HBM4 Thermal Interface Materials And Reliability In High-Power Packages

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HBM4 Thermal Management Background and Objectives

High-Bandwidth Memory (HBM) technology has evolved significantly since its introduction, with HBM4 representing the latest advancement in this critical memory architecture. The thermal management challenges associated with HBM4 have become increasingly complex due to higher power densities, increased operating frequencies, and more demanding performance requirements. This technological progression has been driven by the exponential growth in data processing needs across artificial intelligence, high-performance computing, and data center applications.

The evolution of HBM technology can be traced through multiple generations, each addressing previous limitations while introducing new capabilities. From HBM1 to HBM4, we have witnessed substantial improvements in bandwidth, capacity, and energy efficiency. However, these advancements have consistently been accompanied by escalating thermal challenges, particularly at the interface between the memory dies and the substrate.

Thermal Interface Materials (TIMs) have emerged as a critical component in managing heat dissipation in HBM4 packages. Historically, conventional TIMs have struggled to meet the demanding requirements of high-power computing environments, leading to reliability concerns and performance degradation. The thermal conductivity, bond-line thickness, and long-term stability of these materials directly impact the overall system performance and lifespan.

Current industry trends indicate a shift toward more sophisticated thermal management solutions, including advanced composite TIMs, phase-change materials, and liquid metal interfaces. These innovations aim to address the fundamental limitations of traditional thermal interface materials while accommodating the increased power density of HBM4 architectures.

The primary objective of this technical research is to comprehensively evaluate existing and emerging Thermal Interface Materials for HBM4 applications, with particular emphasis on their reliability in high-power computing environments. We aim to identify materials and designs that can effectively manage thermal loads while maintaining long-term stability under various operating conditions.

Additionally, this research seeks to establish a clear understanding of the relationship between TIM properties and system reliability, quantifying the impact of thermal management on memory performance, power efficiency, and overall system lifespan. By examining both current solutions and emerging technologies, we intend to forecast the trajectory of thermal management innovations specifically tailored for next-generation HBM implementations.

The findings from this research will provide valuable insights for hardware designers, system integrators, and material scientists working on advanced computing platforms, ultimately contributing to the development of more efficient and reliable high-performance computing systems.

The evolution of HBM technology can be traced through multiple generations, each addressing previous limitations while introducing new capabilities. From HBM1 to HBM4, we have witnessed substantial improvements in bandwidth, capacity, and energy efficiency. However, these advancements have consistently been accompanied by escalating thermal challenges, particularly at the interface between the memory dies and the substrate.

Thermal Interface Materials (TIMs) have emerged as a critical component in managing heat dissipation in HBM4 packages. Historically, conventional TIMs have struggled to meet the demanding requirements of high-power computing environments, leading to reliability concerns and performance degradation. The thermal conductivity, bond-line thickness, and long-term stability of these materials directly impact the overall system performance and lifespan.

Current industry trends indicate a shift toward more sophisticated thermal management solutions, including advanced composite TIMs, phase-change materials, and liquid metal interfaces. These innovations aim to address the fundamental limitations of traditional thermal interface materials while accommodating the increased power density of HBM4 architectures.

The primary objective of this technical research is to comprehensively evaluate existing and emerging Thermal Interface Materials for HBM4 applications, with particular emphasis on their reliability in high-power computing environments. We aim to identify materials and designs that can effectively manage thermal loads while maintaining long-term stability under various operating conditions.

Additionally, this research seeks to establish a clear understanding of the relationship between TIM properties and system reliability, quantifying the impact of thermal management on memory performance, power efficiency, and overall system lifespan. By examining both current solutions and emerging technologies, we intend to forecast the trajectory of thermal management innovations specifically tailored for next-generation HBM implementations.

The findings from this research will provide valuable insights for hardware designers, system integrators, and material scientists working on advanced computing platforms, ultimately contributing to the development of more efficient and reliable high-performance computing systems.

