How Does Pressure Affect Plate Heat Exchanger Performance?

JUL 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Pressure Impact on PHE

Pressure plays a crucial role in the performance of plate heat exchangers (PHEs), significantly influencing their heat transfer efficiency and overall effectiveness. The impact of pressure on PHEs can be observed through various mechanisms and phenomena that occur within the exchanger's intricate channel network.

One of the primary effects of pressure on PHE performance is its influence on fluid flow characteristics. As pressure increases, the fluid velocity within the channels tends to rise, leading to enhanced turbulence and improved heat transfer coefficients. This increased turbulence promotes better mixing of the fluid, reducing thermal boundary layers and facilitating more efficient heat exchange between the hot and cold streams.

Furthermore, higher pressure can result in a more uniform distribution of fluid across the plate surface. This improved distribution helps to minimize dead zones or areas of stagnant flow, ensuring that the entire heat transfer area is utilized effectively. Consequently, the overall heat transfer rate of the PHE is enhanced, leading to improved thermal performance.

Pressure also affects the phase change phenomena within PHEs, particularly in applications involving boiling or condensation. In boiling processes, increased pressure raises the saturation temperature of the fluid, potentially altering the boiling regime and heat transfer mechanisms. Similarly, in condensation applications, pressure changes can impact the condensation rate and the formation of liquid films on the plate surfaces.

The mechanical integrity of the PHE is another aspect influenced by pressure. Higher operating pressures necessitate more robust plate designs and gasket materials to prevent leakage and ensure safe operation. This consideration becomes particularly important in high-pressure applications, where the structural integrity of the exchanger must be carefully evaluated and maintained.

It is worth noting that excessive pressure can have detrimental effects on PHE performance. Extremely high pressures may lead to increased pressure drop across the exchanger, resulting in higher pumping power requirements and reduced overall system efficiency. Additionally, excessive pressure can cause plate deformation or damage, compromising the exchanger's performance and longevity.

The relationship between pressure and temperature in PHEs is also significant. As pressure influences the fluid's thermodynamic properties, it indirectly affects the temperature gradients and heat transfer rates within the exchanger. This interplay between pressure and temperature must be carefully considered when designing and optimizing PHE systems for specific applications.

In conclusion, pressure exerts a multifaceted influence on plate heat exchanger performance, affecting fluid dynamics, heat transfer mechanisms, and mechanical considerations. Understanding and optimizing the pressure-related aspects of PHEs is crucial for achieving optimal thermal efficiency and ensuring reliable operation across various industrial applications.

One of the primary effects of pressure on PHE performance is its influence on fluid flow characteristics. As pressure increases, the fluid velocity within the channels tends to rise, leading to enhanced turbulence and improved heat transfer coefficients. This increased turbulence promotes better mixing of the fluid, reducing thermal boundary layers and facilitating more efficient heat exchange between the hot and cold streams.

Furthermore, higher pressure can result in a more uniform distribution of fluid across the plate surface. This improved distribution helps to minimize dead zones or areas of stagnant flow, ensuring that the entire heat transfer area is utilized effectively. Consequently, the overall heat transfer rate of the PHE is enhanced, leading to improved thermal performance.

Pressure also affects the phase change phenomena within PHEs, particularly in applications involving boiling or condensation. In boiling processes, increased pressure raises the saturation temperature of the fluid, potentially altering the boiling regime and heat transfer mechanisms. Similarly, in condensation applications, pressure changes can impact the condensation rate and the formation of liquid films on the plate surfaces.

The mechanical integrity of the PHE is another aspect influenced by pressure. Higher operating pressures necessitate more robust plate designs and gasket materials to prevent leakage and ensure safe operation. This consideration becomes particularly important in high-pressure applications, where the structural integrity of the exchanger must be carefully evaluated and maintained.

It is worth noting that excessive pressure can have detrimental effects on PHE performance. Extremely high pressures may lead to increased pressure drop across the exchanger, resulting in higher pumping power requirements and reduced overall system efficiency. Additionally, excessive pressure can cause plate deformation or damage, compromising the exchanger's performance and longevity.

The relationship between pressure and temperature in PHEs is also significant. As pressure influences the fluid's thermodynamic properties, it indirectly affects the temperature gradients and heat transfer rates within the exchanger. This interplay between pressure and temperature must be carefully considered when designing and optimizing PHE systems for specific applications.

