HBM4 Thermal Interface Reliability: TIM Fatigue And Aging Effects

SEP 12, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HBM4 Thermal Management Background and Objectives

High Bandwidth Memory (HBM) technology has evolved significantly since its introduction, with HBM4 representing the latest advancement in this critical computing component. The thermal management challenges associated with HBM4 have become increasingly complex due to higher power densities, reduced form factors, and more stringent reliability requirements. Historically, HBM technology has progressed from HBM1 through HBM3E, each generation increasing memory bandwidth while simultaneously generating more heat in confined spaces.

The evolution of Thermal Interface Materials (TIMs) has paralleled HBM development, transitioning from simple thermal greases to advanced composite materials designed specifically for high-performance computing applications. These materials serve as critical components in the thermal management stack, facilitating heat transfer from the HBM to cooling solutions. However, the reliability of these interfaces over time has emerged as a significant concern for system designers and manufacturers.

Current industry trends indicate a growing focus on understanding the long-term behavior of TIMs under various operational conditions. The fatigue and aging effects of these materials directly impact the thermal performance and reliability of HBM4 implementations, potentially leading to premature system failures or performance degradation. This concern has been amplified by the increasing deployment of HBM in mission-critical applications such as AI accelerators, high-performance computing systems, and advanced networking equipment.

The primary technical objective of this research is to comprehensively analyze the mechanisms of TIM fatigue and aging in HBM4 applications. This includes investigating how thermal cycling, power fluctuations, and environmental factors contribute to material degradation over time. Additionally, we aim to establish standardized testing methodologies that can accurately predict TIM reliability throughout the expected product lifecycle.

Another key objective is to explore innovative TIM solutions that can maintain thermal performance despite aging effects. This includes evaluating emerging materials such as phase-change metals, carbon-based composites, and novel polymer formulations that promise enhanced durability under extreme thermal conditions. The development of predictive models for TIM behavior represents another critical goal, enabling designers to simulate long-term performance and implement appropriate mitigation strategies.

From a market perspective, this research seeks to address the growing demand for HBM4 solutions with extended operational lifespans, particularly in data center and enterprise computing environments where system downtime carries significant financial implications. By enhancing our understanding of TIM reliability factors, we can contribute to the development of more robust thermal management approaches that support the continued advancement of high-performance memory technologies.

The evolution of Thermal Interface Materials (TIMs) has paralleled HBM development, transitioning from simple thermal greases to advanced composite materials designed specifically for high-performance computing applications. These materials serve as critical components in the thermal management stack, facilitating heat transfer from the HBM to cooling solutions. However, the reliability of these interfaces over time has emerged as a significant concern for system designers and manufacturers.

Current industry trends indicate a growing focus on understanding the long-term behavior of TIMs under various operational conditions. The fatigue and aging effects of these materials directly impact the thermal performance and reliability of HBM4 implementations, potentially leading to premature system failures or performance degradation. This concern has been amplified by the increasing deployment of HBM in mission-critical applications such as AI accelerators, high-performance computing systems, and advanced networking equipment.

The primary technical objective of this research is to comprehensively analyze the mechanisms of TIM fatigue and aging in HBM4 applications. This includes investigating how thermal cycling, power fluctuations, and environmental factors contribute to material degradation over time. Additionally, we aim to establish standardized testing methodologies that can accurately predict TIM reliability throughout the expected product lifecycle.

Another key objective is to explore innovative TIM solutions that can maintain thermal performance despite aging effects. This includes evaluating emerging materials such as phase-change metals, carbon-based composites, and novel polymer formulations that promise enhanced durability under extreme thermal conditions. The development of predictive models for TIM behavior represents another critical goal, enabling designers to simulate long-term performance and implement appropriate mitigation strategies.

From a market perspective, this research seeks to address the growing demand for HBM4 solutions with extended operational lifespans, particularly in data center and enterprise computing environments where system downtime carries significant financial implications. By enhancing our understanding of TIM reliability factors, we can contribute to the development of more robust thermal management approaches that support the continued advancement of high-performance memory technologies.

