure control with limited feedback mechanisms. The reliance on pre-programmed pressure maps rather than real-time combustion feedback results in suboptimal pressure regulation during non-standard operating conditions or as components age.

Integration with other engine systems presents coordination challenges. Modern engines with variable valve timing, turbocharging, and exhaust gas recirculation require sophisticated pressure regulation strategies that must anticipate the effects of these systems on combustion requirements. Current control architectures often lack the necessary predictive capabilities to fully optimize pressure regulation in these complex environments.

The primary challenge in GDI pressure regulation stems from the need to maintain precise fuel pressure across diverse operating conditions. Engine load variations, ambient temperature fluctuations, and altitude changes all demand dynamic pressure adjustments. Current high-pressure fuel pumps often struggle to provide consistent pressure during rapid transient conditions, resulting in momentary pressure drops or spikes that compromise combustion efficiency.

Fuel pressure pulsation represents another significant obstacle in GDI systems. The mechanical operation of high-pressure pumps introduces pressure waves into the fuel rail, causing cycle-to-cycle variations in injection quantity. These pulsations become particularly problematic at low engine speeds and during idle conditions, where they can lead to combustion instability and increased emissions.

Temperature-related challenges further complicate pressure regulation. Cold-start conditions require different pressure profiles compared to fully warmed engine operation. Current systems often employ simplified compensation strategies that fail to account for the complex relationship between fuel temperature, viscosity, and atomization characteristics, resulting in suboptimal combustion during warm-up phases.

Durability concerns also plague existing pressure regulation systems. High-pressure components experience accelerated wear, with pressure regulators and pump components showing significant degradation after extended operation. This deterioration gradually alters pressure regulation characteristics, leading to performance drift over the vehicle's lifetime that is difficult to compensate for through existing control algorithms.

Manufacturing tolerances introduce additional variability in pressure regulation. Component-to-component variations in regulators, pumps, and injectors create inconsistencies across production vehicles. Current calibration approaches typically target average performance, leaving individual vehicles potentially operating outside optimal pressure ranges.

Control system limitations further exacerbate these challenges. Most production GDI systems utilize open-loop pressure control with limited feedback mechanisms. The reliance on pre-programmed pressure maps rather than real-time combustion feedback results in suboptimal pressure regulation during non-standard operating conditions or as components age.

Integration with other engine systems presents coordination challenges. Modern engines with variable valve timing, turbocharging, and exhaust gas recirculation require sophisticated pressure regulation strategies that must anticipate the effects of these systems on combustion requirements. Current control architectures often lack the necessary predictive capabilities to fully optimize pressure regulation in these complex environments.

Current Technical Solutions for Fuel Pressure Consistency

01 High-pressure fuel pump control systems

Advanced control systems for high-pressure fuel pumps in GDI engines that maintain consistent fuel pressure through electronic regulation. These systems utilize sensors to monitor pressure fluctuations and adjust pump operation accordingly, ensuring optimal fuel delivery across various engine operating conditions. The control algorithms can compensate for temperature variations and engine load changes to maintain precise pressure regulation.- High-pressure fuel pump control systems: Advanced control systems for high-pressure fuel pumps in GDI engines help maintain consistent fuel pressure. These systems utilize electronic control units to adjust pump operation based on engine load, speed, and other parameters. By precisely controlling the fuel pump, these systems ensure stable fuel pressure delivery to the injectors, which is critical for optimal combustion efficiency and emissions control in gasoline direct injection engines.

- Pressure regulator valve designs: Specialized pressure regulator valve designs are essential for maintaining consistent fuel pressure in GDI systems. These valves incorporate precision components that respond quickly to pressure fluctuations, ensuring stable fuel delivery across various operating conditions. Advanced regulator designs include features such as temperature compensation and integrated pressure sensors to provide real-time feedback for more accurate pressure control.

