Harnessing Data Analytics for Gas Welding Improvement

AUG 7, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Gas Welding Analytics Background and Objectives

Gas welding has been a cornerstone of industrial manufacturing for over a century, playing a crucial role in joining metals across various sectors. As industries evolve and demand higher precision, efficiency, and quality, the need for technological advancement in welding processes has become increasingly apparent. The integration of data analytics into gas welding represents a significant leap forward in this traditional field, offering the potential to revolutionize welding practices and outcomes.

The primary objective of harnessing data analytics for gas welding improvement is to enhance the overall welding process by leveraging the power of data-driven insights. This approach aims to optimize welding parameters, predict and prevent defects, improve quality control, and increase operational efficiency. By collecting and analyzing vast amounts of data from welding operations, manufacturers can gain unprecedented visibility into their processes, enabling real-time adjustments and long-term improvements.

The evolution of gas welding technology has been gradual, with incremental improvements in equipment, materials, and techniques over the years. However, the advent of Industry 4.0 and the proliferation of sensors, Internet of Things (IoT) devices, and advanced analytics tools have opened up new possibilities for transforming gas welding practices. The integration of these technologies allows for the capture of critical data points throughout the welding process, including temperature, gas flow rates, torch position, and material properties.

As the welding industry faces increasing pressure to meet stringent quality standards, reduce costs, and minimize environmental impact, the adoption of data analytics in gas welding becomes not just an opportunity but a necessity. The technology trend is moving towards creating "smart" welding systems that can adapt in real-time to changing conditions, predict optimal parameters for different materials and configurations, and provide comprehensive documentation for quality assurance and traceability.

The goals of implementing data analytics in gas welding are multifaceted. They include improving weld quality by reducing defects and inconsistencies, increasing productivity through optimized welding parameters and reduced downtime, enhancing safety by identifying potential hazards before they occur, and reducing material waste and energy consumption. Additionally, data analytics can contribute to the development of more efficient training programs for welders, as well as aid in the design of new welding processes and equipment.

As we look to the future, the integration of data analytics with gas welding is expected to pave the way for fully automated and intelligent welding systems. These systems will not only execute welds with unprecedented precision but also continuously learn and improve their performance over time. The ultimate aim is to create a welding ecosystem where human expertise is augmented by artificial intelligence and machine learning, leading to a new era of welding excellence and innovation.

The primary objective of harnessing data analytics for gas welding improvement is to enhance the overall welding process by leveraging the power of data-driven insights. This approach aims to optimize welding parameters, predict and prevent defects, improve quality control, and increase operational efficiency. By collecting and analyzing vast amounts of data from welding operations, manufacturers can gain unprecedented visibility into their processes, enabling real-time adjustments and long-term improvements.

The evolution of gas welding technology has been gradual, with incremental improvements in equipment, materials, and techniques over the years. However, the advent of Industry 4.0 and the proliferation of sensors, Internet of Things (IoT) devices, and advanced analytics tools have opened up new possibilities for transforming gas welding practices. The integration of these technologies allows for the capture of critical data points throughout the welding process, including temperature, gas flow rates, torch position, and material properties.

As the welding industry faces increasing pressure to meet stringent quality standards, reduce costs, and minimize environmental impact, the adoption of data analytics in gas welding becomes not just an opportunity but a necessity. The technology trend is moving towards creating "smart" welding systems that can adapt in real-time to changing conditions, predict optimal parameters for different materials and configurations, and provide comprehensive documentation for quality assurance and traceability.

The goals of implementing data analytics in gas welding are multifaceted. They include improving weld quality by reducing defects and inconsistencies, increasing productivity through optimized welding parameters and reduced downtime, enhancing safety by identifying potential hazards before they occur, and reducing material waste and energy consumption. Additionally, data analytics can contribute to the development of more efficient training programs for welders, as well as aid in the design of new welding processes and equipment.

As we look to the future, the integration of data analytics with gas welding is expected to pave the way for fully automated and intelligent welding systems. These systems will not only execute welds with unprecedented precision but also continuously learn and improve their performance over time. The ultimate aim is to create a welding ecosystem where human expertise is augmented by artificial intelligence and machine learning, leading to a new era of welding excellence and innovation.