In conclusion, pressure exerts a multifaceted influence on plate heat exchanger performance, affecting fluid dynamics, heat transfer mechanisms, and mechanical considerations. Understanding and optimizing the pressure-related aspects of PHEs is crucial for achieving optimal thermal efficiency and ensuring reliable operation across various industrial applications.

Market Demand Analysis

The market demand for plate heat exchangers is experiencing significant growth, driven by the increasing need for energy-efficient heat transfer solutions across various industries. As energy costs continue to rise and environmental regulations become more stringent, businesses are seeking ways to optimize their thermal processes. Plate heat exchangers, known for their compact design and high efficiency, have become a preferred choice in many applications.

The global plate heat exchanger market is expanding rapidly, with projections indicating substantial growth in the coming years. This growth is particularly evident in industries such as chemical processing, food and beverage, HVAC, and power generation. The demand is fueled by the superior performance of plate heat exchangers, especially under varying pressure conditions, which allows for better heat transfer rates and overall system efficiency.

In the chemical processing industry, there is a growing need for heat exchangers that can handle corrosive fluids and operate under high-pressure conditions. Plate heat exchangers, with their ability to withstand different pressure levels, are increasingly being adopted in these challenging environments. The food and beverage sector is another key market, where strict hygiene standards and the need for precise temperature control drive the demand for plate heat exchangers that can perform efficiently under different pressure scenarios.

The HVAC industry is witnessing a shift towards more energy-efficient systems, leading to increased adoption of plate heat exchangers in both residential and commercial applications. The ability of these exchangers to maintain performance under varying pressure conditions makes them ideal for use in heating and cooling systems, where pressure fluctuations are common.

In the power generation sector, the push for cleaner energy sources has led to a rise in demand for plate heat exchangers in applications such as waste heat recovery and geothermal power plants. The performance of these exchangers under different pressure conditions is crucial in maximizing energy recovery and overall plant efficiency.

The market is also seeing a trend towards customized solutions, with manufacturers offering plate heat exchangers designed to operate optimally under specific pressure conditions. This customization is particularly valuable in industries where processes require precise control of temperature and pressure, such as in pharmaceutical manufacturing or specialized chemical processes.

As industries continue to focus on sustainability and energy efficiency, the demand for plate heat exchangers that can maintain high performance under various pressure conditions is expected to grow. This trend is likely to drive further innovations in design and materials, aiming to enhance the pressure-handling capabilities and overall efficiency of plate heat exchangers across different applications and industries.

The global plate heat exchanger market is expanding rapidly, with projections indicating substantial growth in the coming years. This growth is particularly evident in industries such as chemical processing, food and beverage, HVAC, and power generation. The demand is fueled by the superior performance of plate heat exchangers, especially under varying pressure conditions, which allows for better heat transfer rates and overall system efficiency.

In the chemical processing industry, there is a growing need for heat exchangers that can handle corrosive fluids and operate under high-pressure conditions. Plate heat exchangers, with their ability to withstand different pressure levels, are increasingly being adopted in these challenging environments. The food and beverage sector is another key market, where strict hygiene standards and the need for precise temperature control drive the demand for plate heat exchangers that can perform efficiently under different pressure scenarios.

The HVAC industry is witnessing a shift towards more energy-efficient systems, leading to increased adoption of plate heat exchangers in both residential and commercial applications. The ability of these exchangers to maintain performance under varying pressure conditions makes them ideal for use in heating and cooling systems, where pressure fluctuations are common.

In the power generation sector, the push for cleaner energy sources has led to a rise in demand for plate heat exchangers in applications such as waste heat recovery and geothermal power plants. The performance of these exchangers under different pressure conditions is crucial in maximizing energy recovery and overall plant efficiency.

The market is also seeing a trend towards customized solutions, with manufacturers offering plate heat exchangers designed to operate optimally under specific pressure conditions. This customization is particularly valuable in industries where processes require precise control of temperature and pressure, such as in pharmaceutical manufacturing or specialized chemical processes.

As industries continue to focus on sustainability and energy efficiency, the demand for plate heat exchangers that can maintain high performance under various pressure conditions is expected to grow. This trend is likely to drive further innovations in design and materials, aiming to enhance the pressure-handling capabilities and overall efficiency of plate heat exchangers across different applications and industries.

