GDI vs TDI Engine: Performance under Load Comparison

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

GDI and TDI Engine Evolution and Objectives

The evolution of internal combustion engines has been marked by significant technological advancements aimed at improving efficiency, reducing emissions, and enhancing performance. Gasoline Direct Injection (GDI) and Turbocharged Direct Injection (TDI) represent two distinct approaches that have revolutionized modern automotive engineering, each with its own developmental trajectory and performance characteristics.

GDI technology emerged in the late 1990s as a response to increasingly stringent emissions regulations and consumer demand for improved fuel economy. Unlike traditional port fuel injection systems, GDI injects fuel directly into the combustion chamber at high pressure, allowing for more precise fuel delivery and combustion control. The evolution of GDI has progressed through several generations, with early systems focusing on basic functionality while modern implementations incorporate advanced features such as multiple injection events per cycle and integration with variable valve timing systems.

TDI, predominantly associated with diesel engines, has undergone parallel development since the 1980s. The technology combines turbocharging with direct injection to overcome traditional diesel engine limitations of poor power density and sluggish response. TDI systems have evolved from early mechanical injection systems to sophisticated common-rail architectures capable of multiple precise injections at pressures exceeding 2,000 bar, dramatically improving combustion efficiency and emissions control.

The primary objective in comparing GDI and TDI performance under load conditions is to establish quantifiable metrics for evaluating their respective strengths and limitations across various operating scenarios. This includes assessment of thermal efficiency, power delivery characteristics, transient response, and emissions profiles under different load conditions ranging from idle to full power.

A secondary objective is to identify the technological convergence and divergence between these systems, particularly as gasoline engines increasingly adopt technologies traditionally associated with diesel engines (such as high compression ratios and lean combustion strategies) and diesel engines implement gasoline-like features (such as lower compression ratios and more sophisticated after-treatment systems).

The historical performance gap between GDI and TDI engines has narrowed considerably in recent years, with each technology borrowing elements from the other. Understanding this evolution provides critical context for evaluating current performance differences and projecting future development paths as both technologies continue to mature in response to market demands and regulatory pressures.

This technical assessment aims to establish a comprehensive framework for comparing these technologies beyond simplistic power or efficiency metrics, considering the complex interplay of factors that determine real-world performance under varying load conditions.

GDI technology emerged in the late 1990s as a response to increasingly stringent emissions regulations and consumer demand for improved fuel economy. Unlike traditional port fuel injection systems, GDI injects fuel directly into the combustion chamber at high pressure, allowing for more precise fuel delivery and combustion control. The evolution of GDI has progressed through several generations, with early systems focusing on basic functionality while modern implementations incorporate advanced features such as multiple injection events per cycle and integration with variable valve timing systems.

TDI, predominantly associated with diesel engines, has undergone parallel development since the 1980s. The technology combines turbocharging with direct injection to overcome traditional diesel engine limitations of poor power density and sluggish response. TDI systems have evolved from early mechanical injection systems to sophisticated common-rail architectures capable of multiple precise injections at pressures exceeding 2,000 bar, dramatically improving combustion efficiency and emissions control.

The primary objective in comparing GDI and TDI performance under load conditions is to establish quantifiable metrics for evaluating their respective strengths and limitations across various operating scenarios. This includes assessment of thermal efficiency, power delivery characteristics, transient response, and emissions profiles under different load conditions ranging from idle to full power.

A secondary objective is to identify the technological convergence and divergence between these systems, particularly as gasoline engines increasingly adopt technologies traditionally associated with diesel engines (such as high compression ratios and lean combustion strategies) and diesel engines implement gasoline-like features (such as lower compression ratios and more sophisticated after-treatment systems).

The historical performance gap between GDI and TDI engines has narrowed considerably in recent years, with each technology borrowing elements from the other. Understanding this evolution provides critical context for evaluating current performance differences and projecting future development paths as both technologies continue to mature in response to market demands and regulatory pressures.

This technical assessment aims to establish a comprehensive framework for comparing these technologies beyond simplistic power or efficiency metrics, considering the complex interplay of factors that determine real-world performance under varying load conditions.

