How Plate Heat Exchanger Design Influences Heat Distribution?

JUL 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PHE Design Background and Objectives

Plate heat exchangers (PHEs) have been a cornerstone in industrial heat transfer applications since their introduction in the 1920s. These compact and efficient devices have revolutionized thermal management across various sectors, including food processing, chemical manufacturing, and HVAC systems. The evolution of PHE technology has been driven by the continuous pursuit of enhanced heat transfer efficiency, reduced fouling, and improved overall performance.

The primary objective of PHE design is to optimize heat distribution, which directly impacts the exchanger's effectiveness and energy efficiency. This goal has become increasingly crucial in the face of growing environmental concerns and stringent energy regulations. By focusing on how PHE design influences heat distribution, researchers and engineers aim to develop more sustainable and cost-effective solutions for industrial processes.

Over the years, PHE design has progressed from simple, uniform plate patterns to complex, asymmetrical configurations. This evolution has been guided by advancements in computational fluid dynamics (CFD) and materials science, allowing for more precise control over fluid flow and heat transfer characteristics. The interplay between plate geometry, channel configuration, and flow arrangement has emerged as a key area of study in the quest for optimal heat distribution.

Recent technological trends in PHE design include the development of multi-scale surface textures, novel plate materials with enhanced thermal properties, and innovative flow distribution systems. These advancements aim to address longstanding challenges such as uneven temperature profiles, flow maldistribution, and localized hot spots or dead zones within the exchanger.

The ongoing research in PHE design is driven by several factors, including the need for more compact and lightweight exchangers in space-constrained applications, the demand for higher temperature and pressure tolerances in extreme operating conditions, and the push for reduced material usage and manufacturing costs. Additionally, there is a growing emphasis on designs that facilitate easier maintenance and cleaning, thereby extending the operational lifespan of PHEs.

As we look towards the future, the objectives of PHE design are expanding to encompass not only thermal performance but also environmental sustainability and adaptability to emerging energy systems. This includes exploring designs that are compatible with low-GWP refrigerants, renewable energy sources, and waste heat recovery applications. The integration of smart technologies and real-time monitoring capabilities is also becoming a focal point, enabling predictive maintenance and adaptive performance optimization.

The primary objective of PHE design is to optimize heat distribution, which directly impacts the exchanger's effectiveness and energy efficiency. This goal has become increasingly crucial in the face of growing environmental concerns and stringent energy regulations. By focusing on how PHE design influences heat distribution, researchers and engineers aim to develop more sustainable and cost-effective solutions for industrial processes.

Over the years, PHE design has progressed from simple, uniform plate patterns to complex, asymmetrical configurations. This evolution has been guided by advancements in computational fluid dynamics (CFD) and materials science, allowing for more precise control over fluid flow and heat transfer characteristics. The interplay between plate geometry, channel configuration, and flow arrangement has emerged as a key area of study in the quest for optimal heat distribution.

Recent technological trends in PHE design include the development of multi-scale surface textures, novel plate materials with enhanced thermal properties, and innovative flow distribution systems. These advancements aim to address longstanding challenges such as uneven temperature profiles, flow maldistribution, and localized hot spots or dead zones within the exchanger.

The ongoing research in PHE design is driven by several factors, including the need for more compact and lightweight exchangers in space-constrained applications, the demand for higher temperature and pressure tolerances in extreme operating conditions, and the push for reduced material usage and manufacturing costs. Additionally, there is a growing emphasis on designs that facilitate easier maintenance and cleaning, thereby extending the operational lifespan of PHEs.

As we look towards the future, the objectives of PHE design are expanding to encompass not only thermal performance but also environmental sustainability and adaptability to emerging energy systems. This includes exploring designs that are compatible with low-GWP refrigerants, renewable energy sources, and waste heat recovery applications. The integration of smart technologies and real-time monitoring capabilities is also becoming a focal point, enabling predictive maintenance and adaptive performance optimization.

