GDI Engine vs Hybrid Engine: Power Delivery Analysis

AUG 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

GDI and Hybrid Engine Technology Background and Objectives

The evolution of automotive propulsion systems has witnessed significant advancements over the past century, with internal combustion engines (ICEs) serving as the backbone of vehicular mobility. Gasoline Direct Injection (GDI) technology emerged in the late 1990s as a revolutionary approach to fuel delivery, offering improved fuel efficiency and reduced emissions compared to traditional port fuel injection systems. Concurrently, hybrid powertrains began gaining traction in the automotive market, with Toyota's introduction of the Prius in 1997 marking a watershed moment in the commercialization of hybrid technology.

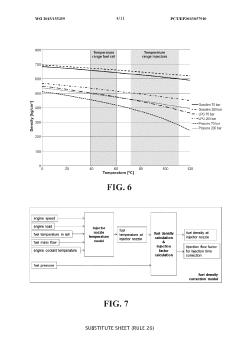

GDI engines operate by injecting fuel directly into the combustion chamber at high pressure, allowing for precise control over the fuel-air mixture and combustion timing. This direct approach enables stratified charge combustion under certain operating conditions, where fuel is concentrated around the spark plug, permitting ultra-lean overall air-fuel ratios. The technology has evolved through multiple generations, with modern systems operating at pressures exceeding 350 bar, facilitating enhanced atomization and mixture formation.

Hybrid powertrains, by contrast, combine conventional internal combustion engines with electric propulsion systems. These configurations range from mild hybrids with limited electric assistance to full hybrids capable of pure electric operation for short distances, and plug-in hybrids that can be charged from external power sources. The integration of these two power sources aims to capitalize on the high energy density of liquid fuels while leveraging the efficiency and zero-emission capabilities of electric propulsion.

The technological trajectory of both GDI and hybrid systems has been largely driven by increasingly stringent emissions regulations and consumer demand for improved fuel economy. The European Union's Euro standards, the United States' Corporate Average Fuel Economy (CAFE) requirements, and similar regulations in other markets have progressively tightened the permissible levels of pollutants and carbon dioxide emissions, necessitating continuous innovation in powertrain technology.

The primary objective of this technical research is to conduct a comprehensive comparative analysis of power delivery characteristics between GDI engines and hybrid powertrains. Specifically, the analysis aims to evaluate transient response, efficiency across various operating conditions, power density, and the overall driving experience delivered by each technology. Additionally, the research seeks to identify potential synergies between GDI and hybrid technologies that could be exploited in next-generation powertrain designs.

Furthermore, this investigation intends to assess the scalability of both technologies across different vehicle segments, from compact passenger cars to light-duty trucks, and their adaptability to emerging market requirements. The findings will inform strategic decision-making regarding powertrain development pathways and investment priorities in an automotive landscape increasingly characterized by electrification and stringent efficiency mandates.

GDI engines operate by injecting fuel directly into the combustion chamber at high pressure, allowing for precise control over the fuel-air mixture and combustion timing. This direct approach enables stratified charge combustion under certain operating conditions, where fuel is concentrated around the spark plug, permitting ultra-lean overall air-fuel ratios. The technology has evolved through multiple generations, with modern systems operating at pressures exceeding 350 bar, facilitating enhanced atomization and mixture formation.

Hybrid powertrains, by contrast, combine conventional internal combustion engines with electric propulsion systems. These configurations range from mild hybrids with limited electric assistance to full hybrids capable of pure electric operation for short distances, and plug-in hybrids that can be charged from external power sources. The integration of these two power sources aims to capitalize on the high energy density of liquid fuels while leveraging the efficiency and zero-emission capabilities of electric propulsion.

The technological trajectory of both GDI and hybrid systems has been largely driven by increasingly stringent emissions regulations and consumer demand for improved fuel economy. The European Union's Euro standards, the United States' Corporate Average Fuel Economy (CAFE) requirements, and similar regulations in other markets have progressively tightened the permissible levels of pollutants and carbon dioxide emissions, necessitating continuous innovation in powertrain technology.

The primary objective of this technical research is to conduct a comprehensive comparative analysis of power delivery characteristics between GDI engines and hybrid powertrains. Specifically, the analysis aims to evaluate transient response, efficiency across various operating conditions, power density, and the overall driving experience delivered by each technology. Additionally, the research seeks to identify potential synergies between GDI and hybrid technologies that could be exploited in next-generation powertrain designs.

Furthermore, this investigation intends to assess the scalability of both technologies across different vehicle segments, from compact passenger cars to light-duty trucks, and their adaptability to emerging market requirements. The findings will inform strategic decision-making regarding powertrain development pathways and investment priorities in an automotive landscape increasingly characterized by electrification and stringent efficiency mandates.

Market Demand Analysis for Efficient Power Delivery Systems

The global automotive industry is witnessing a significant shift toward more efficient power delivery systems, driven by stringent emission regulations and increasing consumer demand for fuel-efficient vehicles. Market research indicates that the efficient power delivery systems market, encompassing both GDI (Gasoline Direct Injection) and hybrid technologies, is projected to grow at a compound annual growth rate of 8.7% between 2023 and 2030, reaching a market value of 98 billion USD by the end of the forecast period.