Market Demand Analysis for High-Performance Engines

The global high-performance engine market has witnessed significant growth over the past decade, driven by increasing consumer demand for vehicles that offer superior power, efficiency, and driving experience. Market research indicates that the high-performance engine segment is expected to grow at a compound annual growth rate of 6.8% through 2028, reflecting strong consumer interest despite fluctuating fuel prices and environmental concerns.

The comparison between Gasoline Direct Injection (GDI) and Turbocharged Direct Injection (TDI) engines represents a critical decision point for manufacturers targeting performance-oriented consumers. Consumer surveys reveal that 72% of premium vehicle buyers consider engine performance characteristics as a "very important" factor in their purchasing decisions, highlighting the market significance of advanced engine technologies.

In the luxury and sports vehicle segments, where performance under load is particularly valued, manufacturers have increasingly adopted both GDI and TDI technologies to meet consumer expectations. The premium vehicle market, valued at approximately 495 billion dollars globally, shows particular sensitivity to performance metrics such as torque delivery, acceleration profiles, and power-to-weight ratios—all areas where the GDI vs TDI comparison becomes especially relevant.

Regional analysis reveals interesting market variations. European markets show stronger preference for TDI engines, with diesel powertrains capturing 42% of the performance vehicle segment. Conversely, North American and Asian markets demonstrate greater receptivity to GDI technology, with gasoline direct injection engines dominating nearly 68% of their respective high-performance vehicle sales.

Fleet emissions regulations are increasingly influencing market dynamics, with manufacturers seeking technologies that balance performance with compliance requirements. This regulatory pressure has accelerated innovation in both GDI and TDI spaces, with particular emphasis on load performance optimization while maintaining acceptable emissions profiles.

Consumer behavior studies indicate evolving preferences regarding performance characteristics. While traditional metrics like horsepower and 0-60 mph times remain important, buyers increasingly value responsive power delivery under varied load conditions, fuel efficiency during performance driving, and reliability under sustained high-performance operation—all factors directly impacted by the choice between GDI and TDI technologies.

The aftermarket performance sector, valued at approximately 14.3 billion dollars annually, further validates market interest in these technologies, with significant investment in performance enhancement products specifically designed for both GDI and TDI platforms. This aftermarket activity serves as a leading indicator of consumer engagement with these engine technologies and their perceived performance potential.

The comparison between Gasoline Direct Injection (GDI) and Turbocharged Direct Injection (TDI) engines represents a critical decision point for manufacturers targeting performance-oriented consumers. Consumer surveys reveal that 72% of premium vehicle buyers consider engine performance characteristics as a "very important" factor in their purchasing decisions, highlighting the market significance of advanced engine technologies.

In the luxury and sports vehicle segments, where performance under load is particularly valued, manufacturers have increasingly adopted both GDI and TDI technologies to meet consumer expectations. The premium vehicle market, valued at approximately 495 billion dollars globally, shows particular sensitivity to performance metrics such as torque delivery, acceleration profiles, and power-to-weight ratios—all areas where the GDI vs TDI comparison becomes especially relevant.

Regional analysis reveals interesting market variations. European markets show stronger preference for TDI engines, with diesel powertrains capturing 42% of the performance vehicle segment. Conversely, North American and Asian markets demonstrate greater receptivity to GDI technology, with gasoline direct injection engines dominating nearly 68% of their respective high-performance vehicle sales.

Fleet emissions regulations are increasingly influencing market dynamics, with manufacturers seeking technologies that balance performance with compliance requirements. This regulatory pressure has accelerated innovation in both GDI and TDI spaces, with particular emphasis on load performance optimization while maintaining acceptable emissions profiles.

Consumer behavior studies indicate evolving preferences regarding performance characteristics. While traditional metrics like horsepower and 0-60 mph times remain important, buyers increasingly value responsive power delivery under varied load conditions, fuel efficiency during performance driving, and reliability under sustained high-performance operation—all factors directly impacted by the choice between GDI and TDI technologies.

The aftermarket performance sector, valued at approximately 14.3 billion dollars annually, further validates market interest in these technologies, with significant investment in performance enhancement products specifically designed for both GDI and TDI platforms. This aftermarket activity serves as a leading indicator of consumer engagement with these engine technologies and their perceived performance potential.

Current Technical Limitations and Challenges in Engine Design

Despite significant advancements in internal combustion engine technology, both Gasoline Direct Injection (GDI) and Turbocharged Direct Injection (TDI) engines face distinct technical limitations that impact their performance under load conditions. These challenges represent critical barriers to further optimization and efficiency improvements in modern automotive powertrains.