Market Demand Analysis for PHE

The global market for plate heat exchangers (PHEs) has been experiencing steady growth, driven by increasing demand across various industries such as chemical processing, food and beverage, HVAC, and power generation. The efficiency and compact design of PHEs make them particularly attractive in applications where space is limited and heat transfer requirements are high.

In recent years, there has been a notable shift towards more energy-efficient and environmentally friendly heat exchange solutions. This trend has significantly boosted the demand for PHEs, as they offer superior heat transfer efficiency compared to traditional shell and tube heat exchangers. The ability of PHEs to achieve higher heat transfer coefficients translates to reduced energy consumption and lower operational costs, aligning with the global push for sustainable industrial practices.

The food and beverage industry has emerged as a key driver of PHE market growth. Stringent hygiene requirements and the need for precise temperature control in food processing have led to increased adoption of PHEs. Their ease of cleaning and ability to maintain product quality make them ideal for applications such as pasteurization, sterilization, and general heating and cooling processes in food production.

Another significant market segment for PHEs is the HVAC industry. As urbanization continues and the construction of commercial and residential buildings rises, the demand for efficient heating and cooling systems grows. PHEs play a crucial role in modern HVAC systems, offering compact and efficient solutions for both large-scale commercial applications and smaller residential units.

The chemical and petrochemical industries also contribute substantially to the PHE market. These sectors require heat exchangers capable of handling corrosive fluids and operating under high pressure and temperature conditions. The versatility of PHEs in terms of material selection and their ability to withstand harsh environments make them well-suited for these demanding applications.

Geographically, Asia-Pacific has emerged as the fastest-growing market for PHEs, driven by rapid industrialization and infrastructure development in countries like China and India. The region's expanding manufacturing sector and increasing focus on energy efficiency are expected to fuel further growth in the coming years.

Looking ahead, the market for PHEs is projected to continue its upward trajectory. Factors such as ongoing technological advancements in PHE design, increasing focus on energy efficiency, and stringent environmental regulations are expected to drive market growth. Additionally, the growing adoption of renewable energy sources and the expansion of district heating and cooling systems present new opportunities for PHE applications, further expanding the market potential.

In recent years, there has been a notable shift towards more energy-efficient and environmentally friendly heat exchange solutions. This trend has significantly boosted the demand for PHEs, as they offer superior heat transfer efficiency compared to traditional shell and tube heat exchangers. The ability of PHEs to achieve higher heat transfer coefficients translates to reduced energy consumption and lower operational costs, aligning with the global push for sustainable industrial practices.

The food and beverage industry has emerged as a key driver of PHE market growth. Stringent hygiene requirements and the need for precise temperature control in food processing have led to increased adoption of PHEs. Their ease of cleaning and ability to maintain product quality make them ideal for applications such as pasteurization, sterilization, and general heating and cooling processes in food production.

Another significant market segment for PHEs is the HVAC industry. As urbanization continues and the construction of commercial and residential buildings rises, the demand for efficient heating and cooling systems grows. PHEs play a crucial role in modern HVAC systems, offering compact and efficient solutions for both large-scale commercial applications and smaller residential units.

The chemical and petrochemical industries also contribute substantially to the PHE market. These sectors require heat exchangers capable of handling corrosive fluids and operating under high pressure and temperature conditions. The versatility of PHEs in terms of material selection and their ability to withstand harsh environments make them well-suited for these demanding applications.

Geographically, Asia-Pacific has emerged as the fastest-growing market for PHEs, driven by rapid industrialization and infrastructure development in countries like China and India. The region's expanding manufacturing sector and increasing focus on energy efficiency are expected to fuel further growth in the coming years.

Looking ahead, the market for PHEs is projected to continue its upward trajectory. Factors such as ongoing technological advancements in PHE design, increasing focus on energy efficiency, and stringent environmental regulations are expected to drive market growth. Additionally, the growing adoption of renewable energy sources and the expansion of district heating and cooling systems present new opportunities for PHE applications, further expanding the market potential.

Current PHE Technology Challenges

Plate Heat Exchangers (PHEs) have become increasingly popular in various industries due to their compact design and high efficiency. However, as the demand for more advanced thermal management solutions grows, several challenges have emerged in current PHE technology, particularly concerning heat distribution.

