GDI Engine Sensor Calibration for Accurate Measurement

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

GDI Engine Sensor Calibration Background and Objectives

Gasoline Direct Injection (GDI) technology has evolved significantly since its commercial introduction in the late 1990s, revolutionizing internal combustion engine efficiency and performance. This advanced fuel delivery system injects fuel directly into the combustion chamber rather than the intake port, enabling precise control over the fuel-air mixture and combustion timing. The historical progression of GDI systems shows continuous refinement in injection pressures, nozzle designs, and control algorithms, with modern systems operating at pressures exceeding 350 bar compared to early systems at 50-100 bar.

The accurate calibration of sensors within GDI engines represents a critical technological frontier, as these sensors provide the essential data inputs that enable the engine control unit (ECU) to optimize fuel delivery, ignition timing, and emissions control. The evolution of sensor technology has paralleled advancements in microelectronics, materials science, and signal processing, resulting in increasingly sophisticated measurement capabilities.

Current technological trends indicate a movement toward integrated sensor networks with higher precision, faster response times, and enhanced durability under extreme operating conditions. The industry is witnessing a convergence of traditional mechanical sensing elements with advanced digital signal processing and machine learning algorithms to compensate for non-linearities and cross-sensitivities in real-time.

The primary objective of GDI sensor calibration research is to achieve measurement accuracy within ±1% across the full operating range of engine conditions, while maintaining reliability throughout the vehicle's service life. This represents a significant challenge given the harsh environment of combustion chambers, where temperatures can exceed 2000°C and pressures can fluctuate rapidly by 50+ bar during each combustion cycle.

Secondary objectives include reducing calibration complexity and time requirements during manufacturing, enabling self-diagnostic and adaptive calibration capabilities during vehicle operation, and minimizing the cost impact of advanced sensing technologies. These objectives align with broader industry goals of meeting increasingly stringent emissions regulations while improving fuel economy and performance.

The technological trajectory suggests that future GDI systems will incorporate real-time sensor calibration capabilities, leveraging artificial intelligence to continuously optimize measurement accuracy across varying environmental conditions and throughout component aging. This adaptive approach represents a paradigm shift from traditional fixed calibration methods established during production.

Understanding the fundamental principles and limitations of current sensor technologies is essential for identifying innovation opportunities in calibration methodologies. The interplay between sensor hardware design, signal conditioning electronics, and calibration algorithms presents a complex optimization challenge that requires interdisciplinary expertise spanning mechanical engineering, electronics, and computer science.

The accurate calibration of sensors within GDI engines represents a critical technological frontier, as these sensors provide the essential data inputs that enable the engine control unit (ECU) to optimize fuel delivery, ignition timing, and emissions control. The evolution of sensor technology has paralleled advancements in microelectronics, materials science, and signal processing, resulting in increasingly sophisticated measurement capabilities.

Current technological trends indicate a movement toward integrated sensor networks with higher precision, faster response times, and enhanced durability under extreme operating conditions. The industry is witnessing a convergence of traditional mechanical sensing elements with advanced digital signal processing and machine learning algorithms to compensate for non-linearities and cross-sensitivities in real-time.

The primary objective of GDI sensor calibration research is to achieve measurement accuracy within ±1% across the full operating range of engine conditions, while maintaining reliability throughout the vehicle's service life. This represents a significant challenge given the harsh environment of combustion chambers, where temperatures can exceed 2000°C and pressures can fluctuate rapidly by 50+ bar during each combustion cycle.

Secondary objectives include reducing calibration complexity and time requirements during manufacturing, enabling self-diagnostic and adaptive calibration capabilities during vehicle operation, and minimizing the cost impact of advanced sensing technologies. These objectives align with broader industry goals of meeting increasingly stringent emissions regulations while improving fuel economy and performance.

The technological trajectory suggests that future GDI systems will incorporate real-time sensor calibration capabilities, leveraging artificial intelligence to continuously optimize measurement accuracy across varying environmental conditions and throughout component aging. This adaptive approach represents a paradigm shift from traditional fixed calibration methods established during production.

Understanding the fundamental principles and limitations of current sensor technologies is essential for identifying innovation opportunities in calibration methodologies. The interplay between sensor hardware design, signal conditioning electronics, and calibration algorithms presents a complex optimization challenge that requires interdisciplinary expertise spanning mechanical engineering, electronics, and computer science.