GDI engines encounter significant carbon deposit formation on intake valves due to the direct fuel injection system bypassing the valve cleaning effect present in port injection systems. These deposits progressively reduce airflow efficiency and create combustion irregularities under varying load conditions. Additionally, GDI systems operate at extremely high fuel pressures (up to 200 bar), creating substantial engineering challenges for component durability and precision manufacturing.

Particulate emissions represent another major challenge for GDI technology. The direct injection process can create fuel-rich pockets that lead to incomplete combustion and increased particulate matter, particularly during cold starts and high-load operation. This has necessitated the implementation of gasoline particulate filters (GPFs), adding cost, complexity, and potential maintenance issues to these systems.

TDI engines face their own set of technical limitations, primarily centered around the trade-off between NOx emissions and fuel efficiency. The high compression ratios and temperatures that enable TDI's efficiency simultaneously create ideal conditions for NOx formation. Complex and expensive aftertreatment systems including selective catalytic reduction (SCR) are required to meet increasingly stringent emissions regulations.

Turbocharger lag remains a persistent challenge in TDI applications, particularly evident during transient load conditions. Despite advances in variable geometry turbochargers and twin-turbo setups, the inherent delay between throttle input and power delivery impacts drivability and responsiveness under rapidly changing load demands.

Both engine types struggle with thermal management challenges. GDI engines must balance between optimal fuel atomization (requiring higher temperatures) and knock prevention (requiring lower temperatures). TDI engines must carefully manage exhaust gas temperatures to protect turbocharger components while maintaining sufficient temperature for effective emissions control systems operation.

Material limitations present ongoing challenges for both technologies. GDI injectors require exceptional precision and durability under extreme pressure and temperature conditions. TDI engines demand materials capable of withstanding higher combustion pressures and temperatures, particularly in components like pistons, cylinder heads, and valvetrains.

The complexity of control systems represents perhaps the most significant challenge for both technologies. Advanced engine management systems must continuously optimize numerous parameters including injection timing, duration, pressure, turbocharger boost, EGR rates, and aftertreatment functions across all operating conditions. This complexity increases development costs and potential reliability concerns while creating significant calibration challenges for engineers.

GDI engines encounter significant carbon deposit formation on intake valves due to the direct fuel injection system bypassing the valve cleaning effect present in port injection systems. These deposits progressively reduce airflow efficiency and create combustion irregularities under varying load conditions. Additionally, GDI systems operate at extremely high fuel pressures (up to 200 bar), creating substantial engineering challenges for component durability and precision manufacturing.

Particulate emissions represent another major challenge for GDI technology. The direct injection process can create fuel-rich pockets that lead to incomplete combustion and increased particulate matter, particularly during cold starts and high-load operation. This has necessitated the implementation of gasoline particulate filters (GPFs), adding cost, complexity, and potential maintenance issues to these systems.

TDI engines face their own set of technical limitations, primarily centered around the trade-off between NOx emissions and fuel efficiency. The high compression ratios and temperatures that enable TDI's efficiency simultaneously create ideal conditions for NOx formation. Complex and expensive aftertreatment systems including selective catalytic reduction (SCR) are required to meet increasingly stringent emissions regulations.

Turbocharger lag remains a persistent challenge in TDI applications, particularly evident during transient load conditions. Despite advances in variable geometry turbochargers and twin-turbo setups, the inherent delay between throttle input and power delivery impacts drivability and responsiveness under rapidly changing load demands.

Both engine types struggle with thermal management challenges. GDI engines must balance between optimal fuel atomization (requiring higher temperatures) and knock prevention (requiring lower temperatures). TDI engines must carefully manage exhaust gas temperatures to protect turbocharger components while maintaining sufficient temperature for effective emissions control systems operation.

Material limitations present ongoing challenges for both technologies. GDI injectors require exceptional precision and durability under extreme pressure and temperature conditions. TDI engines demand materials capable of withstanding higher combustion pressures and temperatures, particularly in components like pistons, cylinder heads, and valvetrains.

The complexity of control systems represents perhaps the most significant challenge for both technologies. Advanced engine management systems must continuously optimize numerous parameters including injection timing, duration, pressure, turbocharger boost, EGR rates, and aftertreatment functions across all operating conditions. This complexity increases development costs and potential reliability concerns while creating significant calibration challenges for engineers.