Market Demand Analysis for Advanced Memory Cooling Solutions

The demand for advanced memory cooling solutions has witnessed unprecedented growth, driven primarily by the rapid evolution of High Bandwidth Memory (HBM) technologies. As data centers and high-performance computing applications continue to expand, the market for thermal management solutions specifically designed for HBM4 has become increasingly critical. Current market analysis indicates that the global thermal interface materials market is projected to grow at a compound annual growth rate of 8.2% through 2028, with the segment dedicated to advanced memory cooling representing a significant portion of this expansion.

The escalating power densities in modern computing architectures have created substantial thermal challenges, particularly for HBM4 implementations where heat dissipation requirements have increased by approximately 30% compared to previous generations. This has directly translated into market demand for more reliable and efficient Thermal Interface Materials (TIMs) that can maintain performance over extended operational lifetimes despite thermal cycling and aging effects.

Industry surveys reveal that data center operators and high-performance computing providers rank thermal reliability as the third most important factor in their procurement decisions, following only performance and energy efficiency. This prioritization stems from the substantial financial implications of thermal-related failures, with unplanned downtime costs averaging $9,000 per minute for enterprise data centers.

The automotive and aerospace sectors are emerging as significant new market segments for advanced memory cooling solutions. As autonomous driving systems and advanced avionics incorporate more sophisticated computing capabilities, the demand for reliable HBM4 cooling solutions that can withstand extreme environmental conditions and operational vibrations has grown substantially. Market research indicates that these sectors are willing to pay premium prices for thermal solutions that demonstrate superior reliability metrics and extended operational lifetimes.

Geographically, North America and Asia-Pacific regions dominate the market demand, collectively accounting for over 70% of global consumption. The Asia-Pacific region, particularly China, South Korea, and Taiwan, shows the highest growth rate due to the concentration of semiconductor manufacturing facilities and increasing investments in artificial intelligence infrastructure.

Consumer expectations are evolving toward solutions that address the specific challenges of TIM fatigue and aging effects. Market surveys indicate that 78% of enterprise customers are willing to invest in premium thermal solutions if they can demonstrate a 40% improvement in long-term reliability compared to standard offerings. This represents a significant shift from previous purchasing patterns that prioritized initial performance over lifecycle considerations.

The market is also witnessing increased demand for environmentally sustainable cooling solutions, with 65% of enterprise customers expressing preference for TIMs with reduced environmental impact. This trend is particularly pronounced in European markets where regulatory frameworks increasingly favor sustainable technologies.

The escalating power densities in modern computing architectures have created substantial thermal challenges, particularly for HBM4 implementations where heat dissipation requirements have increased by approximately 30% compared to previous generations. This has directly translated into market demand for more reliable and efficient Thermal Interface Materials (TIMs) that can maintain performance over extended operational lifetimes despite thermal cycling and aging effects.

Industry surveys reveal that data center operators and high-performance computing providers rank thermal reliability as the third most important factor in their procurement decisions, following only performance and energy efficiency. This prioritization stems from the substantial financial implications of thermal-related failures, with unplanned downtime costs averaging $9,000 per minute for enterprise data centers.

The automotive and aerospace sectors are emerging as significant new market segments for advanced memory cooling solutions. As autonomous driving systems and advanced avionics incorporate more sophisticated computing capabilities, the demand for reliable HBM4 cooling solutions that can withstand extreme environmental conditions and operational vibrations has grown substantially. Market research indicates that these sectors are willing to pay premium prices for thermal solutions that demonstrate superior reliability metrics and extended operational lifetimes.

Geographically, North America and Asia-Pacific regions dominate the market demand, collectively accounting for over 70% of global consumption. The Asia-Pacific region, particularly China, South Korea, and Taiwan, shows the highest growth rate due to the concentration of semiconductor manufacturing facilities and increasing investments in artificial intelligence infrastructure.