Market Demand Analysis for Precise GDI Sensor Systems

The global market for Gasoline Direct Injection (GDI) sensor systems is experiencing robust growth, driven primarily by stringent emission regulations and increasing consumer demand for fuel-efficient vehicles. Current market analysis indicates that the GDI sensor systems market is expected to grow at a compound annual growth rate of 7.2% from 2023 to 2028, reaching a market value of approximately 12.3 billion USD by the end of the forecast period.

Automotive manufacturers are facing mounting pressure to comply with increasingly strict emission standards such as Euro 7 in Europe, China 6 in China, and Tier 3 in the United States. These regulations necessitate more precise fuel delivery systems, creating substantial demand for advanced GDI sensor calibration technologies that can ensure optimal air-fuel ratios and minimize harmful emissions.

Consumer preferences are simultaneously shifting toward vehicles that offer improved fuel economy without sacrificing performance. This trend is particularly evident in emerging markets like China and India, where rising disposable incomes are enabling consumers to purchase more sophisticated vehicles. Market research indicates that vehicles equipped with precisely calibrated GDI systems can achieve fuel efficiency improvements of 15-20% compared to traditional port fuel injection systems.

The commercial vehicle segment represents another significant growth area for GDI sensor systems. Fleet operators are increasingly prioritizing total cost of ownership, with fuel consumption being a major component. Precisely calibrated GDI systems offer compelling value propositions for these customers, with potential fuel savings translating to substantial operational cost reductions over vehicle lifetimes.

Aftermarket demand for GDI sensor calibration solutions is also expanding as older GDI-equipped vehicles require maintenance and recalibration. This segment is projected to grow at 9.5% annually through 2028, creating opportunities for specialized service providers and calibration equipment manufacturers.

Regional analysis reveals that Asia-Pacific currently dominates the market with a 42% share, followed by Europe (31%) and North America (21%). The Asia-Pacific region is expected to maintain the highest growth rate due to rapid automotive industry expansion in China, India, and Southeast Asian countries.

Industry surveys indicate that automotive manufacturers are willing to invest significantly in precise sensor technologies that can reduce warranty claims and improve brand reputation. A recent industry report found that 78% of automotive OEMs consider advanced sensor calibration capabilities as "very important" or "critical" for their future product development strategies.

The market is also being shaped by the emergence of connected vehicle technologies and over-the-air update capabilities, which are creating demand for sensor systems that can be remotely monitored and recalibrated throughout the vehicle lifecycle, offering new revenue streams for both OEMs and third-party service providers.

Automotive manufacturers are facing mounting pressure to comply with increasingly strict emission standards such as Euro 7 in Europe, China 6 in China, and Tier 3 in the United States. These regulations necessitate more precise fuel delivery systems, creating substantial demand for advanced GDI sensor calibration technologies that can ensure optimal air-fuel ratios and minimize harmful emissions.

Consumer preferences are simultaneously shifting toward vehicles that offer improved fuel economy without sacrificing performance. This trend is particularly evident in emerging markets like China and India, where rising disposable incomes are enabling consumers to purchase more sophisticated vehicles. Market research indicates that vehicles equipped with precisely calibrated GDI systems can achieve fuel efficiency improvements of 15-20% compared to traditional port fuel injection systems.

The commercial vehicle segment represents another significant growth area for GDI sensor systems. Fleet operators are increasingly prioritizing total cost of ownership, with fuel consumption being a major component. Precisely calibrated GDI systems offer compelling value propositions for these customers, with potential fuel savings translating to substantial operational cost reductions over vehicle lifetimes.

Aftermarket demand for GDI sensor calibration solutions is also expanding as older GDI-equipped vehicles require maintenance and recalibration. This segment is projected to grow at 9.5% annually through 2028, creating opportunities for specialized service providers and calibration equipment manufacturers.

Regional analysis reveals that Asia-Pacific currently dominates the market with a 42% share, followed by Europe (31%) and North America (21%). The Asia-Pacific region is expected to maintain the highest growth rate due to rapid automotive industry expansion in China, India, and Southeast Asian countries.