- Fuel rail pressure management: Effective fuel rail pressure management systems are crucial for GDI engine performance. These systems incorporate pressure sensors, dampers, and accumulators to minimize pressure pulsations and ensure uniform fuel distribution to all injectors. By maintaining consistent pressure throughout the fuel rail, these technologies help achieve more precise fuel metering and atomization, resulting in improved combustion efficiency and reduced emissions.

- Electronic pressure control integration: Integration of electronic pressure control systems with engine management units enables dynamic fuel pressure regulation in GDI engines. These integrated systems adjust fuel pressure based on real-time engine parameters and driving conditions. Advanced algorithms process data from multiple sensors to optimize fuel pressure for different operating modes, ensuring consistent spray patterns and combustion quality while adapting to changing engine demands.

- Temperature compensation mechanisms: Temperature compensation mechanisms are implemented in GDI fuel systems to maintain consistent pressure despite thermal variations. These systems adjust pressure regulation parameters based on fuel temperature changes that occur during engine operation and ambient temperature fluctuations. By compensating for the effects of temperature on fuel density and viscosity, these mechanisms ensure uniform fuel delivery characteristics across all operating conditions, improving cold-start performance and hot-engine stability.

02 Pressure relief and regulation valves

Specialized pressure relief and regulation valves designed specifically for GDI systems that help maintain consistent fuel pressure. These valves respond to pressure changes in the fuel rail and can quickly adjust to prevent over-pressurization or pressure drops. The mechanical and electronic valve designs incorporate features to minimize pressure pulsations and ensure smooth fuel delivery to injectors.Expand Specific Solutions03 Integrated fuel rail pressure management

Comprehensive fuel rail designs with integrated pressure management features that maintain consistent fuel pressure throughout the GDI system. These systems incorporate dampeners to reduce pressure fluctuations and ensure uniform pressure across all injectors. The integrated approach combines sensors, regulators, and dampening mechanisms to achieve stable pressure profiles even during rapid transient conditions.Expand Specific Solutions04 Electronic control unit optimization

Advanced ECU programming and algorithms specifically designed to optimize fuel pressure regulation in GDI engines. These control strategies use real-time data from multiple sensors to predict pressure requirements and proactively adjust fuel system components. The systems can learn from operating patterns and adapt control parameters to maintain consistent pressure under varying conditions and throughout the engine's service life.Expand Specific Solutions05 Dual-pressure fuel system architectures

Innovative dual-pressure fuel system designs that provide both low and high-pressure fuel supply to GDI engines, ensuring consistent pressure regulation across all operating conditions. These systems use separate pumps and regulation circuits to optimize fuel delivery based on engine demands. The architecture allows for precise pressure control during cold starts, idle, and high-load conditions while improving overall fuel efficiency and emissions performance.Expand Specific Solutions

Key Industry Players in GDI Pressure Control Systems

The GDI Engine Fuel Pressure Regulation market is in a growth phase, with increasing adoption of direct injection technology across global automotive sectors. The market is estimated to reach $12-15 billion by 2027, driven by stringent emission regulations and fuel efficiency demands. Technologically, the field shows moderate maturity with ongoing innovation. Major automotive OEMs like Hyundai, Ford, and Kia are competing with specialized component manufacturers including Bosch, Continental, and Delphi Technologies (PHINIA). Academic-industry collaborations with institutions like Tianjin University and Jilin University are accelerating technological advancement. The competitive landscape features established players focusing on precision control systems while emerging companies develop next-generation solutions for alternative fuel compatibility.

Hyundai Motor Co., Ltd.

