GHG Emission Metrics for Methane Pyrolysis Processes.

SEP 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Methane Pyrolysis GHG Emission Background and Objectives

Methane pyrolysis has emerged as a promising technology for hydrogen production with significantly lower greenhouse gas (GHG) emissions compared to conventional methods. The evolution of this technology can be traced back to early thermal decomposition experiments in the 1960s, but substantial advancements have occurred in the past two decades as climate change concerns have intensified. The technology has progressed from laboratory-scale demonstrations to pilot plants, with increasing focus on process efficiency and carbon capture capabilities.

The global trajectory of methane pyrolysis development shows an accelerating trend, particularly since 2015, when the Paris Climate Agreement established more ambitious decarbonization targets. This acceleration reflects the growing recognition of hydrogen's potential as a clean energy carrier and the need for production methods that minimize carbon emissions. Current research is increasingly focused on optimizing catalysts, reactor designs, and energy inputs to enhance the sustainability profile of methane pyrolysis.

A critical aspect of methane pyrolysis technology is its potential to produce "turquoise hydrogen" - positioned between "gray hydrogen" (from natural gas reforming with CO2 emissions) and "green hydrogen" (from water electrolysis using renewable electricity). This positioning makes accurate GHG emission metrics essential for proper technology assessment and policy development.

The primary technical objective of developing comprehensive GHG emission metrics for methane pyrolysis processes is to establish standardized methodologies for quantifying the full lifecycle emissions. These metrics must account for direct process emissions, upstream methane leakage, energy inputs, and the fate of solid carbon byproducts. Without such metrics, meaningful comparisons between different hydrogen production pathways remain challenging.

Secondary objectives include identifying key emission hotspots within the methane pyrolysis value chain, establishing benchmark performance indicators for different process variants, and creating a framework for continuous improvement in environmental performance. These metrics will also support regulatory compliance and enable market differentiation for low-carbon hydrogen products.

The development of these metrics occurs against a backdrop of evolving hydrogen economy policies worldwide. Major economies including the EU, US, Japan, and China have established hydrogen strategies that emphasize the importance of low-carbon production methods. The EU's hydrogen taxonomy and the US Inflation Reduction Act both include provisions that will require accurate accounting of lifecycle emissions from hydrogen production technologies.

Looking forward, the technical evolution of methane pyrolysis is expected to focus on process intensification, renewable energy integration, and valorization of solid carbon byproducts. Each advancement will necessitate corresponding updates to emission accounting methodologies to maintain accuracy in sustainability assessments.

The global trajectory of methane pyrolysis development shows an accelerating trend, particularly since 2015, when the Paris Climate Agreement established more ambitious decarbonization targets. This acceleration reflects the growing recognition of hydrogen's potential as a clean energy carrier and the need for production methods that minimize carbon emissions. Current research is increasingly focused on optimizing catalysts, reactor designs, and energy inputs to enhance the sustainability profile of methane pyrolysis.

A critical aspect of methane pyrolysis technology is its potential to produce "turquoise hydrogen" - positioned between "gray hydrogen" (from natural gas reforming with CO2 emissions) and "green hydrogen" (from water electrolysis using renewable electricity). This positioning makes accurate GHG emission metrics essential for proper technology assessment and policy development.

The primary technical objective of developing comprehensive GHG emission metrics for methane pyrolysis processes is to establish standardized methodologies for quantifying the full lifecycle emissions. These metrics must account for direct process emissions, upstream methane leakage, energy inputs, and the fate of solid carbon byproducts. Without such metrics, meaningful comparisons between different hydrogen production pathways remain challenging.

Secondary objectives include identifying key emission hotspots within the methane pyrolysis value chain, establishing benchmark performance indicators for different process variants, and creating a framework for continuous improvement in environmental performance. These metrics will also support regulatory compliance and enable market differentiation for low-carbon hydrogen products.