PHE Pressure Challenges

Pressure plays a crucial role in the performance of plate heat exchangers (PHEs), presenting both opportunities and challenges for engineers and designers. One of the primary challenges associated with pressure in PHEs is maintaining structural integrity while maximizing heat transfer efficiency. As operating pressures increase, the mechanical stress on the plates and gaskets also rises, potentially leading to deformation, leakage, or even catastrophic failure if not properly managed.

The design of plate corrugations is particularly sensitive to pressure considerations. While deeper corrugations can enhance turbulence and heat transfer, they also increase the pressure drop across the exchanger. This trade-off becomes more pronounced at higher operating pressures, requiring careful optimization to balance thermal performance with acceptable pressure losses.

Material selection for plates and gaskets becomes increasingly critical as pressure levels rise. Traditional materials may not provide sufficient strength or corrosion resistance under elevated pressure conditions, necessitating the use of more exotic and costly alloys or composite materials. This can significantly impact the overall cost and feasibility of PHE systems in high-pressure applications.

Gasket integrity is another major concern in high-pressure PHE operations. The risk of gasket failure increases with pressure, potentially leading to internal or external leaks. This not only compromises the efficiency of the heat exchanger but can also pose safety and environmental risks, especially when dealing with hazardous fluids.

Flow distribution within the PHE is also affected by pressure variations. Uneven pressure distribution can lead to flow maldistribution, reducing overall heat transfer effectiveness and potentially causing localized overheating or overcooling. Designers must carefully consider inlet and outlet configurations, as well as plate geometry, to ensure uniform flow under varying pressure conditions.

The impact of pressure on fluid properties adds another layer of complexity to PHE design. As pressure increases, the thermophysical properties of fluids can change significantly, affecting heat transfer coefficients and pressure drop calculations. This requires more sophisticated modeling and design approaches to accurately predict PHE performance across a wide range of operating pressures.

Fouling tendencies can also be influenced by pressure, with higher pressures potentially exacerbating fouling in some systems. This necessitates careful consideration of cleaning and maintenance strategies, as well as the potential implementation of fouling mitigation techniques specific to high-pressure operations.

The design of plate corrugations is particularly sensitive to pressure considerations. While deeper corrugations can enhance turbulence and heat transfer, they also increase the pressure drop across the exchanger. This trade-off becomes more pronounced at higher operating pressures, requiring careful optimization to balance thermal performance with acceptable pressure losses.

Material selection for plates and gaskets becomes increasingly critical as pressure levels rise. Traditional materials may not provide sufficient strength or corrosion resistance under elevated pressure conditions, necessitating the use of more exotic and costly alloys or composite materials. This can significantly impact the overall cost and feasibility of PHE systems in high-pressure applications.

Gasket integrity is another major concern in high-pressure PHE operations. The risk of gasket failure increases with pressure, potentially leading to internal or external leaks. This not only compromises the efficiency of the heat exchanger but can also pose safety and environmental risks, especially when dealing with hazardous fluids.

Flow distribution within the PHE is also affected by pressure variations. Uneven pressure distribution can lead to flow maldistribution, reducing overall heat transfer effectiveness and potentially causing localized overheating or overcooling. Designers must carefully consider inlet and outlet configurations, as well as plate geometry, to ensure uniform flow under varying pressure conditions.

The impact of pressure on fluid properties adds another layer of complexity to PHE design. As pressure increases, the thermophysical properties of fluids can change significantly, affecting heat transfer coefficients and pressure drop calculations. This requires more sophisticated modeling and design approaches to accurately predict PHE performance across a wide range of operating pressures.

Fouling tendencies can also be influenced by pressure, with higher pressures potentially exacerbating fouling in some systems. This necessitates careful consideration of cleaning and maintenance strategies, as well as the potential implementation of fouling mitigation techniques specific to high-pressure operations.

Current Pressure Solutions

01 Improved plate design for enhanced heat transfer

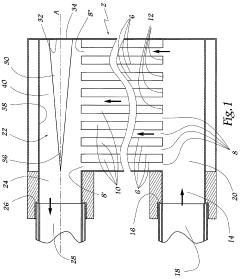

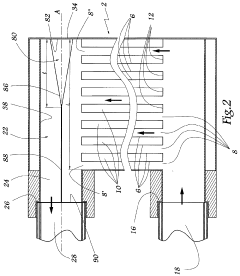

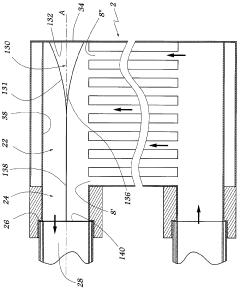

Advanced plate designs incorporate features such as corrugations, dimples, or chevron patterns to increase turbulence and surface area, resulting in improved heat transfer efficiency. These designs optimize fluid flow distribution and reduce fouling, leading to better overall performance of plate heat exchangers.- Improved plate design for enhanced heat transfer: Advanced plate designs, including optimized corrugation patterns and surface geometries, are utilized to increase turbulence and improve heat transfer efficiency in plate heat exchangers. These designs can enhance fluid mixing and reduce fouling, leading to better overall performance.

