HBM4 Qualification Standards: Temperature, Humidity And Vibration

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HBM4 Technology Background and Qualification Objectives

High Bandwidth Memory (HBM) technology has evolved significantly since its introduction, with HBM4 representing the latest advancement in this memory architecture. The development of HBM technology began in the early 2010s as a response to the increasing demand for higher memory bandwidth and capacity in high-performance computing applications. HBM1 was first introduced in 2013, followed by HBM2 in 2016, HBM2E in 2018, and HBM3 in 2021. Each generation has brought substantial improvements in bandwidth, capacity, and energy efficiency.

HBM4 continues this evolutionary trajectory, promising unprecedented memory performance for next-generation AI accelerators, high-performance computing systems, and data center applications. The technology is designed to address the exponential growth in data processing requirements driven by artificial intelligence, machine learning, and big data analytics workloads that demand massive parallel processing capabilities and memory bandwidth.

The qualification standards for HBM4, particularly regarding temperature, humidity, and vibration, are critical aspects of ensuring reliability and performance in diverse operating environments. These standards are established to guarantee that HBM4 memory can maintain optimal functionality under varying conditions that may be encountered in different deployment scenarios, from data centers to edge computing devices.

Temperature qualification for HBM4 is particularly important due to the high power density and heat generation associated with high-performance memory operations. The standards typically define operating temperature ranges, thermal cycling endurance, and heat dissipation requirements. As HBM4 is expected to deliver higher bandwidth than its predecessors, thermal management becomes increasingly challenging, necessitating robust qualification protocols.

Humidity qualification addresses the potential for moisture-related failures, including corrosion, electrical shorts, and degradation of materials. This is especially relevant for HBM4 given its complex 3D stacked die structure and the use of through-silicon vias (TSVs), which could be susceptible to moisture-induced reliability issues if not properly qualified.

Vibration qualification ensures that the mechanical integrity of HBM4 modules remains intact during transportation, installation, and operation. The 3D stacked nature of HBM technology, with multiple memory dies stacked vertically and connected by TSVs, presents unique challenges for mechanical stability under vibration conditions.

The primary objective of establishing comprehensive qualification standards for HBM4 is to ensure that this advanced memory technology can deliver its promised performance benefits while maintaining reliability across diverse operating conditions. These standards serve as a critical foundation for the successful deployment of HBM4 in next-generation computing systems, enabling the continued advancement of data-intensive applications and artificial intelligence capabilities.

HBM4 continues this evolutionary trajectory, promising unprecedented memory performance for next-generation AI accelerators, high-performance computing systems, and data center applications. The technology is designed to address the exponential growth in data processing requirements driven by artificial intelligence, machine learning, and big data analytics workloads that demand massive parallel processing capabilities and memory bandwidth.

The qualification standards for HBM4, particularly regarding temperature, humidity, and vibration, are critical aspects of ensuring reliability and performance in diverse operating environments. These standards are established to guarantee that HBM4 memory can maintain optimal functionality under varying conditions that may be encountered in different deployment scenarios, from data centers to edge computing devices.

Temperature qualification for HBM4 is particularly important due to the high power density and heat generation associated with high-performance memory operations. The standards typically define operating temperature ranges, thermal cycling endurance, and heat dissipation requirements. As HBM4 is expected to deliver higher bandwidth than its predecessors, thermal management becomes increasingly challenging, necessitating robust qualification protocols.

Humidity qualification addresses the potential for moisture-related failures, including corrosion, electrical shorts, and degradation of materials. This is especially relevant for HBM4 given its complex 3D stacked die structure and the use of through-silicon vias (TSVs), which could be susceptible to moisture-induced reliability issues if not properly qualified.

Vibration qualification ensures that the mechanical integrity of HBM4 modules remains intact during transportation, installation, and operation. The 3D stacked nature of HBM technology, with multiple memory dies stacked vertically and connected by TSVs, presents unique challenges for mechanical stability under vibration conditions.

The primary objective of establishing comprehensive qualification standards for HBM4 is to ensure that this advanced memory technology can deliver its promised performance benefits while maintaining reliability across diverse operating conditions. These standards serve as a critical foundation for the successful deployment of HBM4 in next-generation computing systems, enabling the continued advancement of data-intensive applications and artificial intelligence capabilities.