One of the primary challenges is the uneven flow distribution within the exchanger. The complex geometry of PHEs can lead to non-uniform fluid flow across the plates, resulting in localized hot spots or cold regions. This uneven distribution not only reduces overall heat transfer efficiency but also increases the risk of thermal stress and potential material fatigue.

Another significant challenge is fouling and scaling. The narrow channels between plates are prone to accumulation of deposits, which can severely impact heat transfer performance over time. This issue is particularly prevalent in applications involving hard water or fluids with high mineral content. The reduced heat transfer efficiency due to fouling necessitates more frequent maintenance and cleaning, increasing operational costs and downtime.

The design of effective gaskets and seals presents another ongoing challenge. As PHEs operate under varying temperature and pressure conditions, maintaining a reliable seal between plates is crucial. Gasket materials must withstand thermal cycling, chemical exposure, and mechanical stress without degradation or leakage. Failure in this aspect can lead to cross-contamination between fluids or external leaks, compromising both performance and safety.

Optimizing plate geometry for enhanced heat transfer while minimizing pressure drop remains a complex balancing act. While increasing turbulence through complex corrugation patterns can improve heat transfer, it also leads to higher pressure drops, requiring more pumping power. Finding the optimal trade-off between these factors continues to challenge designers and engineers.

The challenge of thermal expansion and contraction is also significant in PHE design. Temperature fluctuations during operation can cause differential expansion between plates and frame components, potentially leading to misalignment, leakage, or structural stress. Addressing this issue requires careful material selection and innovative design solutions to accommodate thermal movement without compromising performance or integrity.

Lastly, the accurate prediction and control of two-phase flow behavior in PHEs remain challenging. In applications involving phase change, such as condensation or evaporation, the complex interactions between liquid and vapor phases within the narrow channels can lead to flow instabilities and reduced heat transfer efficiency. Developing reliable models and design methodologies for two-phase flow in PHEs is an ongoing area of research and development.

One of the primary challenges is the uneven flow distribution within the exchanger. The complex geometry of PHEs can lead to non-uniform fluid flow across the plates, resulting in localized hot spots or cold regions. This uneven distribution not only reduces overall heat transfer efficiency but also increases the risk of thermal stress and potential material fatigue.

Another significant challenge is fouling and scaling. The narrow channels between plates are prone to accumulation of deposits, which can severely impact heat transfer performance over time. This issue is particularly prevalent in applications involving hard water or fluids with high mineral content. The reduced heat transfer efficiency due to fouling necessitates more frequent maintenance and cleaning, increasing operational costs and downtime.

The design of effective gaskets and seals presents another ongoing challenge. As PHEs operate under varying temperature and pressure conditions, maintaining a reliable seal between plates is crucial. Gasket materials must withstand thermal cycling, chemical exposure, and mechanical stress without degradation or leakage. Failure in this aspect can lead to cross-contamination between fluids or external leaks, compromising both performance and safety.

Optimizing plate geometry for enhanced heat transfer while minimizing pressure drop remains a complex balancing act. While increasing turbulence through complex corrugation patterns can improve heat transfer, it also leads to higher pressure drops, requiring more pumping power. Finding the optimal trade-off between these factors continues to challenge designers and engineers.

The challenge of thermal expansion and contraction is also significant in PHE design. Temperature fluctuations during operation can cause differential expansion between plates and frame components, potentially leading to misalignment, leakage, or structural stress. Addressing this issue requires careful material selection and innovative design solutions to accommodate thermal movement without compromising performance or integrity.

Lastly, the accurate prediction and control of two-phase flow behavior in PHEs remain challenging. In applications involving phase change, such as condensation or evaporation, the complex interactions between liquid and vapor phases within the narrow channels can lead to flow instabilities and reduced heat transfer efficiency. Developing reliable models and design methodologies for two-phase flow in PHEs is an ongoing area of research and development.

