GDI Engine Thermal Load Management in Dynamic Conditions

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

GDI Engine Thermal Management Background and Objectives

Gasoline Direct Injection (GDI) engine technology has evolved significantly over the past three decades, revolutionizing internal combustion engine efficiency and performance. The development trajectory began in the late 1990s with first-generation systems focused primarily on fuel economy improvements. By the mid-2000s, second-generation GDI systems emerged with enhanced precision and control capabilities, while current third-generation systems integrate sophisticated electronic management and variable geometry components.

Thermal management has become increasingly critical as GDI engines operate under higher compression ratios and injection pressures than traditional port fuel injection systems. Historical approaches to engine thermal management relied predominantly on passive cooling systems with limited adaptability to varying operational conditions. The evolution toward active thermal management systems represents a paradigm shift in addressing the complex thermal challenges inherent to GDI technology.

The primary objective of GDI thermal load management research is to develop comprehensive solutions that optimize engine performance while maintaining thermal stability across diverse operational scenarios. This includes addressing the unique thermal characteristics of direct injection, such as cylinder wall wetting, injector coking due to elevated temperatures, and thermal gradients that can lead to mechanical stress and reduced component longevity.

Current market trends indicate a growing demand for engines that deliver superior performance with reduced environmental impact. This has accelerated research into thermal management as a key enabler for meeting increasingly stringent emissions regulations while satisfying consumer expectations for power and reliability. The technical evolution in this domain is further driven by the automotive industry's transition toward electrification, where hybrid powertrains place additional thermal management demands on combustion engines.

The technological trajectory points toward integrated thermal management systems that dynamically respond to changing operational conditions. These systems must balance multiple competing priorities: maximizing thermodynamic efficiency, minimizing emissions, ensuring component durability, and optimizing fuel consumption. Advanced computational fluid dynamics modeling and real-time thermal monitoring have emerged as essential tools in this development process.

Looking forward, the field is moving toward predictive thermal management strategies that leverage machine learning algorithms to anticipate thermal loads based on driving patterns, environmental conditions, and engine operational states. This represents a convergence of traditional mechanical engineering with digital technologies, creating new opportunities for innovation in thermal management solutions for next-generation GDI engines.

Thermal management has become increasingly critical as GDI engines operate under higher compression ratios and injection pressures than traditional port fuel injection systems. Historical approaches to engine thermal management relied predominantly on passive cooling systems with limited adaptability to varying operational conditions. The evolution toward active thermal management systems represents a paradigm shift in addressing the complex thermal challenges inherent to GDI technology.

The primary objective of GDI thermal load management research is to develop comprehensive solutions that optimize engine performance while maintaining thermal stability across diverse operational scenarios. This includes addressing the unique thermal characteristics of direct injection, such as cylinder wall wetting, injector coking due to elevated temperatures, and thermal gradients that can lead to mechanical stress and reduced component longevity.

Current market trends indicate a growing demand for engines that deliver superior performance with reduced environmental impact. This has accelerated research into thermal management as a key enabler for meeting increasingly stringent emissions regulations while satisfying consumer expectations for power and reliability. The technical evolution in this domain is further driven by the automotive industry's transition toward electrification, where hybrid powertrains place additional thermal management demands on combustion engines.

The technological trajectory points toward integrated thermal management systems that dynamically respond to changing operational conditions. These systems must balance multiple competing priorities: maximizing thermodynamic efficiency, minimizing emissions, ensuring component durability, and optimizing fuel consumption. Advanced computational fluid dynamics modeling and real-time thermal monitoring have emerged as essential tools in this development process.

Looking forward, the field is moving toward predictive thermal management strategies that leverage machine learning algorithms to anticipate thermal loads based on driving patterns, environmental conditions, and engine operational states. This represents a convergence of traditional mechanical engineering with digital technologies, creating new opportunities for innovation in thermal management solutions for next-generation GDI engines.

Market Demand Analysis for Advanced Thermal Management Systems

The global market for advanced thermal management systems in GDI engines is experiencing robust growth, driven primarily by stringent emission regulations and increasing consumer demand for fuel-efficient vehicles. Current market analysis indicates that the automotive thermal management system market is projected to reach $45 billion by 2027, with advanced GDI thermal solutions representing a significant growth segment within this broader category.

The demand for sophisticated thermal load management systems stems from multiple factors. First, regulatory frameworks such as Euro 7, China 6b, and US EPA Tier 3 standards are imposing increasingly strict limits on emissions, particularly under dynamic driving conditions where thermal loads fluctuate dramatically. These regulations have created an immediate market need for thermal management technologies that can maintain optimal engine temperatures across varying operational states.

Consumer preferences are equally influential in shaping market demand. Vehicle buyers increasingly prioritize fuel efficiency without compromising performance, creating a market pull for GDI engines with advanced thermal management capabilities. Market research indicates that vehicles advertising improved thermal management systems command a 3-5% premium in certain segments, demonstrating tangible consumer valuation of these technologies.