Market Demand Analysis for HBM4 Memory Solutions

The global market for High Bandwidth Memory (HBM) solutions is experiencing unprecedented growth, driven primarily by the explosive expansion of artificial intelligence (AI) applications, high-performance computing (HPC), and data-intensive workloads. As HBM4 emerges as the next generation standard, market demand is being shaped by several critical factors that emphasize the importance of robust qualification standards for temperature, humidity, and vibration.

Data center operators and cloud service providers represent the largest and fastest-growing segment for HBM4 memory solutions. These entities are increasingly deploying AI training and inference systems that require massive memory bandwidth and capacity while maintaining reliability under varying environmental conditions. The market size for data center HBM solutions is projected to grow significantly through 2028, with particular emphasis on solutions that can withstand the thermal challenges of densely packed computing environments.

The automotive sector presents another substantial growth vector for HBM4 memory, particularly in advanced driver-assistance systems (ADAS) and autonomous driving platforms. These applications demand memory solutions that can operate reliably across extreme temperature ranges (-40°C to 125°C) and withstand significant vibration stresses. The automotive memory market's stringent qualification requirements are driving innovations in HBM4 packaging and testing methodologies.

Telecommunications equipment manufacturers are also emerging as key consumers of HBM4 memory, particularly for 5G and future 6G infrastructure. These applications often involve outdoor deployment scenarios where temperature cycling and humidity exposure present significant reliability challenges. The telecom sector's demand for HBM4 is expected to accelerate as edge computing applications proliferate.

Consumer electronics, particularly high-end gaming systems and mobile devices, represent another significant market segment. While less demanding in terms of environmental qualification standards than industrial applications, this segment drives volume production and cost optimization for HBM4 technologies.

Market research indicates that customers across all segments are increasingly prioritizing reliability metrics in their purchasing decisions. Memory failures in AI systems can result in costly downtime and data corruption, making qualification standards for environmental factors a competitive differentiator rather than merely a compliance requirement.

The geographical distribution of HBM4 demand shows concentration in regions with significant data center investments, including North America, East Asia, and Western Europe. However, emerging markets in Southeast Asia and the Middle East are showing accelerated growth rates, often with more challenging environmental conditions that place additional emphasis on temperature and humidity qualification standards.

Data center operators and cloud service providers represent the largest and fastest-growing segment for HBM4 memory solutions. These entities are increasingly deploying AI training and inference systems that require massive memory bandwidth and capacity while maintaining reliability under varying environmental conditions. The market size for data center HBM solutions is projected to grow significantly through 2028, with particular emphasis on solutions that can withstand the thermal challenges of densely packed computing environments.

The automotive sector presents another substantial growth vector for HBM4 memory, particularly in advanced driver-assistance systems (ADAS) and autonomous driving platforms. These applications demand memory solutions that can operate reliably across extreme temperature ranges (-40°C to 125°C) and withstand significant vibration stresses. The automotive memory market's stringent qualification requirements are driving innovations in HBM4 packaging and testing methodologies.

Telecommunications equipment manufacturers are also emerging as key consumers of HBM4 memory, particularly for 5G and future 6G infrastructure. These applications often involve outdoor deployment scenarios where temperature cycling and humidity exposure present significant reliability challenges. The telecom sector's demand for HBM4 is expected to accelerate as edge computing applications proliferate.

Consumer electronics, particularly high-end gaming systems and mobile devices, represent another significant market segment. While less demanding in terms of environmental qualification standards than industrial applications, this segment drives volume production and cost optimization for HBM4 technologies.

Market research indicates that customers across all segments are increasingly prioritizing reliability metrics in their purchasing decisions. Memory failures in AI systems can result in costly downtime and data corruption, making qualification standards for environmental factors a competitive differentiator rather than merely a compliance requirement.

The geographical distribution of HBM4 demand shows concentration in regions with significant data center investments, including North America, East Asia, and Western Europe. However, emerging markets in Southeast Asia and the Middle East are showing accelerated growth rates, often with more challenging environmental conditions that place additional emphasis on temperature and humidity qualification standards.

