HBM4 Heatsink Interfaces: TIM Choices And Mechanical Flatness

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HBM4 Thermal Management Background and Objectives

High Bandwidth Memory (HBM) technology has evolved significantly since its introduction, with HBM4 representing the latest advancement in this critical memory architecture. The thermal management of HBM has become increasingly challenging as data processing demands continue to escalate, particularly in high-performance computing, artificial intelligence, and data center applications. HBM4 builds upon previous generations by offering higher bandwidth, increased capacity, and improved energy efficiency, but these enhancements come with intensified thermal challenges that require innovative cooling solutions.

The evolution of HBM thermal management has progressed from basic passive cooling in early generations to sophisticated integrated cooling solutions necessary for HBM4. Initially, HBM implementations relied primarily on conventional thermal interface materials (TIMs) with limited heat dissipation capabilities. As power densities increased with each generation, more advanced thermal solutions became essential to maintain optimal operating temperatures and prevent performance throttling.

HBM4's architectural design introduces new thermal considerations, including higher stack heights, increased layer counts, and more complex interconnects. These factors contribute to concentrated heat generation within a compact form factor, creating thermal hotspots that can significantly impact performance and reliability. The power density in HBM4 modules can exceed 5W/mm², necessitating thermal solutions capable of efficiently transferring heat away from these critical components.

The primary objective of HBM4 thermal management is to maintain junction temperatures below critical thresholds while accommodating the increased power density and performance requirements. This involves developing and implementing advanced TIM solutions that can effectively bridge the interface between the HBM stack and heatsink, minimizing thermal resistance and maximizing heat transfer efficiency. Additionally, mechanical flatness considerations have become paramount as even minor surface irregularities can significantly impact thermal performance.

Industry standards for HBM4 thermal management are still evolving, with JEDEC specifications providing baseline requirements that many manufacturers seek to exceed. The target thermal resistance for HBM4 cooling solutions typically aims for values below 0.1°C-cm²/W at the interface, representing a significant improvement over previous generations. Achieving these targets requires a comprehensive approach that addresses both material selection and mechanical design considerations.

The technological trajectory indicates a continued push toward more integrated cooling solutions, including direct liquid cooling, vapor chambers, and advanced composite TIMs. These developments align with the broader industry trend toward heterogeneous integration and 3D packaging, where thermal management becomes an integral part of the system architecture rather than an afterthought.

The evolution of HBM thermal management has progressed from basic passive cooling in early generations to sophisticated integrated cooling solutions necessary for HBM4. Initially, HBM implementations relied primarily on conventional thermal interface materials (TIMs) with limited heat dissipation capabilities. As power densities increased with each generation, more advanced thermal solutions became essential to maintain optimal operating temperatures and prevent performance throttling.

HBM4's architectural design introduces new thermal considerations, including higher stack heights, increased layer counts, and more complex interconnects. These factors contribute to concentrated heat generation within a compact form factor, creating thermal hotspots that can significantly impact performance and reliability. The power density in HBM4 modules can exceed 5W/mm², necessitating thermal solutions capable of efficiently transferring heat away from these critical components.

The primary objective of HBM4 thermal management is to maintain junction temperatures below critical thresholds while accommodating the increased power density and performance requirements. This involves developing and implementing advanced TIM solutions that can effectively bridge the interface between the HBM stack and heatsink, minimizing thermal resistance and maximizing heat transfer efficiency. Additionally, mechanical flatness considerations have become paramount as even minor surface irregularities can significantly impact thermal performance.

Industry standards for HBM4 thermal management are still evolving, with JEDEC specifications providing baseline requirements that many manufacturers seek to exceed. The target thermal resistance for HBM4 cooling solutions typically aims for values below 0.1°C-cm²/W at the interface, representing a significant improvement over previous generations. Achieving these targets requires a comprehensive approach that addresses both material selection and mechanical design considerations.