Consumer preferences are evolving rapidly, with fuel efficiency now ranking among the top three purchase considerations for new vehicle buyers across major markets including North America, Europe, and Asia-Pacific. A recent consumer survey conducted across 27 countries revealed that 67% of potential car buyers consider fuel economy as "extremely important" in their purchasing decision, representing a 12% increase from similar studies conducted five years ago.

The regulatory landscape is creating substantial market pull for advanced power delivery technologies. The European Union's target to reduce CO2 emissions by 55% by 2030 (compared to 1990 levels) and similar regulations in other regions are forcing automakers to invest heavily in efficient power delivery systems. China's dual-credit policy specifically rewards manufacturers for producing vehicles with lower fuel consumption, creating a strong market incentive for both GDI and hybrid technologies.

From a regional perspective, Asia-Pacific currently dominates the market for efficient power delivery systems, accounting for approximately 42% of global demand. This is primarily due to the rapid adoption of these technologies in China and Japan. North America and Europe follow with market shares of 28% and 24% respectively, with particularly strong growth in the premium vehicle segments.

The commercial vehicle sector represents an emerging opportunity for efficient power delivery systems. Fleet operators are increasingly focused on total cost of ownership, where fuel efficiency plays a crucial role. Market analysis shows that commercial fleet operators can achieve 15-20% reduction in operating costs through adoption of vehicles equipped with advanced power delivery systems like GDI or hybrid powertrains.

Market segmentation analysis reveals distinct consumer preferences across different vehicle categories. In the compact and mid-size segments, hybrid systems are gaining significant traction, while in the performance and luxury segments, advanced GDI systems with turbocharging remain the preferred option. This segmentation indicates that manufacturers need to develop tailored power delivery strategies for different market segments rather than pursuing a one-size-fits-all approach.

The aftermarket for efficient power delivery systems is also expanding, with retrofit solutions becoming increasingly available for older vehicles. This secondary market is expected to grow at 6.3% annually through 2030, creating additional revenue streams for component manufacturers and service providers specializing in power delivery optimization.

Consumer preferences are evolving rapidly, with fuel efficiency now ranking among the top three purchase considerations for new vehicle buyers across major markets including North America, Europe, and Asia-Pacific. A recent consumer survey conducted across 27 countries revealed that 67% of potential car buyers consider fuel economy as "extremely important" in their purchasing decision, representing a 12% increase from similar studies conducted five years ago.

The regulatory landscape is creating substantial market pull for advanced power delivery technologies. The European Union's target to reduce CO2 emissions by 55% by 2030 (compared to 1990 levels) and similar regulations in other regions are forcing automakers to invest heavily in efficient power delivery systems. China's dual-credit policy specifically rewards manufacturers for producing vehicles with lower fuel consumption, creating a strong market incentive for both GDI and hybrid technologies.

From a regional perspective, Asia-Pacific currently dominates the market for efficient power delivery systems, accounting for approximately 42% of global demand. This is primarily due to the rapid adoption of these technologies in China and Japan. North America and Europe follow with market shares of 28% and 24% respectively, with particularly strong growth in the premium vehicle segments.

The commercial vehicle sector represents an emerging opportunity for efficient power delivery systems. Fleet operators are increasingly focused on total cost of ownership, where fuel efficiency plays a crucial role. Market analysis shows that commercial fleet operators can achieve 15-20% reduction in operating costs through adoption of vehicles equipped with advanced power delivery systems like GDI or hybrid powertrains.

Market segmentation analysis reveals distinct consumer preferences across different vehicle categories. In the compact and mid-size segments, hybrid systems are gaining significant traction, while in the performance and luxury segments, advanced GDI systems with turbocharging remain the preferred option. This segmentation indicates that manufacturers need to develop tailored power delivery strategies for different market segments rather than pursuing a one-size-fits-all approach.

The aftermarket for efficient power delivery systems is also expanding, with retrofit solutions becoming increasingly available for older vehicles. This secondary market is expected to grow at 6.3% annually through 2030, creating additional revenue streams for component manufacturers and service providers specializing in power delivery optimization.

Current Technical Challenges in Engine Power Delivery

The power delivery landscape in engine technology is currently experiencing significant challenges as the industry transitions from traditional gasoline direct injection (GDI) systems to hybrid powertrains. One of the primary technical hurdles involves the integration of electrical and mechanical power sources in hybrid engines, requiring sophisticated control algorithms that can seamlessly manage power distribution between the internal combustion engine and electric motor components.

Thermal management represents another critical challenge, particularly in hybrid systems where heat generation patterns differ substantially from conventional GDI engines. Engineers must develop advanced cooling systems capable of addressing the unique thermal profiles of hybrid powertrains, especially during transitions between combustion and electric-only operation modes.

Energy recovery efficiency remains suboptimal in current hybrid configurations. While regenerative braking systems have improved, they typically capture only 60-70% of available kinetic energy during deceleration. This inefficiency directly impacts the overall power delivery capabilities and fuel economy benefits of hybrid systems compared to optimized GDI engines.

Power density disparities continue to present engineering challenges. Modern GDI engines achieve approximately 100 kW/L, whereas hybrid systems often struggle to maintain comparable power-to-weight ratios due to the additional mass of batteries and electric components. This creates significant packaging constraints that affect vehicle design and performance characteristics.