Current Qualification Challenges for HBM4 Technology

The qualification of HBM4 (High Bandwidth Memory 4) technology presents significant challenges due to its complex architecture and demanding performance requirements. Current qualification standards for temperature, humidity, and vibration testing are struggling to keep pace with the advanced design of HBM4 memory modules, which feature higher density, increased bandwidth, and more intricate 3D stacking compared to previous generations.

Temperature qualification poses particular difficulties as HBM4's increased power density generates more heat within confined spaces. Traditional temperature cycling tests (typically -40°C to 125°C) may be insufficient for accurately predicting reliability in real-world applications where thermal gradients across the stacked dies can be more severe and localized. The thermal interface materials and through-silicon vias (TSVs) in HBM4 create unique thermal pathways that conventional qualification methods fail to adequately stress test.

Humidity testing presents another significant challenge. The increased number of interconnects and smaller feature sizes in HBM4 make these components more susceptible to moisture-induced failures. Current JEDEC standards for humidity testing (e.g., 85°C/85% RH) may not accurately represent the moisture penetration patterns in HBM4's complex 3D structure, particularly at the interfaces between different materials and layers.

Vibration qualification faces complications due to the resonant frequencies of HBM4's stacked die configuration. The mechanical response of these stacked structures differs significantly from traditional memory packages. Current vibration test protocols may not adequately capture the stress concentrations that occur at the interfaces between dies or at the connection points with the interposer. The increased mass of HBM4 modules also creates different inertial forces during vibration events compared to previous memory technologies.

The miniaturization of interconnects in HBM4 further complicates qualification efforts. With bump pitches continuing to shrink (now approaching 40μm or less), the mechanical integrity of these connections becomes increasingly vulnerable to thermo-mechanical stresses. Current qualification methods may not detect subtle degradation in these microscopic structures that could lead to latent failures.

Combined stress testing represents perhaps the most significant gap in current qualification standards. Real-world operating conditions rarely present temperature, humidity, or vibration stresses in isolation. HBM4 devices experience complex interactions between these environmental factors, yet current qualification approaches typically test each parameter separately, potentially missing critical failure modes that emerge only under combined stress conditions.

Industry stakeholders are increasingly recognizing that qualification standards must evolve to address these challenges, with efforts underway to develop more sophisticated test methodologies that better represent the unique characteristics and failure mechanisms of advanced HBM4 technology.

Temperature qualification poses particular difficulties as HBM4's increased power density generates more heat within confined spaces. Traditional temperature cycling tests (typically -40°C to 125°C) may be insufficient for accurately predicting reliability in real-world applications where thermal gradients across the stacked dies can be more severe and localized. The thermal interface materials and through-silicon vias (TSVs) in HBM4 create unique thermal pathways that conventional qualification methods fail to adequately stress test.

Humidity testing presents another significant challenge. The increased number of interconnects and smaller feature sizes in HBM4 make these components more susceptible to moisture-induced failures. Current JEDEC standards for humidity testing (e.g., 85°C/85% RH) may not accurately represent the moisture penetration patterns in HBM4's complex 3D structure, particularly at the interfaces between different materials and layers.

Vibration qualification faces complications due to the resonant frequencies of HBM4's stacked die configuration. The mechanical response of these stacked structures differs significantly from traditional memory packages. Current vibration test protocols may not adequately capture the stress concentrations that occur at the interfaces between dies or at the connection points with the interposer. The increased mass of HBM4 modules also creates different inertial forces during vibration events compared to previous memory technologies.

The miniaturization of interconnects in HBM4 further complicates qualification efforts. With bump pitches continuing to shrink (now approaching 40μm or less), the mechanical integrity of these connections becomes increasingly vulnerable to thermo-mechanical stresses. Current qualification methods may not detect subtle degradation in these microscopic structures that could lead to latent failures.

Combined stress testing represents perhaps the most significant gap in current qualification standards. Real-world operating conditions rarely present temperature, humidity, or vibration stresses in isolation. HBM4 devices experience complex interactions between these environmental factors, yet current qualification approaches typically test each parameter separately, potentially missing critical failure modes that emerge only under combined stress conditions.

Industry stakeholders are increasingly recognizing that qualification standards must evolve to address these challenges, with efforts underway to develop more sophisticated test methodologies that better represent the unique characteristics and failure mechanisms of advanced HBM4 technology.