The technological trajectory indicates a continued push toward more integrated cooling solutions, including direct liquid cooling, vapor chambers, and advanced composite TIMs. These developments align with the broader industry trend toward heterogeneous integration and 3D packaging, where thermal management becomes an integral part of the system architecture rather than an afterthought.

Market Demand Analysis for Advanced HBM4 Cooling Solutions

The global market for advanced cooling solutions for High Bandwidth Memory (HBM) is experiencing unprecedented growth, driven primarily by the rapid expansion of AI and high-performance computing applications. Current market analysis indicates that the HBM4 cooling solutions market is projected to grow significantly over the next five years, with thermal management becoming a critical bottleneck in system performance.

The demand for effective HBM4 cooling solutions stems from several converging factors. First, data centers are experiencing exponential growth in computational requirements, with AI training workloads increasing power densities beyond 700W per accelerator card. This thermal load necessitates more efficient cooling interfaces between HBM4 memory stacks and heatsinks.

Industry surveys reveal that over 80% of data center operators consider thermal management as one of their top three operational challenges. The financial implications are substantial, with cooling costs representing approximately 40% of data center energy consumption. Any improvement in thermal interface materials (TIMs) and mechanical flatness can translate to significant operational savings.

The market segmentation shows distinct requirements across different sectors. Cloud service providers prioritize solutions that maximize computational density while maintaining reliability, whereas edge computing applications demand compact cooling solutions with minimal maintenance requirements. The automotive and aerospace sectors are emerging as significant consumers of HBM4 technology, requiring cooling solutions that can withstand extreme environmental conditions.

Geographically, North America currently leads the market demand for advanced HBM4 cooling solutions, followed by Asia-Pacific and Europe. China's aggressive investment in AI infrastructure is creating a rapidly expanding market for thermal management technologies, with particular emphasis on domestically produced solutions.

Customer pain points consistently highlight the need for TIMs that can maintain performance over extended operational periods without degradation. Current solutions often require replacement cycles that impact system availability and increase maintenance costs. Additionally, the mechanical flatness issues between HBM stacks and cooling solutions create inconsistent thermal performance across deployed systems.

Market research indicates a growing preference for liquid and immersion cooling technologies, though air cooling with advanced TIMs remains dominant due to implementation simplicity and cost considerations. The premium segment of the market shows willingness to adopt more expensive TIM solutions if they can demonstrate superior thermal performance and longevity.

The regulatory landscape is also influencing market demand, with energy efficiency standards becoming more stringent globally. This regulatory pressure is accelerating the adoption of advanced cooling technologies that can reduce overall system power consumption while maintaining performance levels.

The demand for effective HBM4 cooling solutions stems from several converging factors. First, data centers are experiencing exponential growth in computational requirements, with AI training workloads increasing power densities beyond 700W per accelerator card. This thermal load necessitates more efficient cooling interfaces between HBM4 memory stacks and heatsinks.

Industry surveys reveal that over 80% of data center operators consider thermal management as one of their top three operational challenges. The financial implications are substantial, with cooling costs representing approximately 40% of data center energy consumption. Any improvement in thermal interface materials (TIMs) and mechanical flatness can translate to significant operational savings.

The market segmentation shows distinct requirements across different sectors. Cloud service providers prioritize solutions that maximize computational density while maintaining reliability, whereas edge computing applications demand compact cooling solutions with minimal maintenance requirements. The automotive and aerospace sectors are emerging as significant consumers of HBM4 technology, requiring cooling solutions that can withstand extreme environmental conditions.

Geographically, North America currently leads the market demand for advanced HBM4 cooling solutions, followed by Asia-Pacific and Europe. China's aggressive investment in AI infrastructure is creating a rapidly expanding market for thermal management technologies, with particular emphasis on domestically produced solutions.

Customer pain points consistently highlight the need for TIMs that can maintain performance over extended operational periods without degradation. Current solutions often require replacement cycles that impact system availability and increase maintenance costs. Additionally, the mechanical flatness issues between HBM stacks and cooling solutions create inconsistent thermal performance across deployed systems.