The development of these metrics occurs against a backdrop of evolving hydrogen economy policies worldwide. Major economies including the EU, US, Japan, and China have established hydrogen strategies that emphasize the importance of low-carbon production methods. The EU's hydrogen taxonomy and the US Inflation Reduction Act both include provisions that will require accurate accounting of lifecycle emissions from hydrogen production technologies.

Looking forward, the technical evolution of methane pyrolysis is expected to focus on process intensification, renewable energy integration, and valorization of solid carbon byproducts. Each advancement will necessitate corresponding updates to emission accounting methodologies to maintain accuracy in sustainability assessments.

Market Demand Analysis for Low-Carbon Hydrogen Production

The global hydrogen market is experiencing a significant shift towards low-carbon production methods, driven by increasing environmental concerns and stringent emissions regulations. Current market size for hydrogen stands at approximately 70 million tonnes annually, with traditional production methods accounting for over 95% of this volume. These conventional processes, primarily steam methane reforming (SMR), generate substantial carbon emissions—approximately 830 million tonnes of CO2 annually, equivalent to the combined emissions of the UK and Indonesia.

Methane pyrolysis represents a promising alternative in this landscape, offering hydrogen production with significantly reduced greenhouse gas emissions. Market analysis indicates growing demand for low-carbon hydrogen across multiple sectors, with industrial applications currently dominating consumption at 72% of total demand, followed by refining (24%) and transportation (4%).

The demand for clean hydrogen is projected to grow substantially, with estimates suggesting a potential market expansion to 500-800 million tonnes by 2050, representing a compound annual growth rate of approximately 7-9%. This growth is primarily driven by decarbonization efforts in hard-to-abate sectors such as steel production, chemical manufacturing, and heavy transportation.

Regional analysis reveals varying market dynamics. Europe leads policy support for low-carbon hydrogen with ambitious targets under the European Green Deal, aiming for 40 GW of electrolyzer capacity by 2030. Asia-Pacific, particularly Japan, South Korea, and China, demonstrates strong market potential due to limited domestic energy resources and aggressive decarbonization commitments.

Economic factors significantly influence market adoption rates. Current production costs for methane pyrolysis hydrogen range between $1.50-2.50/kg, positioning it competitively against other low-carbon production methods like electrolysis ($3-7/kg) while offering substantial emissions advantages over conventional SMR ($1-2/kg with 9-12 kg CO2/kg H2).

Carbon pricing mechanisms are emerging as critical market drivers. Regions with established carbon markets show accelerated adoption of low-carbon hydrogen technologies. Analysis indicates that carbon prices exceeding $50-70/tonne CO2 make methane pyrolysis economically competitive with conventional production methods without additional subsidies.

Industry stakeholders increasingly recognize the value of methane pyrolysis in meeting sustainability commitments while maintaining economic viability. Survey data from major industrial hydrogen consumers indicates 67% plan to incorporate low-carbon hydrogen in their decarbonization strategies by 2030, with methane pyrolysis specifically mentioned by 38% of respondents as a technology of interest.

Methane pyrolysis represents a promising alternative in this landscape, offering hydrogen production with significantly reduced greenhouse gas emissions. Market analysis indicates growing demand for low-carbon hydrogen across multiple sectors, with industrial applications currently dominating consumption at 72% of total demand, followed by refining (24%) and transportation (4%).

The demand for clean hydrogen is projected to grow substantially, with estimates suggesting a potential market expansion to 500-800 million tonnes by 2050, representing a compound annual growth rate of approximately 7-9%. This growth is primarily driven by decarbonization efforts in hard-to-abate sectors such as steel production, chemical manufacturing, and heavy transportation.

Regional analysis reveals varying market dynamics. Europe leads policy support for low-carbon hydrogen with ambitious targets under the European Green Deal, aiming for 40 GW of electrolyzer capacity by 2030. Asia-Pacific, particularly Japan, South Korea, and China, demonstrates strong market potential due to limited domestic energy resources and aggressive decarbonization commitments.