Current PHE Design Solutions

01 Plate design optimization for heat distribution

Optimizing the design of heat exchanger plates to improve heat distribution efficiency. This includes modifications to plate geometry, surface patterns, and flow channel configurations to enhance heat transfer and reduce thermal resistance.- Plate design for improved heat distribution: Innovative plate designs in heat exchangers can enhance heat distribution. This includes features like optimized flow channels, turbulence-inducing patterns, and variable plate thicknesses to promote uniform heat transfer across the exchanger surface.

- Flow arrangement optimization: Optimizing the flow arrangement in plate heat exchangers can significantly improve heat distribution. This involves strategic placement of inlet and outlet ports, implementing multi-pass configurations, and designing flow distributors to ensure even fluid distribution across plates.

- Advanced materials for enhanced heat transfer: Utilizing advanced materials in plate construction can improve heat distribution. This includes high thermal conductivity materials, surface treatments to enhance heat transfer, and composite materials that combine desirable thermal and mechanical properties.

- Computational modeling for heat distribution analysis: Employing computational fluid dynamics (CFD) and thermal modeling techniques can optimize heat distribution in plate heat exchangers. These tools allow for detailed analysis of flow patterns, temperature gradients, and heat transfer coefficients, leading to improved designs.

- Modular and customizable plate configurations: Developing modular and customizable plate configurations allows for tailored heat distribution solutions. This approach enables the creation of heat exchanger designs that can be adapted to specific process requirements, fluid properties, and operating conditions.

02 Flow distribution techniques

Implementing various flow distribution techniques to ensure uniform heat distribution across the plate heat exchanger. This may involve the use of flow distributors, baffles, or specially designed inlet and outlet configurations to achieve optimal fluid distribution and heat transfer.Expand Specific Solutions03 Material selection for enhanced heat transfer

Selecting appropriate materials for plate construction to maximize heat transfer efficiency. This includes the use of high thermal conductivity materials, corrosion-resistant alloys, or composite materials to improve overall heat exchanger performance.Expand Specific Solutions04 Advanced sealing and gasket technologies

Developing and implementing advanced sealing and gasket technologies to prevent leakage and maintain optimal heat distribution. This includes the use of innovative gasket materials, sealing techniques, and plate compression methods to ensure efficient heat transfer between fluid streams.Expand Specific Solutions05 Computational modeling and simulation

Utilizing computational fluid dynamics (CFD) and thermal modeling techniques to analyze and optimize heat distribution in plate heat exchangers. This involves the use of advanced software tools to simulate fluid flow, heat transfer, and thermal stress, enabling the design of more efficient and reliable heat exchangers.Expand Specific Solutions

Key Players in PHE Industry

The plate heat exchanger design market is in a mature growth stage, with a global market size estimated to exceed $5 billion by 2025. Technological advancements are driving innovation in heat distribution efficiency and compact designs. Key players like Alfa Laval, Danfoss, and Gree Electric Appliances are leading the market with advanced solutions. Emerging companies such as Zhejiang Sanhua Intelligent Controls and Reaction Engines are introducing novel technologies, particularly in areas like microchannel heat exchangers and aerospace applications. The industry is seeing increased focus on energy efficiency and sustainability, with companies investing in R&D to develop more eco-friendly and high-performance heat exchanger designs.

Alfa Laval Corporate AB

Technical Solution: Alfa Laval has developed advanced plate heat exchanger designs that significantly influence heat distribution. Their AlfaNova fusion-bonded plate heat exchangers use a patented Active Core Technology, which creates a highly efficient heat transfer surface[1]. This technology allows for a more uniform heat distribution across the plates, reducing thermal stress and improving overall performance. The company has also introduced asymmetric plate designs that create a turbulent flow pattern, enhancing heat transfer efficiency by up to 25% compared to traditional symmetric designs[2]. Additionally, Alfa Laval's PressureSecure design ensures optimal plate alignment and gasket sealing, maintaining consistent heat distribution even under high-pressure conditions[3].