- Flow distribution optimization: Techniques for optimizing flow distribution within plate heat exchangers are implemented to ensure uniform fluid flow across the plates. This includes the use of specially designed inlet and outlet ports, as well as internal flow guides, to minimize dead zones and improve overall heat transfer efficiency.

- Material selection for enhanced thermal conductivity: The selection of high thermal conductivity materials for plate construction, such as advanced alloys or composite materials, is employed to improve heat transfer rates. These materials can also offer improved corrosion resistance and longer service life for the heat exchanger.

- Gasket and sealing innovations: Advanced gasket designs and sealing technologies are developed to prevent leakage and maintain optimal performance. These innovations can include improved gasket materials, enhanced sealing techniques, and designs that reduce thermal stress on the gaskets.

- Performance monitoring and control systems: Integration of sophisticated monitoring and control systems to optimize plate heat exchanger performance in real-time. These systems can include sensors for temperature, pressure, and flow rate, as well as algorithms for predictive maintenance and automatic adjustment of operating parameters.

02 Optimized flow distribution and channel configuration

Innovative channel configurations and flow distribution techniques are employed to enhance the performance of plate heat exchangers. These include multi-pass arrangements, variable plate spacing, and strategic placement of inlet/outlet ports to ensure uniform fluid distribution and minimize pressure drop across the exchanger.Expand Specific Solutions03 Advanced sealing and gasket technologies

High-performance gaskets and sealing methods are developed to prevent leakage and improve the overall efficiency of plate heat exchangers. These technologies ensure better fluid containment, allow for higher operating pressures, and extend the lifespan of the exchanger while maintaining optimal heat transfer performance.Expand Specific Solutions04 Material selection for enhanced durability and efficiency

The use of advanced materials, such as high-grade stainless steel, titanium, or specialized alloys, improves the corrosion resistance, thermal conductivity, and overall durability of plate heat exchangers. This results in extended operational life and maintained high performance even in challenging environments.Expand Specific Solutions05 Integration of smart monitoring and control systems

Incorporation of intelligent monitoring and control systems enables real-time performance optimization of plate heat exchangers. These systems can adjust operating parameters, detect fouling or inefficiencies, and schedule maintenance, leading to improved overall performance and energy efficiency.Expand Specific Solutions

Key PHE Manufacturers

The market for plate heat exchanger technology is in a mature stage, with a global market size estimated to be in the billions of dollars. The competitive landscape is characterized by established players like Alfa Laval, Kelvion, and SWEP, who have extensive experience and advanced technological capabilities. These companies are continuously innovating to improve heat exchanger performance under various pressure conditions. The technology's maturity is evident in its widespread adoption across industries, from HVAC to chemical processing. However, there is still room for innovation, particularly in enhancing efficiency and adapting to new applications, as demonstrated by ongoing research and development efforts from companies like Mitsubishi Electric and Daikin Industries.

Alfa Laval Corporate AB

Technical Solution: Alfa Laval has developed advanced plate heat exchangers that optimize performance under varying pressure conditions. Their technology incorporates asymmetric plate designs and variable plate gaps to enhance heat transfer efficiency[1]. The company's AlfaNova fusion-bonded plate heat exchangers can withstand pressures up to 130 bar (1885 psi)[2], making them suitable for high-pressure applications. Alfa Laval's PressureSecure design ensures a robust plate pack that maintains optimal plate alignment even under extreme pressure fluctuations, reducing the risk of leakage and improving overall reliability[3].

Strengths: High pressure tolerance, innovative plate designs for efficiency, and robust construction. Weaknesses: Potentially higher cost due to advanced materials and manufacturing processes.