Economic factors significantly influence market adoption rates. Current production costs for methane pyrolysis hydrogen range between $1.50-2.50/kg, positioning it competitively against other low-carbon production methods like electrolysis ($3-7/kg) while offering substantial emissions advantages over conventional SMR ($1-2/kg with 9-12 kg CO2/kg H2).

Carbon pricing mechanisms are emerging as critical market drivers. Regions with established carbon markets show accelerated adoption of low-carbon hydrogen technologies. Analysis indicates that carbon prices exceeding $50-70/tonne CO2 make methane pyrolysis economically competitive with conventional production methods without additional subsidies.

Industry stakeholders increasingly recognize the value of methane pyrolysis in meeting sustainability commitments while maintaining economic viability. Survey data from major industrial hydrogen consumers indicates 67% plan to incorporate low-carbon hydrogen in their decarbonization strategies by 2030, with methane pyrolysis specifically mentioned by 38% of respondents as a technology of interest.

Current Status and Challenges in Methane Pyrolysis Emissions Measurement

Methane pyrolysis has emerged as a promising technology for hydrogen production with significantly lower greenhouse gas (GHG) emissions compared to conventional methods. However, accurately measuring and quantifying these emissions remains a complex challenge. Currently, the field lacks standardized methodologies specifically designed for methane pyrolysis processes, creating inconsistencies in emissions reporting across different implementations and research groups.

The primary challenge in emissions measurement for methane pyrolysis stems from the diverse reactor designs and operating conditions employed. Molten metal, molten salt, plasma, and thermal decomposition reactors each present unique emission profiles that require tailored measurement approaches. This technological diversity has hindered the development of universal measurement protocols, resulting in data that is often difficult to compare across studies.

Globally, research institutions and companies are working to address these measurement challenges with varying approaches. European research centers have focused on developing comprehensive life cycle assessment (LCA) frameworks that account for both direct and indirect emissions from methane pyrolysis. In North America, efforts have concentrated on real-time monitoring technologies, while Asian research groups have made advances in carbon accounting methodologies specific to solid carbon byproducts.

A significant technical barrier is accurately quantifying fugitive methane emissions, which can substantially impact the overall GHG footprint of the process. Current detection systems often lack the sensitivity required to measure small leaks that, cumulatively, may represent a significant portion of total emissions. Studies indicate that these undetected emissions could potentially offset the climate benefits of methane pyrolysis if not properly addressed.

Another challenge lies in accounting for the full lifecycle emissions, particularly those associated with the solid carbon byproduct. While carbon sequestration in solid form represents a potential climate benefit, methodologies to verify long-term carbon stability and quantify potential degradation emissions remain underdeveloped. This creates uncertainty in lifecycle emissions calculations and complicates technology comparisons.

Energy input measurement presents additional complications, as different energy sources used to drive the pyrolysis process carry varying emission factors. Renewable electricity integration can dramatically reduce the carbon footprint, but methodologies to accurately attribute these benefits in mixed-grid scenarios are still evolving. This creates discrepancies in reported emissions based on energy accounting approaches rather than actual process differences.

Regulatory frameworks further complicate the landscape, with different regions employing varying standards for emissions reporting. This regulatory fragmentation has led to inconsistent data collection practices and reporting metrics, making technology assessment and policy development more challenging on a global scale.

The primary challenge in emissions measurement for methane pyrolysis stems from the diverse reactor designs and operating conditions employed. Molten metal, molten salt, plasma, and thermal decomposition reactors each present unique emission profiles that require tailored measurement approaches. This technological diversity has hindered the development of universal measurement protocols, resulting in data that is often difficult to compare across studies.

Globally, research institutions and companies are working to address these measurement challenges with varying approaches. European research centers have focused on developing comprehensive life cycle assessment (LCA) frameworks that account for both direct and indirect emissions from methane pyrolysis. In North America, efforts have concentrated on real-time monitoring technologies, while Asian research groups have made advances in carbon accounting methodologies specific to solid carbon byproducts.