Current Temperature, Humidity and Vibration Testing Approaches

01 HBM4 Testing and Qualification Protocols

High Bandwidth Memory 4 (HBM4) requires rigorous testing protocols to ensure reliability and performance. These qualification standards include thermal cycling tests, electrical performance verification, and stress testing under various operating conditions. The testing procedures validate memory stack integrity, signal integrity, and thermal management capabilities to meet industry standards for high-performance computing applications.- HBM4 Testing and Qualification Protocols: High Bandwidth Memory 4 qualification standards involve comprehensive testing protocols to ensure reliability and performance. These protocols include thermal cycling tests, voltage stress tests, and data integrity verification under various operating conditions. The qualification process validates that HBM4 modules meet industry specifications for bandwidth, latency, and power efficiency before mass production and integration into high-performance computing systems.

- HBM4 Interface and Interoperability Standards: Standardization of HBM4 interfaces ensures compatibility across different hardware platforms. These standards define signal integrity requirements, pin configurations, and communication protocols between memory modules and host processors. Interoperability testing verifies that HBM4 components from different manufacturers can work together seamlessly, which is critical for system integration in data centers and high-performance computing environments.

- HBM4 Thermal Management and Power Efficiency Validation: Qualification standards for HBM4 include rigorous thermal management testing to ensure reliable operation under heavy computational loads. These standards specify maximum operating temperatures, heat dissipation requirements, and power consumption thresholds. Validation procedures measure energy efficiency metrics and verify that cooling solutions adequately address the high-density memory stacks characteristic of HBM4 architecture.

- HBM4 Performance Benchmarking and Bandwidth Verification: Performance qualification for HBM4 involves standardized benchmarking to verify bandwidth capabilities, data transfer rates, and memory access latencies. These standards establish minimum performance thresholds that must be met across various workloads and application scenarios. Testing procedures measure actual versus theoretical bandwidth under different traffic patterns and validate that HBM4 modules deliver the expected performance improvements over previous generations.

- HBM4 Reliability and Endurance Certification: Reliability qualification standards for HBM4 focus on long-term durability and error resilience. These standards include endurance testing for write cycles, data retention verification, and error correction capability assessment. Certification procedures evaluate mean time between failures, bit error rates, and system behavior under fault conditions to ensure that HBM4 modules maintain data integrity throughout their expected operational lifetime in enterprise and high-performance computing environments.

02 HBM4 Interface and Compatibility Standards

HBM4 qualification standards define interface specifications and compatibility requirements with existing systems. These standards ensure proper integration with various computing platforms and memory controllers. The interface specifications cover signal timing, voltage levels, and protocol requirements that enable interoperability across different hardware implementations while maintaining backward compatibility where possible.Expand Specific Solutions03 HBM4 Performance Benchmarking Requirements

Performance benchmarking is a critical component of HBM4 qualification standards. These requirements establish minimum thresholds for bandwidth, latency, and throughput under standardized test conditions. The benchmarking protocols include measurements of data transfer rates, power efficiency metrics, and performance scaling across different workloads to ensure the memory meets the demands of next-generation computing applications.Expand Specific Solutions04 HBM4 Reliability and Endurance Certification

Reliability and endurance certification for HBM4 involves extensive testing for long-term stability and error rates. The qualification standards specify minimum endurance levels, error correction capabilities, and mean time between failures. Testing includes accelerated aging tests, data retention verification, and error rate measurements under various environmental conditions to ensure the memory can withstand extended use in high-performance computing environments.Expand Specific Solutions05 HBM4 Power Management and Thermal Standards

Power management and thermal qualification standards for HBM4 establish requirements for energy efficiency and heat dissipation. These standards define acceptable power consumption levels at different operating states, thermal design power limits, and cooling requirements. The qualification process includes testing for power state transitions, thermal throttling behavior, and temperature gradient management across the memory stack to ensure reliable operation in compact, high-performance systems.Expand Specific Solutions

Key Industry Players in HBM4 Development

The HBM4 qualification standards market is in its early growth phase, characterized by increasing demand for high-bandwidth memory solutions in data centers, AI applications, and high-performance computing. The market size is projected to expand significantly as HBM4 adoption accelerates across industries requiring advanced memory solutions. From a technical maturity perspective, companies like Samsung Electronics and SK Hynix are leading development, while semiconductor players such as Wuxi China Resources Semico and Semiconductor Energy Laboratory are advancing testing methodologies for temperature, humidity, and vibration resistance. Research institutions including Korea Research Institute of Standards & Science and academic players like Peking University are contributing to standardization efforts. The competitive landscape features collaboration between memory manufacturers, testing equipment providers, and research organizations to establish robust qualification protocols that ensure HBM4 reliability under extreme environmental conditions.