Market Demand for Advanced Gas Welding Solutions

The global market for advanced gas welding solutions is experiencing significant growth, driven by the increasing demand for precision and efficiency in manufacturing processes across various industries. As industries continue to evolve and adopt more sophisticated production techniques, the need for improved gas welding technologies has become paramount. This demand is particularly evident in sectors such as automotive, aerospace, construction, and energy, where the quality of welding directly impacts product performance and safety.

In the automotive industry, the shift towards lightweight materials and complex designs has created a need for advanced welding techniques that can handle diverse materials while maintaining structural integrity. Aerospace manufacturers require high-precision welding solutions to ensure the safety and reliability of aircraft components. The construction sector is seeking more efficient and cost-effective welding methods to improve productivity in large-scale projects. Similarly, the energy sector, including oil and gas, renewable energy, and power generation, demands robust welding solutions capable of withstanding extreme conditions.

The market is also being shaped by the growing emphasis on automation and robotics in manufacturing processes. This trend is driving the demand for gas welding solutions that can be seamlessly integrated with automated systems, offering enhanced precision, consistency, and speed. Additionally, there is a rising interest in eco-friendly welding technologies that reduce emissions and energy consumption, aligning with global sustainability goals.

Data analytics is emerging as a critical component in addressing these market demands. By harnessing the power of data, manufacturers can optimize welding processes, predict maintenance needs, and improve overall quality control. This data-driven approach is particularly valuable in industries where weld quality is crucial, such as in the production of pressure vessels, pipelines, and structural components for buildings and bridges.

The market is also witnessing a surge in demand for portable and versatile gas welding equipment, catering to the needs of on-site welding operations in construction and maintenance sectors. This trend is driven by the increasing number of infrastructure projects and the need for flexible welding solutions that can be deployed in various environments.

As industries continue to push the boundaries of manufacturing capabilities, the demand for advanced gas welding solutions is expected to grow further. This growth is likely to be fueled by ongoing technological advancements, stricter quality standards, and the continuous pursuit of operational efficiency across industries.

In the automotive industry, the shift towards lightweight materials and complex designs has created a need for advanced welding techniques that can handle diverse materials while maintaining structural integrity. Aerospace manufacturers require high-precision welding solutions to ensure the safety and reliability of aircraft components. The construction sector is seeking more efficient and cost-effective welding methods to improve productivity in large-scale projects. Similarly, the energy sector, including oil and gas, renewable energy, and power generation, demands robust welding solutions capable of withstanding extreme conditions.

The market is also being shaped by the growing emphasis on automation and robotics in manufacturing processes. This trend is driving the demand for gas welding solutions that can be seamlessly integrated with automated systems, offering enhanced precision, consistency, and speed. Additionally, there is a rising interest in eco-friendly welding technologies that reduce emissions and energy consumption, aligning with global sustainability goals.

Data analytics is emerging as a critical component in addressing these market demands. By harnessing the power of data, manufacturers can optimize welding processes, predict maintenance needs, and improve overall quality control. This data-driven approach is particularly valuable in industries where weld quality is crucial, such as in the production of pressure vessels, pipelines, and structural components for buildings and bridges.

The market is also witnessing a surge in demand for portable and versatile gas welding equipment, catering to the needs of on-site welding operations in construction and maintenance sectors. This trend is driven by the increasing number of infrastructure projects and the need for flexible welding solutions that can be deployed in various environments.

As industries continue to push the boundaries of manufacturing capabilities, the demand for advanced gas welding solutions is expected to grow further. This growth is likely to be fueled by ongoing technological advancements, stricter quality standards, and the continuous pursuit of operational efficiency across industries.

Current Challenges in Gas Welding Data Analytics

Gas welding data analytics faces several significant challenges that hinder its full potential in improving welding processes. One of the primary obstacles is the lack of standardized data collection methods across the industry. Different welding equipment manufacturers and operators often use proprietary systems, resulting in inconsistent data formats and quality. This heterogeneity makes it difficult to aggregate and compare data from various sources, limiting the scope and effectiveness of analytics.

Another challenge is the sheer volume and complexity of data generated during gas welding processes. Modern welding equipment can produce vast amounts of real-time data on parameters such as temperature, pressure, gas flow rates, and arc stability. Processing and analyzing this high-velocity, high-volume data in real-time requires sophisticated hardware and software infrastructure, which many organizations struggle to implement effectively.