Transient response management presents unique difficulties in hybrid architectures. The inherent lag in power delivery during mode transitions can create noticeable hesitation that affects drivability. Current control systems require further refinement to eliminate these momentary power gaps that are largely absent in well-tuned GDI engines.

Durability concerns have emerged regarding component longevity under variable load conditions. The frequent cycling between combustion and electric power in hybrid systems creates stress patterns that differ significantly from the more consistent operational profile of GDI engines, potentially reducing service life of critical components.

Cost-effectiveness remains a substantial barrier to widespread adoption of hybrid technology. The additional complexity of dual power sources increases manufacturing costs by approximately 15-25% compared to equivalent GDI engines, creating market resistance despite potential long-term operational savings.

Emissions compliance under real-world driving conditions continues to challenge both technologies. While hybrids demonstrate advantages in urban environments, their emissions profile under high-load highway conditions can sometimes exceed that of advanced GDI systems equipped with the latest catalytic technology, particularly regarding particulate matter and NOx emissions.

Thermal management represents another critical challenge, particularly in hybrid systems where heat generation patterns differ substantially from conventional GDI engines. Engineers must develop advanced cooling systems capable of addressing the unique thermal profiles of hybrid powertrains, especially during transitions between combustion and electric-only operation modes.

Energy recovery efficiency remains suboptimal in current hybrid configurations. While regenerative braking systems have improved, they typically capture only 60-70% of available kinetic energy during deceleration. This inefficiency directly impacts the overall power delivery capabilities and fuel economy benefits of hybrid systems compared to optimized GDI engines.

Power density disparities continue to present engineering challenges. Modern GDI engines achieve approximately 100 kW/L, whereas hybrid systems often struggle to maintain comparable power-to-weight ratios due to the additional mass of batteries and electric components. This creates significant packaging constraints that affect vehicle design and performance characteristics.

Transient response management presents unique difficulties in hybrid architectures. The inherent lag in power delivery during mode transitions can create noticeable hesitation that affects drivability. Current control systems require further refinement to eliminate these momentary power gaps that are largely absent in well-tuned GDI engines.

Durability concerns have emerged regarding component longevity under variable load conditions. The frequent cycling between combustion and electric power in hybrid systems creates stress patterns that differ significantly from the more consistent operational profile of GDI engines, potentially reducing service life of critical components.

Cost-effectiveness remains a substantial barrier to widespread adoption of hybrid technology. The additional complexity of dual power sources increases manufacturing costs by approximately 15-25% compared to equivalent GDI engines, creating market resistance despite potential long-term operational savings.

Emissions compliance under real-world driving conditions continues to challenge both technologies. While hybrids demonstrate advantages in urban environments, their emissions profile under high-load highway conditions can sometimes exceed that of advanced GDI systems equipped with the latest catalytic technology, particularly regarding particulate matter and NOx emissions.

Comparative Analysis of Current Power Delivery Solutions

01 GDI Engine Integration in Hybrid Systems

Gasoline Direct Injection (GDI) engines can be effectively integrated with hybrid powertrains to optimize fuel efficiency and power delivery. This integration allows for precise fuel control and combustion management while leveraging electric power assistance. The combination enables dynamic switching between combustion and electric power sources based on driving conditions, resulting in improved overall system efficiency and reduced emissions.- GDI Engine Integration with Hybrid Systems: Gasoline Direct Injection (GDI) engines can be effectively integrated with hybrid powertrains to optimize fuel efficiency and power delivery. This integration allows for precise fuel control in the combustion process while leveraging electric power assistance. The combination enables dynamic switching between combustion and electric power sources based on driving conditions, resulting in improved overall system efficiency and reduced emissions.

- Power Management Systems for Hybrid GDI Vehicles: Advanced power management systems coordinate between GDI engines and electric motors in hybrid vehicles to optimize power delivery. These systems utilize sophisticated control algorithms to determine the optimal power split between the combustion engine and electric motor based on factors such as battery state of charge, driver demand, and vehicle speed. The management systems ensure seamless transitions between power sources while maximizing efficiency and performance.

- Regenerative Braking and Energy Recovery in GDI Hybrids: Hybrid vehicles with GDI engines employ regenerative braking systems to recover kinetic energy during deceleration and braking. This recovered energy is converted to electrical energy and stored in the battery system for later use. The integration of regenerative braking with GDI technology allows for more efficient energy utilization throughout the drive cycle, extending the electric-only driving range and reducing fuel consumption in hybrid operation modes.

- Torque Distribution and Control in GDI Hybrid Powertrains: Specialized torque distribution systems in GDI hybrid vehicles manage power delivery between the combustion engine and electric motor. These systems dynamically allocate torque based on driving conditions to optimize performance, efficiency, and drivability. Advanced control units monitor multiple vehicle parameters to determine the ideal torque split, enabling features such as electric boost during acceleration, engine load optimization, and smooth transitions between power sources.

- Emissions Reduction Strategies in GDI Hybrid Systems: GDI hybrid systems incorporate various emissions reduction strategies to meet stringent environmental regulations. These include precise fuel injection timing, optimized combustion processes, and coordinated operation with the electric powertrain to minimize emissions during cold starts and high-load conditions. The hybrid system can also enable engine-off operation in urban environments, completely eliminating tailpipe emissions during electric-only driving while maintaining the extended range capabilities of the GDI engine.