Consumer expectations are evolving toward solutions that address the specific challenges of TIM fatigue and aging effects. Market surveys indicate that 78% of enterprise customers are willing to invest in premium thermal solutions if they can demonstrate a 40% improvement in long-term reliability compared to standard offerings. This represents a significant shift from previous purchasing patterns that prioritized initial performance over lifecycle considerations.

The market is also witnessing increased demand for environmentally sustainable cooling solutions, with 65% of enterprise customers expressing preference for TIMs with reduced environmental impact. This trend is particularly pronounced in European markets where regulatory frameworks increasingly favor sustainable technologies.

TIM Reliability Challenges in High-Performance Computing

Thermal Interface Materials (TIMs) play a critical role in high-performance computing systems, particularly in advanced memory technologies like HBM4. As computing demands increase exponentially, the thermal management challenges have become more pronounced, with TIM reliability emerging as a significant concern for system stability and longevity.

The high-density packaging of HBM4 creates unprecedented thermal challenges, with heat fluxes exceeding 500 W/cm² in localized hotspots. This thermal stress directly impacts the TIM materials positioned between the memory dies and heat spreaders, subjecting them to extreme operating conditions that accelerate degradation mechanisms.

TIM fatigue represents one of the most pressing reliability issues in high-performance computing environments. The continuous thermal cycling that occurs during normal operation—where systems rapidly heat during computational loads and cool during idle periods—creates mechanical stress at the interface. This cyclic stress leads to pump-out effects, where the TIM material gradually migrates away from critical thermal junctions, creating voids that significantly reduce thermal conductivity.

Aging effects compound these reliability challenges, as TIMs experience property degradation over time even under constant temperature conditions. Chemical changes within the material matrix, including polymer cross-linking, filler settling, and interfacial delamination, progressively reduce thermal performance. Studies have shown that some TIM materials can lose up to 30% of their thermal conductivity within the first year of operation in high-temperature environments.

The reliability issues are further exacerbated by the three-dimensional stacking architecture of HBM4, which creates complex thermal gradients across multiple die layers. These non-uniform temperature distributions induce differential expansion rates that place additional mechanical stress on the TIM materials, accelerating fatigue mechanisms and creating reliability concerns that weren't present in previous memory generations.

Moisture absorption presents another significant challenge, particularly in data center environments with variable humidity levels. TIM materials can absorb atmospheric moisture over time, leading to changes in thermal conductivity and potentially causing corrosion at the interface with metal heat spreaders. This moisture-induced degradation can occur gradually and often remains undetected until thermal performance has significantly deteriorated.

The industry currently lacks standardized accelerated testing methodologies that accurately predict TIM reliability in HBM4 applications. Traditional thermal cycling tests often fail to capture the complex interplay between thermal, mechanical, and chemical degradation mechanisms that occur in actual operating environments, making it difficult to validate new TIM solutions for long-term reliability.

The high-density packaging of HBM4 creates unprecedented thermal challenges, with heat fluxes exceeding 500 W/cm² in localized hotspots. This thermal stress directly impacts the TIM materials positioned between the memory dies and heat spreaders, subjecting them to extreme operating conditions that accelerate degradation mechanisms.

TIM fatigue represents one of the most pressing reliability issues in high-performance computing environments. The continuous thermal cycling that occurs during normal operation—where systems rapidly heat during computational loads and cool during idle periods—creates mechanical stress at the interface. This cyclic stress leads to pump-out effects, where the TIM material gradually migrates away from critical thermal junctions, creating voids that significantly reduce thermal conductivity.

Aging effects compound these reliability challenges, as TIMs experience property degradation over time even under constant temperature conditions. Chemical changes within the material matrix, including polymer cross-linking, filler settling, and interfacial delamination, progressively reduce thermal performance. Studies have shown that some TIM materials can lose up to 30% of their thermal conductivity within the first year of operation in high-temperature environments.

The reliability issues are further exacerbated by the three-dimensional stacking architecture of HBM4, which creates complex thermal gradients across multiple die layers. These non-uniform temperature distributions induce differential expansion rates that place additional mechanical stress on the TIM materials, accelerating fatigue mechanisms and creating reliability concerns that weren't present in previous memory generations.