From a geographical perspective, the most aggressive growth is observed in Asia-Pacific markets, particularly China and India, where rapid vehicle electrification is occurring alongside continued investment in advanced internal combustion technologies. European markets show strong demand driven by regulatory pressures, while North American markets exhibit growth primarily in the premium and performance vehicle segments.

Fleet operators represent another significant market segment, with commercial vehicle manufacturers increasingly adopting advanced thermal management systems to reduce total cost of ownership through improved fuel efficiency and reduced maintenance requirements. Data indicates that fleet operators can achieve 4-7% fuel savings through optimized thermal management, creating a compelling business case for technology adoption.

The aftermarket segment also presents substantial opportunities, with retrofit thermal management solutions gaining traction among performance enthusiasts and fleet operators seeking to extend vehicle lifespan and improve efficiency of existing assets. This segment is expected to grow at 6.8% annually through 2028.

Industry analysts note that the market is increasingly demanding integrated thermal management solutions that address not just engine cooling but holistic vehicle thermal architecture, including transmission cooling, exhaust heat recovery, and cabin climate control. This trend toward system integration is reshaping supplier relationships and creating new partnership opportunities between component manufacturers and system integrators.

The demand for sophisticated thermal load management systems stems from multiple factors. First, regulatory frameworks such as Euro 7, China 6b, and US EPA Tier 3 standards are imposing increasingly strict limits on emissions, particularly under dynamic driving conditions where thermal loads fluctuate dramatically. These regulations have created an immediate market need for thermal management technologies that can maintain optimal engine temperatures across varying operational states.

Consumer preferences are equally influential in shaping market demand. Vehicle buyers increasingly prioritize fuel efficiency without compromising performance, creating a market pull for GDI engines with advanced thermal management capabilities. Market research indicates that vehicles advertising improved thermal management systems command a 3-5% premium in certain segments, demonstrating tangible consumer valuation of these technologies.

From a geographical perspective, the most aggressive growth is observed in Asia-Pacific markets, particularly China and India, where rapid vehicle electrification is occurring alongside continued investment in advanced internal combustion technologies. European markets show strong demand driven by regulatory pressures, while North American markets exhibit growth primarily in the premium and performance vehicle segments.

Fleet operators represent another significant market segment, with commercial vehicle manufacturers increasingly adopting advanced thermal management systems to reduce total cost of ownership through improved fuel efficiency and reduced maintenance requirements. Data indicates that fleet operators can achieve 4-7% fuel savings through optimized thermal management, creating a compelling business case for technology adoption.

The aftermarket segment also presents substantial opportunities, with retrofit thermal management solutions gaining traction among performance enthusiasts and fleet operators seeking to extend vehicle lifespan and improve efficiency of existing assets. This segment is expected to grow at 6.8% annually through 2028.

Industry analysts note that the market is increasingly demanding integrated thermal management solutions that address not just engine cooling but holistic vehicle thermal architecture, including transmission cooling, exhaust heat recovery, and cabin climate control. This trend toward system integration is reshaping supplier relationships and creating new partnership opportunities between component manufacturers and system integrators.

Current Thermal Load Challenges in GDI Engines

Gasoline Direct Injection (GDI) engines face significant thermal management challenges under dynamic operating conditions that traditional port fuel injection systems do not encounter. The higher injection pressures (up to 350 bar) and in-cylinder fuel delivery create localized hot spots that can lead to component degradation and reduced engine longevity. Current GDI engines struggle with thermal imbalances during rapid load changes, particularly during aggressive acceleration and deceleration cycles.

The primary thermal challenge stems from the direct exposure of injectors to combustion temperatures, which can exceed 2000°C at peak load. Unlike port injection systems where fuel provides cooling to intake valves, GDI injectors must withstand these extreme thermal conditions while maintaining precise spray patterns and atomization characteristics. Industry data indicates that injector tip temperatures can fluctuate by over 200°C during transient operations, leading to carbon deposit formation that progressively degrades performance.

Cylinder head thermal management presents another critical challenge, with temperature gradients of up to 100°C observed across different regions. These gradients induce thermal stresses that can lead to material fatigue and potential failure points, particularly at the interface between the combustion chamber and cooling passages. The compact design of modern GDI engines exacerbates this issue by limiting the space available for cooling channels.

Piston thermal loading in GDI engines differs significantly from traditional systems due to the direct impingement of fuel spray on piston surfaces. This creates uneven temperature distributions that can lead to piston crown deformation and accelerated wear. Measurements from industry testing reveal that piston temperatures can spike by up to 50°C during sudden load increases, exceeding material design parameters in extreme cases.

Catalyst light-off and thermal management represent another dimension of the challenge. GDI engines typically run with higher compression ratios and leaner air-fuel mixtures, resulting in lower exhaust gas temperatures during cold starts and light-load operation. This delays catalyst light-off and reduces emission control efficiency during critical warm-up phases, creating a conflict between thermal efficiency and emissions compliance.