Data quality and reliability present additional hurdles. Welding environments are often harsh, with extreme temperatures, electromagnetic interference, and physical vibrations that can affect sensor accuracy. Ensuring the integrity and accuracy of collected data under these conditions is crucial for meaningful analytics but remains a significant technical challenge.

The integration of legacy systems with modern data analytics platforms poses another obstacle. Many welding operations still rely on older equipment that lacks advanced data collection capabilities. Retrofitting these systems or finding ways to incorporate their limited data into comprehensive analytics frameworks is both technically challenging and potentially cost-prohibitive for many organizations.

Privacy and security concerns also impede the widespread adoption of data analytics in gas welding. Proprietary welding processes and parameters are often considered trade secrets, making companies hesitant to share data or adopt cloud-based analytics solutions. Ensuring data security and compliance with industry regulations while maintaining the benefits of collaborative data analysis remains a delicate balance.

The shortage of skilled personnel who can effectively interpret and act upon welding data analytics results is another significant challenge. The field requires a unique combination of welding expertise and data science skills, which is not commonly found in the workforce. This skills gap limits the ability of many organizations to fully leverage the insights generated by data analytics tools.

Lastly, the dynamic nature of welding processes presents challenges for predictive analytics models. Welding conditions can vary significantly based on factors such as material properties, environmental conditions, and operator skill. Developing robust models that can accurately predict outcomes across this wide range of variables requires continuous refinement and validation, which can be resource-intensive and time-consuming.

Another challenge is the sheer volume and complexity of data generated during gas welding processes. Modern welding equipment can produce vast amounts of real-time data on parameters such as temperature, pressure, gas flow rates, and arc stability. Processing and analyzing this high-velocity, high-volume data in real-time requires sophisticated hardware and software infrastructure, which many organizations struggle to implement effectively.

Data quality and reliability present additional hurdles. Welding environments are often harsh, with extreme temperatures, electromagnetic interference, and physical vibrations that can affect sensor accuracy. Ensuring the integrity and accuracy of collected data under these conditions is crucial for meaningful analytics but remains a significant technical challenge.

The integration of legacy systems with modern data analytics platforms poses another obstacle. Many welding operations still rely on older equipment that lacks advanced data collection capabilities. Retrofitting these systems or finding ways to incorporate their limited data into comprehensive analytics frameworks is both technically challenging and potentially cost-prohibitive for many organizations.

Privacy and security concerns also impede the widespread adoption of data analytics in gas welding. Proprietary welding processes and parameters are often considered trade secrets, making companies hesitant to share data or adopt cloud-based analytics solutions. Ensuring data security and compliance with industry regulations while maintaining the benefits of collaborative data analysis remains a delicate balance.

The shortage of skilled personnel who can effectively interpret and act upon welding data analytics results is another significant challenge. The field requires a unique combination of welding expertise and data science skills, which is not commonly found in the workforce. This skills gap limits the ability of many organizations to fully leverage the insights generated by data analytics tools.

Lastly, the dynamic nature of welding processes presents challenges for predictive analytics models. Welding conditions can vary significantly based on factors such as material properties, environmental conditions, and operator skill. Developing robust models that can accurately predict outcomes across this wide range of variables requires continuous refinement and validation, which can be resource-intensive and time-consuming.

Existing Data Analytics Solutions for Gas Welding

01 Improved welding torch design

Advancements in welding torch design for gas welding, including ergonomic improvements, better heat management, and enhanced gas flow control. These improvements lead to increased efficiency, precision, and user comfort during welding operations.- Improved welding torch design: Advancements in welding torch design for gas welding, including optimized nozzle configurations, ergonomic handles, and improved gas flow control mechanisms. These enhancements contribute to better flame control, increased efficiency, and improved user comfort during welding operations.

- Gas mixture optimization: Development of optimized gas mixtures for specific welding applications, including precise ratios of fuel gases and oxygen. These tailored mixtures enhance flame characteristics, improve heat distribution, and contribute to better weld quality and efficiency in gas welding processes.

- Advanced welding consumables: Introduction of innovative welding consumables, such as improved filler rods and fluxes, specifically designed for gas welding applications. These advanced materials contribute to enhanced weld strength, reduced porosity, and improved overall weld quality.