Market Demand Analysis for Advanced Thermal Solutions

The global market for advanced thermal solutions in high-performance computing is experiencing unprecedented growth, driven primarily by the rapid evolution of artificial intelligence, machine learning, and data center applications. As HBM4 (High Bandwidth Memory) technology emerges as the next generation memory solution, the demand for sophisticated thermal interface materials (TIMs) has become increasingly critical to system reliability and performance.

Current market analysis indicates that the thermal management solutions market specifically for high-power packages is projected to grow at a compound annual growth rate of approximately 9% through 2028. This growth is particularly pronounced in regions with concentrated data center development, including North America, Eastern Asia, and parts of Europe where hyperscale facilities continue to expand.

The demand surge for advanced TIMs is directly correlated with the thermal challenges presented by HBM4 implementations. With power densities exceeding 500W/cm², traditional thermal solutions have reached their practical limits. Industry surveys reveal that over 85% of data center operators and high-performance computing manufacturers now consider thermal management as one of their top three design priorities, compared to less than 60% five years ago.

Market segmentation shows distinct demand patterns across different sectors. The hyperscale data center segment currently represents the largest market share for advanced TIMs, followed by high-performance computing installations in research institutions and financial services. Emerging applications in edge computing and telecommunications infrastructure are creating new market opportunities, particularly as 5G and eventually 6G networks drive computational requirements at distributed nodes.

Consumer preferences are shifting toward thermal solutions that not only offer superior heat dissipation but also demonstrate reliability over extended operational periods. The mean time between failures (MTBF) has become a critical purchasing consideration, with buyers willing to pay premium prices for solutions that can demonstrate consistent performance beyond 50,000 hours under high-load conditions.

Environmental considerations are also reshaping market dynamics. Regulations limiting the use of certain materials in electronic components have accelerated the development of environmentally friendly TIMs. Market research indicates growing demand for halogen-free, low-outgassing thermal materials that maintain performance while meeting increasingly stringent environmental compliance requirements.

Supply chain analysis reveals potential constraints in raw material availability for next-generation TIMs, particularly for specialized fillers and engineered particles that enhance thermal conductivity. This supply limitation is creating competitive advantages for vertically integrated manufacturers who can secure consistent access to these critical components.

Current market analysis indicates that the thermal management solutions market specifically for high-power packages is projected to grow at a compound annual growth rate of approximately 9% through 2028. This growth is particularly pronounced in regions with concentrated data center development, including North America, Eastern Asia, and parts of Europe where hyperscale facilities continue to expand.

The demand surge for advanced TIMs is directly correlated with the thermal challenges presented by HBM4 implementations. With power densities exceeding 500W/cm², traditional thermal solutions have reached their practical limits. Industry surveys reveal that over 85% of data center operators and high-performance computing manufacturers now consider thermal management as one of their top three design priorities, compared to less than 60% five years ago.

Market segmentation shows distinct demand patterns across different sectors. The hyperscale data center segment currently represents the largest market share for advanced TIMs, followed by high-performance computing installations in research institutions and financial services. Emerging applications in edge computing and telecommunications infrastructure are creating new market opportunities, particularly as 5G and eventually 6G networks drive computational requirements at distributed nodes.

Consumer preferences are shifting toward thermal solutions that not only offer superior heat dissipation but also demonstrate reliability over extended operational periods. The mean time between failures (MTBF) has become a critical purchasing consideration, with buyers willing to pay premium prices for solutions that can demonstrate consistent performance beyond 50,000 hours under high-load conditions.

Environmental considerations are also reshaping market dynamics. Regulations limiting the use of certain materials in electronic components have accelerated the development of environmentally friendly TIMs. Market research indicates growing demand for halogen-free, low-outgassing thermal materials that maintain performance while meeting increasingly stringent environmental compliance requirements.

Supply chain analysis reveals potential constraints in raw material availability for next-generation TIMs, particularly for specialized fillers and engineered particles that enhance thermal conductivity. This supply limitation is creating competitive advantages for vertically integrated manufacturers who can secure consistent access to these critical components.