Moisture absorption presents another significant challenge, particularly in data center environments with variable humidity levels. TIM materials can absorb atmospheric moisture over time, leading to changes in thermal conductivity and potentially causing corrosion at the interface with metal heat spreaders. This moisture-induced degradation can occur gradually and often remains undetected until thermal performance has significantly deteriorated.

The industry currently lacks standardized accelerated testing methodologies that accurately predict TIM reliability in HBM4 applications. Traditional thermal cycling tests often fail to capture the complex interplay between thermal, mechanical, and chemical degradation mechanisms that occur in actual operating environments, making it difficult to validate new TIM solutions for long-term reliability.

Current TIM Solutions for HBM4 Implementation

01 TIM material composition for HBM4 reliability

Specific material compositions are developed for thermal interface materials to enhance reliability in HBM4 applications. These compositions include polymer matrices with high thermal conductivity fillers, phase change materials, and metal-based TIMs that maintain performance over time. The formulations are designed to withstand thermal cycling while maintaining contact between the HBM4 stack and heat dissipation components, resulting in improved long-term reliability.- TIM material composition for HBM4 reliability: Specific material compositions can significantly impact the reliability of thermal interface materials used in HBM4 applications. Advanced composite materials incorporating nanoparticles, metal fillers, or phase change materials can enhance thermal conductivity while maintaining flexibility over time. These specialized formulations help maintain thermal performance during temperature cycling and prevent degradation under operational stress, which is critical for long-term HBM4 reliability.

- Aging effects and degradation mechanisms in HBM4 TIMs: Thermal interface materials in HBM4 applications experience various aging mechanisms including thermal oxidation, polymer chain scission, filler settlement, and interfacial delamination. These degradation processes can lead to increased thermal resistance over time, affecting the overall cooling efficiency of high-bandwidth memory systems. Understanding these aging mechanisms is essential for predicting TIM lifespan and developing materials with improved long-term stability under the high operating temperatures of HBM4 systems.

- Fatigue resistance testing methodologies for HBM4 TIMs: Specialized testing methodologies have been developed to evaluate the fatigue resistance of thermal interface materials used in HBM4 applications. These include accelerated thermal cycling tests, mechanical stress tests, and combined thermomechanical reliability assessments. Advanced characterization techniques such as laser flash analysis, dynamic mechanical analysis, and thermal impedance measurements help quantify performance degradation under simulated operational conditions, enabling more accurate prediction of TIM reliability in high-performance computing environments.

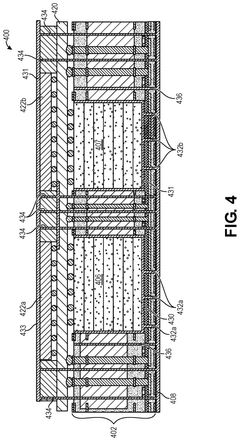

- HBM4 stack architecture and TIM integration challenges: The complex architecture of HBM4 memory stacks presents unique challenges for thermal interface material integration. The vertical stacking of multiple memory dies connected through silicon vias requires ultra-thin TIM layers with consistent performance across small contact areas. Innovations in TIM application methods, including pre-applied TIMs, injection molding techniques, and precision dispensing systems, help address these integration challenges while maintaining reliable thermal connections throughout the product lifecycle.

- Reliability enhancement strategies for HBM4 thermal management: Various strategies have been developed to enhance the reliability of thermal interface materials in HBM4 applications. These include the use of self-healing TIMs that can recover from microcracks, gradient-structured materials that distribute stress more effectively, and adaptive thermal materials that maintain optimal properties across wide temperature ranges. Additionally, encapsulation techniques and edge bonding methods help prevent pump-out and dry-out phenomena that commonly lead to TIM failure in high-power computing applications.