Strengths: Superior heat transfer efficiency, reduced thermal stress, and high-pressure tolerance. Weaknesses: Higher initial cost compared to traditional designs, and potential complexity in maintenance for advanced models.

Mitsubishi Electric Corp.

Technical Solution: Mitsubishi Electric has developed innovative plate heat exchanger designs that significantly impact heat distribution. Their patented "Dimple Plate" technology creates turbulent flow patterns within the exchanger, enhancing heat transfer efficiency by up to 30% compared to conventional flat plates[4]. The company has also introduced a variable plate thickness design, where thicker plates are used in high-stress areas to improve durability and maintain consistent heat distribution. Mitsubishi's advanced computational fluid dynamics (CFD) modeling allows for precise optimization of plate geometries, resulting in more uniform heat distribution and reduced hot spots[5]. Furthermore, their eco-friendly refrigerant-compatible designs ensure efficient heat distribution while meeting environmental regulations[6].

Strengths: High heat transfer efficiency, improved durability, and environmentally friendly designs. Weaknesses: Potentially higher manufacturing costs and complexity in plate production.

Core PHE Heat Distribution Innovations

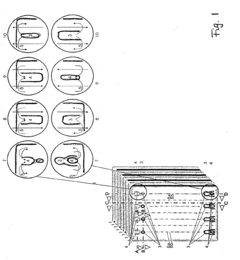

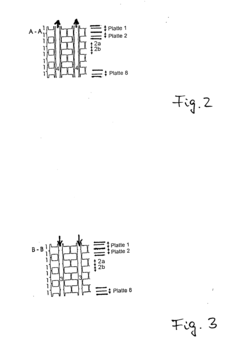

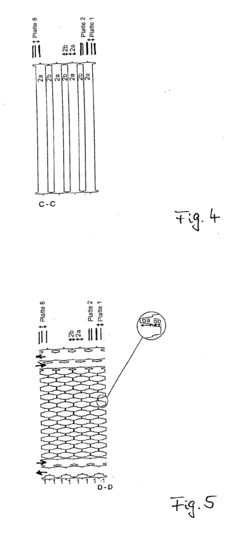

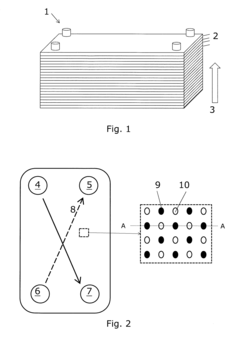

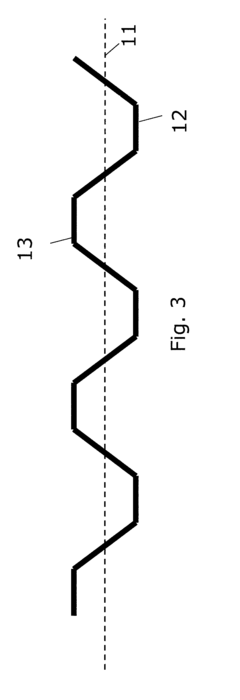

Plate heat exchanger

PatentInactiveEP1691158A1

Innovation

- A plate heat exchanger design featuring a stack of plates with alternating cocurrent and countercurrent flow paths, smooth unprofiled surfaces, and strategically placed distribution and collection channels to facilitate laminar flow, optimizing plate spacing for low pressure loss and high heat transfer efficiency.

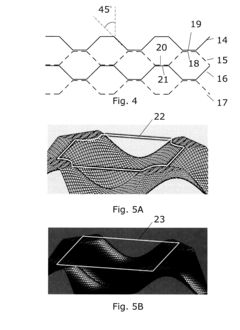

Plate heat exchanger

PatentInactiveUS20160146543A1

Innovation

- A plate heat exchanger with dimples arranged in a matrix pattern, where the dimples have a specific circumference-to-distance ratio, allowing for increased strength and reduced plate thickness while maintaining thermal efficiency, by optimizing the contact area and pressure distribution.