Market research indicates a growing preference for liquid and immersion cooling technologies, though air cooling with advanced TIMs remains dominant due to implementation simplicity and cost considerations. The premium segment of the market shows willingness to adopt more expensive TIM solutions if they can demonstrate superior thermal performance and longevity.

The regulatory landscape is also influencing market demand, with energy efficiency standards becoming more stringent globally. This regulatory pressure is accelerating the adoption of advanced cooling technologies that can reduce overall system power consumption while maintaining performance levels.

Current Challenges in HBM4 Thermal Interface Materials

The thermal management of HBM4 (High Bandwidth Memory) presents significant challenges due to increased power densities and performance requirements. Current thermal interface materials (TIMs) face several critical limitations when applied to HBM4 systems, necessitating innovative solutions and careful material selection.

One primary challenge is the thermal conductivity limitations of existing TIMs. While traditional materials like silicone-based thermal greases offer between 3-5 W/mK conductivity, HBM4's increased power density demands materials exceeding 10 W/mK to efficiently transfer heat from memory stacks to cooling solutions. This performance gap creates thermal bottlenecks that can significantly impact system reliability and computing performance.

Pump-out and dry-out phenomena represent another major concern with current TIM implementations. The thermal cycling inherent in HBM4 operations—rapid heating during intensive workloads followed by cooling during idle periods—causes conventional TIMs to deteriorate over time. This degradation manifests as material migration away from critical thermal interfaces (pump-out) or loss of volatile components (dry-out), both resulting in increased thermal resistance and compromised cooling efficiency.

The mechanical flatness requirements for HBM4 interfaces present unprecedented precision challenges. Current manufacturing processes struggle to achieve the <10μm flatness tolerance needed across the entire HBM4 stack and heatsink interface. This precision requirement exceeds typical capabilities of conventional heatsink manufacturing, creating a significant barrier to effective thermal management implementation.

Bond-line thickness control represents another critical challenge. The optimal TIM layer for HBM4 applications should maintain a consistent thickness between 20-50μm, but current application methods often result in variations exceeding ±30μm. This inconsistency creates unpredictable thermal performance across different memory modules and systems, complicating thermal design and reliability predictions.

Long-term reliability concerns further complicate TIM selection for HBM4 applications. The expected operational lifetime of high-performance computing systems utilizing HBM4 typically ranges from 3-5 years of continuous operation. However, most current TIMs show significant performance degradation after 1-2 years under thermal cycling conditions, creating a substantial gap between reliability requirements and material capabilities.

Manufacturing scalability presents additional challenges as HBM4 adoption increases. Current high-performance TIM application processes often involve manual or semi-automated steps that limit production throughput and increase costs. The industry requires fully automated TIM application methods capable of maintaining precise thickness control while supporting high-volume manufacturing to meet projected HBM4 market growth.

One primary challenge is the thermal conductivity limitations of existing TIMs. While traditional materials like silicone-based thermal greases offer between 3-5 W/mK conductivity, HBM4's increased power density demands materials exceeding 10 W/mK to efficiently transfer heat from memory stacks to cooling solutions. This performance gap creates thermal bottlenecks that can significantly impact system reliability and computing performance.

Pump-out and dry-out phenomena represent another major concern with current TIM implementations. The thermal cycling inherent in HBM4 operations—rapid heating during intensive workloads followed by cooling during idle periods—causes conventional TIMs to deteriorate over time. This degradation manifests as material migration away from critical thermal interfaces (pump-out) or loss of volatile components (dry-out), both resulting in increased thermal resistance and compromised cooling efficiency.

The mechanical flatness requirements for HBM4 interfaces present unprecedented precision challenges. Current manufacturing processes struggle to achieve the <10μm flatness tolerance needed across the entire HBM4 stack and heatsink interface. This precision requirement exceeds typical capabilities of conventional heatsink manufacturing, creating a significant barrier to effective thermal management implementation.