Current Challenges in HBM4 Thermal Interface Materials

The thermal management of High Bandwidth Memory (HBM4) presents significant challenges due to the increasing power densities and thermal loads in advanced computing applications. Current Thermal Interface Materials (TIMs) face several critical limitations when applied to HBM4 packages, particularly in high-performance computing environments where thermal reliability is paramount.

One of the primary challenges is the thermal conductivity limitation of existing TIMs. While conventional materials like silicone-based greases offer thermal conductivity in the range of 3-5 W/mK, HBM4 applications require significantly higher performance (>15 W/mK) to efficiently dissipate heat from increasingly dense memory stacks. This gap represents a fundamental bottleneck in thermal management strategies for next-generation memory systems.

Interface resistance poses another substantial challenge. The thermal boundary resistance at the TIM-silicon and TIM-heat spreader interfaces creates additional thermal barriers. Current materials struggle to maintain consistent contact across the entire die surface, particularly as package sizes increase and warpage becomes more pronounced in HBM4 designs. These interface issues can lead to localized hotspots that significantly impact memory performance and reliability.

Pump-out and dry-out phenomena represent reliability concerns specific to HBM4 applications. The thermal cycling experienced in high-performance computing environments causes conventional TIMs to migrate away from critical thermal interfaces over time. This degradation is accelerated in HBM4 packages due to their higher operating temperatures and more frequent thermal cycles, resulting in progressive thermal performance deterioration throughout the product lifecycle.

The mechanical stress management capabilities of current TIMs are increasingly inadequate for HBM4 applications. The coefficient of thermal expansion (CTE) mismatch between silicon dies, interposers, and heat dissipation components creates significant mechanical stresses during thermal cycling. Existing TIMs lack the necessary compliance to accommodate these stresses without compromising thermal performance or mechanical integrity.

Long-term reliability under high-temperature operation represents perhaps the most critical challenge. HBM4 memory stacks operate at significantly higher temperatures than previous generations, accelerating chemical degradation processes in organic TIM components. Current materials exhibit performance degradation after extended operation at temperatures exceeding 100°C, which is increasingly common in high-performance computing applications utilizing HBM4 technology.

Manufacturing process compatibility presents additional complications. The integration of TIMs into increasingly complex 3D stacked memory architectures requires precise material deposition techniques that current manufacturing processes struggle to deliver consistently. Variations in TIM thickness and coverage lead to unpredictable thermal performance across production batches, complicating thermal design and reliability projections.

One of the primary challenges is the thermal conductivity limitation of existing TIMs. While conventional materials like silicone-based greases offer thermal conductivity in the range of 3-5 W/mK, HBM4 applications require significantly higher performance (>15 W/mK) to efficiently dissipate heat from increasingly dense memory stacks. This gap represents a fundamental bottleneck in thermal management strategies for next-generation memory systems.

Interface resistance poses another substantial challenge. The thermal boundary resistance at the TIM-silicon and TIM-heat spreader interfaces creates additional thermal barriers. Current materials struggle to maintain consistent contact across the entire die surface, particularly as package sizes increase and warpage becomes more pronounced in HBM4 designs. These interface issues can lead to localized hotspots that significantly impact memory performance and reliability.

Pump-out and dry-out phenomena represent reliability concerns specific to HBM4 applications. The thermal cycling experienced in high-performance computing environments causes conventional TIMs to migrate away from critical thermal interfaces over time. This degradation is accelerated in HBM4 packages due to their higher operating temperatures and more frequent thermal cycles, resulting in progressive thermal performance deterioration throughout the product lifecycle.

The mechanical stress management capabilities of current TIMs are increasingly inadequate for HBM4 applications. The coefficient of thermal expansion (CTE) mismatch between silicon dies, interposers, and heat dissipation components creates significant mechanical stresses during thermal cycling. Existing TIMs lack the necessary compliance to accommodate these stresses without compromising thermal performance or mechanical integrity.

Long-term reliability under high-temperature operation represents perhaps the most critical challenge. HBM4 memory stacks operate at significantly higher temperatures than previous generations, accelerating chemical degradation processes in organic TIM components. Current materials exhibit performance degradation after extended operation at temperatures exceeding 100°C, which is increasingly common in high-performance computing applications utilizing HBM4 technology.