Wuxi China Resources Semico Co. Ltd.

Technical Solution: Wuxi China Resources Semico has developed an integrated HBM4 qualification platform specifically tailored for high-volume manufacturing environments. Their technical solution incorporates parallel stress testing capabilities that can simultaneously evaluate multiple HBM4 modules under varying environmental conditions, significantly reducing qualification cycle time. The company's approach includes specialized vibration fixtures that replicate server rack, automotive, and consumer device vibration profiles with six degrees of freedom motion control and real-time electrical performance monitoring. Their temperature-humidity qualification standards implement gradient stress conditions that evaluate not just absolute limits but transition behaviors, with particular attention to condensation prevention during rapid temperature changes. Wuxi Semico's methodology includes advanced X-ray tomography for non-destructive evaluation of microbump integrity before and after environmental stress, with automated image processing to detect sub-micron structural changes.

Strengths: High-volume manufacturing experience provides practical insights into qualification requirements; comprehensive testing capabilities spanning multiple application environments. Weaknesses: Qualification standards may be optimized for manufacturing efficiency rather than detecting all potential failure modes; relatively new entrant to advanced memory qualification compared to established testing laboratories.

Littelfuse, Inc.

Technical Solution: Littelfuse has developed a comprehensive HBM4 qualification framework specifically addressing transient protection during environmental stress conditions. Their technical solution integrates temperature-humidity-bias (THB) testing with electrostatic discharge (ESD) evaluation to ensure HBM4 modules maintain performance under combined environmental and electrical stresses. The company's approach includes proprietary vibration fixtures that allow for in-situ electrical performance monitoring during mechanical stress application, with capabilities to detect intermittent connection failures that might otherwise go unnoticed in sequential testing. Littelfuse's qualification standards incorporate accelerated thermal cycling between -65°C and 150°C with controlled ramp rates of 10°C/minute to evaluate solder joint reliability in the microbump array, which is particularly critical for HBM4's increased density and reduced pitch compared to previous generations.

Strengths: Extensive expertise in circuit protection and reliability testing; well-established testing infrastructure for combined electrical and environmental stress evaluation. Weaknesses: Primary focus on protection components rather than complete memory systems; qualification standards may emphasize overvoltage protection more than other failure modes.

Critical Technical Standards and Specifications for HBM4

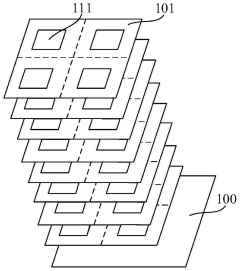

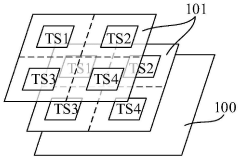

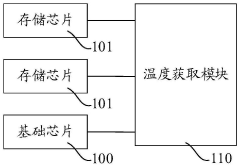

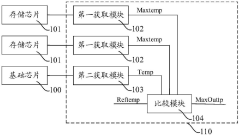

Storage system

PatentPendingCN117234835A

Innovation

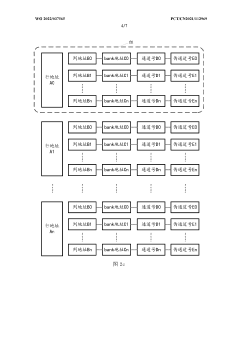

- Design a storage system, including a basic chip and multiple stacked memory chips. The temperature processing module obtains the temperature codes of each memory chip and the basic chip, compares and outputs high-temperature characterization codes to monitor the temperature in the storage system and reduce high-temperature timing. Risk of conflict. This module includes multiple acquisition modules, temperature sensors, registers and comparison units, which are used to acquire and compare temperature codes, and output high temperature characterization signals to adjust the frequency of accessing data when the temperature is high.