- Automated gas welding systems: Development of automated and semi-automated gas welding systems, incorporating robotics and computer-controlled mechanisms. These systems improve precision, consistency, and productivity in gas welding operations, particularly for repetitive or complex welding tasks.

- Safety and monitoring enhancements: Implementation of advanced safety features and monitoring systems in gas welding equipment. These improvements include gas leak detection, flame-out protection, and real-time monitoring of welding parameters, enhancing operator safety and overall process control.

02 Gas mixture optimization

Development of optimized gas mixtures for specific welding applications, resulting in improved weld quality, reduced porosity, and enhanced control over the welding process. This includes the use of shielding gases and innovative gas delivery systems.Expand Specific Solutions03 Advanced welding techniques

Introduction of new gas welding techniques and methodologies, such as pulsed gas welding or hybrid processes combining gas welding with other welding methods. These advancements aim to improve weld quality, increase productivity, and expand the range of materials that can be welded effectively.Expand Specific Solutions04 Automation and robotics integration

Integration of automation and robotics in gas welding processes, including computer-controlled systems for precise gas flow regulation, automated torch positioning, and real-time monitoring of welding parameters. These improvements enhance consistency, reduce human error, and increase overall welding efficiency.Expand Specific Solutions05 Safety and environmental enhancements

Development of safety features and environmentally friendly improvements in gas welding equipment and processes. This includes better fume extraction systems, reduced gas consumption, and the use of eco-friendly materials in welding equipment manufacturing.Expand Specific Solutions

Key Players in Gas Welding Analytics Industry

The gas welding improvement sector through data analytics is in a growth phase, with increasing market size driven by Industry 4.0 trends. The technology's maturity is moderate, with established players like Fronius International GmbH and Illinois Tool Works Inc. leading innovation. Emerging companies such as Suxin IoT Technology and Powermig Automacao e Soldagem are introducing advanced solutions, indicating a competitive landscape. Major industrial gas suppliers like Linde GmbH and Air Liquide SA are also key players, leveraging their expertise to enhance welding processes. The market shows potential for further expansion as manufacturers seek to optimize efficiency and quality through data-driven approaches.

Fronius International GmbH

Technical Solution: Fronius has developed an advanced data analytics system for gas welding improvement called WeldCube. This system collects and analyzes real-time welding data from multiple welding systems, providing comprehensive insights into the welding process. WeldCube utilizes machine learning algorithms to optimize welding parameters, predict maintenance needs, and identify quality issues[1]. The system integrates with Fronius' TPS/i power sources, enabling precise control over gas flow rates and arc characteristics. Additionally, Fronius has implemented digital twin technology to simulate and optimize welding processes before physical implementation[2].

Strengths: Comprehensive data collection and analysis, integration with existing Fronius equipment, predictive maintenance capabilities. Weaknesses: May require significant investment in compatible Fronius equipment, potential complexity for smaller operations.

Illinois Tool Works Inc.

Technical Solution: ITW has developed the Miller Insight Centerpoint welding information management system, which leverages data analytics to improve gas welding processes. The system collects real-time data from welding equipment, including gas flow rates, arc stability, and weld quality metrics. Insight Centerpoint uses advanced algorithms to analyze this data, providing actionable insights to optimize welding parameters and reduce waste. The system also incorporates a user-friendly dashboard for easy monitoring and reporting of welding performance[3]. ITW has further enhanced this technology with the integration of artificial intelligence for predictive maintenance and automated parameter adjustment[4].

Strengths: User-friendly interface, comprehensive data collection and analysis, AI-driven predictive capabilities. Weaknesses: May require specific Miller equipment for full functionality, potential learning curve for operators.

Core Innovations in Gas Welding Data Processing

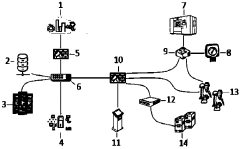

THE SYSTEM THAT PROVIDES DATA ANALYSIS IN THE WELDING PROCESS

PatentInactiveTR201814004A1

Innovation

- A system utilizing sensors and electronic cards with embedded software to collect, analyze, and transmit welding parameters, including current, voltage, and wire speed, and integrate with database management programs for real-time monitoring and quality control, while ensuring secure network connectivity and data integrity through a cell firewall.