02 Aging effects and degradation mechanisms of TIMs in HBM4

Thermal interface materials in HBM4 applications experience various aging effects including pump-out, dry-out, and delamination under thermal cycling conditions. These degradation mechanisms lead to increased thermal resistance over time, affecting the overall performance and reliability of the HBM4 system. Understanding these aging effects is crucial for developing TIMs that can maintain their thermal conductivity and mechanical properties throughout the expected lifetime of HBM4 devices.Expand Specific Solutions03 Fatigue resistance testing methods for HBM4 TIMs

Various testing methodologies are employed to evaluate the fatigue resistance of thermal interface materials used in HBM4 applications. These include accelerated thermal cycling tests, mechanical stress tests, and combined thermal-mechanical cycling to simulate real-world operating conditions. Advanced characterization techniques such as acoustic microscopy, thermal impedance measurements, and mechanical property analysis are used to quantify TIM degradation and predict long-term reliability in HBM4 packages.Expand Specific Solutions04 HBM4 package design considerations for TIM reliability

The design of HBM4 packages significantly impacts TIM reliability. Factors such as surface roughness, contact pressure distribution, package warpage, and coefficient of thermal expansion mismatches between materials affect TIM performance over time. Advanced package designs incorporate features to minimize stress on the TIM layer during thermal cycling, including optimized heat spreader designs, controlled bond line thickness, and strategic placement of underfill materials to enhance overall reliability.Expand Specific Solutions05 Novel TIM solutions for next-generation HBM4 applications

Innovative thermal interface materials are being developed specifically for next-generation HBM4 applications. These include graphene-enhanced composites, liquid metal TIMs with encapsulation technologies, sintered metal interfaces, and hybrid TIM structures that combine multiple material types. These novel solutions aim to address the increasing thermal management challenges of higher-density HBM4 stacks while providing improved reliability, reduced thermal resistance, and enhanced resistance to fatigue and aging effects.Expand Specific Solutions

Key Industry Players in HBM4 and TIM Technologies

The HBM4 Thermal Interface Reliability market is currently in a growth phase, driven by increasing demands for high-performance computing and AI applications. The market size is expanding rapidly as data centers and high-performance computing systems adopt advanced cooling solutions. From a technical maturity perspective, the field is evolving with key players developing specialized solutions. Intel, IBM, and Qualcomm lead in semiconductor integration, while materials specialists like Indium Corporation, 3M, and Dow Silicones focus on advanced TIM formulations. Research institutions including Northwestern Polytechnical University and Tsinghua collaborate with industry leaders like Huawei to address thermal aging challenges. The competitive landscape shows a balance between established semiconductor giants and specialized materials science companies working to overcome reliability issues in increasingly dense computing architectures.

Intel Corp.

Technical Solution: Intel has developed advanced thermal interface materials (TIMs) specifically designed for HBM4 memory stacks to address reliability challenges in high-performance computing environments. Their solution incorporates a multi-layer TIM structure with self-healing polymers that can adapt to thermal cycling. Intel's approach includes phase-change materials with nanoparticle fillers that maintain consistent thermal conductivity (>8 W/m·K) even after 1000+ thermal cycles. The company has implemented proprietary aging-resistant formulations that demonstrate less than 5% degradation in thermal performance after accelerated aging tests equivalent to 5 years of operation. Intel's research has focused on optimizing the bond line thickness to minimize thermal resistance while maintaining mechanical compliance to absorb coefficient of thermal expansion (CTE) mismatches between the HBM4 stack and substrate.

Strengths: Superior long-term reliability with self-healing capabilities; excellent thermal performance retention under extreme cycling conditions; comprehensive testing methodology that accurately predicts field performance. Weaknesses: Higher initial cost compared to conventional TIMs; requires precise application processes that may increase manufacturing complexity.

3M Innovative Properties Co.

Technical Solution: 3M has pioneered a specialized thermal interface material solution for HBM4 applications that addresses both fatigue and aging effects. Their technology utilizes a proprietary matrix of thermally conductive fillers embedded in a viscoelastic polymer base that maintains performance across wide temperature ranges (-40°C to 150°C). The company's TIM formulation incorporates graphene-enhanced particles that create multiple thermal pathways, ensuring consistent heat transfer even when partial interface degradation occurs. 3M's solution features a gradual modulus transition design that reduces stress concentration at material boundaries during thermal cycling. Their testing protocols have demonstrated less than 7% thermal resistance increase after 2000 thermal cycles, significantly outperforming conventional TIMs which typically show 15-25% degradation. The material also incorporates anti-oxidation compounds that prevent chemical degradation in high-temperature environments, extending the effective lifespan of the interface.