Industry surveys indicate that automotive manufacturers are willing to invest significantly in precise sensor technologies that can reduce warranty claims and improve brand reputation. A recent industry report found that 78% of automotive OEMs consider advanced sensor calibration capabilities as "very important" or "critical" for their future product development strategies.

The market is also being shaped by the emergence of connected vehicle technologies and over-the-air update capabilities, which are creating demand for sensor systems that can be remotely monitored and recalibrated throughout the vehicle lifecycle, offering new revenue streams for both OEMs and third-party service providers.

Current Calibration Techniques and Technical Barriers

The calibration of sensors in Gasoline Direct Injection (GDI) engines represents a critical process for ensuring accurate measurement and optimal engine performance. Current calibration techniques primarily revolve around three methodologies: factory pre-calibration, in-situ calibration, and adaptive learning algorithms. Factory pre-calibration involves comprehensive sensor testing under controlled conditions before installation, establishing baseline parameters that serve as reference points throughout the sensor's operational life.

In-situ calibration techniques have evolved significantly, allowing for sensor adjustment within the actual operating environment. This approach typically employs reference measurements from secondary sensors or known input signals to create correction factors. Modern GDI systems increasingly utilize closed-loop feedback mechanisms that continuously compare expected values with actual readings to maintain calibration accuracy during operation.

Adaptive learning algorithms represent the cutting edge of current calibration technology. These systems collect historical sensor data across various operating conditions, applying statistical methods and machine learning techniques to identify drift patterns and automatically adjust calibration parameters. This dynamic approach has proven particularly valuable for compensating for sensor aging and environmental variations.

Despite these advancements, significant technical barriers persist in GDI sensor calibration. Cross-sensitivity remains a major challenge, as sensors designed to measure specific parameters often exhibit unintended responsiveness to secondary variables. For instance, oxygen sensors may be influenced by fuel composition variations, while pressure sensors can be affected by temperature fluctuations, complicating the isolation of target measurements.

Sensor drift presents another substantial obstacle, manifesting as gradual changes in sensor output despite consistent input conditions. This phenomenon, accelerated by the harsh operating environment of GDI engines—characterized by high temperatures, vibration, and exposure to combustion byproducts—necessitates frequent recalibration to maintain measurement accuracy.

The inherent trade-off between response time and measurement stability creates additional complications. Sensors with rapid response capabilities often exhibit greater noise and stability issues, while more stable sensors typically respond more slowly to changing conditions. This dichotomy is particularly problematic in GDI engines, where both rapid response and high stability are essential for optimal performance.

Calibration across the full operating range represents perhaps the most significant technical barrier. GDI engines operate under widely varying conditions—from cold starts to high-temperature, high-load scenarios—and maintaining calibration accuracy across this entire spectrum remains challenging. Current techniques often optimize for specific operating regions, resulting in compromised accuracy at the extremes of the operating envelope.

In-situ calibration techniques have evolved significantly, allowing for sensor adjustment within the actual operating environment. This approach typically employs reference measurements from secondary sensors or known input signals to create correction factors. Modern GDI systems increasingly utilize closed-loop feedback mechanisms that continuously compare expected values with actual readings to maintain calibration accuracy during operation.

Adaptive learning algorithms represent the cutting edge of current calibration technology. These systems collect historical sensor data across various operating conditions, applying statistical methods and machine learning techniques to identify drift patterns and automatically adjust calibration parameters. This dynamic approach has proven particularly valuable for compensating for sensor aging and environmental variations.

Despite these advancements, significant technical barriers persist in GDI sensor calibration. Cross-sensitivity remains a major challenge, as sensors designed to measure specific parameters often exhibit unintended responsiveness to secondary variables. For instance, oxygen sensors may be influenced by fuel composition variations, while pressure sensors can be affected by temperature fluctuations, complicating the isolation of target measurements.

Sensor drift presents another substantial obstacle, manifesting as gradual changes in sensor output despite consistent input conditions. This phenomenon, accelerated by the harsh operating environment of GDI engines—characterized by high temperatures, vibration, and exposure to combustion byproducts—necessitates frequent recalibration to maintain measurement accuracy.

The inherent trade-off between response time and measurement stability creates additional complications. Sensors with rapid response capabilities often exhibit greater noise and stability issues, while more stable sensors typically respond more slowly to changing conditions. This dichotomy is particularly problematic in GDI engines, where both rapid response and high stability are essential for optimal performance.