Bond-line thickness control represents another critical challenge. The optimal TIM layer for HBM4 applications should maintain a consistent thickness between 20-50μm, but current application methods often result in variations exceeding ±30μm. This inconsistency creates unpredictable thermal performance across different memory modules and systems, complicating thermal design and reliability predictions.

Long-term reliability concerns further complicate TIM selection for HBM4 applications. The expected operational lifetime of high-performance computing systems utilizing HBM4 typically ranges from 3-5 years of continuous operation. However, most current TIMs show significant performance degradation after 1-2 years under thermal cycling conditions, creating a substantial gap between reliability requirements and material capabilities.

Manufacturing scalability presents additional challenges as HBM4 adoption increases. Current high-performance TIM application processes often involve manual or semi-automated steps that limit production throughput and increase costs. The industry requires fully automated TIM application methods capable of maintaining precise thickness control while supporting high-volume manufacturing to meet projected HBM4 market growth.

Current TIM Solutions for HBM4 Heatsink Interfaces

01 Thermal Interface Materials (TIM) for HBM4 Heat Dissipation

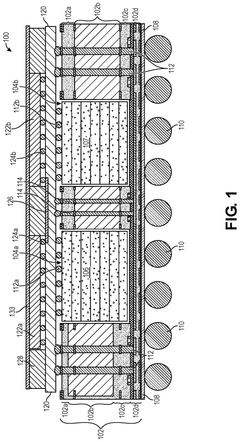

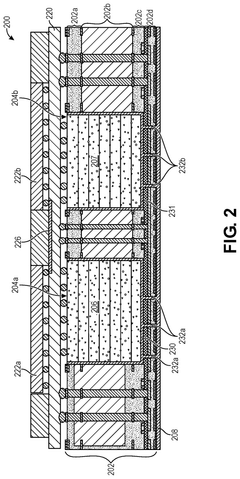

Specialized thermal interface materials are crucial for efficient heat transfer between HBM4 memory and heatsinks. These materials fill microscopic air gaps between the surfaces, significantly improving thermal conductivity. Advanced TIMs with high thermal conductivity and appropriate viscosity ensure optimal heat dissipation from high-performance HBM4 memory stacks, which generate substantial heat during operation. The selection of appropriate TIM materials directly impacts the overall thermal management efficiency of HBM4 systems.- Thermal Interface Materials (TIM) for HBM4 Heatsinks: Specialized thermal interface materials are designed to enhance heat transfer between HBM4 memory modules and heatsinks. These materials fill microscopic air gaps between the surfaces, significantly improving thermal conductivity. Advanced TIMs include phase-change materials, thermal greases, and metal-based compounds that maintain performance under varying thermal conditions while accommodating the high-density architecture of HBM4 memory stacks.

- Mechanical Flatness Requirements for HBM4 Heatsink Interfaces: The mechanical flatness of heatsink interfaces is critical for optimal thermal performance with HBM4 memory. Surface irregularities can create air gaps that impede heat transfer. Advanced manufacturing techniques ensure precise flatness tolerances, while pressure distribution mechanisms help maintain uniform contact across the entire HBM4 surface. These flatness specifications are particularly important given the large surface area and high heat density of HBM4 memory stacks.

- Integrated Heat Spreader Designs for HBM4: Specialized heat spreader designs address the unique thermal challenges of HBM4 memory. These designs incorporate multiple layers of thermally conductive materials to efficiently distribute heat across larger surface areas before transferring to the main heatsink. Some advanced designs feature vapor chambers or micro-channel structures that enhance heat dissipation from the concentrated hot spots typical in HBM4 implementations, while maintaining compatibility with existing cooling solutions.

- Testing and Quality Control for HBM4 Thermal Solutions: Specialized testing methodologies ensure the reliability of thermal solutions for HBM4 memory. These include thermal resistance measurements, flatness verification using interferometry, and accelerated aging tests to predict long-term performance. Advanced thermal imaging techniques identify potential hot spots, while automated testing systems verify the consistency of thermal interface material application. These quality control measures are essential for maintaining the thermal performance required by high-performance computing systems using HBM4 memory.