Kelvion PHE GmbH

Technical Solution: Kelvion has developed a range of plate heat exchangers designed to perform optimally under various pressure conditions. Their NX series features a unique plate corrugation pattern that enhances turbulence and heat transfer efficiency while minimizing pressure drop[4]. Kelvion's high-pressure plate heat exchangers can operate at pressures up to 100 bar (1450 psi)[5], catering to demanding industrial applications. The company's PressureSecure technology incorporates reinforced plate designs and advanced gasket systems to maintain seal integrity under fluctuating pressure conditions, ensuring long-term reliability and minimizing maintenance requirements[6].

Strengths: Wide range of pressure-optimized designs, advanced plate technology for efficiency. Weaknesses: May have limitations in extremely high-pressure applications compared to some competitors.

Pressure-Related Patents

Plate heat exchanger

PatentWO2001073366A1

Innovation

- Incorporating an attached member within the outlet manifold that continuously reduces the fluid passage section from the bottom of the manifold, such as a conical body, to enhance fluid distribution and reduce pressure losses.

Plate heat exchanger

PatentInactiveEP1269100A1

Innovation

- Incorporating an attached member within the outlet manifold that continuously reduces the fluid passage section from the bottom, enhancing fluid distribution and reducing pressure losses by increasing dynamic pressure and homogenizing static pressure differences between channels.

PHE Design Optimization

Plate heat exchanger (PHE) design optimization is a critical process that aims to enhance the overall performance and efficiency of these heat transfer devices. The optimization process involves careful consideration of various design parameters, including plate geometry, flow arrangement, and material selection. One of the key factors influencing PHE performance is pressure, which plays a significant role in determining the heat transfer coefficients and overall thermal efficiency.

To optimize PHE design with respect to pressure, engineers must first understand the relationship between pressure and heat transfer. As pressure increases, the fluid's density and viscosity change, affecting the flow characteristics and heat transfer coefficients. Higher pressures generally lead to improved heat transfer rates due to increased turbulence and better fluid mixing. However, excessive pressure can also result in increased pumping power requirements and potential structural issues.

A crucial aspect of PHE design optimization is the selection of appropriate plate corrugation patterns. These patterns significantly influence the pressure drop and heat transfer characteristics of the exchanger. Chevron patterns, for instance, are widely used due to their ability to create turbulence and enhance heat transfer. By adjusting the chevron angle and depth, designers can fine-tune the balance between heat transfer performance and pressure drop.

Another important consideration in PHE design optimization is the flow arrangement. Counter-current flow configurations typically offer superior heat transfer performance compared to parallel flow arrangements. However, the pressure drop characteristics of these configurations must be carefully evaluated to ensure optimal overall performance. Multi-pass arrangements can also be employed to further enhance heat transfer while managing pressure drop.

Material selection is another critical factor in PHE design optimization. The choice of plate material affects not only the thermal conductivity but also the pressure resistance of the exchanger. High-strength materials like titanium or certain stainless steel alloys can withstand higher pressures, allowing for more compact designs and improved heat transfer rates. However, the cost implications of using such materials must be weighed against the performance benefits.

Advanced computational fluid dynamics (CFD) simulations and optimization algorithms play a crucial role in modern PHE design processes. These tools allow engineers to model and analyze the complex interactions between pressure, flow, and heat transfer within the exchanger. By utilizing these advanced techniques, designers can iteratively refine plate geometries, flow paths, and other parameters to achieve optimal performance under specific pressure conditions.

In conclusion, PHE design optimization with respect to pressure involves a multifaceted approach that considers various interrelated factors. By carefully balancing these elements and leveraging advanced design tools, engineers can develop highly efficient plate heat exchangers tailored to specific operating conditions and performance requirements.

To optimize PHE design with respect to pressure, engineers must first understand the relationship between pressure and heat transfer. As pressure increases, the fluid's density and viscosity change, affecting the flow characteristics and heat transfer coefficients. Higher pressures generally lead to improved heat transfer rates due to increased turbulence and better fluid mixing. However, excessive pressure can also result in increased pumping power requirements and potential structural issues.

A crucial aspect of PHE design optimization is the selection of appropriate plate corrugation patterns. These patterns significantly influence the pressure drop and heat transfer characteristics of the exchanger. Chevron patterns, for instance, are widely used due to their ability to create turbulence and enhance heat transfer. By adjusting the chevron angle and depth, designers can fine-tune the balance between heat transfer performance and pressure drop.