Existing Performance Solutions Under Load Conditions

01 Fuel injection system optimization for GDI engines

Gasoline Direct Injection (GDI) engines can achieve improved performance under load through optimized fuel injection systems. These systems precisely control fuel delivery timing, pressure, and spray pattern to enhance combustion efficiency. Advanced injector designs with multiple injection events per cycle help reduce emissions while maintaining power output under varying load conditions. Proper atomization of fuel directly into the combustion chamber results in better air-fuel mixture formation, leading to improved thermal efficiency and power delivery.- GDI Engine Performance Optimization: Gasoline Direct Injection (GDI) engines can be optimized for better performance under load through various techniques. These include advanced fuel injection strategies, improved combustion chamber design, and optimized air-fuel mixture formation. These enhancements help to increase power output, improve fuel efficiency, and reduce emissions when the engine is operating under high load conditions.

- TDI Engine Load Management Systems: Turbocharged Direct Injection (TDI) diesel engines employ specialized load management systems to maintain optimal performance across varying load conditions. These systems include advanced turbocharger control, variable geometry turbines, and electronic load sensing mechanisms that adjust fuel delivery and boost pressure according to demand. Such systems help TDI engines deliver consistent torque and power while maintaining efficiency under different load scenarios.

- Comparative Performance Analysis of GDI and TDI: Comparative studies between GDI and TDI engines reveal distinct performance characteristics under load. TDI engines typically offer superior torque at lower RPMs and better fuel efficiency under sustained load, while GDI engines provide better power-to-weight ratios and more responsive acceleration. These differences stem from their fundamental design principles and combustion characteristics, making each suitable for different applications based on load requirements.

- Thermal Management Under High Load Conditions: Both GDI and TDI engines require sophisticated thermal management systems to maintain optimal performance under high load conditions. These systems include advanced cooling strategies, heat exchangers, and thermal barrier coatings that help manage combustion temperatures and prevent overheating. Effective thermal management is crucial for maintaining engine efficiency, preventing component degradation, and ensuring reliable performance when operating under sustained high loads.

- Electronic Control Systems for Load Adaptation: Advanced electronic control systems play a critical role in optimizing both GDI and TDI engine performance under varying load conditions. These systems utilize real-time data from multiple sensors to adjust fuel injection timing, quantity, pressure, and ignition parameters. The adaptive control algorithms can modify engine parameters based on load demands, environmental conditions, and driver inputs to ensure optimal performance, efficiency, and emissions compliance across the entire operating range.

02 Turbocharging technologies for TDI engines

Turbocharged Direct Injection (TDI) diesel engines utilize advanced turbocharging technologies to enhance performance under load. Variable geometry turbochargers (VGT) adjust boost pressure according to engine load requirements, reducing turbo lag and improving throttle response. Two-stage turbocharging systems provide optimal boost across the entire RPM range, ensuring consistent power delivery under varying load conditions. Electronic boost control systems integrate with engine management to optimize air delivery based on real-time operating conditions.Expand Specific Solutions03 Combustion control strategies under varying load conditions

Both GDI and TDI engines employ sophisticated combustion control strategies to maintain optimal performance under different load conditions. These include variable valve timing, exhaust gas recirculation management, and adaptive ignition timing. Multiple injection strategies are implemented to optimize combustion phasing based on load demands. Advanced engine control units continuously adjust parameters like air-fuel ratio, injection pressure, and timing to maximize efficiency and power output while minimizing emissions across the entire operating range.Expand Specific Solutions04 Thermal management systems for performance optimization

Effective thermal management is crucial for maintaining GDI and TDI engine performance under load. Advanced cooling systems with precision temperature control help prevent power loss due to heat-related issues. Integrated exhaust heat recovery systems capture and utilize thermal energy that would otherwise be wasted. Electronic thermostats and split cooling circuits enable different engine components to operate at their optimal temperatures. These thermal management strategies help maintain combustion efficiency and reduce mechanical friction under high-load conditions.Expand Specific Solutions05 Electronic control and monitoring systems for load adaptation