A significant technical barrier is accurately quantifying fugitive methane emissions, which can substantially impact the overall GHG footprint of the process. Current detection systems often lack the sensitivity required to measure small leaks that, cumulatively, may represent a significant portion of total emissions. Studies indicate that these undetected emissions could potentially offset the climate benefits of methane pyrolysis if not properly addressed.

Another challenge lies in accounting for the full lifecycle emissions, particularly those associated with the solid carbon byproduct. While carbon sequestration in solid form represents a potential climate benefit, methodologies to verify long-term carbon stability and quantify potential degradation emissions remain underdeveloped. This creates uncertainty in lifecycle emissions calculations and complicates technology comparisons.

Energy input measurement presents additional complications, as different energy sources used to drive the pyrolysis process carry varying emission factors. Renewable electricity integration can dramatically reduce the carbon footprint, but methodologies to accurately attribute these benefits in mixed-grid scenarios are still evolving. This creates discrepancies in reported emissions based on energy accounting approaches rather than actual process differences.

Regulatory frameworks further complicate the landscape, with different regions employing varying standards for emissions reporting. This regulatory fragmentation has led to inconsistent data collection practices and reporting metrics, making technology assessment and policy development more challenging on a global scale.

Current Methodologies for Methane Pyrolysis Emissions Quantification

01 Methane pyrolysis technologies for hydrogen production with reduced GHG emissions

Methane pyrolysis processes can produce hydrogen with significantly lower greenhouse gas emissions compared to traditional methods like steam methane reforming. These processes thermally decompose methane into hydrogen and solid carbon, avoiding CO2 emissions. Various reactor designs and catalysts are employed to optimize the efficiency and reduce the energy requirements of the pyrolysis process, thereby minimizing the overall carbon footprint of hydrogen production.- Methane pyrolysis technologies for hydrogen production with reduced GHG emissions: Methane pyrolysis processes that convert methane into hydrogen and solid carbon without producing CO2 emissions. These technologies offer a cleaner alternative to traditional hydrogen production methods like steam methane reforming. The process typically involves thermal decomposition of methane at high temperatures, resulting in hydrogen gas and solid carbon that can be easily sequestered or utilized in other applications, thereby reducing overall greenhouse gas emissions.

- GHG emission measurement and monitoring systems for pyrolysis processes: Systems and methods for measuring, monitoring, and verifying greenhouse gas emissions from methane pyrolysis processes. These technologies include specialized sensors, data collection frameworks, and analytical tools that provide accurate metrics for carbon intensity, emission factors, and overall environmental impact. Such systems enable operators to quantify emission reductions, validate carbon credits, and ensure compliance with environmental regulations.

- Carbon capture and utilization in methane pyrolysis: Techniques for capturing, handling, and utilizing the solid carbon byproduct from methane pyrolysis processes. These methods focus on the collection, processing, and application of carbon black or graphite produced during pyrolysis, turning what could be a waste product into valuable materials for industries such as construction, electronics, or advanced materials. By effectively managing the carbon output, these processes maximize the greenhouse gas reduction potential of methane pyrolysis.

- Catalyst systems for optimizing methane pyrolysis efficiency: Advanced catalyst technologies that enhance the efficiency and reduce the energy requirements of methane pyrolysis processes. These catalysts lower the activation energy needed for methane decomposition, allowing the process to occur at lower temperatures and with improved conversion rates. By optimizing reaction conditions and improving energy efficiency, these catalyst systems significantly reduce the overall carbon footprint and greenhouse gas emissions associated with hydrogen production.

- Life cycle assessment frameworks for methane pyrolysis processes: Comprehensive methodologies for evaluating the full environmental impact of methane pyrolysis processes from cradle to grave. These frameworks incorporate metrics for energy consumption, resource utilization, emissions across the value chain, and comparative analyses with alternative hydrogen production methods. By providing standardized approaches to quantify greenhouse gas emissions throughout the entire life cycle, these assessment tools enable more accurate comparison between different technologies and inform decision-making for sustainable implementation.