Regulatory Compliance in Welding Analytics

In the realm of gas welding improvement through data analytics, regulatory compliance plays a crucial role in ensuring safety, quality, and legal adherence. The welding industry is subject to various regulations and standards set by national and international bodies, which must be carefully considered when implementing data-driven solutions.

One of the primary regulatory bodies in this field is the American Welding Society (AWS), which establishes comprehensive standards for welding processes, including gas welding. These standards cover aspects such as welding procedures, welder qualification, and quality control measures. When integrating data analytics into gas welding processes, it is essential to ensure that the resulting improvements align with AWS guidelines and do not compromise compliance.

Occupational Safety and Health Administration (OSHA) regulations also significantly impact welding operations. OSHA mandates specific safety protocols for welding activities, including proper ventilation, personal protective equipment (PPE), and fire prevention measures. Data analytics solutions must be designed to support and enhance compliance with these safety regulations, potentially by monitoring environmental conditions, tracking PPE usage, or predicting potential hazards.

International standards, such as those set by the International Organization for Standardization (ISO), further complicate the regulatory landscape. ISO 3834, which specifies quality requirements for fusion welding of metallic materials, is particularly relevant. Data analytics implementations must consider how to support and demonstrate compliance with such standards, potentially through automated documentation and quality assurance processes.

Environmental regulations also play a role in welding analytics. Agencies like the Environmental Protection Agency (EPA) in the United States regulate emissions and waste management in industrial processes, including welding. Data-driven solutions can help monitor and optimize gas consumption, reducing emissions and improving environmental compliance.

When developing data analytics systems for gas welding, it is crucial to incorporate features that facilitate regulatory reporting and auditing. This may include automated data logging, real-time compliance monitoring, and the generation of standardized reports that meet regulatory requirements. Such features not only ensure compliance but also streamline the auditing process and reduce the administrative burden on welding operations.

Moreover, as data analytics often involves the collection and processing of sensitive information, compliance with data protection regulations such as the General Data Protection Regulation (GDPR) in the European Union or the California Consumer Privacy Act (CCPA) in the United States must be considered. This includes implementing appropriate data security measures and ensuring proper handling of any personal data that may be collected in the process of welding analytics.

One of the primary regulatory bodies in this field is the American Welding Society (AWS), which establishes comprehensive standards for welding processes, including gas welding. These standards cover aspects such as welding procedures, welder qualification, and quality control measures. When integrating data analytics into gas welding processes, it is essential to ensure that the resulting improvements align with AWS guidelines and do not compromise compliance.

Occupational Safety and Health Administration (OSHA) regulations also significantly impact welding operations. OSHA mandates specific safety protocols for welding activities, including proper ventilation, personal protective equipment (PPE), and fire prevention measures. Data analytics solutions must be designed to support and enhance compliance with these safety regulations, potentially by monitoring environmental conditions, tracking PPE usage, or predicting potential hazards.

International standards, such as those set by the International Organization for Standardization (ISO), further complicate the regulatory landscape. ISO 3834, which specifies quality requirements for fusion welding of metallic materials, is particularly relevant. Data analytics implementations must consider how to support and demonstrate compliance with such standards, potentially through automated documentation and quality assurance processes.

Environmental regulations also play a role in welding analytics. Agencies like the Environmental Protection Agency (EPA) in the United States regulate emissions and waste management in industrial processes, including welding. Data-driven solutions can help monitor and optimize gas consumption, reducing emissions and improving environmental compliance.

When developing data analytics systems for gas welding, it is crucial to incorporate features that facilitate regulatory reporting and auditing. This may include automated data logging, real-time compliance monitoring, and the generation of standardized reports that meet regulatory requirements. Such features not only ensure compliance but also streamline the auditing process and reduce the administrative burden on welding operations.

Moreover, as data analytics often involves the collection and processing of sensitive information, compliance with data protection regulations such as the General Data Protection Regulation (GDPR) in the European Union or the California Consumer Privacy Act (CCPA) in the United States must be considered. This includes implementing appropriate data security measures and ensuring proper handling of any personal data that may be collected in the process of welding analytics.