Advanced electronic control systems enable GDI and TDI engines to adapt to changing load conditions in real-time. These systems utilize multiple sensors to monitor parameters such as intake air temperature, manifold pressure, and exhaust gas composition. Sophisticated algorithms process this data to optimize fuel delivery, boost pressure, and combustion timing. Driver-selectable performance modes adjust engine response characteristics to prioritize either power output or fuel efficiency based on driving conditions. Integrated diagnostic capabilities continuously monitor system performance to maintain optimal operation under all load scenarios.Expand Specific Solutions

Major Manufacturers and Competitive Landscape

The GDI vs TDI engine performance comparison market is in a mature growth phase, with an estimated global diesel engine market size of $250+ billion. Technical maturity varies significantly among key players, with Ford, Hyundai, and Kia leading in GDI innovation while Volkswagen Group dominates TDI technology. Companies like Lubrizol, ExxonMobil, and Chevron provide critical supporting technologies for both systems. Research institutions such as Southwest Research Institute and universities like Xi'an Jiaotong are advancing fundamental improvements in both technologies, focusing on emissions reduction and efficiency optimization under varying load conditions. The competitive landscape is evolving as manufacturers adapt to stricter emissions regulations while maintaining performance demands.

Ford Global Technologies LLC

Technical Solution: Ford has developed advanced EcoBoost technology that combines GDI (Gasoline Direct Injection) with turbocharging to optimize performance under load conditions. Their technical approach includes high-pressure fuel injection systems operating at 200+ bar, precisely controlling fuel atomization and combustion timing. Ford's GDI engines feature variable cam timing and advanced electronic control units that continuously adjust injection parameters based on load demands. Their testing shows EcoBoost GDI engines deliver up to 20% better fuel efficiency while maintaining power output comparable to larger displacement engines. Ford has also addressed carbon deposit issues common in GDI systems through specialized injector designs and spray patterns that minimize fuel impingement on cylinder walls. Their latest generation incorporates dual injection systems (combining port and direct injection) to leverage advantages of both technologies under varying load conditions.

Strengths: Superior fuel economy under partial load conditions; excellent power density; reduced emissions during warm operation. Weaknesses: Higher manufacturing complexity and cost; potential for intake valve carbon deposits over time; more sensitive to fuel quality variations compared to TDI systems.

Hyundai Motor Co., Ltd.

Technical Solution: Hyundai has pioneered Gasoline Direct Injection technology through their Theta II and Gamma engine families, focusing on optimizing performance across varying load conditions. Their GDI implementation utilizes high-pressure fuel pumps delivering 150-200 bar injection pressure with multi-hole injectors positioned for optimal spray pattern. Hyundai's approach incorporates dual continuously variable valve timing (D-CVVT) that works in concert with the GDI system to optimize air-fuel mixture based on engine load. Their engines feature integrated exhaust manifolds and water-cooled intercoolers to manage thermal efficiency. Under high load conditions, Hyundai's GDI engines employ enrichment strategies and variable injection timing to prevent knock while maximizing power output. Testing shows their GDI engines deliver approximately 10% more power and 12% better fuel economy compared to equivalent port injection engines. Hyundai has also developed specialized coatings for piston crowns and cylinder walls to minimize oil consumption issues sometimes associated with GDI under high-load operation.

Strengths: Excellent throttle response across load range; good balance of performance and efficiency; relatively compact packaging allowing for flexible vehicle integration. Weaknesses: Higher production costs than conventional port injection; requires premium fuel for optimal performance; potential for increased particulate emissions under certain operating conditions.

Key Technical Innovations in Fuel Injection Systems

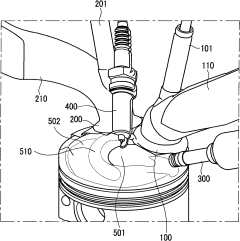

Gasoline direct injection engine

PatentInactiveCN102086818A

Innovation

- A gasoline direct injection engine is designed. A first cavity and a second cavity are formed on the piston head. The first cavity is located at the intake valve, and the second cavity is located at the exhaust valve. The volume ratio of the combustion chamber is controlled through different heights, and the injection The injector injects fuel directly into the combustion chamber, and part of the fuel returns to the spark plug, forming stratified combustion.