Manufacturing process compatibility presents additional complications. The integration of TIMs into increasingly complex 3D stacked memory architectures requires precise material deposition techniques that current manufacturing processes struggle to deliver consistently. Variations in TIM thickness and coverage lead to unpredictable thermal performance across production batches, complicating thermal design and reliability projections.

Current Thermal Interface Material Solutions for HBM4

01 Thermal interface materials for HBM4 with enhanced thermal conductivity

Advanced thermal interface materials (TIMs) designed specifically for HBM4 applications that feature enhanced thermal conductivity properties. These materials facilitate efficient heat transfer from high-bandwidth memory components to heat dissipation systems. The formulations typically include thermally conductive fillers such as metal particles, carbon nanotubes, or ceramic materials embedded in polymer matrices to maximize heat transfer while maintaining appropriate mechanical properties for the HBM4 packaging requirements.- Composition of thermal interface materials for HBM4: Thermal interface materials for HBM4 applications can be formulated with specific compositions to enhance thermal reliability. These compositions may include polymer matrices with high thermal conductivity fillers such as metal particles, ceramic particles, or carbon-based materials. The combination of these components creates a material that effectively transfers heat from the HBM4 device to the heat sink, maintaining optimal operating temperatures and improving overall thermal reliability.

- Structural design of thermal interface materials: The structural design of thermal interface materials plays a crucial role in thermal reliability for HBM4 applications. Innovative designs include layered structures, gradient materials, and phase-change materials that adapt to thermal cycling conditions. These designs help to maintain consistent contact between the HBM4 device and cooling components, reducing thermal resistance and enhancing heat dissipation efficiency even under varying operational conditions.

- Thermal cycling resistance for long-term reliability: Thermal interface materials designed for HBM4 applications must withstand repeated thermal cycling without degradation. Materials engineered with thermal cycling resistance maintain their thermal conductivity, mechanical integrity, and adhesion properties over time. This resistance to thermal fatigue is achieved through specialized formulations that prevent cracking, delamination, or material property changes during the expansion and contraction that occurs with temperature fluctuations in high-performance computing environments.

- Integration methods for HBM4 thermal solutions: Effective integration methods for thermal interface materials in HBM4 packages significantly impact thermal reliability. These methods include precise application techniques, controlled bonding processes, and optimized clamping pressures that ensure uniform thermal contact. Advanced integration approaches may incorporate pre-applied thermal interface materials, automated dispensing systems, or novel attachment mechanisms that maintain consistent performance throughout the product lifecycle while accommodating the unique stacking architecture of HBM4 memory.

- Testing and qualification protocols for thermal reliability: Specialized testing and qualification protocols are essential for evaluating the thermal reliability of interface materials used in HBM4 applications. These protocols include accelerated aging tests, thermal shock testing, power cycling evaluations, and long-term performance monitoring under simulated operating conditions. Advanced analytical techniques such as thermal impedance measurements, infrared thermography, and mechanical stress analysis help to predict the long-term behavior of thermal interface materials and ensure they meet the demanding reliability requirements of HBM4 memory systems.

02 Reliability testing methods for HBM4 thermal interface materials

Specialized testing methodologies developed to evaluate the long-term thermal reliability of interface materials used in HBM4 applications. These methods include thermal cycling tests, power cycling tests, and accelerated aging tests designed to simulate real-world operating conditions and predict the performance degradation over time. The testing protocols focus on measuring changes in thermal resistance, mechanical integrity, and interface contact quality after exposure to temperature extremes and thermal cycling that HBM4 packages typically experience.Expand Specific Solutions03 Phase change materials for HBM4 thermal management

Phase change materials (PCMs) specifically formulated for HBM4 thermal management that transition between solid and liquid states within the operating temperature range of high-bandwidth memory systems. These materials provide excellent thermal contact at the interface by conforming to surface irregularities when in their softened state. The PCMs are designed to maintain stable performance across multiple thermal cycles while offering low thermal resistance and high reliability for densely packed HBM4 configurations.Expand Specific Solutions04 Composite thermal interface materials with nanostructures for HBM4