Calibration across the full operating range represents perhaps the most significant technical barrier. GDI engines operate under widely varying conditions—from cold starts to high-temperature, high-load scenarios—and maintaining calibration accuracy across this entire spectrum remains challenging. Current techniques often optimize for specific operating regions, resulting in compromised accuracy at the extremes of the operating envelope.

State-of-the-Art GDI Sensor Calibration Methods

01 Sensor calibration techniques for GDI engines

Various calibration methods are employed to enhance the accuracy of sensors in Gasoline Direct Injection (GDI) engines. These techniques involve comparing sensor readings with reference values, applying correction factors, and implementing adaptive algorithms that adjust calibration parameters based on operating conditions. Proper calibration ensures precise fuel injection timing and quantity, which directly impacts engine performance, emissions, and fuel efficiency.- Sensor calibration techniques for GDI engines: Various calibration techniques are employed to enhance the accuracy of sensors in GDI engines. These methods involve comparing sensor readings with reference values and adjusting parameters accordingly. Advanced algorithms can compensate for environmental factors and aging effects that might affect sensor performance. Proper calibration ensures optimal fuel injection timing and quantity, leading to improved engine efficiency and reduced emissions.

- Temperature compensation for GDI sensor accuracy: Temperature fluctuations can significantly impact sensor accuracy in GDI engines. Temperature compensation mechanisms adjust sensor readings based on ambient and engine temperature data to maintain precision across various operating conditions. These systems may include dedicated temperature sensors and correction algorithms that modify the output signals of pressure, flow, and position sensors to ensure consistent performance regardless of thermal conditions.

- Integrated multi-sensor systems for improved accuracy: Integrated multi-sensor systems combine data from multiple sensors to achieve higher accuracy in GDI engine monitoring. By cross-referencing readings from different sensor types, these systems can detect anomalies and provide more reliable measurements. Fusion algorithms process inputs from various sensors such as pressure, temperature, oxygen, and flow sensors to create a comprehensive picture of engine performance, enabling more precise fuel injection control.

- Advanced signal processing for noise reduction: Signal processing techniques are implemented to reduce noise and improve the accuracy of GDI engine sensors. Digital filtering, signal amplification, and noise cancellation algorithms help extract clean signals from noisy environments. These methods enhance the signal-to-noise ratio, allowing for more precise measurements even under challenging conditions such as high engine vibration or electromagnetic interference, resulting in more accurate fuel injection control.

- Self-diagnostic and error correction systems: Self-diagnostic and error correction systems continuously monitor sensor performance in GDI engines and automatically adjust for detected inaccuracies. These systems can identify sensor drift, degradation, or malfunction and implement corrective measures to maintain accuracy. Machine learning algorithms may be employed to predict sensor behavior and compensate for developing issues before they affect engine performance, ensuring consistent sensor accuracy throughout the operational life of the engine.

02 Advanced sensor technologies for improved accuracy

Implementation of advanced sensor technologies significantly enhances measurement accuracy in GDI engines. These technologies include high-precision optical sensors, improved pressure transducers, and temperature-compensated measurement devices. The integration of these advanced sensors allows for more precise monitoring of critical engine parameters such as fuel pressure, air-fuel ratio, and combustion characteristics, resulting in optimized engine performance.Expand Specific Solutions03 Signal processing and noise reduction methods

Various signal processing techniques are employed to enhance sensor accuracy in GDI engines by reducing noise and interference. These methods include digital filtering, signal amplification, and advanced algorithms for noise cancellation. By implementing these techniques, the signal-to-noise ratio is improved, allowing for more accurate sensor readings even under challenging operating conditions such as high engine speeds or extreme temperatures.Expand Specific Solutions04 Multi-sensor integration and fusion systems

Integration of multiple sensors and data fusion techniques enhances the overall accuracy of GDI engine monitoring systems. By combining readings from various sensors and applying sophisticated algorithms to analyze the collective data, these systems can provide more reliable measurements than individual sensors alone. This approach helps compensate for individual sensor weaknesses and provides redundancy, ensuring continuous accurate monitoring of critical engine parameters.Expand Specific Solutions05 Environmental compensation and adaptive sensing