02 Carbon capture and utilization in methane pyrolysis

Methane pyrolysis processes produce solid carbon as a byproduct, which can be captured and utilized in various applications. This solid carbon sequestration represents a significant advantage for GHG emission reduction compared to processes that release CO2. The captured carbon can be used in materials manufacturing, construction, or soil amendment, providing additional environmental benefits and potentially creating a circular economy approach to carbon management in hydrogen production.Expand Specific Solutions03 Energy efficiency metrics and renewable integration in methane pyrolysis

The energy efficiency of methane pyrolysis processes directly impacts their greenhouse gas emission profiles. Various metrics are used to evaluate the energy consumption and associated emissions, including thermal efficiency, specific energy consumption, and carbon intensity. Integration with renewable energy sources can further reduce the carbon footprint of these processes. Advanced heat recovery systems and process optimization techniques are employed to minimize energy requirements and associated emissions.Expand Specific Solutions04 Life cycle assessment and GHG emission quantification methodologies

Comprehensive life cycle assessment methodologies are applied to quantify the greenhouse gas emissions associated with methane pyrolysis processes. These assessments consider emissions from feedstock extraction, transportation, processing, and end-use applications. Standardized metrics such as global warming potential, carbon intensity, and CO2-equivalent emissions are used to compare different hydrogen production pathways. These methodologies help identify hotspots for emission reduction and support decision-making for technology deployment.Expand Specific Solutions05 Innovative reactor designs for emission reduction in methane pyrolysis

Novel reactor designs specifically engineered for methane pyrolysis can significantly reduce greenhouse gas emissions. These include molten metal reactors, plasma-assisted reactors, and fluidized bed systems that enhance conversion efficiency and reduce energy requirements. Advanced control systems monitor and optimize process parameters to minimize emissions. Some designs incorporate direct heating methods or catalytic materials that lower the temperature requirements, thereby reducing the overall carbon footprint of the process.Expand Specific Solutions

Key Industry Players in Methane Pyrolysis Technology

The methane pyrolysis GHG emission metrics market is currently in an early growth phase, characterized by increasing research activity but limited commercial deployment. Market size is expanding as hydrogen demand grows globally, with methane pyrolysis offering lower carbon footprint compared to traditional methods. Technologically, the field shows moderate maturity with significant ongoing development. Leading players include established energy corporations like Shell, ExxonMobil, and BASF developing proprietary processes, alongside specialized innovators like Molten Industries and Acceleware focusing on novel approaches. Academic institutions (Nanjing University, Harbin Institute of Technology) and research organizations (TNO, CSIR) are advancing fundamental understanding, while energy majors leverage their infrastructure advantages to scale promising technologies toward commercial viability.

ExxonMobil Chemical Patents, Inc.

Technical Solution: ExxonMobil Chemical Patents has developed a catalytic methane pyrolysis process that utilizes proprietary transition metal catalysts supported on structured carbon materials to enhance reaction kinetics at lower temperatures (700-900°C). Their technology employs a fluidized bed reactor design that maximizes methane conversion while minimizing energy requirements. ExxonMobil's GHG emission metrics framework for this process incorporates detailed carbon accounting across the entire value chain, including natural gas extraction, processing, transportation, and the pyrolysis process itself. Their methodology quantifies emissions in terms of CO2-equivalent per gigajoule of hydrogen energy content (kgCO2e/GJ H2), allowing for standardized comparison with other energy carriers. The company's life cycle assessment includes methane leakage estimates based on their own field measurements from production operations, typically reporting leakage rates of 0.2-0.5%. Their analysis demonstrates potential GHG reductions of 60-75% compared to conventional steam methane reforming, depending on the energy source used for process heating and upstream methane emissions management practices.