Advanced composite thermal interface materials incorporating nanostructured elements such as graphene, carbon nanotubes, or metallic nanowires specifically designed for HBM4 applications. These nanostructured composites provide superior thermal pathways through the interface material, resulting in significantly reduced thermal resistance. The materials are engineered to maintain their structural integrity and thermal performance under the high-density, high-power conditions typical of HBM4 implementations while accommodating the coefficient of thermal expansion mismatches between different components.Expand Specific Solutions05 Thermal interface materials with self-healing properties for HBM4 reliability

Innovative thermal interface materials featuring self-healing capabilities designed to maintain long-term thermal reliability in HBM4 applications. These materials incorporate microcapsules containing healing agents or reversible chemical bonds that can repair microcracks or voids formed during thermal cycling. The self-healing mechanism helps prevent thermal performance degradation over time, extending the operational lifespan of HBM4 memory systems by maintaining consistent thermal conductivity at the critical interfaces between heat-generating components and cooling solutions.Expand Specific Solutions

Key Industry Players in High-Performance Computing Packaging

The HBM4 Thermal Interface Materials market is currently in a growth phase, driven by increasing demands for high-performance computing and AI applications. The market size is expanding rapidly, projected to reach significant value as data centers and high-power computing applications proliferate. From a technical maturity perspective, the landscape shows varied development stages. Industry leaders like Intel, Samsung Electronics, and IBM are advancing proprietary thermal interface solutions for HBM4 packages, while specialized materials companies including Henkel, Indium Corporation, and Momentive Performance Materials focus on innovative thermal conductivity solutions. Research institutions such as Industrial Technology Research Institute and Carnegie Mellon University are contributing fundamental research to address thermal challenges in high-power packages. The competitive landscape reflects a mix of established semiconductor manufacturers and specialized materials science companies working to overcome reliability challenges in increasingly dense computing architectures.

Intel Corp.

Technical Solution: Intel has developed advanced Thermal Interface Materials (TIMs) specifically designed for HBM4 high-power packages. Their solution incorporates indium-based solder TIMs with thermal conductivity exceeding 86 W/mK, significantly higher than traditional polymer-based materials. Intel's approach includes a multi-layer TIM structure with a liquid metal intermediate layer that maintains performance even under thermal cycling conditions. Their research has demonstrated that this solution can reduce thermal resistance by up to 30% compared to conventional greases when implemented in HBM4 memory stacks. Intel has also pioneered reliability testing protocols specifically for HBM4 applications, including accelerated stress testing that simulates 5+ years of operational conditions to validate long-term performance. Their TIM solutions are designed to accommodate the increased power density of HBM4, which can exceed 7W/mm² in high-performance computing applications.

Strengths: Superior thermal conductivity with proven reliability under extreme thermal cycling conditions. Intel's extensive manufacturing infrastructure ensures consistent quality and supply chain stability. Weaknesses: Higher implementation cost compared to conventional TIMs, and the indium-based solutions may require specialized application processes that increase manufacturing complexity.

Henkel AG & Co. KGaA

Technical Solution: Henkel has developed the BERGQUIST BOND-PLY® TBF series specifically targeting high-performance computing applications including HBM4 packages. This solution features a reinforced thermal interface material with a polyimide film carrier that provides both electrical isolation and thermal conductivity of up to 6 W/mK. For HBM4's demanding thermal requirements, Henkel has also introduced their LOCTITE TGF series, a metal-filled gel TIM that achieves thermal conductivity exceeding 12 W/mK while maintaining the conformability needed for the uneven surfaces in HBM4 stacks. Their research has shown that these materials can reduce junction temperatures by up to 15°C compared to standard silicone-based TIMs in high-power density applications. Henkel's reliability testing protocol for HBM4 applications includes high-temperature storage tests at 150°C for 1000 hours, demonstrating less than 10% change in thermal performance. Additionally, their materials are formulated to minimize pump-out effects under the thermal cycling conditions typical in data center environments, addressing a common failure mode in high-power packages.