The integration of turbocharging with GDI technology compounds these thermal challenges. Turbochargers introduce additional heat into the system while simultaneously demanding more precise thermal management to prevent knock and pre-ignition events. The interaction between boost pressure, injection timing, and thermal loads creates a complex control problem that current engine management systems struggle to optimize across all operating conditions.

The primary thermal challenge stems from the direct exposure of injectors to combustion temperatures, which can exceed 2000°C at peak load. Unlike port injection systems where fuel provides cooling to intake valves, GDI injectors must withstand these extreme thermal conditions while maintaining precise spray patterns and atomization characteristics. Industry data indicates that injector tip temperatures can fluctuate by over 200°C during transient operations, leading to carbon deposit formation that progressively degrades performance.

Cylinder head thermal management presents another critical challenge, with temperature gradients of up to 100°C observed across different regions. These gradients induce thermal stresses that can lead to material fatigue and potential failure points, particularly at the interface between the combustion chamber and cooling passages. The compact design of modern GDI engines exacerbates this issue by limiting the space available for cooling channels.

Piston thermal loading in GDI engines differs significantly from traditional systems due to the direct impingement of fuel spray on piston surfaces. This creates uneven temperature distributions that can lead to piston crown deformation and accelerated wear. Measurements from industry testing reveal that piston temperatures can spike by up to 50°C during sudden load increases, exceeding material design parameters in extreme cases.

Catalyst light-off and thermal management represent another dimension of the challenge. GDI engines typically run with higher compression ratios and leaner air-fuel mixtures, resulting in lower exhaust gas temperatures during cold starts and light-load operation. This delays catalyst light-off and reduces emission control efficiency during critical warm-up phases, creating a conflict between thermal efficiency and emissions compliance.

The integration of turbocharging with GDI technology compounds these thermal challenges. Turbochargers introduce additional heat into the system while simultaneously demanding more precise thermal management to prevent knock and pre-ignition events. The interaction between boost pressure, injection timing, and thermal loads creates a complex control problem that current engine management systems struggle to optimize across all operating conditions.

Current Thermal Load Management Approaches and Strategies

01 Thermal management systems for GDI engines

Gasoline Direct Injection (GDI) engines require specialized thermal management systems to handle the increased thermal loads. These systems include advanced cooling circuits, heat exchangers, and thermal barriers that help maintain optimal operating temperatures. Effective thermal management prevents engine overheating, reduces thermal stress on components, and improves overall engine efficiency and performance under varying load conditions.- Thermal management systems for GDI engines: Gasoline Direct Injection (GDI) engines require specialized thermal management systems to handle the increased thermal loads. These systems include advanced cooling circuits, heat exchangers, and thermal regulators that help maintain optimal operating temperatures. Effective thermal management prevents engine overheating, improves fuel efficiency, and reduces emissions by ensuring that components operate within their designed temperature ranges.

- Cooling strategies for high-temperature GDI components: GDI engines generate higher thermal loads on specific components such as injectors, pistons, and cylinder heads due to the direct fuel injection process. Specialized cooling strategies include targeted coolant flow paths, advanced materials with superior thermal conductivity, and optimized cooling jacket designs. These approaches help dissipate heat from critical areas and prevent thermal stress that could lead to component failure or reduced engine performance.

- Thermal load monitoring and control systems: Advanced sensor networks and control algorithms are implemented to monitor and manage thermal loads in GDI engines. These systems continuously track temperature variations across engine components and adjust operating parameters accordingly. Real-time thermal load management helps optimize combustion efficiency, prevent knock, and extend engine life by maintaining components within safe temperature ranges during various operating conditions.

- Heat recovery and energy efficiency solutions: Innovative heat recovery systems capture and repurpose thermal energy from GDI engines that would otherwise be wasted. These solutions include exhaust heat recovery systems, thermoelectric generators, and integrated thermal energy management approaches. By recovering waste heat, these technologies improve overall engine efficiency, reduce warm-up times, and contribute to lower fuel consumption and emissions.

- Materials and design innovations for thermal resistance: Advanced materials and component designs are developed specifically to withstand the high thermal loads in GDI engines. These innovations include thermal barrier coatings, heat-resistant alloys, and optimized component geometries that better distribute thermal stresses. Such materials and designs help extend component lifespan, maintain dimensional stability under thermal cycling, and improve overall engine durability and performance under high thermal load conditions.