Environmental Impact of Data-Driven Gas Welding

The implementation of data-driven gas welding techniques has significant implications for environmental sustainability in the manufacturing sector. By leveraging advanced analytics and machine learning algorithms, companies can optimize their welding processes, leading to reduced energy consumption and minimized waste production. This approach not only enhances operational efficiency but also contributes to a smaller carbon footprint.

One of the primary environmental benefits of data-driven gas welding is the reduction in gas consumption. Through real-time monitoring and predictive analytics, welding systems can adjust gas flow rates dynamically, ensuring optimal usage without excess. This precision in gas management can lead to substantial reductions in greenhouse gas emissions associated with the welding process. Furthermore, by minimizing overuse of welding gases, companies can decrease their reliance on non-renewable resources and reduce the environmental impact of gas production and transportation.

The improved accuracy and consistency achieved through data analytics also contribute to a decrease in material waste. By optimizing welding parameters based on historical data and real-time feedback, the occurrence of defects and the need for rework are significantly reduced. This not only conserves raw materials but also minimizes the energy required for additional processing and waste disposal. The reduction in scrap metal and other waste materials translates to less landfill usage and fewer resources expended on recycling processes.

Energy efficiency is another crucial aspect of the environmental impact of data-driven gas welding. Advanced analytics enable the fine-tuning of power settings, reducing overall energy consumption without compromising weld quality. This optimization extends to idle time reduction and improved equipment utilization, further decreasing the energy footprint of welding operations. The cumulative effect of these energy-saving measures can lead to substantial reductions in electricity consumption and associated carbon emissions.

Moreover, the implementation of data-driven techniques in gas welding can contribute to the development of more sustainable manufacturing practices. By providing detailed insights into the welding process, companies can identify opportunities for further environmental improvements, such as the integration of renewable energy sources or the development of more eco-friendly welding consumables. The data collected can also support lifecycle assessments, enabling manufacturers to make informed decisions about material selection and process design with environmental considerations in mind.

In conclusion, the environmental impact of data-driven gas welding is predominantly positive, offering significant potential for reducing resource consumption, minimizing waste, and improving overall sustainability in manufacturing processes. As these technologies continue to evolve and become more widely adopted, their role in promoting environmentally responsible industrial practices is likely to grow, contributing to broader efforts in combating climate change and resource depletion.

One of the primary environmental benefits of data-driven gas welding is the reduction in gas consumption. Through real-time monitoring and predictive analytics, welding systems can adjust gas flow rates dynamically, ensuring optimal usage without excess. This precision in gas management can lead to substantial reductions in greenhouse gas emissions associated with the welding process. Furthermore, by minimizing overuse of welding gases, companies can decrease their reliance on non-renewable resources and reduce the environmental impact of gas production and transportation.

The improved accuracy and consistency achieved through data analytics also contribute to a decrease in material waste. By optimizing welding parameters based on historical data and real-time feedback, the occurrence of defects and the need for rework are significantly reduced. This not only conserves raw materials but also minimizes the energy required for additional processing and waste disposal. The reduction in scrap metal and other waste materials translates to less landfill usage and fewer resources expended on recycling processes.

Energy efficiency is another crucial aspect of the environmental impact of data-driven gas welding. Advanced analytics enable the fine-tuning of power settings, reducing overall energy consumption without compromising weld quality. This optimization extends to idle time reduction and improved equipment utilization, further decreasing the energy footprint of welding operations. The cumulative effect of these energy-saving measures can lead to substantial reductions in electricity consumption and associated carbon emissions.

Moreover, the implementation of data-driven techniques in gas welding can contribute to the development of more sustainable manufacturing practices. By providing detailed insights into the welding process, companies can identify opportunities for further environmental improvements, such as the integration of renewable energy sources or the development of more eco-friendly welding consumables. The data collected can also support lifecycle assessments, enabling manufacturers to make informed decisions about material selection and process design with environmental considerations in mind.

In conclusion, the environmental impact of data-driven gas welding is predominantly positive, offering significant potential for reducing resource consumption, minimizing waste, and improving overall sustainability in manufacturing processes. As these technologies continue to evolve and become more widely adopted, their role in promoting environmentally responsible industrial practices is likely to grow, contributing to broader efforts in combating climate change and resource depletion.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!