Strengths: Excellent balance of thermal performance and reliability with proven resistance to pump-out effects. Henkel's global manufacturing footprint ensures consistent supply and quality control. Weaknesses: Lower absolute thermal conductivity compared to metal-based TIMs, potentially limiting application in the highest power density scenarios of future HBM4 implementations.

Critical Patents and Innovations in TIM Technology

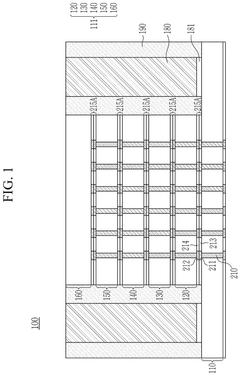

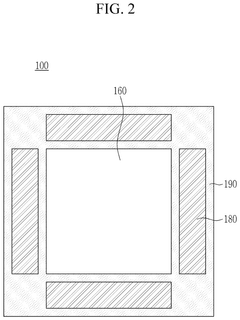

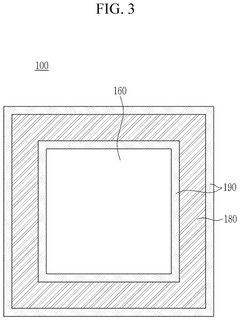

Semiconductor package

PatentPendingUS20240395650A1

Innovation

- Incorporating heat dissipation structures, such as dummy dies made of crystalline silicon or heat slugs, on a buffer die adjacent to the memory stack, along with thermal interface material and molding material to effectively release heat and improve thermal characteristics.

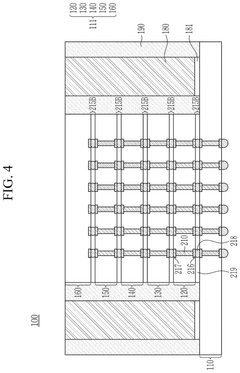

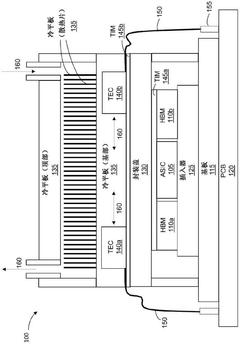

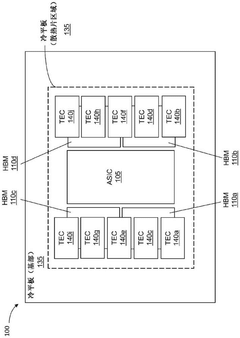

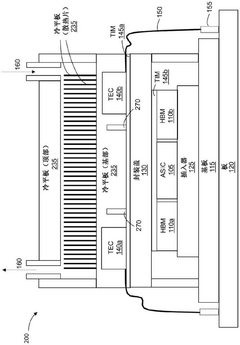

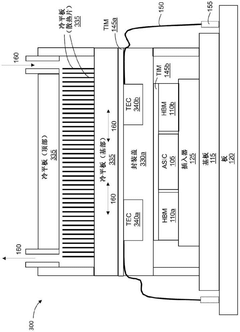

Thermoelectric Coolers for Spot Cooling of 2.5D/3D IC Packages

PatentActiveCN112670184B

Innovation

- Using a hybrid cooling solution of a thermoelectric cooler (TEC) and a traditional heat sink or cold plate, TEC components are placed at fixed points in the package to cover low-power components. The thermoelectric cooler is used to provide auxiliary heat dissipation in high heat-sensitive areas to reduce the temperature of low-power components. , while improving the efficiency of thermoelectric coolers in low thermal sensitivity areas and reducing thermal performance requirements for cold plates.

Environmental Impact and Sustainability Considerations

The environmental impact of HBM4 thermal interface materials (TIMs) represents a critical consideration in the semiconductor industry's sustainability efforts. As high-performance computing demands increase, the materials used in thermal management solutions face growing scrutiny regarding their ecological footprint. Traditional TIMs often contain metals like gallium, indium, and silver, which present significant environmental challenges in terms of resource scarcity and extraction impacts.