Technical Solution: Hyundai's GDI fuel pressure regulation system employs their "Precision Pressure Management" technology that utilizes a cam-driven high-pressure pump with electronic flow control. Their system can maintain pressures between 30-250 bar with precision control within ±3 bar across all operating conditions. The technology incorporates a dual-feedback approach using both rail pressure sensors and indirect combustion quality monitoring to continuously optimize fuel pressure. Hyundai's fuel rail design features internal damping chambers that minimize pressure fluctuations and ensure consistent delivery to all injectors. Their control strategy includes adaptive pressure mapping that automatically adjusts baseline targets based on engine operating conditions, ambient temperature, and fuel quality detection. The system also features specialized pressure regulation modes for cold-start, warm-up, and high-load conditions that optimize atomization while meeting emissions requirements. Hyundai has implemented a unique pressure pulsation compensation algorithm that analyzes and counteracts cyclical pressure variations caused by the pumping mechanism. Their latest generation includes predictive pressure control that anticipates fuel demand based on driver behavior patterns and road conditions, reducing response lag during sudden acceleration events.

Strengths: Excellent cost-to-performance ratio; compact system design with minimal packaging requirements; highly reliable with proven durability in diverse operating conditions. Weaknesses: Slightly lower maximum pressure capability compared to premium competitors; less sophisticated pressure ripple cancellation; more limited adaptability to alternative fuels.

Ford Global Technologies LLC

Technical Solution: Ford's GDI fuel pressure regulation technology utilizes a dual-mode approach with their patented "Dynamic Pressure Adaptive Control" system. Their high-pressure pump features variable stroke control that modulates fuel delivery based on real-time engine demands, capable of generating pressures from 40 to 280 bar. The system incorporates both mechanical pressure limiting valves and electronic pressure control valves working in tandem to provide redundancy and precise regulation. Ford's technology includes a unique fuel rail design with internal flow channels that minimize pressure pulsations and ensure uniform pressure across all injectors. Their control strategy employs predictive algorithms that anticipate pressure requirements based on driver inputs and engine operating conditions, reducing response lag by up to 30%. The system also features adaptive pressure mapping that automatically adjusts baseline pressure targets based on fuel quality detection, combustion feedback, and emission requirements. Ford has implemented specialized pressure regulation strategies for cold-start and warm-up phases that optimize atomization while minimizing emissions during these critical periods. Their latest systems include cylinder-specific pressure compensation that accounts for individual injector flow characteristics.

Strengths: Excellent pressure stability during rapid transients; highly efficient pump design with minimal parasitic losses; robust fail-safe mechanisms that maintain drivability even during partial system failures. Weaknesses: Slightly more complex calibration requirements; higher sensitivity to fuel quality variations; requires more frequent maintenance intervals for optimal performance.