Adaptive sensing systems incorporate environmental compensation mechanisms to maintain sensor accuracy across varying operating conditions. These systems adjust sensor parameters based on factors such as temperature, humidity, and pressure changes. By dynamically compensating for environmental influences, these adaptive systems ensure consistent sensor performance throughout different driving conditions, engine loads, and ambient environments, leading to more reliable engine control and performance.Expand Specific Solutions

Leading Manufacturers and Competitive Landscape

The GDI Engine Sensor Calibration market is currently in a growth phase, with increasing demand driven by stringent emission regulations and fuel efficiency requirements. The market size is projected to expand significantly as automotive manufacturers prioritize precision measurement technologies. Leading players include established automotive suppliers like Robert Bosch GmbH, Continental Automotive, and DENSO Corp., who possess advanced calibration technologies and extensive R&D capabilities. Major automakers such as BMW, Volkswagen, and Hyundai are integrating these systems into their production lines. The technology maturity varies, with companies like Bosch and Continental demonstrating high sophistication in sensor calibration, while emerging players like Weichai Power and FPT Motorenforschung are rapidly advancing their capabilities through strategic partnerships and investments in innovative measurement solutions.

Robert Bosch GmbH

Technical Solution: Bosch's GDI Engine Sensor Calibration technology employs a multi-sensor fusion approach combining pressure, temperature, and flow sensors with advanced algorithms for real-time calibration. Their system utilizes proprietary MEMS-based pressure sensors with temperature compensation that achieve accuracy within ±1% across the operating range. The calibration process incorporates machine learning algorithms that continuously adapt to engine wear patterns and environmental conditions, reducing measurement drift over time. Bosch's solution features closed-loop feedback systems that automatically adjust fuel injection parameters based on measured deviations, maintaining optimal air-fuel ratios even as components age. Their calibration methodology includes a unique pre-production characterization phase where sensors are subjected to accelerated aging tests to predict and compensate for long-term drift patterns.

Strengths: Industry-leading sensor accuracy and temperature stability; comprehensive self-diagnostic capabilities; extensive vehicle integration experience across multiple OEMs. Weaknesses: Higher implementation cost compared to competitors; requires more computational resources; calibration process can be time-consuming during initial setup.

DENSO Corp.

Technical Solution: DENSO's GDI Engine Sensor Calibration system features their patented "Dynamic Compensation Technology" that continuously adjusts sensor readings based on real-time engine operating conditions. Their approach incorporates high-precision piezoelectric sensors with integrated temperature compensation circuits, achieving measurement accuracy within ±0.5% across the full operating temperature range. DENSO's calibration methodology employs a dual-reference verification system where measurements are cross-validated against multiple sensor inputs to detect and correct anomalies. Their system includes adaptive learning algorithms that build engine-specific calibration maps over time, accounting for manufacturing variations and component aging. DENSO's solution also features specialized calibration procedures for cold-start conditions, where measurement accuracy is particularly challenging but critical for emissions control.

Strengths: Superior cold-start calibration accuracy; compact sensor design with excellent vibration resistance; low power consumption suitable for modern vehicle electrical architectures. Weaknesses: More complex installation requirements; higher initial cost; requires periodic software updates to maintain optimal performance.

Key Patents and Technical Innovations in Sensor Calibration

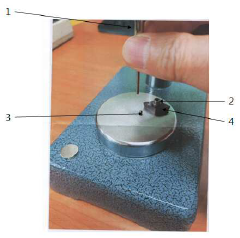

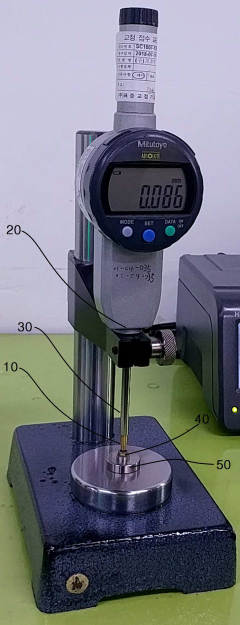

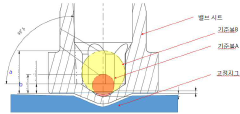

Apparatus for measuring inner of valve seat for gdi engine injector

PatentActiveKR1020200125250A

Innovation

- An apparatus with a reference ball-integrated jig, composed of reference balls of different sizes, is used to automate the measurement process, preventing slippage and ensuring accurate positioning on the inner surface of the valve seat.