PHE Material Advancements

Material advancements in plate heat exchanger (PHE) design have significantly influenced heat distribution efficiency and overall performance. Recent developments in material science have led to the introduction of new alloys and composites that offer superior thermal conductivity, corrosion resistance, and mechanical strength. These innovations have enabled the creation of thinner, more durable plates that enhance heat transfer while reducing the overall size and weight of PHEs.

One of the most notable advancements is the use of titanium alloys in PHE construction. Titanium's excellent corrosion resistance and high strength-to-weight ratio make it ideal for applications in aggressive environments, such as seawater cooling systems. The material's ability to withstand high temperatures and pressures has expanded the operational range of PHEs, allowing for more efficient heat distribution in extreme conditions.

Stainless steel remains a popular choice for PHE plates, but recent improvements in its composition have enhanced its performance. Advanced grades of stainless steel, such as super duplex and high-molybdenum austenitic steels, offer increased resistance to pitting and crevice corrosion. These materials maintain their integrity in harsh chemical environments, ensuring consistent heat distribution over extended periods of operation.

The introduction of polymer-based materials in PHE design has opened new possibilities for low-temperature applications. Specialized thermoplastics and fluoropolymers provide excellent chemical resistance and can operate effectively in corrosive environments where traditional metallic materials may fail. While these materials have lower thermal conductivity compared to metals, their unique properties allow for innovative plate designs that compensate for this limitation.

Composite materials, combining the strengths of different substances, are emerging as promising candidates for PHE plates. Carbon fiber reinforced polymers (CFRP) offer high strength, low weight, and good thermal conductivity. These composites can be engineered to have specific thermal expansion coefficients, reducing thermal stress and improving the overall lifespan of the exchanger.

Nanotechnology has also made its mark on PHE material advancements. Nanocoatings applied to plate surfaces can significantly enhance heat transfer by altering surface properties at the molecular level. These coatings can increase hydrophobicity, reduce fouling, and improve overall heat exchange efficiency. Additionally, the incorporation of nanoparticles into base materials has shown promise in enhancing thermal conductivity without compromising other material properties.

The ongoing research in advanced ceramics presents exciting possibilities for future PHE designs. Materials such as silicon carbide and aluminum nitride offer exceptional thermal conductivity and chemical resistance. While currently limited by manufacturing challenges and cost considerations, these ceramics have the potential to revolutionize heat distribution in high-temperature and corrosive applications.

One of the most notable advancements is the use of titanium alloys in PHE construction. Titanium's excellent corrosion resistance and high strength-to-weight ratio make it ideal for applications in aggressive environments, such as seawater cooling systems. The material's ability to withstand high temperatures and pressures has expanded the operational range of PHEs, allowing for more efficient heat distribution in extreme conditions.

Stainless steel remains a popular choice for PHE plates, but recent improvements in its composition have enhanced its performance. Advanced grades of stainless steel, such as super duplex and high-molybdenum austenitic steels, offer increased resistance to pitting and crevice corrosion. These materials maintain their integrity in harsh chemical environments, ensuring consistent heat distribution over extended periods of operation.

The introduction of polymer-based materials in PHE design has opened new possibilities for low-temperature applications. Specialized thermoplastics and fluoropolymers provide excellent chemical resistance and can operate effectively in corrosive environments where traditional metallic materials may fail. While these materials have lower thermal conductivity compared to metals, their unique properties allow for innovative plate designs that compensate for this limitation.

Composite materials, combining the strengths of different substances, are emerging as promising candidates for PHE plates. Carbon fiber reinforced polymers (CFRP) offer high strength, low weight, and good thermal conductivity. These composites can be engineered to have specific thermal expansion coefficients, reducing thermal stress and improving the overall lifespan of the exchanger.

Nanotechnology has also made its mark on PHE material advancements. Nanocoatings applied to plate surfaces can significantly enhance heat transfer by altering surface properties at the molecular level. These coatings can increase hydrophobicity, reduce fouling, and improve overall heat exchange efficiency. Additionally, the incorporation of nanoparticles into base materials has shown promise in enhancing thermal conductivity without compromising other material properties.