Strengths: Lower operating temperatures than non-catalytic processes, reducing energy requirements; established infrastructure and expertise in natural gas handling; potential for integration with existing refinery operations. Weaknesses: Catalyst deactivation issues from carbon deposition require periodic regeneration; process still produces some CO2 from catalyst regeneration; full commercial scale demonstration remains in development.

Shell Oil Co.

Technical Solution: Shell Oil has developed an advanced methane pyrolysis process called the Shell Blue Hydrogen Process that converts natural gas into hydrogen and solid carbon. Their technology utilizes a proprietary molten metal catalyst system (typically tin or nickel-bismuth alloys) in a bubble column reactor design that enables efficient thermal decomposition of methane at temperatures around 1000-1200°C. The process achieves significant GHG emission reductions compared to conventional steam methane reforming (SMR) by eliminating direct CO2 emissions. Shell's life cycle assessment methodology incorporates comprehensive boundary conditions including upstream methane emissions, energy inputs for heating, and potential carbon sequestration benefits from the solid carbon byproduct. Their GHG metrics framework accounts for both direct process emissions and indirect emissions from electricity consumption, with reported potential for up to 80% lower carbon footprint compared to conventional hydrogen production methods.

Strengths: Eliminates direct CO2 emissions associated with conventional hydrogen production; produces valuable solid carbon that can be sequestered or commercialized; lower overall energy requirements than electrolysis. Weaknesses: Still requires significant heat input which may come from fossil sources; upstream methane leakage remains a concern; technology still at demonstration scale rather than full commercial deployment.

Critical Technologies for Accurate GHG Accounting in Pyrolysis

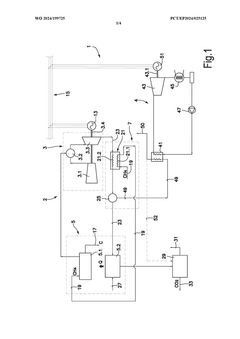

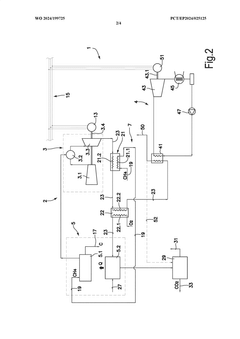

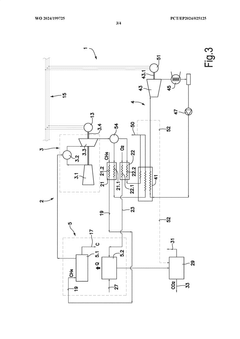

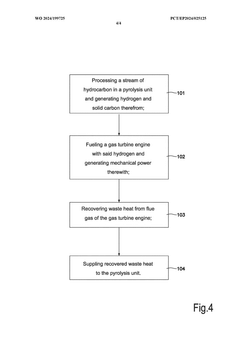

Methane-pyrolysis based gas turbine system and method

PatentWO2024199725A1

Innovation

- A methane-pyrolysis based gas turbine system that includes a pyrolysis unit to generate hydrogen from natural gas, a heat generator to provide heat to the pyrolysis reactor, and a waste heat recovery arrangement to reuse waste heat from the gas turbine engine, reducing the thermal energy needed for pyrolysis and minimizing carbon dioxide emissions.

Pyrolysis of waste flare gas for power generation

PatentPendingUS20250116400A1

Innovation

- Integrating pyrolysis of waste methane from a gas processing flare header with power generation, where a portion of the flare gas is routed to a pyrolysis chamber, heated in the absence of oxygen to decompose methane into hydrogen and solid carbon, and the hydrogen is then mixed with fuel gas to generate power.

Life Cycle Assessment Frameworks for Methane Pyrolysis

Life Cycle Assessment (LCA) frameworks provide essential methodologies for evaluating the environmental impacts of methane pyrolysis processes across their entire lifecycle. These frameworks typically follow ISO 14040 and 14044 standards, which establish a structured approach including goal and scope definition, inventory analysis, impact assessment, and interpretation phases.