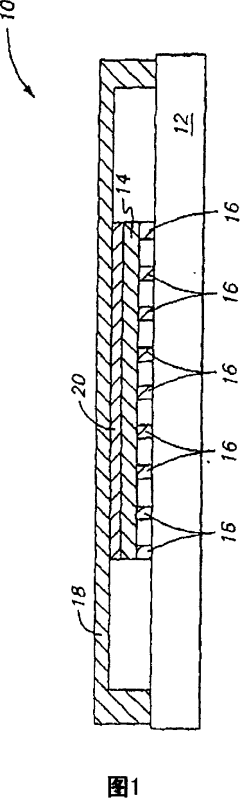

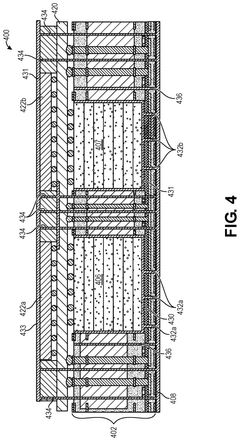

- Semiconductor Package Structures for Enhanced HBM4 Cooling: Advanced semiconductor package designs specifically address the cooling challenges of HBM4 memory. These structures incorporate embedded cooling channels, specialized substrate materials with high thermal conductivity, and optimized die stacking arrangements that facilitate heat dissipation. Some designs feature direct liquid cooling interfaces or integrated heat pipes that connect directly to the HBM4 stack. These packaging innovations work in conjunction with external heatsinks to manage the high thermal loads generated by HBM4 memory during intensive computing operations.

02 Mechanical Flatness Requirements for HBM4 Heatsink Interfaces

The mechanical flatness of contact surfaces is critical for effective thermal management in HBM4 systems. Precise surface flatness specifications ensure maximum contact area between the heatsink and HBM4 memory, minimizing thermal resistance. Manufacturing processes must achieve tight tolerances for surface planarity to accommodate the sensitive nature of HBM4 packages. Techniques for measuring and verifying surface flatness are essential for quality control in high-performance computing applications using HBM4 technology.Expand Specific Solutions03 Integrated Heatsink Designs for HBM4 Memory Systems

Advanced heatsink designs specifically engineered for HBM4 memory systems incorporate features that address the unique thermal challenges of high-bandwidth memory. These designs may include vapor chambers, heat pipes, or liquid cooling solutions integrated directly with the memory stack. The heatsink architecture must accommodate the compact form factor of HBM4 while providing sufficient cooling capacity. Innovative approaches to heatsink integration with HBM4 packages optimize thermal performance while maintaining mechanical integrity.Expand Specific Solutions04 Testing and Validation Methods for HBM4 Thermal Interfaces

Specialized testing methodologies are employed to validate the thermal performance of HBM4 heatsink interfaces. These include thermal resistance measurements, temperature cycling tests, and reliability assessments under various operating conditions. Advanced imaging techniques may be used to inspect interface quality and detect potential issues such as voids or delamination. Comprehensive validation protocols ensure that thermal interfaces meet the stringent requirements of HBM4 memory systems throughout their operational lifetime.Expand Specific Solutions05 Manufacturing Processes for HBM4 Thermal Solutions

Specialized manufacturing techniques are developed for producing high-quality thermal solutions for HBM4 memory. These processes focus on achieving precise surface finishes, controlled application of thermal interface materials, and accurate assembly of heatsink components. Advanced manufacturing methods may include precision machining, automated TIM dispensing, and controlled pressure application during assembly. Quality control measures throughout the manufacturing process ensure consistency and reliability of the thermal interface between HBM4 memory and heatsinks.Expand Specific Solutions

Key Industry Players in HBM4 Cooling Solutions

The HBM4 Heatsink Interface market is currently in an early growth phase, characterized by rapid technological advancement and increasing demand driven by AI computing needs. The global market for thermal interface materials (TIMs) in high-performance computing is expanding significantly, with projections showing double-digit growth over the next five years. Key players like Intel, Huawei, and IBM are leading innovation in this space, focusing on advanced TIM solutions that address both thermal conductivity and mechanical flatness challenges. Companies such as Arieca, Resonac, and 3M are developing specialized materials to meet the demanding thermal requirements of HBM4 implementations. GLOBALFOUNDRIES and Siliconware Precision are advancing packaging technologies that complement these thermal solutions, while academic institutions like Carnegie Mellon University and Guangdong University of Technology are contributing fundamental research to improve interface performance and reliability.