The ongoing research in advanced ceramics presents exciting possibilities for future PHE designs. Materials such as silicon carbide and aluminum nitride offer exceptional thermal conductivity and chemical resistance. While currently limited by manufacturing challenges and cost considerations, these ceramics have the potential to revolutionize heat distribution in high-temperature and corrosive applications.

Energy Efficiency in PHE Design

Energy efficiency is a critical aspect of plate heat exchanger (PHE) design, directly impacting the overall performance and operational costs of thermal systems. The design of PHEs plays a crucial role in optimizing heat distribution and maximizing energy efficiency. One of the key factors influencing energy efficiency is the plate geometry, including corrugation patterns and angles. Advanced plate designs with enhanced turbulence promoters can significantly improve heat transfer coefficients while minimizing pressure drop, leading to more efficient heat exchange processes.

The arrangement of flow channels within the PHE also contributes to energy efficiency. Multi-pass configurations and strategic flow distributions can enhance heat transfer rates and reduce thermal gradients across the exchanger. By optimizing the number of plates and their arrangement, designers can achieve a balance between heat transfer area and fluid velocity, ensuring optimal energy utilization.

Material selection is another vital consideration in PHE design for energy efficiency. High thermal conductivity materials, such as titanium or high-grade stainless steel, can improve heat transfer rates. Additionally, the use of thin plates with low thermal resistance further enhances energy efficiency by reducing the overall thermal resistance of the system.

The incorporation of advanced sealing technologies and gasket designs contributes to maintaining the integrity of flow channels and preventing cross-contamination between fluids. This not only ensures operational safety but also maintains the intended heat transfer efficiency by preventing unwanted mixing or leakage.

Computational fluid dynamics (CFD) simulations and advanced modeling techniques have become indispensable tools in optimizing PHE designs for energy efficiency. These tools allow designers to analyze flow patterns, identify areas of poor distribution, and optimize plate geometries to achieve uniform heat transfer across the entire exchanger surface.

Furthermore, the integration of smart control systems and real-time monitoring capabilities in modern PHE designs enables dynamic adjustment of operating parameters. This adaptability ensures that the exchanger operates at peak efficiency across varying load conditions, contributing to overall energy savings in industrial processes.

In conclusion, the energy efficiency of plate heat exchangers is intricately linked to their design features. By focusing on plate geometry, flow arrangement, material selection, and incorporating advanced technologies, designers can significantly enhance heat distribution and overall energy efficiency in PHE systems.

The arrangement of flow channels within the PHE also contributes to energy efficiency. Multi-pass configurations and strategic flow distributions can enhance heat transfer rates and reduce thermal gradients across the exchanger. By optimizing the number of plates and their arrangement, designers can achieve a balance between heat transfer area and fluid velocity, ensuring optimal energy utilization.

Material selection is another vital consideration in PHE design for energy efficiency. High thermal conductivity materials, such as titanium or high-grade stainless steel, can improve heat transfer rates. Additionally, the use of thin plates with low thermal resistance further enhances energy efficiency by reducing the overall thermal resistance of the system.

The incorporation of advanced sealing technologies and gasket designs contributes to maintaining the integrity of flow channels and preventing cross-contamination between fluids. This not only ensures operational safety but also maintains the intended heat transfer efficiency by preventing unwanted mixing or leakage.

Computational fluid dynamics (CFD) simulations and advanced modeling techniques have become indispensable tools in optimizing PHE designs for energy efficiency. These tools allow designers to analyze flow patterns, identify areas of poor distribution, and optimize plate geometries to achieve uniform heat transfer across the entire exchanger surface.

Furthermore, the integration of smart control systems and real-time monitoring capabilities in modern PHE designs enables dynamic adjustment of operating parameters. This adaptability ensures that the exchanger operates at peak efficiency across varying load conditions, contributing to overall energy savings in industrial processes.

In conclusion, the energy efficiency of plate heat exchangers is intricately linked to their design features. By focusing on plate geometry, flow arrangement, material selection, and incorporating advanced technologies, designers can significantly enhance heat distribution and overall energy efficiency in PHE systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!