For methane pyrolysis specifically, LCA frameworks must account for several unique process characteristics. The system boundaries should encompass natural gas extraction, transportation, the pyrolysis process itself, solid carbon handling, and hydrogen purification and distribution. Functional units are typically defined as either per unit of hydrogen produced (e.g., per kg H₂) or per unit of energy delivered (e.g., per MJ), allowing for standardized comparison with alternative hydrogen production pathways.

Current LCA frameworks applied to methane pyrolysis vary in their treatment of co-produced solid carbon. Some studies adopt allocation approaches based on economic value or energy content, while others use system expansion methods that consider the displacement of carbon black production through conventional processes. This methodological choice significantly influences the overall GHG emission results.

Temporal considerations present another challenge in LCA frameworks for methane pyrolysis. The technology remains at varying technology readiness levels (TRLs), requiring careful handling of data uncertainty and technology maturation projections. Most frameworks incorporate sensitivity analyses to address these uncertainties, particularly regarding energy inputs, catalyst performance, and carbon valorization pathways.

Regional factors also play a crucial role in LCA frameworks. The carbon intensity of electricity used in the process, methane leakage rates in regional natural gas infrastructure, and transportation distances for both feedstock and products can dramatically alter the environmental profile of methane pyrolysis operations.

Advanced LCA frameworks are beginning to incorporate dynamic modeling approaches that account for changing grid electricity mixes over the facility lifetime, evolving regulatory environments, and potential technology improvements. These dynamic assessments provide more realistic projections of lifecycle emissions compared to static models based solely on current technology performance.

Harmonization efforts are underway to develop standardized LCA frameworks specifically tailored to emerging hydrogen production technologies, including methane pyrolysis. These initiatives aim to establish consistent methodological choices, system boundaries, and data quality requirements to enable fair comparison across different hydrogen production pathways and support evidence-based policy development.

For methane pyrolysis specifically, LCA frameworks must account for several unique process characteristics. The system boundaries should encompass natural gas extraction, transportation, the pyrolysis process itself, solid carbon handling, and hydrogen purification and distribution. Functional units are typically defined as either per unit of hydrogen produced (e.g., per kg H₂) or per unit of energy delivered (e.g., per MJ), allowing for standardized comparison with alternative hydrogen production pathways.

Current LCA frameworks applied to methane pyrolysis vary in their treatment of co-produced solid carbon. Some studies adopt allocation approaches based on economic value or energy content, while others use system expansion methods that consider the displacement of carbon black production through conventional processes. This methodological choice significantly influences the overall GHG emission results.

Temporal considerations present another challenge in LCA frameworks for methane pyrolysis. The technology remains at varying technology readiness levels (TRLs), requiring careful handling of data uncertainty and technology maturation projections. Most frameworks incorporate sensitivity analyses to address these uncertainties, particularly regarding energy inputs, catalyst performance, and carbon valorization pathways.

Regional factors also play a crucial role in LCA frameworks. The carbon intensity of electricity used in the process, methane leakage rates in regional natural gas infrastructure, and transportation distances for both feedstock and products can dramatically alter the environmental profile of methane pyrolysis operations.

Advanced LCA frameworks are beginning to incorporate dynamic modeling approaches that account for changing grid electricity mixes over the facility lifetime, evolving regulatory environments, and potential technology improvements. These dynamic assessments provide more realistic projections of lifecycle emissions compared to static models based solely on current technology performance.

Harmonization efforts are underway to develop standardized LCA frameworks specifically tailored to emerging hydrogen production technologies, including methane pyrolysis. These initiatives aim to establish consistent methodological choices, system boundaries, and data quality requirements to enable fair comparison across different hydrogen production pathways and support evidence-based policy development.