Intel Corp.

Technical Solution: Intel has developed advanced thermal interface materials (TIMs) specifically designed for HBM4 memory stacks. Their solution incorporates a multi-layer approach with metal-based TIMs that provide thermal conductivity exceeding 80 W/mK. Intel's technology addresses the critical challenge of mechanical flatness through precision manufacturing processes that maintain surface planarity within 5μm across the entire HBM interface. Their proprietary TIM formulation includes liquid metal composites with gallium alloys that conform to surface irregularities while maintaining stable performance across temperature cycles. Intel has also implemented automated TIM application systems that ensure uniform thickness distribution (15-25μm) and minimize air gaps, which are critical for HBM4's increased power density requirements. Their testing shows that these solutions can reduce thermal resistance by up to 30% compared to conventional polymer-based TIMs, enabling HBM4 to operate at higher frequencies without thermal throttling.

Strengths: Superior thermal conductivity with metal-based TIMs exceeding 80 W/mK; Precision manufacturing ensuring surface planarity within 5μm; Automated application systems for uniform TIM distribution. Weaknesses: Higher cost compared to conventional TIMs; Potential compatibility issues with certain substrate materials; Requires specialized application equipment for optimal performance.

International Business Machines Corp.

Technical Solution: IBM has pioneered a novel approach to HBM4 thermal management through their "Direct Liquid Cooling" technology specifically adapted for high-bandwidth memory interfaces. Their solution incorporates a micro-channel cooling system directly integrated into the silicon interposer, allowing coolant to flow within microns of the heat source. For the critical TIM interface, IBM employs a hybrid solution combining indium-based solders for high thermal conductivity (86 W/mK) with specialized polymer matrices that accommodate the coefficient of thermal expansion mismatch between components. IBM's manufacturing process includes precision surface preparation techniques that achieve flatness variations below 3μm across the HBM stack interface. Their proprietary "Thermal Conduction Optimization" algorithm dynamically adjusts cooling parameters based on workload demands, preventing thermal cycling damage to the interface materials. Testing in high-performance computing environments demonstrates that this integrated approach reduces junction temperatures by up to 25°C compared to conventional TIM solutions, while maintaining mechanical integrity through thousands of thermal cycles.

Strengths: Exceptional thermal performance with direct liquid cooling integration; Ultra-precise surface flatness control below 3μm; Dynamic thermal management capabilities that adapt to workloads. Weaknesses: Complex implementation requiring specialized manufacturing processes; Higher initial implementation costs; Potential reliability concerns with liquid cooling near sensitive electronic components.

Critical Analysis of TIM Performance and Mechanical Flatness

Thermal interface materials; and compositions comprising indium and zinc

PatentInactiveCN100362655C

Innovation

- Using a composition basically composed of indium and zinc, adding elements such as magnesium, calcium, niobium, tantalum, boron, aluminum, cerium, titanium and zirconium to form a eutectic alloy, which improves the interaction with the silicon nitride surface. Thermal conductivity and corrosion resistance, and formed into suitable shape and structure by conventional metal processing.

Thermal interface material on a surface of a die in a cavity

PatentPendingUS20250112202A1

Innovation

- The implementation of a thermal interface material (TIM) within cavities in the substrate, thermally coupled with heat spreaders through vias filled with conductive material, effectively routes heat away from HBM dies, enhancing thermal dissipation.