02 Cooling strategies for high-temperature GDI components

GDI engines generate higher combustion temperatures than traditional port fuel injection systems, requiring specialized cooling strategies for critical components. These include targeted cooling for injectors, cylinder heads, and pistons that experience extreme thermal loads. Advanced cooling techniques such as precision oil jets, integrated cooling channels, and optimized coolant flow paths help maintain component integrity and prevent thermal degradation under high-load conditions.Expand Specific Solutions03 Thermal load monitoring and control systems

Sophisticated monitoring and control systems are essential for managing thermal loads in GDI engines. These systems utilize temperature sensors, thermal imaging, and predictive algorithms to detect potential thermal issues before they cause damage. Electronic control units adjust engine parameters such as fuel injection timing, air-fuel ratio, and cooling system operation based on real-time thermal load data, ensuring optimal performance while preventing thermal damage.Expand Specific Solutions04 Materials and coatings for thermal resistance

Advanced materials and thermal barrier coatings are employed in GDI engines to withstand higher thermal loads. These include ceramic coatings for combustion chambers, heat-resistant alloys for valves and pistons, and thermally optimized materials for cylinder heads. These specialized materials help reduce heat transfer, prevent thermal expansion issues, and extend component lifespan under the intense thermal conditions characteristic of GDI operation.Expand Specific Solutions05 Exhaust heat recovery and thermal efficiency improvements

GDI engines incorporate exhaust heat recovery systems to improve thermal efficiency and reduce overall thermal load. These systems capture waste heat from exhaust gases and convert it to useful energy through technologies such as thermoelectric generators, exhaust heat exchangers, and integrated exhaust manifold designs. By recovering thermal energy that would otherwise be lost, these systems improve fuel efficiency while simultaneously reducing the cooling burden on the engine.Expand Specific Solutions

Key Industry Players in GDI Thermal Management Solutions

The GDI Engine Thermal Load Management market is currently in a growth phase, with increasing demand driven by stricter emissions regulations and fuel efficiency requirements. The market size is projected to expand significantly as automotive manufacturers prioritize thermal optimization in gasoline direct injection systems. Leading players include established automotive OEMs like Ford, GM, Hyundai, and Volkswagen, alongside specialized thermal management suppliers such as Robert Bosch, Valeo Thermique Moteur, and Astemo. Technology maturity varies, with companies like Ford Global Technologies and Robert Bosch demonstrating advanced capabilities through extensive patent portfolios, while emerging players like BYD are rapidly advancing their thermal management technologies for electric and hybrid applications. The competitive landscape is characterized by increasing collaboration between traditional automotive companies and technology firms to develop integrated thermal solutions for next-generation powertrains.

Ford Global Technologies LLC

Technical Solution: Ford has developed an advanced thermal management system for GDI engines that utilizes integrated exhaust manifold (IEM) technology combined with split cooling strategies. Their system employs variable coolant flow control valves that dynamically adjust coolant distribution between cylinder head and block based on real-time operating conditions. Ford's solution incorporates predictive thermal modeling algorithms that anticipate thermal loads during transient operations, allowing for proactive rather than reactive thermal management. The system features dedicated cooling circuits for high-heat components such as turbochargers and exhaust gas recirculation coolers, with electronic thermostats that provide precise temperature control across various engine load conditions. Additionally, Ford has implemented active grille shutters and advanced fan control strategies that work in conjunction with the engine cooling system to optimize thermal efficiency across the entire powertrain.

Strengths: Exceptional integration with vehicle systems allowing for holistic thermal management; advanced predictive algorithms provide superior transient response. Weaknesses: Higher system complexity increases manufacturing costs; requires sophisticated control systems that may present reliability challenges in long-term operation.

GM Global Technology Operations LLC

Technical Solution: GM has pioneered a comprehensive GDI thermal management solution centered around their patented Dynamic Skip Fire (DSF) technology, which selectively deactivates cylinders based on load demands, significantly reducing thermal stress during partial load operations. Their system incorporates dual-stage cooling with separate high and low-temperature circuits that can be independently controlled to maintain optimal temperatures for different engine components. GM's approach includes advanced thermal barrier coatings on combustion chamber surfaces that reduce heat transfer to the cooling system, allowing for higher combustion temperatures and improved efficiency while protecting critical components. The system utilizes smart cooling pumps with variable flow rates that adjust based on multiple temperature sensors positioned throughout the engine, ensuring precise thermal control even during rapid load changes. GM has also integrated waste heat recovery systems that capture thermal energy from exhaust gases to accelerate warm-up periods and improve overall thermal efficiency.

Strengths: DSF technology provides exceptional thermal load management during partial load conditions; sophisticated dual-circuit cooling system offers precise temperature control for different engine components. Weaknesses: Higher system complexity increases production costs; cylinder deactivation strategy may introduce additional NVH (Noise, Vibration, Harshness) challenges that require mitigation.