Core Innovations in GDI Pressure Regulation

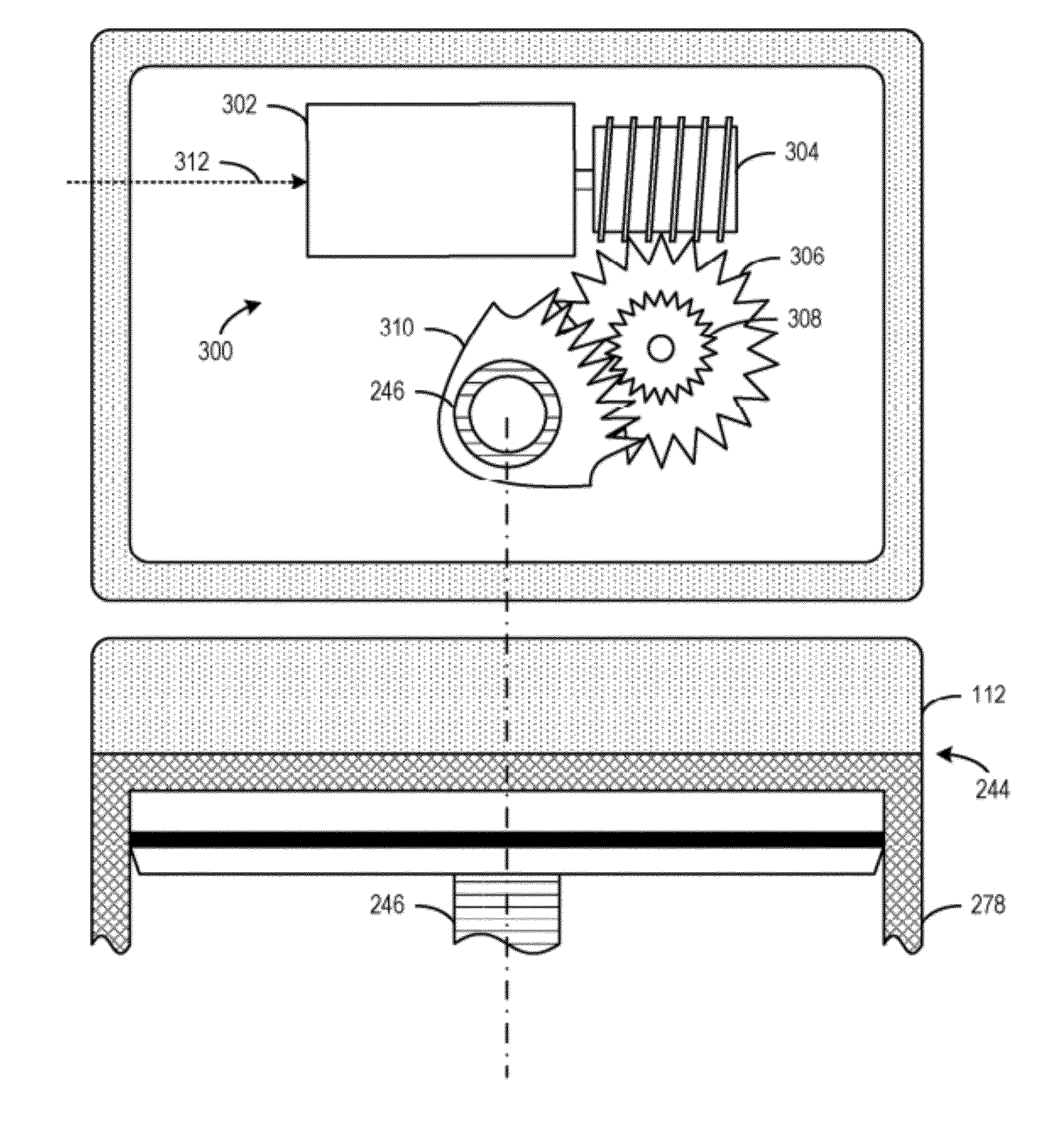

Fuel system with electrically-controllable mechanical pressure regulator

PatentInactiveUS8210156B2

Innovation

- A fuel system utilizing a mechanical fuel pressure regulator with a spring preload adjustable by an electric motor, which dynamically adjusts the set-point fuel pressure in response to operating conditions, allowing for quick compensation of pressure pulsations and reduced energy consumption by maintaining the preload mechanically when the motor is not operating.

Control System Of Low Pressure Fuel Pump For Gasoline Direct Injection Engie And Mehod Thereof

PatentInactiveCN104675552A

Innovation

- By setting dynamic fuel pressure in the low-pressure fuel pump, the target pressure of the fuel pump is adjusted according to factors such as vehicle speed, fuel tank level change rate, temperature, and atmospheric pressure to prevent the occurrence of air lock and improve the performance of the high-pressure fuel pump. Boosts the fuel pressure of the low-pressure pump in the event of a malfunction.

Emissions Standards Impact on GDI Pressure Technology

Emissions standards worldwide have evolved significantly over the past two decades, directly influencing the development trajectory of Gasoline Direct Injection (GDI) pressure regulation technologies. The introduction of Euro 6, China 6, and US Tier 3 standards has placed unprecedented demands on vehicle manufacturers to reduce particulate matter (PM) and NOx emissions, while simultaneously improving fuel efficiency and performance.