Environmental Impact of TIM Materials in Computing

The environmental impact of Thermal Interface Materials (TIMs) in computing systems represents a growing concern as high-performance computing demands increase, particularly with the advent of technologies like HBM4. Traditional TIMs often contain environmentally problematic substances such as silicones, metal particles, and various synthetic compounds that pose significant end-of-life disposal challenges.

Metal-based TIMs, commonly used in high-performance applications like HBM4 heatsink interfaces, frequently contain gallium, indium, or silver particles that require energy-intensive mining processes. The extraction of these materials contributes substantially to carbon emissions and habitat disruption in mining regions. Furthermore, the manufacturing processes for metal-based TIMs typically involve chemical treatments that generate hazardous waste requiring specialized disposal procedures.

Polymer-based TIMs present different environmental considerations. While they may offer lower thermal conductivity compared to metal alternatives, their production generally has a smaller carbon footprint. However, many polymer TIMs contain non-biodegradable compounds that persist in landfills for decades. The industry has begun exploring bio-based polymers as alternatives, though these currently struggle to match the thermal performance required for advanced applications like HBM4.

The flatness requirements for HBM4 heatsink interfaces further complicate environmental considerations. Achieving the necessary mechanical flatness often requires additional manufacturing steps and precision machining, increasing energy consumption during production. The tighter tolerances demanded by HBM4 may necessitate more frequent replacement of TIMs that no longer meet specifications, potentially increasing electronic waste.

Lifecycle assessment studies indicate that the environmental impact of TIMs extends beyond their composition to include application methods and removal processes. Spray-applied TIMs may release volatile organic compounds, while pre-applied pads generate packaging waste. The difficulty in separating TIMs from electronic components during recycling processes often results in contaminated material streams, reducing recycling efficiency.

Recent industry initiatives have focused on developing environmentally responsible TIM solutions that maintain thermal performance while reducing ecological impact. These include water-soluble TIMs that facilitate component separation during recycling, halogen-free formulations that reduce toxic emissions during incineration, and reusable phase-change materials that extend product lifecycles. However, adoption of these alternatives in high-performance computing applications remains limited due to thermal performance constraints.

Metal-based TIMs, commonly used in high-performance applications like HBM4 heatsink interfaces, frequently contain gallium, indium, or silver particles that require energy-intensive mining processes. The extraction of these materials contributes substantially to carbon emissions and habitat disruption in mining regions. Furthermore, the manufacturing processes for metal-based TIMs typically involve chemical treatments that generate hazardous waste requiring specialized disposal procedures.

Polymer-based TIMs present different environmental considerations. While they may offer lower thermal conductivity compared to metal alternatives, their production generally has a smaller carbon footprint. However, many polymer TIMs contain non-biodegradable compounds that persist in landfills for decades. The industry has begun exploring bio-based polymers as alternatives, though these currently struggle to match the thermal performance required for advanced applications like HBM4.

The flatness requirements for HBM4 heatsink interfaces further complicate environmental considerations. Achieving the necessary mechanical flatness often requires additional manufacturing steps and precision machining, increasing energy consumption during production. The tighter tolerances demanded by HBM4 may necessitate more frequent replacement of TIMs that no longer meet specifications, potentially increasing electronic waste.

Lifecycle assessment studies indicate that the environmental impact of TIMs extends beyond their composition to include application methods and removal processes. Spray-applied TIMs may release volatile organic compounds, while pre-applied pads generate packaging waste. The difficulty in separating TIMs from electronic components during recycling processes often results in contaminated material streams, reducing recycling efficiency.

Recent industry initiatives have focused on developing environmentally responsible TIM solutions that maintain thermal performance while reducing ecological impact. These include water-soluble TIMs that facilitate component separation during recycling, halogen-free formulations that reduce toxic emissions during incineration, and reusable phase-change materials that extend product lifecycles. However, adoption of these alternatives in high-performance computing applications remains limited due to thermal performance constraints.