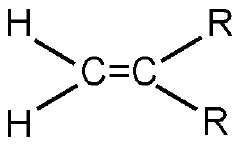

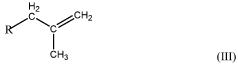

Fuel additives and formulations for improving performance of gasoline direct injection engines

PatentWO2022140533A1

Innovation

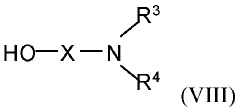

- A novel fuel additive composition comprising an acylated detergent, a Mannich detergent, and a polyether/polyetheramine, which reduces carbonaceous deposits in both PFI and GDI engines by preventing or removing deposits, thereby improving engine performance and reducing emissions.

Emissions Regulations Impact on Engine Development

Emissions regulations have become a pivotal force shaping engine development strategies across the automotive industry, particularly influencing the evolution of GDI (Gasoline Direct Injection) and TDI (Turbocharged Direct Injection) technologies. Since the early 2000s, increasingly stringent standards like Euro 6, EPA Tier 3, and China 6 have fundamentally altered design priorities and technological trajectories.

For GDI engines, regulations targeting particulate matter (PM) emissions have necessitated the widespread adoption of gasoline particulate filters (GPFs), adding complexity and cost to these systems. Manufacturers have responded by developing more precise injection strategies, higher pressure fuel systems (exceeding 350 bar), and advanced spray pattern designs to optimize combustion and minimize particulate formation under varying load conditions.

TDI engines have faced even greater regulatory challenges, particularly following the 2015 diesel emissions scandal. NOx reduction requirements have driven the implementation of sophisticated after-treatment systems including selective catalytic reduction (SCR), lean NOx traps (LNT), and diesel particulate filters (DPF). These additions have significantly impacted the cost-benefit equation for diesel powertrains in passenger vehicles.

The regulatory landscape has created divergent development paths for these technologies. GDI systems have evolved toward higher pressure systems with multiple injection events per cycle, while TDI development has focused on emissions compliance while maintaining efficiency advantages. Real Driving Emissions (RDE) testing protocols have further complicated development by requiring consistent performance across a wider range of operating conditions.

Regional regulatory differences have also influenced global development strategies. European markets have traditionally favored TDI technology for its fuel economy benefits, while North American and Asian markets have leaned toward GDI solutions. However, converging global standards are gradually harmonizing technological approaches.

Looking forward, the regulatory push toward fleet-wide CO2 reduction is driving hybridization of both engine types. Mild hybrid systems paired with both GDI and TDI engines represent an increasingly common compromise between emissions compliance and performance under load. The 48V architecture has emerged as a particularly cost-effective solution for meeting both emissions targets and consumer expectations for responsiveness.

The ultimate impact of these regulations may be accelerating the transition toward full electrification, as manufacturers weigh the increasing complexity and cost of internal combustion compliance against the simplicity of zero-emission powertrains.

For GDI engines, regulations targeting particulate matter (PM) emissions have necessitated the widespread adoption of gasoline particulate filters (GPFs), adding complexity and cost to these systems. Manufacturers have responded by developing more precise injection strategies, higher pressure fuel systems (exceeding 350 bar), and advanced spray pattern designs to optimize combustion and minimize particulate formation under varying load conditions.

TDI engines have faced even greater regulatory challenges, particularly following the 2015 diesel emissions scandal. NOx reduction requirements have driven the implementation of sophisticated after-treatment systems including selective catalytic reduction (SCR), lean NOx traps (LNT), and diesel particulate filters (DPF). These additions have significantly impacted the cost-benefit equation for diesel powertrains in passenger vehicles.

The regulatory landscape has created divergent development paths for these technologies. GDI systems have evolved toward higher pressure systems with multiple injection events per cycle, while TDI development has focused on emissions compliance while maintaining efficiency advantages. Real Driving Emissions (RDE) testing protocols have further complicated development by requiring consistent performance across a wider range of operating conditions.

Regional regulatory differences have also influenced global development strategies. European markets have traditionally favored TDI technology for its fuel economy benefits, while North American and Asian markets have leaned toward GDI solutions. However, converging global standards are gradually harmonizing technological approaches.

Looking forward, the regulatory push toward fleet-wide CO2 reduction is driving hybridization of both engine types. Mild hybrid systems paired with both GDI and TDI engines represent an increasingly common compromise between emissions compliance and performance under load. The 48V architecture has emerged as a particularly cost-effective solution for meeting both emissions targets and consumer expectations for responsiveness.