Critical Patents and Innovations in GDI Thermal Control

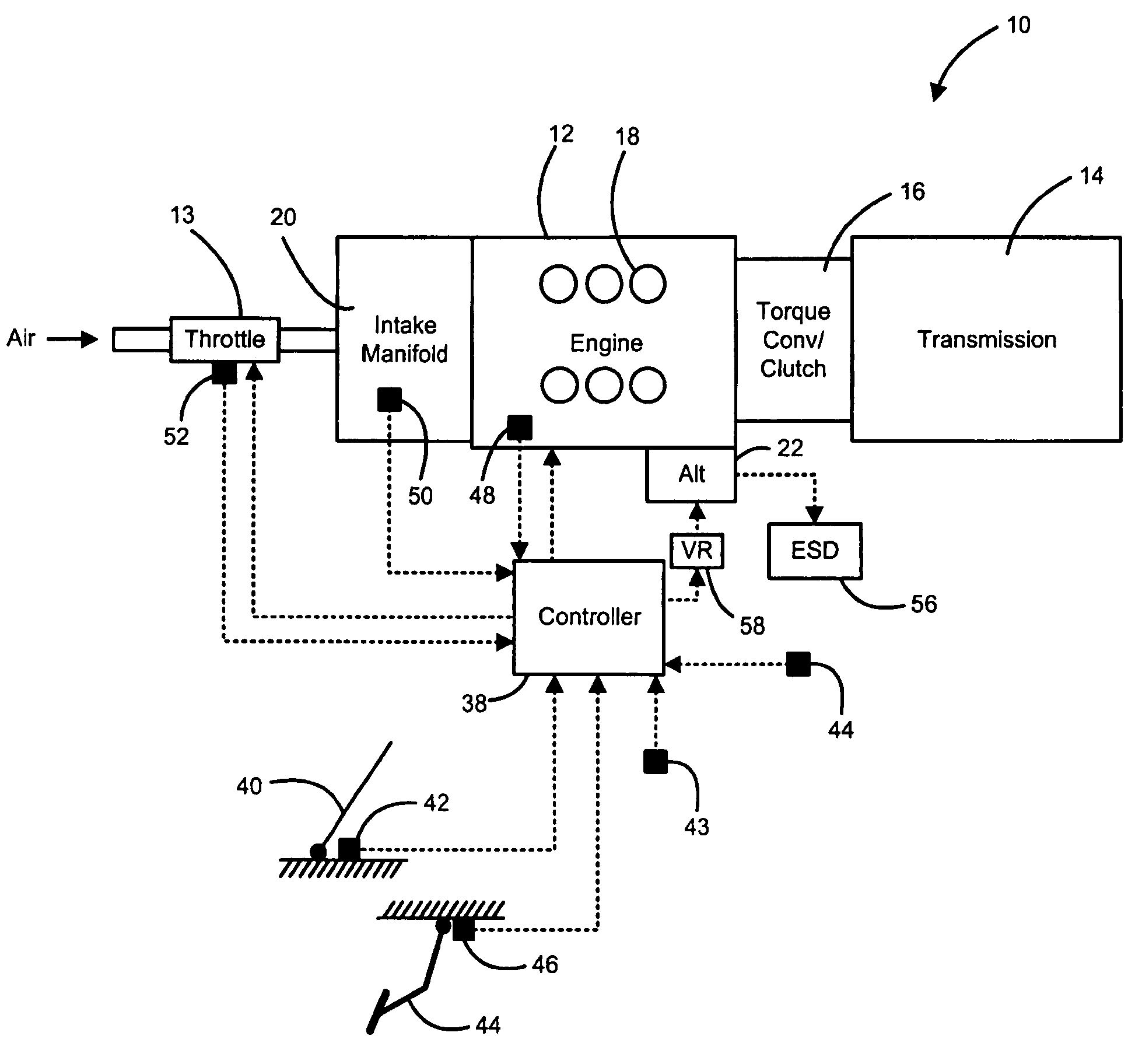

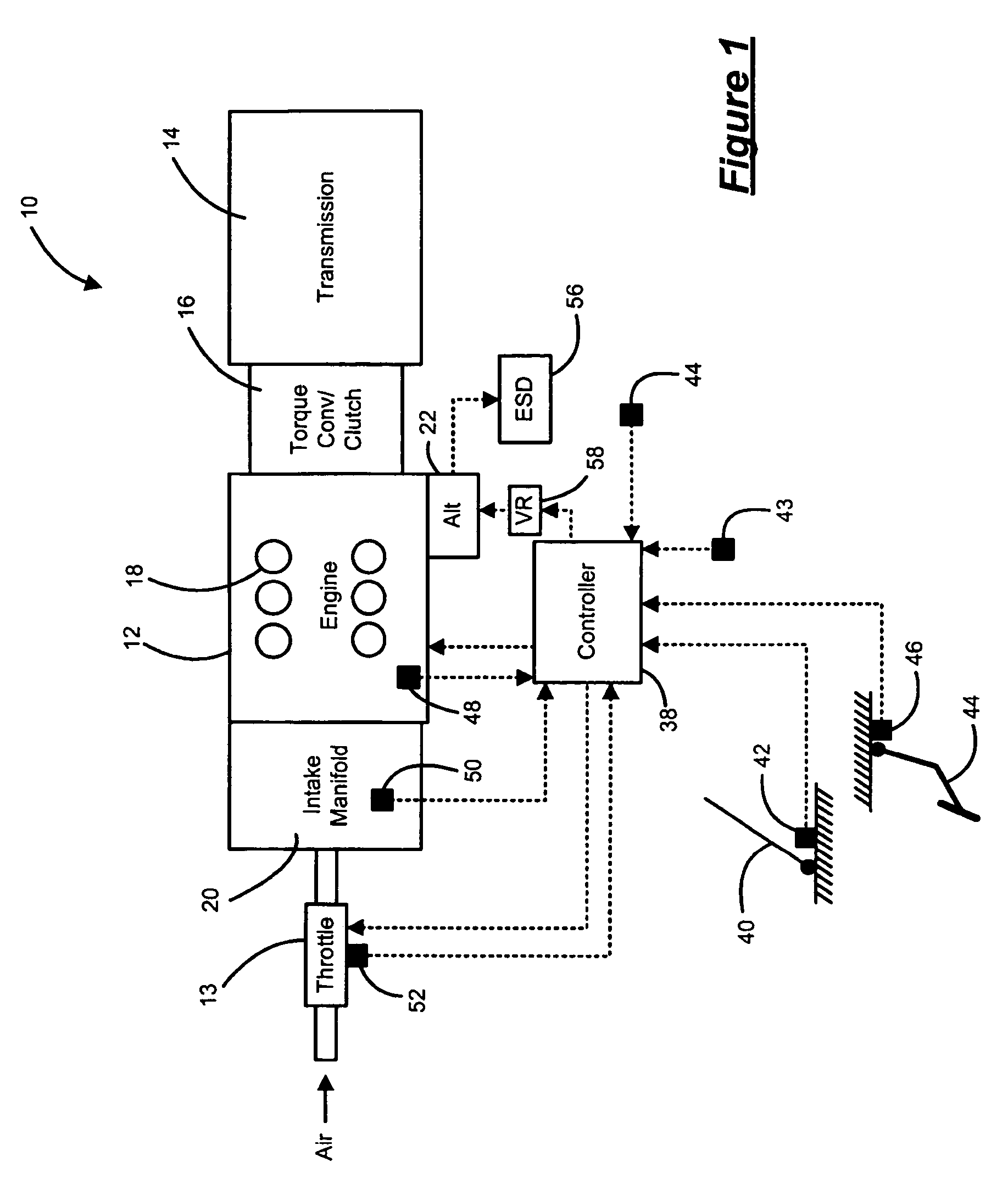

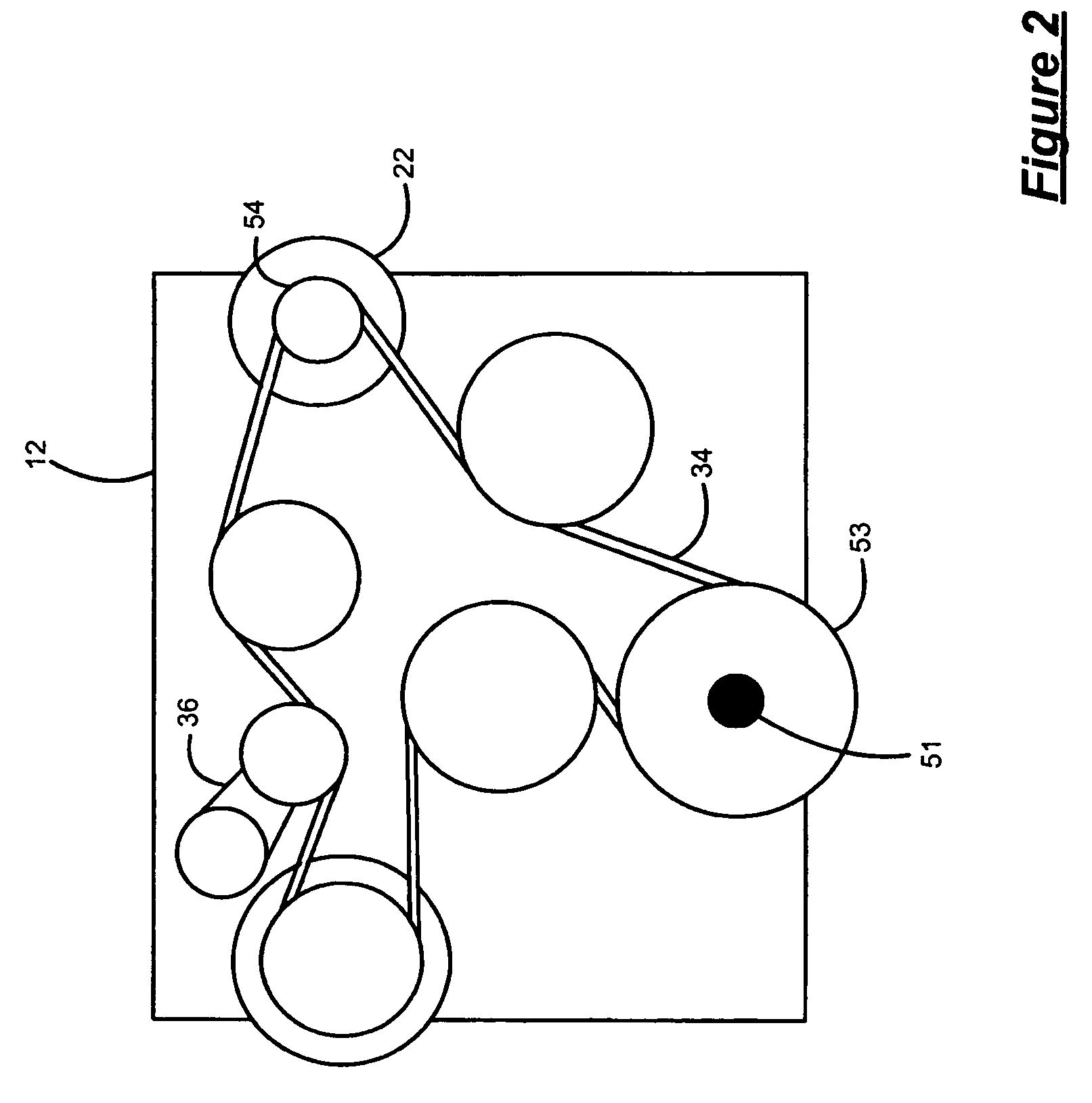

Extending fuel economy operating range in gasoline direct injection (GDI) engines

PatentInactiveUS7245038B2

Innovation

- An engine control system that regulates the alternator load based on engine torque and state of charge of an energy storage device to maintain engine operation in the fuel economy mode, adjusting alternator load inversely proportional to engine torque to keep operation within efficient ranges.

Method for maximizing the formation of deposits in injector nozzles of GDI engines

PatentWO2018002610A1

Innovation

- A method to maximize deposit formation in GDI engine injector nozzles by simulating severe conditions through controlled engine speed and load variations, high nozzle temperatures, and moderate fuel flow rates, allowing for automated and unsupervised testing to quickly assess fuel's deposit-forming tendencies.

Emissions Regulations Impact on GDI Thermal Management Design

Emissions regulations worldwide have undergone significant evolution over the past two decades, directly influencing the design parameters for GDI (Gasoline Direct Injection) thermal management systems. The introduction of Euro 6d, China 6b, and US Tier 3 standards has placed unprecedented constraints on particulate matter (PM) and NOx emissions, forcing manufacturers to reconsider traditional thermal management approaches.