Another important consideration in PHE design optimization is the flow arrangement. Counter-current flow configurations typically offer superior heat transfer performance compared to parallel flow arrangements. However, the pressure drop characteristics of these configurations must be carefully evaluated to ensure optimal overall performance. Multi-pass arrangements can also be employed to further enhance heat transfer while managing pressure drop.

Material selection is another critical factor in PHE design optimization. The choice of plate material affects not only the thermal conductivity but also the pressure resistance of the exchanger. High-strength materials like titanium or certain stainless steel alloys can withstand higher pressures, allowing for more compact designs and improved heat transfer rates. However, the cost implications of using such materials must be weighed against the performance benefits.

Advanced computational fluid dynamics (CFD) simulations and optimization algorithms play a crucial role in modern PHE design processes. These tools allow engineers to model and analyze the complex interactions between pressure, flow, and heat transfer within the exchanger. By utilizing these advanced techniques, designers can iteratively refine plate geometries, flow paths, and other parameters to achieve optimal performance under specific pressure conditions.

In conclusion, PHE design optimization with respect to pressure involves a multifaceted approach that considers various interrelated factors. By carefully balancing these elements and leveraging advanced design tools, engineers can develop highly efficient plate heat exchangers tailored to specific operating conditions and performance requirements.

Energy Efficiency Impact

Pressure plays a significant role in the energy efficiency of plate heat exchangers. As pressure increases, the heat transfer coefficient generally improves, leading to enhanced thermal performance. This is primarily due to the increased turbulence and mixing of fluids within the exchanger, which promotes better heat transfer between the hot and cold streams.

Higher pressure can also result in a more compact design, as it allows for smaller flow passages and thinner plates. This reduction in size can lead to lower material costs and a smaller footprint, which is particularly beneficial in space-constrained applications. Additionally, the reduced fluid volume within the exchanger can result in faster response times to changes in operating conditions, potentially improving overall system efficiency.

However, it's important to note that increasing pressure is not always a straightforward path to improved energy efficiency. As pressure rises, so does the pumping power required to circulate fluids through the exchanger. This increased pumping energy can offset some of the gains in heat transfer efficiency, necessitating a careful balance between pressure and overall system performance.

The relationship between pressure and fouling is another critical factor affecting energy efficiency. Higher pressures can sometimes exacerbate fouling issues, particularly in applications with particulate-laden fluids. Fouling reduces heat transfer effectiveness over time, leading to decreased energy efficiency and potentially increased maintenance requirements.

Pressure drop across the plate heat exchanger is a key consideration in energy efficiency assessments. While higher pressures can improve heat transfer, they also typically result in greater pressure drops. This pressure loss must be carefully managed to minimize the energy input required for fluid circulation, ensuring that the overall system remains as efficient as possible.

In terms of material selection and design, increased pressure necessitates stronger, more robust construction. This can lead to thicker plates or reinforced designs, which may slightly reduce heat transfer efficiency due to increased thermal resistance. However, advanced materials and manufacturing techniques can help mitigate these effects, allowing for high-pressure operation without significant compromises in thermal performance.

Higher pressure can also result in a more compact design, as it allows for smaller flow passages and thinner plates. This reduction in size can lead to lower material costs and a smaller footprint, which is particularly beneficial in space-constrained applications. Additionally, the reduced fluid volume within the exchanger can result in faster response times to changes in operating conditions, potentially improving overall system efficiency.

However, it's important to note that increasing pressure is not always a straightforward path to improved energy efficiency. As pressure rises, so does the pumping power required to circulate fluids through the exchanger. This increased pumping energy can offset some of the gains in heat transfer efficiency, necessitating a careful balance between pressure and overall system performance.

The relationship between pressure and fouling is another critical factor affecting energy efficiency. Higher pressures can sometimes exacerbate fouling issues, particularly in applications with particulate-laden fluids. Fouling reduces heat transfer effectiveness over time, leading to decreased energy efficiency and potentially increased maintenance requirements.

Pressure drop across the plate heat exchanger is a key consideration in energy efficiency assessments. While higher pressures can improve heat transfer, they also typically result in greater pressure drops. This pressure loss must be carefully managed to minimize the energy input required for fluid circulation, ensuring that the overall system remains as efficient as possible.

In terms of material selection and design, increased pressure necessitates stronger, more robust construction. This can lead to thicker plates or reinforced designs, which may slightly reduce heat transfer efficiency due to increased thermal resistance. However, advanced materials and manufacturing techniques can help mitigate these effects, allowing for high-pressure operation without significant compromises in thermal performance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!