Access method and system for memory, memory access management module, energy efficiency ratio controller and computer-readable storage medium

PatentWO2022037565A1

Innovation

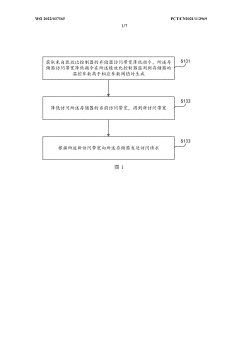

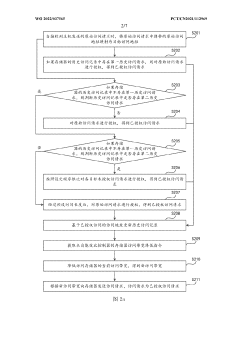

- The energy efficiency ratio controller monitors the temperature control parameters of the memory, generates memory access bandwidth reduction instructions, reduces the current access bandwidth, and optimizes address mapping and authorization rules through the memory access management module to reduce the number of activations and precharges, and reduce power consumption and temperature.

Reliability Engineering Considerations for HBM4 Implementation

Reliability engineering for HBM4 implementation requires comprehensive qualification standards to ensure operational stability under various environmental conditions. The qualification process for HBM4 memory must address temperature, humidity, and vibration factors that significantly impact performance and longevity in high-performance computing environments.

Temperature qualification for HBM4 follows JEDEC standards with extended parameters due to the dense packaging architecture. Testing typically includes temperature cycling between -40°C and 125°C, with particular attention to thermal resistance at the silicon interposer interfaces. The thermal management challenges are exacerbated by HBM4's increased bandwidth and power density compared to previous generations, necessitating more rigorous thermal qualification protocols.

Humidity testing for HBM4 focuses on moisture sensitivity levels (MSL) and biased humidity-temperature stress tests. The multi-layer structure of HBM4 creates numerous potential failure points where moisture ingress could cause delamination or corrosion. Industry standards require HBM4 components to withstand 85% relative humidity at 85°C for at least 1000 hours without performance degradation, with additional requirements for condensation resistance during power cycling.

Vibration qualification standards for HBM4 address both shipping conditions and operational environments. Random vibration testing typically follows MIL-STD-810G methodologies, with frequencies ranging from 20Hz to 2000Hz. The complex 3D structure of HBM4, particularly the microbumps and through-silicon vias (TSVs), creates unique vulnerability points that must withstand mechanical stress without developing microcracks or solder joint failures.

Reliability engineering for HBM4 must also consider the interaction effects between these environmental factors. Combined environmental testing protocols evaluate performance under simultaneous thermal cycling and vibration, which more accurately represents real-world conditions in data centers or edge computing deployments.

Advanced reliability modeling techniques, including finite element analysis and physics-of-failure approaches, are increasingly employed to predict HBM4 behavior under extreme conditions. These models help establish acceleration factors for qualification testing and provide insights into potential failure mechanisms before physical testing begins.

The qualification standards for HBM4 continue to evolve as implementation scenarios expand beyond traditional high-performance computing into automotive, aerospace, and industrial applications, each with unique environmental challenges requiring specialized reliability considerations.

Temperature qualification for HBM4 follows JEDEC standards with extended parameters due to the dense packaging architecture. Testing typically includes temperature cycling between -40°C and 125°C, with particular attention to thermal resistance at the silicon interposer interfaces. The thermal management challenges are exacerbated by HBM4's increased bandwidth and power density compared to previous generations, necessitating more rigorous thermal qualification protocols.

Humidity testing for HBM4 focuses on moisture sensitivity levels (MSL) and biased humidity-temperature stress tests. The multi-layer structure of HBM4 creates numerous potential failure points where moisture ingress could cause delamination or corrosion. Industry standards require HBM4 components to withstand 85% relative humidity at 85°C for at least 1000 hours without performance degradation, with additional requirements for condensation resistance during power cycling.

Vibration qualification standards for HBM4 address both shipping conditions and operational environments. Random vibration testing typically follows MIL-STD-810G methodologies, with frequencies ranging from 20Hz to 2000Hz. The complex 3D structure of HBM4, particularly the microbumps and through-silicon vias (TSVs), creates unique vulnerability points that must withstand mechanical stress without developing microcracks or solder joint failures.