02 Power Management and Distribution Systems

Advanced power management systems coordinate between GDI engines and electric motors in hybrid vehicles to optimize power delivery. These systems include sophisticated controllers that determine the optimal power split between the combustion engine and electric motor based on factors such as vehicle speed, load requirements, and battery state of charge. The power distribution mechanisms ensure smooth transitions between power sources while maximizing efficiency and performance.Expand Specific Solutions03 Fuel Efficiency Enhancement Technologies

Various technologies are employed to enhance fuel efficiency in GDI hybrid systems. These include cylinder deactivation, variable valve timing, advanced thermal management, and regenerative braking systems. By optimizing combustion processes in the GDI engine and recovering energy during deceleration through the hybrid system, these technologies significantly reduce fuel consumption while maintaining or improving power delivery characteristics.Expand Specific Solutions04 Control Strategies for Hybrid GDI Systems

Sophisticated control strategies are implemented to manage the operation of hybrid GDI systems. These strategies include predictive algorithms that anticipate power demands, adaptive control systems that learn from driving patterns, and mode-switching logic that determines when to use electric power, combustion power, or both. The control systems optimize parameters such as injection timing, spark timing, and electric motor assistance to balance performance, efficiency, and emissions.Expand Specific Solutions05 Energy Recovery and Storage Systems

Hybrid vehicles with GDI engines incorporate advanced energy recovery and storage systems. These systems capture kinetic energy during deceleration and braking, converting it to electrical energy stored in batteries or capacitors. The stored energy is then used to assist the GDI engine during acceleration or to power the vehicle in electric-only mode. Innovations in battery technology, power electronics, and energy management algorithms maximize the efficiency of these recovery and storage systems.Expand Specific Solutions

Key Industry Players in GDI and Hybrid Engine Development

The GDI Engine vs Hybrid Engine power delivery landscape is currently in a mature growth phase, with the global market estimated at $150-200 billion annually. Technologically, hybrid engines have reached commercial maturity while GDI systems continue evolving. Leading automotive manufacturers like Toyota, Hyundai, and Ford have established strong positions through significant R&D investments, with Toyota dominating hybrid technology through its Synergy Drive system. Meanwhile, BYD and Kia are rapidly advancing with innovative power delivery solutions. Chinese manufacturers including FAW and Foton are gaining market share through cost-effective implementations. The competitive dynamics are shifting as Volkswagen, Honda, and other established players accelerate their transition strategies between these powertrain technologies to meet increasingly stringent emissions regulations.

Hyundai Motor Co., Ltd.

Technical Solution: Hyundai has developed advanced GDI (Gasoline Direct Injection) technology through their Smartstream engine family, featuring high-pressure direct injection systems operating at up to 350 bar. Their GDI engines incorporate dual-port injection systems that combine the benefits of direct injection with port fuel injection to address carbon deposit issues. Hyundai's hybrid power delivery system integrates their GDI engines with electric motors in a parallel hybrid configuration, utilizing a 1.6L GDI engine paired with electric motors and a lithium-ion polymer battery pack. The system employs sophisticated power management algorithms that optimize the transition between combustion and electric power based on driving conditions, load requirements, and battery state of charge. Their Active Shift Control technology reduces gear shift time by 30% in hybrid transmissions, improving both efficiency and driving experience.

Strengths: Superior fuel efficiency with up to 40% thermal efficiency in some GDI applications; reduced emissions through precise fuel metering; excellent power density. Weaknesses: Higher manufacturing costs compared to conventional engines; potential for increased particulate emissions requiring additional filtration systems; complexity of dual power source management in hybrid configurations.

Toyota Motor Corp.

Technical Solution: Toyota has pioneered hybrid power delivery systems with their Hybrid Synergy Drive technology, which has evolved through multiple generations since the first Prius. Their latest hybrid systems feature a combination of Atkinson-cycle engines with direct injection technology and electric motors. Toyota's D-4S dual injection system combines both direct and port fuel injection methods, allowing the engine control unit to select the optimal injection method based on driving conditions. In their hybrid configuration, Toyota employs a power-split device (planetary gear set) that enables the system to operate in series, parallel, or combined modes depending on driving conditions. This allows seamless transitions between electric-only, engine-only, or combined power delivery. Toyota's hybrid battery management system incorporates predictive energy management that analyzes route information, traffic conditions, and driving patterns to optimize power delivery and regenerative braking strategies, improving overall efficiency by up to 20% compared to non-predictive systems.

Strengths: Exceptional reliability with proven durability exceeding 300,000 miles in many cases; seamless power delivery between combustion and electric sources; sophisticated energy recovery systems. Weaknesses: Less engaging driving dynamics compared to some competitors; higher initial cost premium for hybrid technology; additional weight from dual powertrain components.