These stringent regulations have catalyzed a shift toward higher fuel pressure systems in GDI engines. Traditional GDI systems operating at 100-150 bar are increasingly being replaced by enhanced systems capable of 200-350 bar operation. This pressure increase directly correlates with improved fuel atomization, resulting in more complete combustion and reduced particulate formation.

The implementation of Real Driving Emissions (RDE) testing protocols in Europe and similar on-road verification methods in other markets has further emphasized the need for consistent pressure regulation across diverse operating conditions. Manufacturers must now ensure fuel pressure stability not only in laboratory settings but also during actual driving scenarios involving temperature fluctuations, altitude changes, and varying load demands.

Particulate Number (PN) limits have become particularly influential in driving pressure regulation innovation. The correlation between higher injection pressures and reduced particulate emissions has been extensively documented, with research indicating that increasing pressure from 200 bar to 350 bar can reduce PN emissions by up to 40% under certain operating conditions.

Cold-start emissions requirements have similarly impacted pressure regulation strategies. Enhanced pressure control during engine warm-up phases has become critical, as approximately 80% of particulate emissions in standardized test cycles occur during the first 200 seconds of operation. Advanced pressure regulation systems now incorporate specific cold-start algorithms to optimize atomization during these critical phases.

The regulatory landscape continues to evolve, with Euro 7, China 7, and next-generation US standards under development. These forthcoming regulations are expected to further tighten emission limits and expand the conditions under which vehicles must demonstrate compliance. Industry forecasts suggest that GDI pressure requirements may increase to 400-500 bar within the next decade to meet these emerging standards.

The regulatory-driven pressure increases have created cascading engineering challenges throughout the fuel system, necessitating innovations in pump technology, injector design, and electronic control strategies. Material science advancements have become particularly important as components must withstand higher pressures while maintaining durability targets of 150,000+ miles of operation.

These stringent regulations have catalyzed a shift toward higher fuel pressure systems in GDI engines. Traditional GDI systems operating at 100-150 bar are increasingly being replaced by enhanced systems capable of 200-350 bar operation. This pressure increase directly correlates with improved fuel atomization, resulting in more complete combustion and reduced particulate formation.

The implementation of Real Driving Emissions (RDE) testing protocols in Europe and similar on-road verification methods in other markets has further emphasized the need for consistent pressure regulation across diverse operating conditions. Manufacturers must now ensure fuel pressure stability not only in laboratory settings but also during actual driving scenarios involving temperature fluctuations, altitude changes, and varying load demands.

Particulate Number (PN) limits have become particularly influential in driving pressure regulation innovation. The correlation between higher injection pressures and reduced particulate emissions has been extensively documented, with research indicating that increasing pressure from 200 bar to 350 bar can reduce PN emissions by up to 40% under certain operating conditions.

Cold-start emissions requirements have similarly impacted pressure regulation strategies. Enhanced pressure control during engine warm-up phases has become critical, as approximately 80% of particulate emissions in standardized test cycles occur during the first 200 seconds of operation. Advanced pressure regulation systems now incorporate specific cold-start algorithms to optimize atomization during these critical phases.

The regulatory landscape continues to evolve, with Euro 7, China 7, and next-generation US standards under development. These forthcoming regulations are expected to further tighten emission limits and expand the conditions under which vehicles must demonstrate compliance. Industry forecasts suggest that GDI pressure requirements may increase to 400-500 bar within the next decade to meet these emerging standards.

The regulatory-driven pressure increases have created cascading engineering challenges throughout the fuel system, necessitating innovations in pump technology, injector design, and electronic control strategies. Material science advancements have become particularly important as components must withstand higher pressures while maintaining durability targets of 150,000+ miles of operation.

Durability and Reliability Testing Methodologies

Durability and reliability testing methodologies for GDI Engine Fuel Pressure Regulation systems require comprehensive protocols that simulate real-world conditions while accelerating wear patterns. These methodologies typically incorporate both accelerated life testing and long-duration endurance testing to ensure consistent fuel pressure regulation throughout the vehicle's lifecycle.