Reliability engineering for HBM4 must also consider the interaction effects between these environmental factors. Combined environmental testing protocols evaluate performance under simultaneous thermal cycling and vibration, which more accurately represents real-world conditions in data centers or edge computing deployments.

Advanced reliability modeling techniques, including finite element analysis and physics-of-failure approaches, are increasingly employed to predict HBM4 behavior under extreme conditions. These models help establish acceleration factors for qualification testing and provide insights into potential failure mechanisms before physical testing begins.

The qualification standards for HBM4 continue to evolve as implementation scenarios expand beyond traditional high-performance computing into automotive, aerospace, and industrial applications, each with unique environmental challenges requiring specialized reliability considerations.

Supply Chain Implications of Stringent Qualification Standards

The implementation of stringent qualification standards for HBM4 memory, particularly regarding temperature, humidity, and vibration parameters, creates significant ripple effects throughout the semiconductor supply chain. Manufacturers must adapt their production processes to meet these enhanced requirements, often necessitating substantial investments in advanced testing equipment and quality control systems. These capital expenditures can create entry barriers for smaller suppliers, potentially consolidating the supply base to fewer, larger entities capable of meeting the rigorous standards.

Component suppliers face increased pressure to deliver materials that can withstand more extreme environmental conditions. This includes substrate manufacturers, silicon producers, and packaging specialists who must all align their capabilities with the heightened qualification requirements. The need for specialized materials that maintain integrity under wider temperature ranges and higher humidity levels may lead to supply constraints, especially during initial implementation phases.

Testing and validation processes become more complex and time-consuming under stringent qualification standards. This extends product development cycles and time-to-market, creating potential bottlenecks in the supply chain. Organizations must allocate additional resources for comprehensive testing regimens that accurately simulate real-world environmental stresses, including vibration testing that mimics transportation and operational conditions.

Geographical considerations emerge as another critical factor, as different regions experience varying environmental conditions. Suppliers located in areas with extreme climates may need to implement more robust controls to ensure consistent manufacturing environments. This could lead to regionalization of certain supply chain elements, with specialized production occurring in locations with optimal environmental conditions for sensitive manufacturing processes.

Inventory management strategies must evolve to accommodate longer qualification periods and potentially higher rejection rates during the transition to stricter standards. This may necessitate increased buffer stocks and more sophisticated forecasting models to prevent supply disruptions. The financial implications extend beyond direct manufacturing costs to include potential insurance premium increases related to product reliability guarantees.

Cross-industry collaboration becomes essential as these stringent standards affect multiple technology sectors. Automotive, aerospace, and telecommunications industries—all increasingly dependent on high-performance memory—must align their supply chain expectations and qualification requirements. This convergence of standards across industries could ultimately streamline qualification processes but requires significant coordination during implementation phases.

Component suppliers face increased pressure to deliver materials that can withstand more extreme environmental conditions. This includes substrate manufacturers, silicon producers, and packaging specialists who must all align their capabilities with the heightened qualification requirements. The need for specialized materials that maintain integrity under wider temperature ranges and higher humidity levels may lead to supply constraints, especially during initial implementation phases.

Testing and validation processes become more complex and time-consuming under stringent qualification standards. This extends product development cycles and time-to-market, creating potential bottlenecks in the supply chain. Organizations must allocate additional resources for comprehensive testing regimens that accurately simulate real-world environmental stresses, including vibration testing that mimics transportation and operational conditions.

Geographical considerations emerge as another critical factor, as different regions experience varying environmental conditions. Suppliers located in areas with extreme climates may need to implement more robust controls to ensure consistent manufacturing environments. This could lead to regionalization of certain supply chain elements, with specialized production occurring in locations with optimal environmental conditions for sensitive manufacturing processes.

Inventory management strategies must evolve to accommodate longer qualification periods and potentially higher rejection rates during the transition to stricter standards. This may necessitate increased buffer stocks and more sophisticated forecasting models to prevent supply disruptions. The financial implications extend beyond direct manufacturing costs to include potential insurance premium increases related to product reliability guarantees.

Cross-industry collaboration becomes essential as these stringent standards affect multiple technology sectors. Automotive, aerospace, and telecommunications industries—all increasingly dependent on high-performance memory—must align their supply chain expectations and qualification requirements. This convergence of standards across industries could ultimately streamline qualification processes but requires significant coordination during implementation phases.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!