Critical Patents and Innovations in Engine Power Technology

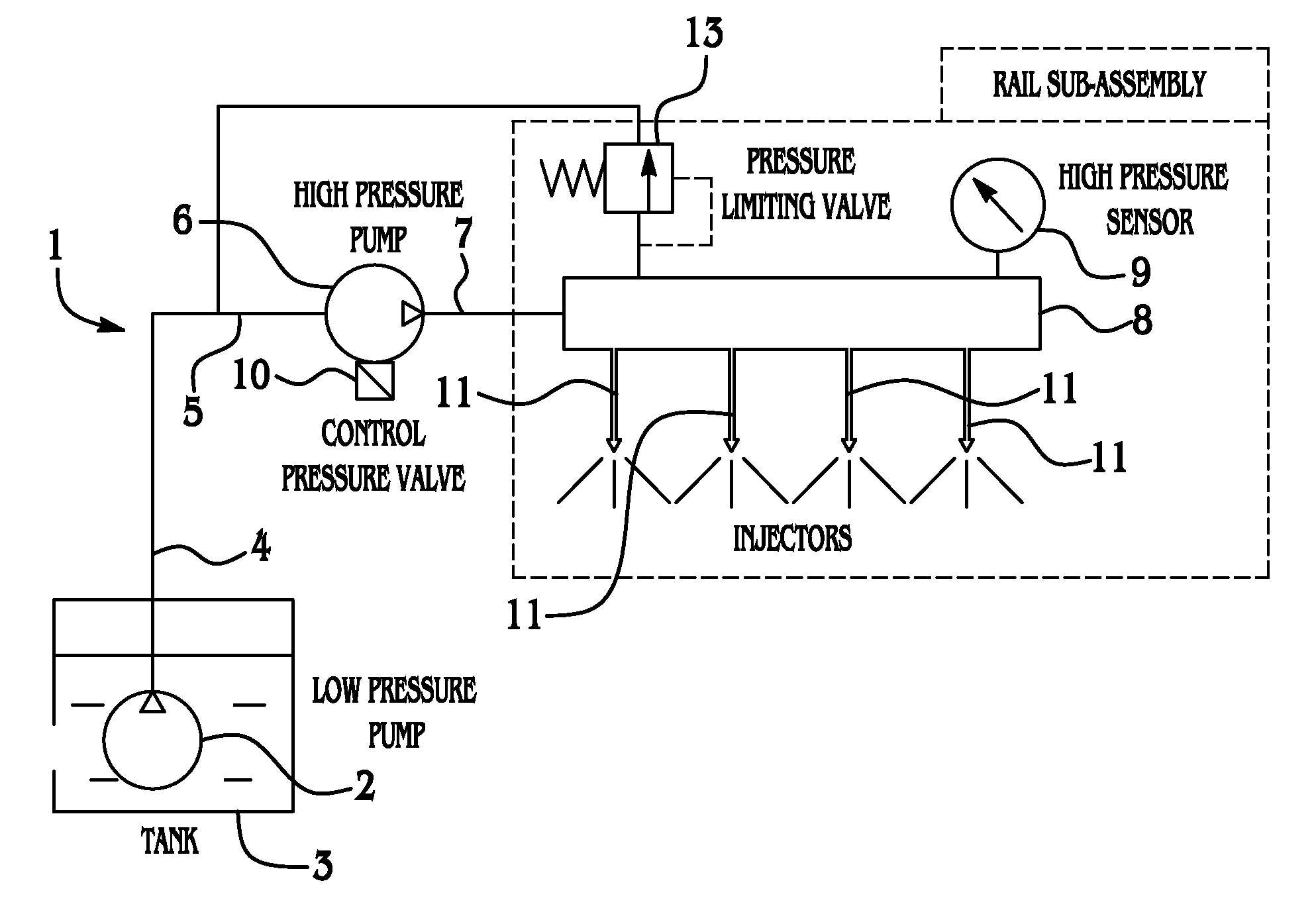

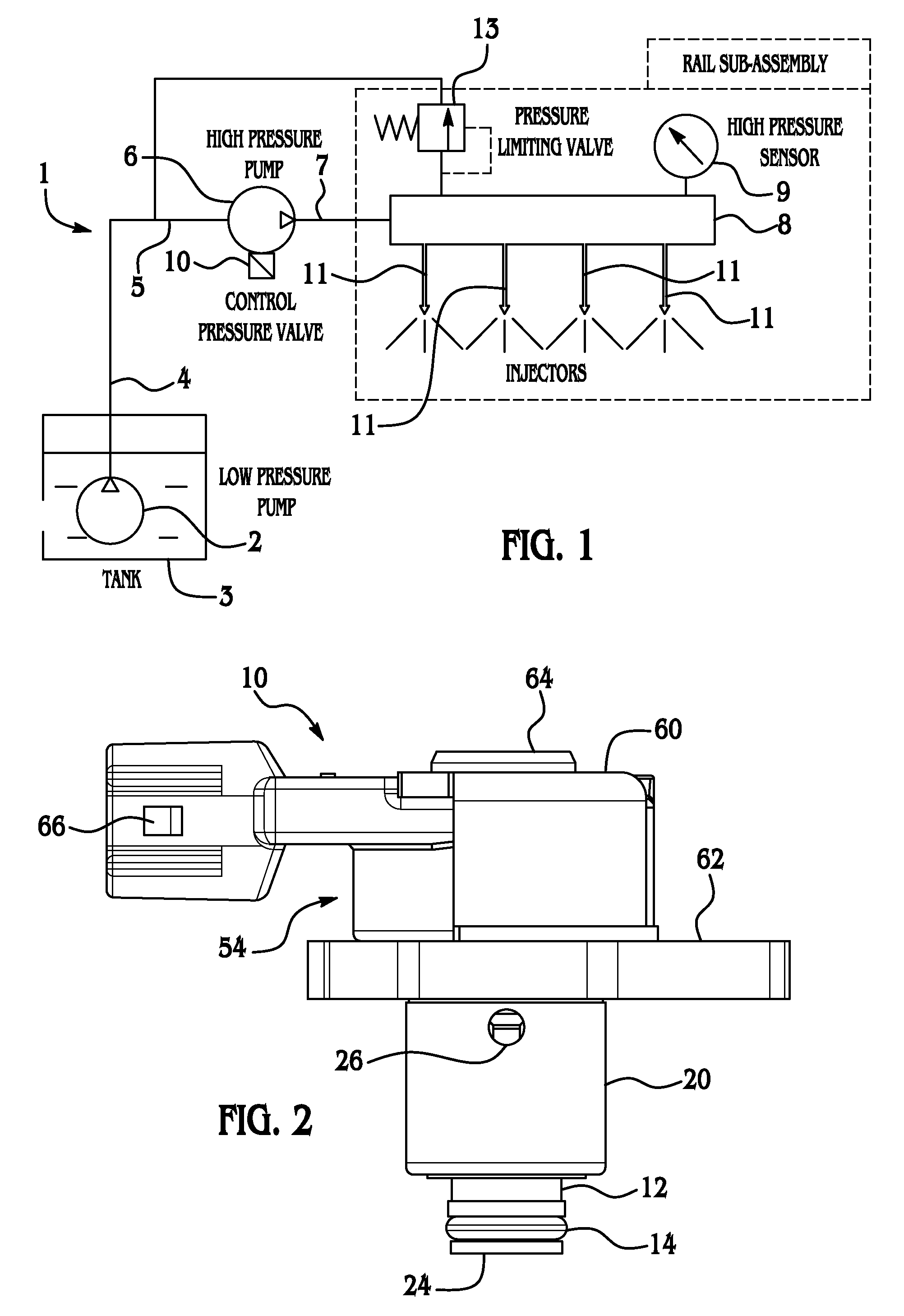

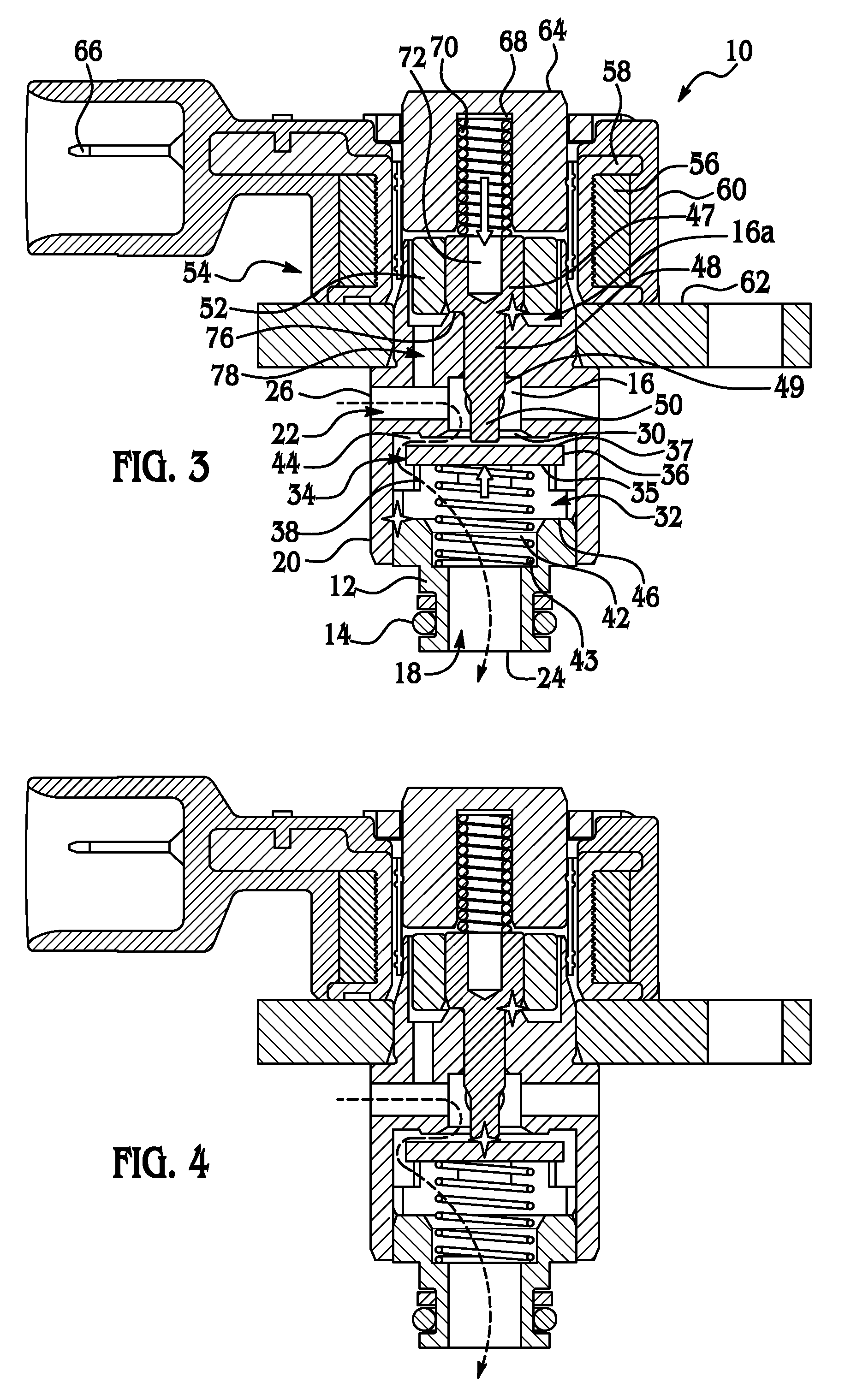

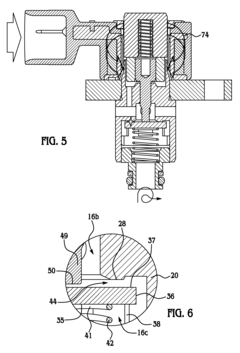

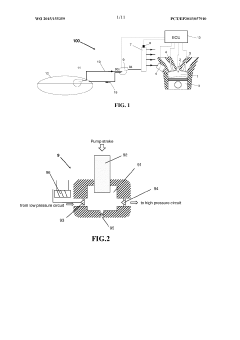

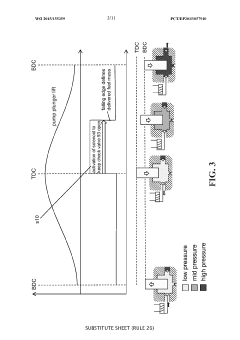

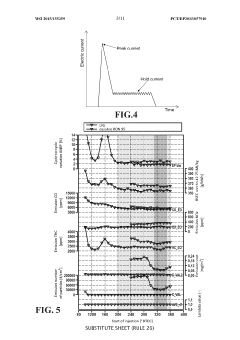

Control valve for a gas direct injection fuel system

PatentInactiveUS20080203347A1

Innovation

- A control valve design featuring a poppet mechanism and actuator system that regulates fluid communication between fluid paths, utilizing dual springs and an electrical actuator to manage pressure and flow rates, allowing for precise control of fuel injection by transitioning between open and closed states rapidly in response to engine conditions.

LPG direct injection engine

PatentWO2015155359A1

Innovation

- An LPG direct injection engine with a high-pressure pump and electronic control unit for precise liquefied petroleum gas injection between 360° and 60° BTDC, optimized valve overlap, and cylinder deactivation system to reduce emissions and improve efficiency.

Emissions Regulations Impact on Engine Technology Development

Emissions regulations have become a pivotal force shaping engine technology development globally, creating a complex landscape for both GDI (Gasoline Direct Injection) and hybrid engine technologies. Since the early 2000s, increasingly stringent standards like Euro 6d in Europe, Tier 3 in the US, and China 6 have fundamentally altered design priorities and technological trajectories in the automotive industry.