Accelerated testing protocols for fuel pressure regulators include thermal cycling tests that rapidly alternate between extreme temperature conditions (-40°C to 150°C) to evaluate material integrity and sealing capabilities under thermal stress. These tests typically run for 1,000 to 5,000 cycles, representing years of operational temperature variations compressed into weeks of testing.

Pressure pulsation testing represents another critical methodology, where regulators are subjected to rapid pressure fluctuations at frequencies matching or exceeding normal engine operation. This test evaluates the regulator's dynamic response characteristics and identifies potential fatigue failure points in diaphragms, springs, and valve seats that could compromise pressure consistency.

Contamination resistance testing introduces calibrated particulate matter and chemical contaminants into the fuel system to evaluate filter efficiency and material compatibility. This methodology is particularly important for GDI systems operating at higher pressures (up to 200 bar), where even minor contamination can significantly impact injector performance and pressure regulation.

Vibration and shock testing employs multi-axis vibration tables that reproduce the harsh mechanical environment of engine operation. Test profiles typically follow industry standards such as ISO 16750-3, with test durations ranging from 100 to 500 hours to identify potential mechanical failures in regulator components that could affect pressure consistency.

Environmental exposure chambers simulate various climatic conditions including humidity cycling, salt spray exposure, and chemical exposure to evaluate corrosion resistance and material degradation. These tests are critical for predicting the long-term reliability of external regulator components and electrical connections in diverse operating environments.

Endurance testing methodologies involve continuous operation under varying load conditions, typically running for 3,000 to 5,000 hours to simulate the full service life of the component. During these tests, pressure regulation accuracy is continuously monitored to detect any drift or degradation in performance that might occur gradually over time.

Statistical analysis techniques such as Weibull analysis and accelerated life testing models are employed to extrapolate test results to predict field reliability with confidence intervals. These methodologies help establish mean time between failures (MTBF) metrics and validate design life requirements for fuel pressure regulation systems.

Accelerated testing protocols for fuel pressure regulators include thermal cycling tests that rapidly alternate between extreme temperature conditions (-40°C to 150°C) to evaluate material integrity and sealing capabilities under thermal stress. These tests typically run for 1,000 to 5,000 cycles, representing years of operational temperature variations compressed into weeks of testing.

Pressure pulsation testing represents another critical methodology, where regulators are subjected to rapid pressure fluctuations at frequencies matching or exceeding normal engine operation. This test evaluates the regulator's dynamic response characteristics and identifies potential fatigue failure points in diaphragms, springs, and valve seats that could compromise pressure consistency.

Contamination resistance testing introduces calibrated particulate matter and chemical contaminants into the fuel system to evaluate filter efficiency and material compatibility. This methodology is particularly important for GDI systems operating at higher pressures (up to 200 bar), where even minor contamination can significantly impact injector performance and pressure regulation.

Vibration and shock testing employs multi-axis vibration tables that reproduce the harsh mechanical environment of engine operation. Test profiles typically follow industry standards such as ISO 16750-3, with test durations ranging from 100 to 500 hours to identify potential mechanical failures in regulator components that could affect pressure consistency.

Environmental exposure chambers simulate various climatic conditions including humidity cycling, salt spray exposure, and chemical exposure to evaluate corrosion resistance and material degradation. These tests are critical for predicting the long-term reliability of external regulator components and electrical connections in diverse operating environments.

Endurance testing methodologies involve continuous operation under varying load conditions, typically running for 3,000 to 5,000 hours to simulate the full service life of the component. During these tests, pressure regulation accuracy is continuously monitored to detect any drift or degradation in performance that might occur gradually over time.

Statistical analysis techniques such as Weibull analysis and accelerated life testing models are employed to extrapolate test results to predict field reliability with confidence intervals. These methodologies help establish mean time between failures (MTBF) metrics and validate design life requirements for fuel pressure regulation systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!