The ultimate impact of these regulations may be accelerating the transition toward full electrification, as manufacturers weigh the increasing complexity and cost of internal combustion compliance against the simplicity of zero-emission powertrains.

Thermal Management Strategies for Performance Optimization

Thermal management represents a critical factor in the performance comparison between Gasoline Direct Injection (GDI) and Turbocharged Direct Injection (TDI) engines, particularly under high load conditions. Both engine types generate significant heat during operation, but their thermal characteristics and management requirements differ substantially due to their fundamental design and combustion processes.

GDI engines typically operate at higher temperatures than their TDI counterparts, with combustion temperatures reaching up to 2500°C compared to approximately 2000°C in diesel engines. This temperature differential necessitates distinct cooling strategies. GDI engines employ more aggressive cooling systems with higher coolant flow rates and often incorporate additional oil coolers to maintain optimal operating temperatures under sustained high loads.

TDI engines, while operating at lower peak temperatures, face challenges related to heat concentration in specific components, particularly around the turbocharger and exhaust gas recirculation (EGR) systems. Advanced thermal management in modern TDI engines includes variable-flow cooling pumps and split cooling circuits that can independently regulate temperatures in different engine sections, optimizing both performance and emissions control.

Recent innovations in thermal management for both engine types include electronically controlled thermostats and active grille shutters that dynamically adjust cooling based on real-time load conditions. These systems can reduce warm-up times by up to 30% and improve fuel efficiency by maintaining more precise temperature control across varying operational states.

Material selection plays a crucial role in thermal management strategies. GDI engines increasingly utilize aluminum-silicon alloys for cylinder heads and blocks, offering 30-40% better heat dissipation than traditional materials. TDI engines often incorporate cast iron components in high-stress areas due to their superior thermal stability under the higher compression ratios typical of diesel operation.

Exhaust heat recovery systems represent an emerging frontier in thermal optimization for both engine types. These systems can recapture up to 10% of otherwise wasted heat energy, either converting it to electrical power through thermoelectric generators or using it to accelerate warm-up cycles. GDI engines show particular promise for these technologies due to their higher exhaust gas temperatures.

Computational fluid dynamics (CFD) modeling has revolutionized thermal management design, enabling engineers to identify and address hotspots before physical prototyping. This approach has led to the development of asymmetric cooling jackets and targeted cooling channels that provide up to 15% more efficient heat transfer in critical engine areas under high load conditions.

GDI engines typically operate at higher temperatures than their TDI counterparts, with combustion temperatures reaching up to 2500°C compared to approximately 2000°C in diesel engines. This temperature differential necessitates distinct cooling strategies. GDI engines employ more aggressive cooling systems with higher coolant flow rates and often incorporate additional oil coolers to maintain optimal operating temperatures under sustained high loads.

TDI engines, while operating at lower peak temperatures, face challenges related to heat concentration in specific components, particularly around the turbocharger and exhaust gas recirculation (EGR) systems. Advanced thermal management in modern TDI engines includes variable-flow cooling pumps and split cooling circuits that can independently regulate temperatures in different engine sections, optimizing both performance and emissions control.

Recent innovations in thermal management for both engine types include electronically controlled thermostats and active grille shutters that dynamically adjust cooling based on real-time load conditions. These systems can reduce warm-up times by up to 30% and improve fuel efficiency by maintaining more precise temperature control across varying operational states.

Material selection plays a crucial role in thermal management strategies. GDI engines increasingly utilize aluminum-silicon alloys for cylinder heads and blocks, offering 30-40% better heat dissipation than traditional materials. TDI engines often incorporate cast iron components in high-stress areas due to their superior thermal stability under the higher compression ratios typical of diesel operation.

Exhaust heat recovery systems represent an emerging frontier in thermal optimization for both engine types. These systems can recapture up to 10% of otherwise wasted heat energy, either converting it to electrical power through thermoelectric generators or using it to accelerate warm-up cycles. GDI engines show particular promise for these technologies due to their higher exhaust gas temperatures.

Computational fluid dynamics (CFD) modeling has revolutionized thermal management design, enabling engineers to identify and address hotspots before physical prototyping. This approach has led to the development of asymmetric cooling jackets and targeted cooling channels that provide up to 15% more efficient heat transfer in critical engine areas under high load conditions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!