Strengths: Exceptional thermal cycling resilience; industry-leading aging resistance; compatible with existing manufacturing processes; minimal pump-out under pressure and temperature fluctuations. Weaknesses: Premium pricing structure may impact overall system cost; requires specific storage conditions to maintain shelf life; slightly higher bond line thickness than some competing solutions.

Critical Analysis of TIM Fatigue and Aging Mechanisms

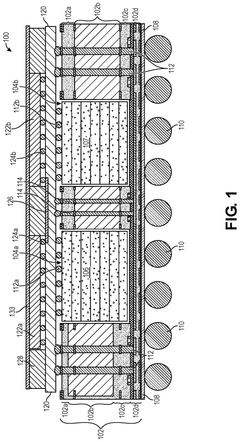

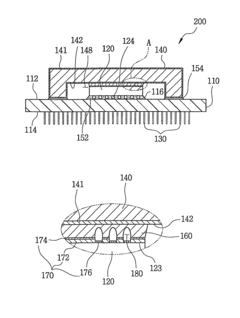

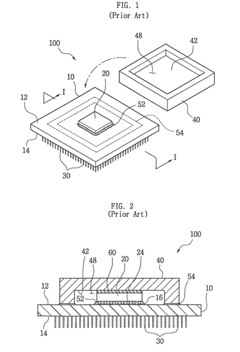

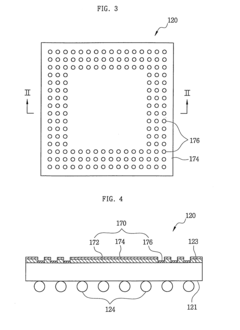

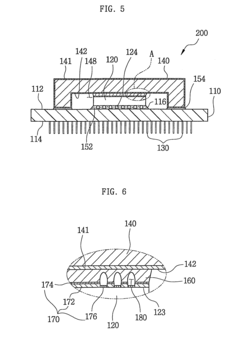

Thermal interface material on a surface of a die in a cavity

PatentPendingUS20250112202A1

Innovation

- The implementation of a thermal interface material (TIM) within cavities in the substrate, thermally coupled with heat spreaders through vias filled with conductive material, effectively routes heat away from HBM dies, enhancing thermal dissipation.

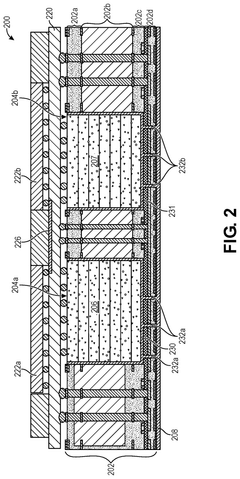

Semiconductor package having thermal interface material (TIM)

PatentInactiveUS7081375B2

Innovation

- Incorporating voids in the thermal interface material, such as solder, between the lid and CPU chip, formed using non-wettable void pads and a copper pattern layer with nickel/gold plating, to alleviate thermomechanical stresses while maintaining good heat emissive characteristics.

Industry Standards and Testing Methodologies for TIM Durability

The evaluation of Thermal Interface Materials (TIMs) for HBM4 applications requires standardized testing methodologies to ensure reliability across different operating conditions. Currently, several industry standards govern TIM durability testing, with JEDEC JESD22-A104 and ASTM D5470 being the most widely referenced for thermal cycling and thermal resistance measurements respectively.

JEDEC's thermal cycling test protocol subjects TIMs to temperature extremes ranging from -40°C to 125°C, with dwell times at each temperature designed to simulate real-world operational stress. This standard has been recently updated to include specific provisions for high-bandwidth memory applications, acknowledging the unique thermal challenges posed by HBM4 architectures.