Method for maximizing the formation of deposits in injector nozzles of GDI engines

PatentWO2018002610A1

Innovation

- A method to maximize deposit formation in GDI engine injector nozzles by simulating severe conditions through controlled engine speed and load variations, high nozzle temperatures, and moderate fuel flow rates, allowing for automated and unsupervised testing to quickly assess fuel's deposit-forming tendencies.

Environmental Impact and Emission Standards Compliance

The calibration of GDI engine sensors plays a pivotal role in environmental protection and regulatory compliance across global markets. Increasingly stringent emission standards, such as Euro 7 in Europe, China 6b, and EPA Tier 3 in the United States, demand unprecedented precision in fuel delivery and combustion control. Accurate sensor calibration directly impacts the formation of pollutants including NOx, particulate matter, and unburned hydrocarbons, with even minor calibration errors potentially causing significant compliance violations.

Recent studies demonstrate that properly calibrated GDI systems can reduce particulate emissions by up to 40% compared to poorly calibrated counterparts. This reduction is critical as urban air quality regulations continue to tighten, with many metropolitan areas implementing low emission zones that restrict vehicles failing to meet specific standards. The economic implications of non-compliance are substantial, with manufacturers facing penalties exceeding $100 million for emission violations in recent years.

Advanced calibration methodologies incorporate real-world driving conditions into testing protocols, addressing the gap between laboratory certification and actual on-road emissions. This approach aligns with Worldwide Harmonized Light Vehicles Test Procedure (WLTP) and Real Driving Emissions (RDE) testing requirements, ensuring vehicles maintain environmental performance throughout their operational lifecycle.

The environmental impact extends beyond regulated pollutants to include CO2 emissions, which are directly linked to fuel efficiency. Precise sensor calibration can improve fuel economy by 3-7%, contributing significantly to corporate average fuel economy (CAFE) targets and greenhouse gas reduction commitments. This efficiency gain represents a dual benefit of environmental protection and consumer cost savings.

Emerging regulatory frameworks are increasingly focusing on lifetime compliance, requiring sensors to maintain calibration accuracy throughout the vehicle's service life. This trend necessitates development of self-diagnostic and adaptive calibration systems that can compensate for sensor degradation over time. Manufacturers are now implementing on-board diagnostic systems that continuously monitor sensor performance against environmental compliance parameters.

The global variation in emission standards creates additional complexity for sensor calibration, requiring flexible systems that can adapt to different regulatory environments. This has prompted the development of region-specific calibration maps and over-the-air update capabilities to ensure vehicles remain compliant despite regulatory evolution or geographic transitions.

Looking forward, the integration of machine learning algorithms in calibration processes promises to further enhance environmental performance by predicting and adapting to changing conditions, potentially reducing emissions by an additional 10-15% compared to conventional static calibration approaches.

Recent studies demonstrate that properly calibrated GDI systems can reduce particulate emissions by up to 40% compared to poorly calibrated counterparts. This reduction is critical as urban air quality regulations continue to tighten, with many metropolitan areas implementing low emission zones that restrict vehicles failing to meet specific standards. The economic implications of non-compliance are substantial, with manufacturers facing penalties exceeding $100 million for emission violations in recent years.

Advanced calibration methodologies incorporate real-world driving conditions into testing protocols, addressing the gap between laboratory certification and actual on-road emissions. This approach aligns with Worldwide Harmonized Light Vehicles Test Procedure (WLTP) and Real Driving Emissions (RDE) testing requirements, ensuring vehicles maintain environmental performance throughout their operational lifecycle.

The environmental impact extends beyond regulated pollutants to include CO2 emissions, which are directly linked to fuel efficiency. Precise sensor calibration can improve fuel economy by 3-7%, contributing significantly to corporate average fuel economy (CAFE) targets and greenhouse gas reduction commitments. This efficiency gain represents a dual benefit of environmental protection and consumer cost savings.