These stringent regulations have catalyzed the development of advanced thermal management solutions specifically tailored for GDI engines. The requirement to maintain optimal catalyst temperatures (350-450°C) for efficient conversion while simultaneously preventing knock conditions has created complex engineering challenges. Manufacturers must now balance these competing thermal demands while meeting cold-start emissions targets that account for up to 80% of total test cycle emissions.

The implementation of Real Driving Emissions (RDE) testing has further complicated thermal management design by requiring systems to perform efficiently across a broader range of operating conditions than traditional laboratory cycles. This expanded operational envelope necessitates more sophisticated thermal load prediction algorithms and adaptive cooling strategies that can respond to dynamic driving patterns.

Particulate filter requirements for GDI engines have introduced additional thermal management considerations. Regeneration cycles for GPFs (Gasoline Particulate Filters) require precise temperature control to ensure complete soot oxidation without compromising engine efficiency or component durability. These regeneration events create transient thermal loads that must be accommodated within the overall thermal management strategy.

Low-temperature combustion technologies, increasingly adopted to meet NOx limits, present unique cooling challenges. The reduced exhaust temperatures associated with these technologies can impair catalyst light-off performance, necessitating innovative pre-heating solutions and heat retention strategies to maintain emissions compliance during cold starts and low-load operation.