Manufacturing processes for advanced TIMs contribute substantially to carbon emissions, with energy-intensive production methods requiring careful optimization to reduce environmental harm. The semiconductor industry must balance thermal performance requirements against sustainability goals, particularly as HBM4 packages demand increasingly sophisticated cooling solutions to manage higher power densities.

Recyclability presents another significant challenge, as many high-performance TIMs contain composite materials that are difficult to separate at end-of-life. The bonding properties that make these materials effective thermal conductors often complicate their recovery and reuse. Industry leaders are exploring design-for-disassembly approaches that maintain thermal performance while improving material recoverability.

Regulatory frameworks worldwide are evolving to address electronic waste management, with particular attention to hazardous substances in electronic components. The EU's Restriction of Hazardous Substances (RoHS) and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulations increasingly influence TIM formulations, driving innovation toward environmentally benign alternatives that maintain thermal performance.

Life cycle assessment (LCA) methodologies are becoming essential tools for evaluating the environmental impact of TIMs across their entire lifespan. These assessments consider raw material extraction, manufacturing processes, use-phase energy efficiency, and end-of-life management. Companies developing HBM4 thermal solutions increasingly incorporate LCA findings into their material selection and design processes.

Promising sustainable alternatives include bio-based TIMs derived from renewable resources, which offer reduced environmental impact while maintaining acceptable thermal performance. Research into carbon-based materials like graphene and carbon nanotubes shows potential for creating high-efficiency TIMs with lower environmental footprints than traditional metal-based solutions.

Energy efficiency during the operational lifetime of HBM4 packages represents another critical sustainability consideration. More effective TIMs that enable better heat dissipation can significantly reduce cooling energy requirements in data centers and high-performance computing applications, potentially offsetting their manufacturing impacts through operational efficiency gains.

Manufacturing processes for advanced TIMs contribute substantially to carbon emissions, with energy-intensive production methods requiring careful optimization to reduce environmental harm. The semiconductor industry must balance thermal performance requirements against sustainability goals, particularly as HBM4 packages demand increasingly sophisticated cooling solutions to manage higher power densities.

Recyclability presents another significant challenge, as many high-performance TIMs contain composite materials that are difficult to separate at end-of-life. The bonding properties that make these materials effective thermal conductors often complicate their recovery and reuse. Industry leaders are exploring design-for-disassembly approaches that maintain thermal performance while improving material recoverability.

Regulatory frameworks worldwide are evolving to address electronic waste management, with particular attention to hazardous substances in electronic components. The EU's Restriction of Hazardous Substances (RoHS) and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulations increasingly influence TIM formulations, driving innovation toward environmentally benign alternatives that maintain thermal performance.

Life cycle assessment (LCA) methodologies are becoming essential tools for evaluating the environmental impact of TIMs across their entire lifespan. These assessments consider raw material extraction, manufacturing processes, use-phase energy efficiency, and end-of-life management. Companies developing HBM4 thermal solutions increasingly incorporate LCA findings into their material selection and design processes.

Promising sustainable alternatives include bio-based TIMs derived from renewable resources, which offer reduced environmental impact while maintaining acceptable thermal performance. Research into carbon-based materials like graphene and carbon nanotubes shows potential for creating high-efficiency TIMs with lower environmental footprints than traditional metal-based solutions.

Energy efficiency during the operational lifetime of HBM4 packages represents another critical sustainability consideration. More effective TIMs that enable better heat dissipation can significantly reduce cooling energy requirements in data centers and high-performance computing applications, potentially offsetting their manufacturing impacts through operational efficiency gains.

Reliability Testing Methodologies for HBM4 Packages

Reliability testing for HBM4 packages requires comprehensive methodologies to ensure performance under extreme conditions. These methodologies must address the unique challenges posed by high-bandwidth memory interfaces operating in high-power environments.