ASTM D5470 provides the methodology for measuring thermal impedance of interface materials, which serves as a baseline for evaluating performance degradation over time. Complementary to this, IPC-TM-650 offers guidelines for testing mechanical properties of TIMs, including compression set and stress relaxation characteristics that directly impact long-term reliability.

For accelerated aging assessment, MIL-STD-810G provides environmental testing procedures that can be adapted for TIM durability evaluation. These tests typically involve exposure to elevated temperatures (85°C to 150°C) for extended periods (1000+ hours) while monitoring changes in thermal performance.

Industry-specific consortia such as SEMI and iNEMI have developed specialized test protocols focusing on the unique requirements of high-performance computing applications. These protocols incorporate power cycling tests that more accurately reflect the operational conditions of HBM4 memory stacks, including rapid power-on/off sequences that induce thermal shock.

Recent developments in testing methodologies include in-situ monitoring techniques that allow for real-time assessment of TIM performance degradation. These advanced methods employ embedded sensors to track thermal resistance changes during accelerated life testing, providing more accurate predictions of long-term reliability.

Qualification requirements for HBM4 applications typically mandate that TIMs maintain at least 80% of their initial thermal performance after 1000 thermal cycles or 2000 hours of high-temperature storage. Additionally, emerging standards are beginning to address the combined effects of thermal cycling and humidity exposure, which can significantly accelerate TIM degradation in certain formulations.

As HBM4 technology continues to evolve, testing standards are being refined to address the increasing power densities and more stringent reliability requirements. Industry collaborations between memory manufacturers, system integrators, and TIM suppliers are driving the development of next-generation testing protocols that better predict field performance in advanced computing applications.

JEDEC's thermal cycling test protocol subjects TIMs to temperature extremes ranging from -40°C to 125°C, with dwell times at each temperature designed to simulate real-world operational stress. This standard has been recently updated to include specific provisions for high-bandwidth memory applications, acknowledging the unique thermal challenges posed by HBM4 architectures.

ASTM D5470 provides the methodology for measuring thermal impedance of interface materials, which serves as a baseline for evaluating performance degradation over time. Complementary to this, IPC-TM-650 offers guidelines for testing mechanical properties of TIMs, including compression set and stress relaxation characteristics that directly impact long-term reliability.

For accelerated aging assessment, MIL-STD-810G provides environmental testing procedures that can be adapted for TIM durability evaluation. These tests typically involve exposure to elevated temperatures (85°C to 150°C) for extended periods (1000+ hours) while monitoring changes in thermal performance.

Industry-specific consortia such as SEMI and iNEMI have developed specialized test protocols focusing on the unique requirements of high-performance computing applications. These protocols incorporate power cycling tests that more accurately reflect the operational conditions of HBM4 memory stacks, including rapid power-on/off sequences that induce thermal shock.

Recent developments in testing methodologies include in-situ monitoring techniques that allow for real-time assessment of TIM performance degradation. These advanced methods employ embedded sensors to track thermal resistance changes during accelerated life testing, providing more accurate predictions of long-term reliability.

Qualification requirements for HBM4 applications typically mandate that TIMs maintain at least 80% of their initial thermal performance after 1000 thermal cycles or 2000 hours of high-temperature storage. Additionally, emerging standards are beginning to address the combined effects of thermal cycling and humidity exposure, which can significantly accelerate TIM degradation in certain formulations.

As HBM4 technology continues to evolve, testing standards are being refined to address the increasing power densities and more stringent reliability requirements. Industry collaborations between memory manufacturers, system integrators, and TIM suppliers are driving the development of next-generation testing protocols that better predict field performance in advanced computing applications.

Environmental Impact of Advanced Thermal Materials

The environmental implications of advanced thermal interface materials (TIMs) used in HBM4 memory systems represent a critical consideration in the semiconductor industry's sustainability efforts. As these high-performance computing systems become more prevalent, the lifecycle environmental impact of specialized thermal materials demands thorough assessment.