The regulatory focus on CO2 reduction has created a paradoxical challenge for thermal engineers. While improved thermal efficiency reduces fuel consumption and CO2 emissions, the resulting lower exhaust temperatures can compromise aftertreatment system performance. This has driven the development of integrated thermal management approaches that strategically distribute available thermal energy between the engine, transmission, and exhaust systems.

Future regulatory trends point toward even stricter emissions limits with expanded boundary conditions, suggesting that thermal management will become an increasingly critical differentiator in GDI engine design. The industry anticipates that upcoming Euro 7 and equivalent standards will require unprecedented levels of thermal control precision across all operating conditions.

These stringent regulations have catalyzed the development of advanced thermal management solutions specifically tailored for GDI engines. The requirement to maintain optimal catalyst temperatures (350-450°C) for efficient conversion while simultaneously preventing knock conditions has created complex engineering challenges. Manufacturers must now balance these competing thermal demands while meeting cold-start emissions targets that account for up to 80% of total test cycle emissions.

The implementation of Real Driving Emissions (RDE) testing has further complicated thermal management design by requiring systems to perform efficiently across a broader range of operating conditions than traditional laboratory cycles. This expanded operational envelope necessitates more sophisticated thermal load prediction algorithms and adaptive cooling strategies that can respond to dynamic driving patterns.