Temperature cycling testing (TCT) represents a cornerstone methodology, subjecting HBM4 packages to rapid temperature fluctuations between -40°C and 125°C. This process evaluates the thermal expansion coefficient mismatch between different materials in the package, particularly at the interface between silicon dies and thermal interface materials (TIMs). Standard protocols typically involve 1,000 to 3,000 cycles with dwell times of 10-15 minutes at temperature extremes.

High-temperature storage life (HTSL) testing complements TCT by exposing packages to sustained elevated temperatures (typically 125°C to 150°C) for extended periods (1,000+ hours). This methodology specifically evaluates TIM degradation mechanisms, including material migration, phase separation, and chemical breakdown that may compromise thermal conductivity over time.

Power cycling testing introduces another critical dimension by applying actual operational power loads in rapid succession. This methodology simulates real-world usage patterns where processors experience frequent power state transitions. The resulting thermal expansion and contraction specifically stress the TIM-die and TIM-heat spreader interfaces, revealing potential delamination or pump-out effects.

Humidity testing under bias (THB) exposes packages to high humidity (85% RH) and elevated temperature (85°C) while electrically biased. This methodology evaluates moisture penetration at interface boundaries and potential corrosion mechanisms that may compromise package integrity.

Mechanical shock and vibration testing methodologies assess physical resilience, particularly important for HBM4 packages deployed in edge computing or industrial environments. Standard protocols include 1,500G shock testing and variable frequency vibration testing from 5Hz to 500Hz.

Advanced reliability methodologies incorporate in-situ monitoring techniques during testing. Transient thermal impedance measurements can detect subtle changes in thermal resistance across interfaces before catastrophic failure occurs. Similarly, acoustic microscopy enables non-destructive evaluation of interface integrity throughout the testing process.

Accelerated life testing methodologies apply statistical models (Arrhenius equations, Weibull distributions) to extrapolate long-term reliability from accelerated test data. These approaches are essential for predicting the 7-10 year operational lifespan expected from HBM4 packages in enterprise applications.

Temperature cycling testing (TCT) represents a cornerstone methodology, subjecting HBM4 packages to rapid temperature fluctuations between -40°C and 125°C. This process evaluates the thermal expansion coefficient mismatch between different materials in the package, particularly at the interface between silicon dies and thermal interface materials (TIMs). Standard protocols typically involve 1,000 to 3,000 cycles with dwell times of 10-15 minutes at temperature extremes.

High-temperature storage life (HTSL) testing complements TCT by exposing packages to sustained elevated temperatures (typically 125°C to 150°C) for extended periods (1,000+ hours). This methodology specifically evaluates TIM degradation mechanisms, including material migration, phase separation, and chemical breakdown that may compromise thermal conductivity over time.

Power cycling testing introduces another critical dimension by applying actual operational power loads in rapid succession. This methodology simulates real-world usage patterns where processors experience frequent power state transitions. The resulting thermal expansion and contraction specifically stress the TIM-die and TIM-heat spreader interfaces, revealing potential delamination or pump-out effects.

Humidity testing under bias (THB) exposes packages to high humidity (85% RH) and elevated temperature (85°C) while electrically biased. This methodology evaluates moisture penetration at interface boundaries and potential corrosion mechanisms that may compromise package integrity.

Mechanical shock and vibration testing methodologies assess physical resilience, particularly important for HBM4 packages deployed in edge computing or industrial environments. Standard protocols include 1,500G shock testing and variable frequency vibration testing from 5Hz to 500Hz.

Advanced reliability methodologies incorporate in-situ monitoring techniques during testing. Transient thermal impedance measurements can detect subtle changes in thermal resistance across interfaces before catastrophic failure occurs. Similarly, acoustic microscopy enables non-destructive evaluation of interface integrity throughout the testing process.

Accelerated life testing methodologies apply statistical models (Arrhenius equations, Weibull distributions) to extrapolate long-term reliability from accelerated test data. These approaches are essential for predicting the 7-10 year operational lifespan expected from HBM4 packages in enterprise applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!