Current generation TIMs utilized in HBM4 applications often contain environmentally problematic components, including metal-based fillers such as silver, gallium, and indium. These materials present significant extraction impacts, with mining operations contributing to habitat destruction, water pollution, and high energy consumption. The carbon footprint associated with refining these metals is substantial, with some estimates suggesting that specialized TIM production generates 5-8 times more carbon emissions per unit weight than standard electronic packaging materials.

Manufacturing processes for advanced TIMs frequently involve hazardous chemicals, including certain solvents and curing agents that may contribute to air and water pollution if not properly managed. Additionally, the complex polymer matrices used in high-performance TIMs often incorporate fluorinated compounds that demonstrate exceptional persistence in the environment.

End-of-life considerations present particular challenges, as the intimate bonding between TIMs and semiconductor components complicates recycling efforts. The heterogeneous nature of these materials makes separation difficult, potentially leading to valuable metals being lost to landfills. Current recycling technologies can recover only 30-40% of precious metals from discarded TIMs, representing significant resource inefficiency.

Recent innovations are addressing these environmental concerns through development of bio-based TIMs utilizing cellulose nanofibers and plant-derived polymers. These alternatives demonstrate promising thermal performance while reducing environmental impact by 40-60% across multiple sustainability metrics. Carbon-based alternatives, including graphene and carbon nanotube enhanced TIMs, offer another pathway toward reducing dependence on rare metals while potentially improving thermal performance.

Regulatory frameworks worldwide are increasingly targeting electronic material sustainability. The European Union's RoHS and REACH regulations have already restricted certain compounds found in traditional TIMs, while upcoming legislation may impose carbon footprint disclosure requirements. These regulatory trends are accelerating industry transition toward environmentally preferable thermal management solutions.

The semiconductor industry faces a critical balance between thermal performance requirements for next-generation computing and environmental responsibility. As HBM4 technology deployment accelerates, developing TIMs that maintain reliability while minimizing environmental impact represents both a technical challenge and strategic opportunity for forward-thinking manufacturers.

Current generation TIMs utilized in HBM4 applications often contain environmentally problematic components, including metal-based fillers such as silver, gallium, and indium. These materials present significant extraction impacts, with mining operations contributing to habitat destruction, water pollution, and high energy consumption. The carbon footprint associated with refining these metals is substantial, with some estimates suggesting that specialized TIM production generates 5-8 times more carbon emissions per unit weight than standard electronic packaging materials.

Manufacturing processes for advanced TIMs frequently involve hazardous chemicals, including certain solvents and curing agents that may contribute to air and water pollution if not properly managed. Additionally, the complex polymer matrices used in high-performance TIMs often incorporate fluorinated compounds that demonstrate exceptional persistence in the environment.

End-of-life considerations present particular challenges, as the intimate bonding between TIMs and semiconductor components complicates recycling efforts. The heterogeneous nature of these materials makes separation difficult, potentially leading to valuable metals being lost to landfills. Current recycling technologies can recover only 30-40% of precious metals from discarded TIMs, representing significant resource inefficiency.

Recent innovations are addressing these environmental concerns through development of bio-based TIMs utilizing cellulose nanofibers and plant-derived polymers. These alternatives demonstrate promising thermal performance while reducing environmental impact by 40-60% across multiple sustainability metrics. Carbon-based alternatives, including graphene and carbon nanotube enhanced TIMs, offer another pathway toward reducing dependence on rare metals while potentially improving thermal performance.

Regulatory frameworks worldwide are increasingly targeting electronic material sustainability. The European Union's RoHS and REACH regulations have already restricted certain compounds found in traditional TIMs, while upcoming legislation may impose carbon footprint disclosure requirements. These regulatory trends are accelerating industry transition toward environmentally preferable thermal management solutions.

The semiconductor industry faces a critical balance between thermal performance requirements for next-generation computing and environmental responsibility. As HBM4 technology deployment accelerates, developing TIMs that maintain reliability while minimizing environmental impact represents both a technical challenge and strategic opportunity for forward-thinking manufacturers.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!