Emerging regulatory frameworks are increasingly focusing on lifetime compliance, requiring sensors to maintain calibration accuracy throughout the vehicle's service life. This trend necessitates development of self-diagnostic and adaptive calibration systems that can compensate for sensor degradation over time. Manufacturers are now implementing on-board diagnostic systems that continuously monitor sensor performance against environmental compliance parameters.

The global variation in emission standards creates additional complexity for sensor calibration, requiring flexible systems that can adapt to different regulatory environments. This has prompted the development of region-specific calibration maps and over-the-air update capabilities to ensure vehicles remain compliant despite regulatory evolution or geographic transitions.

Looking forward, the integration of machine learning algorithms in calibration processes promises to further enhance environmental performance by predicting and adapting to changing conditions, potentially reducing emissions by an additional 10-15% compared to conventional static calibration approaches.

Cost-Benefit Analysis of Advanced Calibration Technologies

The implementation of advanced calibration technologies for GDI (Gasoline Direct Injection) engine sensors requires careful cost-benefit analysis to determine their economic viability. Initial investment costs for high-precision calibration equipment typically range from $50,000 to $250,000, depending on the sophistication level and measurement capabilities. These systems include specialized hardware, software platforms, and integration components necessary for comprehensive sensor calibration.

Operational expenses must also be considered, including maintenance contracts (approximately 10-15% of initial investment annually), specialized training for technicians ($5,000-$10,000 per technician), and periodic system updates. However, these costs should be weighed against the substantial benefits that precise calibration delivers.

The primary financial benefit stems from improved fuel efficiency, with properly calibrated GDI systems demonstrating 3-7% better fuel economy compared to poorly calibrated counterparts. For a medium-sized automotive manufacturer producing 500,000 vehicles annually, this translates to significant fuel savings over vehicle lifetimes and enhanced brand reputation for efficiency.

Quality improvements represent another major benefit, with advanced calibration reducing warranty claims by 15-25% for issues related to engine performance, emissions, and drivability. The average cost of a GDI-related warranty claim ranges from $800 to $2,500, making this reduction particularly valuable. Additionally, regulatory compliance benefits cannot be overlooked, as precise calibration helps manufacturers meet increasingly stringent emissions standards, avoiding potential fines that can reach millions of dollars.

Return on investment (ROI) analysis indicates that most advanced calibration systems achieve breakeven within 18-36 months, depending on production volume and implementation scope. Companies implementing these technologies report long-term cost advantages through reduced testing cycles, with calibration time decreasing by 30-50% compared to traditional methods.

The scalability factor also enhances the cost-benefit ratio, as modern calibration platforms can often be expanded to accommodate new sensor types or additional testing parameters with incremental rather than replacement costs. This adaptability extends the useful life of the initial investment and improves the overall financial proposition of advanced calibration technologies for GDI engine sensors.

Operational expenses must also be considered, including maintenance contracts (approximately 10-15% of initial investment annually), specialized training for technicians ($5,000-$10,000 per technician), and periodic system updates. However, these costs should be weighed against the substantial benefits that precise calibration delivers.

The primary financial benefit stems from improved fuel efficiency, with properly calibrated GDI systems demonstrating 3-7% better fuel economy compared to poorly calibrated counterparts. For a medium-sized automotive manufacturer producing 500,000 vehicles annually, this translates to significant fuel savings over vehicle lifetimes and enhanced brand reputation for efficiency.

Quality improvements represent another major benefit, with advanced calibration reducing warranty claims by 15-25% for issues related to engine performance, emissions, and drivability. The average cost of a GDI-related warranty claim ranges from $800 to $2,500, making this reduction particularly valuable. Additionally, regulatory compliance benefits cannot be overlooked, as precise calibration helps manufacturers meet increasingly stringent emissions standards, avoiding potential fines that can reach millions of dollars.

Return on investment (ROI) analysis indicates that most advanced calibration systems achieve breakeven within 18-36 months, depending on production volume and implementation scope. Companies implementing these technologies report long-term cost advantages through reduced testing cycles, with calibration time decreasing by 30-50% compared to traditional methods.

The scalability factor also enhances the cost-benefit ratio, as modern calibration platforms can often be expanded to accommodate new sensor types or additional testing parameters with incremental rather than replacement costs. This adaptability extends the useful life of the initial investment and improves the overall financial proposition of advanced calibration technologies for GDI engine sensors.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!