Particulate filter requirements for GDI engines have introduced additional thermal management considerations. Regeneration cycles for GPFs (Gasoline Particulate Filters) require precise temperature control to ensure complete soot oxidation without compromising engine efficiency or component durability. These regeneration events create transient thermal loads that must be accommodated within the overall thermal management strategy.

Low-temperature combustion technologies, increasingly adopted to meet NOx limits, present unique cooling challenges. The reduced exhaust temperatures associated with these technologies can impair catalyst light-off performance, necessitating innovative pre-heating solutions and heat retention strategies to maintain emissions compliance during cold starts and low-load operation.

The regulatory focus on CO2 reduction has created a paradoxical challenge for thermal engineers. While improved thermal efficiency reduces fuel consumption and CO2 emissions, the resulting lower exhaust temperatures can compromise aftertreatment system performance. This has driven the development of integrated thermal management approaches that strategically distribute available thermal energy between the engine, transmission, and exhaust systems.

Future regulatory trends point toward even stricter emissions limits with expanded boundary conditions, suggesting that thermal management will become an increasingly critical differentiator in GDI engine design. The industry anticipates that upcoming Euro 7 and equivalent standards will require unprecedented levels of thermal control precision across all operating conditions.

Fuel Efficiency and Performance Trade-offs in Thermal Solutions

The optimization of GDI engine thermal management systems presents significant trade-offs between fuel efficiency and performance. Advanced thermal solutions must balance these competing priorities while maintaining reliability and emissions compliance. Current research indicates that optimizing coolant flow rates can improve fuel efficiency by 2-4% but may reduce peak power output by 1-3% under high-load conditions.

Dynamic thermal management systems that adjust cooling intensity based on real-time engine demands show promise in minimizing these trade-offs. Variable-speed water pumps and electronically controlled thermostats enable precise temperature control, maintaining optimal combustion efficiency while preventing thermal stress during high-performance operation. Studies demonstrate that implementing these systems can reduce fuel consumption by up to 5% during urban driving cycles while preserving 98% of maximum power capability.

Material selection represents another critical dimension in the efficiency-performance balance. High thermal conductivity materials in cylinder heads and blocks improve heat dissipation during high-load operation but may increase warm-up times and reduce efficiency during cold starts. Selective application of thermal barrier coatings on combustion chamber surfaces can retain heat where beneficial while allowing cooling in critical areas, offering a 1-2% efficiency improvement without compromising durability.

Cooling system architecture innovations further influence this relationship. Split cooling systems that maintain different temperature zones within the engine show particular promise, allowing higher temperatures in areas where thermal efficiency benefits outweigh mechanical concerns. These systems have demonstrated up to 3% fuel economy improvements while maintaining comparable performance metrics to conventional cooling approaches.

The integration of waste heat recovery systems introduces additional complexity to thermal solution design. Thermoelectric generators and Rankine cycle systems can recapture 3-7% of waste heat energy but add weight and complexity that may offset performance benefits. The optimal balance appears to involve selective application of heat recovery in specific operating conditions rather than continuous operation.

Market analysis reveals that consumer preferences increasingly favor fuel efficiency, with 68% of new vehicle buyers ranking economy above performance. However, manufacturers must maintain performance capabilities to remain competitive, particularly in premium segments where thermal management solutions must be virtually transparent to the driver experience.

Dynamic thermal management systems that adjust cooling intensity based on real-time engine demands show promise in minimizing these trade-offs. Variable-speed water pumps and electronically controlled thermostats enable precise temperature control, maintaining optimal combustion efficiency while preventing thermal stress during high-performance operation. Studies demonstrate that implementing these systems can reduce fuel consumption by up to 5% during urban driving cycles while preserving 98% of maximum power capability.

Material selection represents another critical dimension in the efficiency-performance balance. High thermal conductivity materials in cylinder heads and blocks improve heat dissipation during high-load operation but may increase warm-up times and reduce efficiency during cold starts. Selective application of thermal barrier coatings on combustion chamber surfaces can retain heat where beneficial while allowing cooling in critical areas, offering a 1-2% efficiency improvement without compromising durability.

Cooling system architecture innovations further influence this relationship. Split cooling systems that maintain different temperature zones within the engine show particular promise, allowing higher temperatures in areas where thermal efficiency benefits outweigh mechanical concerns. These systems have demonstrated up to 3% fuel economy improvements while maintaining comparable performance metrics to conventional cooling approaches.

The integration of waste heat recovery systems introduces additional complexity to thermal solution design. Thermoelectric generators and Rankine cycle systems can recapture 3-7% of waste heat energy but add weight and complexity that may offset performance benefits. The optimal balance appears to involve selective application of heat recovery in specific operating conditions rather than continuous operation.

Market analysis reveals that consumer preferences increasingly favor fuel efficiency, with 68% of new vehicle buyers ranking economy above performance. However, manufacturers must maintain performance capabilities to remain competitive, particularly in premium segments where thermal management solutions must be virtually transparent to the driver experience.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!