For GDI engines, these regulations have accelerated the adoption of sophisticated emission control systems. Manufacturers have invested heavily in particulate filters, advanced catalytic converters, and more precise fuel injection strategies to address the inherent particulate matter challenges of direct injection technology. The regulatory pressure has pushed GDI technology toward higher precision components and more complex control algorithms to optimize combustion efficiency while minimizing emissions.

Hybrid powertrains have experienced significant growth partly as a regulatory compliance strategy. The ability to operate in electric-only mode for portions of standardized test cycles provides manufacturers with flexibility in meeting fleet-wide emission targets. This regulatory advantage has accelerated development in battery technology, power electronics, and energy management systems that optimize the interaction between combustion and electric propulsion.

Regional variations in emission standards have created distinct technology pathways. European regulations focusing heavily on CO2 reduction have favored diesel and hybrid technologies, while stringent NOx and particulate matter limits in North America and Asia have pushed different technological solutions. These regional differences significantly impact how manufacturers approach power delivery optimization across global markets.

The timeline for implementation of new standards has become a critical factor in technology development cycles. The automotive industry typically requires 3-5 years for new powertrain development, but regulatory timelines often compress these cycles, forcing accelerated innovation or strategic compliance approaches like fleet averaging or technology phase-in periods.

Looking forward, upcoming regulations like Euro 7 and equivalent standards in other regions will likely further narrow the viability window for conventional GDI engines while creating additional incentives for hybridization. The regulatory trajectory suggests a continued push toward electrification, with hybrid technologies serving as a transitional technology while infrastructure and consumer acceptance for full electrification develops.

The economic impact of these regulations has transformed the cost structure of engine development, with compliance-related engineering now representing up to 30% of powertrain development budgets according to industry estimates. This economic reality has accelerated industry consolidation and technology sharing agreements as manufacturers seek to distribute these regulatory compliance costs.

For GDI engines, these regulations have accelerated the adoption of sophisticated emission control systems. Manufacturers have invested heavily in particulate filters, advanced catalytic converters, and more precise fuel injection strategies to address the inherent particulate matter challenges of direct injection technology. The regulatory pressure has pushed GDI technology toward higher precision components and more complex control algorithms to optimize combustion efficiency while minimizing emissions.

Hybrid powertrains have experienced significant growth partly as a regulatory compliance strategy. The ability to operate in electric-only mode for portions of standardized test cycles provides manufacturers with flexibility in meeting fleet-wide emission targets. This regulatory advantage has accelerated development in battery technology, power electronics, and energy management systems that optimize the interaction between combustion and electric propulsion.