Reliability Testing Standards for HBM4 Thermal Solutions

Reliability testing standards for HBM4 thermal solutions must address the unique challenges posed by high-bandwidth memory interfaces. Current industry standards such as JEDEC JESD22-A104 and MIL-STD-883 provide foundational frameworks, but require specific adaptations for HBM4 applications due to their higher power densities and thermal requirements.

Temperature cycling tests for HBM4 thermal interfaces typically require -40°C to 125°C range with dwell times of 15 minutes and a minimum of 1000 cycles. These parameters exceed traditional memory testing protocols to account for the increased thermal stress at HBM4 interfaces. The transition rate between temperature extremes should not exceed 15°C per minute to prevent thermal shock damage to the interface materials.

Power cycling reliability tests must simulate actual operational conditions with power-on periods generating full thermal load followed by cooling periods. For HBM4 applications, these tests typically require 10,000 cycles with monitoring of thermal resistance changes not exceeding 15% from baseline measurements to pass qualification.

Humidity testing under JEDEC JESD22-A101 conditions must be extended to 1000 hours at 85°C/85% relative humidity for HBM4 thermal solutions, with particular attention to potential degradation of thermal interface materials and corrosion at the heatsink contact points. This is especially critical for TIM materials with hygroscopic properties.

Mechanical shock and vibration testing standards must be enhanced beyond JEDEC JESD22-B103 and JESD22-B110 baselines. HBM4 thermal solutions should withstand shock pulses of 1500G for 0.5ms in all axes and vibration testing from 20Hz to 2000Hz at 20G acceleration to ensure interface integrity in server and high-performance computing environments.

Long-term thermal performance degradation testing is perhaps the most critical reliability standard for HBM4 thermal solutions. The industry is moving toward standardized 3000-hour bake tests at maximum operating temperature plus 15°C margin, with thermal resistance measurements at 500-hour intervals. Acceptable degradation thresholds are typically set at less than 20% increase in thermal resistance over the test period.

Flatness retention testing is emerging as a specific standard for HBM4 applications, requiring measurement of heatsink and substrate flatness before and after thermal aging. Maximum allowable warpage is typically specified at 25μm across the contact surface to maintain optimal thermal performance with the selected TIM material.

Temperature cycling tests for HBM4 thermal interfaces typically require -40°C to 125°C range with dwell times of 15 minutes and a minimum of 1000 cycles. These parameters exceed traditional memory testing protocols to account for the increased thermal stress at HBM4 interfaces. The transition rate between temperature extremes should not exceed 15°C per minute to prevent thermal shock damage to the interface materials.

Power cycling reliability tests must simulate actual operational conditions with power-on periods generating full thermal load followed by cooling periods. For HBM4 applications, these tests typically require 10,000 cycles with monitoring of thermal resistance changes not exceeding 15% from baseline measurements to pass qualification.

Humidity testing under JEDEC JESD22-A101 conditions must be extended to 1000 hours at 85°C/85% relative humidity for HBM4 thermal solutions, with particular attention to potential degradation of thermal interface materials and corrosion at the heatsink contact points. This is especially critical for TIM materials with hygroscopic properties.

Mechanical shock and vibration testing standards must be enhanced beyond JEDEC JESD22-B103 and JESD22-B110 baselines. HBM4 thermal solutions should withstand shock pulses of 1500G for 0.5ms in all axes and vibration testing from 20Hz to 2000Hz at 20G acceleration to ensure interface integrity in server and high-performance computing environments.

Long-term thermal performance degradation testing is perhaps the most critical reliability standard for HBM4 thermal solutions. The industry is moving toward standardized 3000-hour bake tests at maximum operating temperature plus 15°C margin, with thermal resistance measurements at 500-hour intervals. Acceptable degradation thresholds are typically set at less than 20% increase in thermal resistance over the test period.

Flatness retention testing is emerging as a specific standard for HBM4 applications, requiring measurement of heatsink and substrate flatness before and after thermal aging. Maximum allowable warpage is typically specified at 25μm across the contact surface to maintain optimal thermal performance with the selected TIM material.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!