Policy and Carbon Market Implications for Pyrolysis-Based Hydrogen

The policy landscape for hydrogen production is rapidly evolving as governments worldwide implement strategies to reduce greenhouse gas emissions. Methane pyrolysis offers a unique position within this framework, as it produces hydrogen with significantly lower carbon emissions compared to traditional steam methane reforming. Current policies in major economies are beginning to recognize this advantage, with several countries including pyrolysis-based hydrogen in their classification systems for clean hydrogen production methods.

In the European Union, the Renewable Energy Directive II and the EU Hydrogen Strategy provide frameworks that could potentially benefit pyrolysis technologies, though specific provisions for methane pyrolysis are still developing. The EU's carbon border adjustment mechanism may also create favorable conditions for low-carbon hydrogen production methods like pyrolysis.

The United States has introduced substantial incentives through the Inflation Reduction Act, which includes production tax credits for clean hydrogen. These credits are calculated based on lifecycle GHG emissions, potentially positioning pyrolysis-based hydrogen favorably if its emissions metrics can be verified to meet the threshold requirements.

In carbon markets, methane pyrolysis presents interesting opportunities due to its solid carbon byproduct. The carbon produced can be sequestered or utilized in various applications, potentially generating additional revenue streams through carbon credits. Current voluntary carbon markets are beginning to develop methodologies for accounting for emissions reductions from innovative hydrogen production methods, though standardized protocols specifically for pyrolysis are still emerging.

A key policy challenge remains the establishment of standardized GHG accounting methodologies for methane pyrolysis. Without clear metrics and verification protocols, the integration of pyrolysis-based hydrogen into existing policy frameworks and carbon markets remains complicated. Industry stakeholders are advocating for life-cycle assessment approaches that fully account for the emissions benefits of pyrolysis compared to conventional hydrogen production methods.

The regulatory treatment of the solid carbon byproduct represents another policy consideration. If classified as a valuable product rather than a waste stream, this could significantly improve the economic and environmental case for pyrolysis technologies. Some jurisdictions are beginning to develop frameworks for carbon utilization that could support this classification.

As climate policies continue to strengthen globally, the comparative emissions advantage of pyrolysis-based hydrogen is likely to translate into increasing policy support and market opportunities, particularly in regions with ambitious decarbonization targets and well-developed carbon pricing mechanisms.

In the European Union, the Renewable Energy Directive II and the EU Hydrogen Strategy provide frameworks that could potentially benefit pyrolysis technologies, though specific provisions for methane pyrolysis are still developing. The EU's carbon border adjustment mechanism may also create favorable conditions for low-carbon hydrogen production methods like pyrolysis.

The United States has introduced substantial incentives through the Inflation Reduction Act, which includes production tax credits for clean hydrogen. These credits are calculated based on lifecycle GHG emissions, potentially positioning pyrolysis-based hydrogen favorably if its emissions metrics can be verified to meet the threshold requirements.

In carbon markets, methane pyrolysis presents interesting opportunities due to its solid carbon byproduct. The carbon produced can be sequestered or utilized in various applications, potentially generating additional revenue streams through carbon credits. Current voluntary carbon markets are beginning to develop methodologies for accounting for emissions reductions from innovative hydrogen production methods, though standardized protocols specifically for pyrolysis are still emerging.

A key policy challenge remains the establishment of standardized GHG accounting methodologies for methane pyrolysis. Without clear metrics and verification protocols, the integration of pyrolysis-based hydrogen into existing policy frameworks and carbon markets remains complicated. Industry stakeholders are advocating for life-cycle assessment approaches that fully account for the emissions benefits of pyrolysis compared to conventional hydrogen production methods.

The regulatory treatment of the solid carbon byproduct represents another policy consideration. If classified as a valuable product rather than a waste stream, this could significantly improve the economic and environmental case for pyrolysis technologies. Some jurisdictions are beginning to develop frameworks for carbon utilization that could support this classification.

As climate policies continue to strengthen globally, the comparative emissions advantage of pyrolysis-based hydrogen is likely to translate into increasing policy support and market opportunities, particularly in regions with ambitious decarbonization targets and well-developed carbon pricing mechanisms.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!