Regional variations in emission standards have created distinct technology pathways. European regulations focusing heavily on CO2 reduction have favored diesel and hybrid technologies, while stringent NOx and particulate matter limits in North America and Asia have pushed different technological solutions. These regional differences significantly impact how manufacturers approach power delivery optimization across global markets.

The timeline for implementation of new standards has become a critical factor in technology development cycles. The automotive industry typically requires 3-5 years for new powertrain development, but regulatory timelines often compress these cycles, forcing accelerated innovation or strategic compliance approaches like fleet averaging or technology phase-in periods.

Looking forward, upcoming regulations like Euro 7 and equivalent standards in other regions will likely further narrow the viability window for conventional GDI engines while creating additional incentives for hybridization. The regulatory trajectory suggests a continued push toward electrification, with hybrid technologies serving as a transitional technology while infrastructure and consumer acceptance for full electrification develops.

The economic impact of these regulations has transformed the cost structure of engine development, with compliance-related engineering now representing up to 30% of powertrain development budgets according to industry estimates. This economic reality has accelerated industry consolidation and technology sharing agreements as manufacturers seek to distribute these regulatory compliance costs.

Fuel Economy and Performance Trade-offs Analysis

The analysis of fuel economy and performance trade-offs between GDI (Gasoline Direct Injection) engines and hybrid powertrains reveals significant differences in how these technologies balance efficiency and power delivery. GDI engines typically offer 15-20% better fuel economy compared to traditional port fuel injection systems, primarily through more precise fuel metering and higher compression ratios. However, this improvement pales in comparison to hybrid systems, which can achieve 30-50% better fuel economy in urban driving conditions through energy recuperation and electric-only operation.

Performance metrics show interesting contrasts between these technologies. GDI engines deliver immediate power response with no lag in acceleration, maintaining traditional driving dynamics that appeal to enthusiasts. Their torque curve peaks at mid-range RPMs (typically 2500-4000 RPM), optimizing highway driving efficiency. Hybrid systems, conversely, offer maximum torque at zero RPM through their electric motors, providing superior low-end acceleration but often sacrificing top-end performance.

Real-world testing data indicates that GDI engines maintain consistent performance across various driving conditions, while hybrids show dramatic efficiency variations. In city environments with frequent stops, hybrids demonstrate exceptional efficiency advantages of up to 60% over GDI counterparts. However, this advantage narrows significantly to 10-15% during sustained highway cruising where regenerative braking opportunities are limited.

The weight-to-power ratio presents another critical trade-off. GDI engines typically weigh 20-30% less than comparable hybrid systems, resulting in better power-to-weight ratios in smaller vehicle platforms. This weight difference impacts not only acceleration but also handling characteristics, with GDI-powered vehicles often demonstrating superior cornering abilities and driver engagement.

Cost-benefit analysis reveals that GDI technology adds approximately $800-1,200 to vehicle production costs compared to conventional engines, while hybrid systems add $3,000-6,000. The fuel economy improvements of GDI systems typically reach ROI within 3-4 years of average driving, while hybrids require 5-7 years to recoup their premium through fuel savings alone. This economic equation shifts dramatically with changing fuel prices, making hybrid systems increasingly attractive as fuel costs rise.

Environmental impact assessments show that while GDI engines produce fewer CO2 emissions than traditional engines, they generate more particulate matter. Hybrid systems significantly reduce both CO2 and particulate emissions during operation, though their battery production carries a higher initial carbon footprint that requires approximately 20,000-30,000 miles of driving to offset.

Performance metrics show interesting contrasts between these technologies. GDI engines deliver immediate power response with no lag in acceleration, maintaining traditional driving dynamics that appeal to enthusiasts. Their torque curve peaks at mid-range RPMs (typically 2500-4000 RPM), optimizing highway driving efficiency. Hybrid systems, conversely, offer maximum torque at zero RPM through their electric motors, providing superior low-end acceleration but often sacrificing top-end performance.

Real-world testing data indicates that GDI engines maintain consistent performance across various driving conditions, while hybrids show dramatic efficiency variations. In city environments with frequent stops, hybrids demonstrate exceptional efficiency advantages of up to 60% over GDI counterparts. However, this advantage narrows significantly to 10-15% during sustained highway cruising where regenerative braking opportunities are limited.

The weight-to-power ratio presents another critical trade-off. GDI engines typically weigh 20-30% less than comparable hybrid systems, resulting in better power-to-weight ratios in smaller vehicle platforms. This weight difference impacts not only acceleration but also handling characteristics, with GDI-powered vehicles often demonstrating superior cornering abilities and driver engagement.

Cost-benefit analysis reveals that GDI technology adds approximately $800-1,200 to vehicle production costs compared to conventional engines, while hybrid systems add $3,000-6,000. The fuel economy improvements of GDI systems typically reach ROI within 3-4 years of average driving, while hybrids require 5-7 years to recoup their premium through fuel savings alone. This economic equation shifts dramatically with changing fuel prices, making hybrid systems increasingly attractive as fuel costs rise.

Environmental impact assessments show that while GDI engines produce fewer CO2 emissions than traditional engines, they generate more particulate matter. Hybrid systems significantly reduce both CO2 and particulate emissions during operation, though their battery production carries a higher initial carbon footprint that requires approximately 20,000-30,000 miles of driving to offset.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!