How Structural Ceramics Enhance the Durability of Cutting Tools

SEP 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Structural Ceramics Evolution and Performance Goals

Structural ceramics have undergone significant evolution since their initial application in cutting tools during the mid-20th century. The journey began with simple alumina (Al2O3) ceramics that offered improved hardness over traditional carbide tools but suffered from brittleness and thermal shock sensitivity. The 1970s marked a pivotal advancement with the introduction of silicon nitride (Si3N4) ceramics, which demonstrated superior fracture toughness while maintaining excellent hardness characteristics.

The 1980s and 1990s witnessed the development of ceramic matrix composites (CMCs) and the incorporation of whisker reinforcements, particularly silicon carbide (SiC) whiskers in alumina matrices. These innovations addressed the inherent brittleness of monolithic ceramics while preserving their wear resistance properties. Concurrently, zirconia-toughened alumina (ZTA) emerged as another significant advancement, utilizing transformation toughening mechanisms to enhance crack propagation resistance.

The early 2000s saw the rise of nanostructured ceramics and multilayer coating technologies, enabling unprecedented control over microstructure and surface properties. Recent developments have focused on functionally graded materials (FGMs) that feature composition gradients designed to optimize performance across different regions of the cutting tool. These advancements have progressively expanded the application range of ceramic cutting tools from initial use in finishing operations to increasingly demanding roughing applications.

Performance goals for structural ceramics in cutting tools have evolved in response to industry demands for higher productivity and sustainability. Current objectives include achieving hot hardness exceeding 93 HRA at temperatures above 1000°C, fracture toughness values greater than 7 MPa·m1/2, and thermal shock resistance parameters (R) above 250 W/m. Additionally, modern ceramic cutting tools aim to maintain edge integrity for cutting distances exceeding 5000 meters when machining hardened steels and superalloys.

Future performance targets emphasize multifunctionality, with goals to develop self-diagnostic capabilities through embedded sensors that can monitor tool wear and predict failure. Environmental considerations are driving research toward ceramics that can be manufactured with reduced energy consumption and potentially recycled at end-of-life. The ultimate aspiration is to create ceramic cutting tools capable of dry machining operations across all material classes, eliminating the need for coolants while maintaining tool life comparable to or exceeding that of conventional tools used with cooling systems.

The technological trajectory suggests that next-generation structural ceramics will likely incorporate elements of biomimicry, adopting hierarchical structures inspired by natural materials to achieve unprecedented combinations of toughness and hardness. This evolution continues to push the boundaries of cutting tool performance in increasingly demanding manufacturing environments.

The 1980s and 1990s witnessed the development of ceramic matrix composites (CMCs) and the incorporation of whisker reinforcements, particularly silicon carbide (SiC) whiskers in alumina matrices. These innovations addressed the inherent brittleness of monolithic ceramics while preserving their wear resistance properties. Concurrently, zirconia-toughened alumina (ZTA) emerged as another significant advancement, utilizing transformation toughening mechanisms to enhance crack propagation resistance.

The early 2000s saw the rise of nanostructured ceramics and multilayer coating technologies, enabling unprecedented control over microstructure and surface properties. Recent developments have focused on functionally graded materials (FGMs) that feature composition gradients designed to optimize performance across different regions of the cutting tool. These advancements have progressively expanded the application range of ceramic cutting tools from initial use in finishing operations to increasingly demanding roughing applications.

Performance goals for structural ceramics in cutting tools have evolved in response to industry demands for higher productivity and sustainability. Current objectives include achieving hot hardness exceeding 93 HRA at temperatures above 1000°C, fracture toughness values greater than 7 MPa·m1/2, and thermal shock resistance parameters (R) above 250 W/m. Additionally, modern ceramic cutting tools aim to maintain edge integrity for cutting distances exceeding 5000 meters when machining hardened steels and superalloys.

Future performance targets emphasize multifunctionality, with goals to develop self-diagnostic capabilities through embedded sensors that can monitor tool wear and predict failure. Environmental considerations are driving research toward ceramics that can be manufactured with reduced energy consumption and potentially recycled at end-of-life. The ultimate aspiration is to create ceramic cutting tools capable of dry machining operations across all material classes, eliminating the need for coolants while maintaining tool life comparable to or exceeding that of conventional tools used with cooling systems.

The technological trajectory suggests that next-generation structural ceramics will likely incorporate elements of biomimicry, adopting hierarchical structures inspired by natural materials to achieve unprecedented combinations of toughness and hardness. This evolution continues to push the boundaries of cutting tool performance in increasingly demanding manufacturing environments.

Market Demand Analysis for Advanced Cutting Tools

The global market for advanced cutting tools has been experiencing robust growth, driven primarily by the expansion of manufacturing sectors such as automotive, aerospace, defense, and general machinery. Current market analysis indicates that the structural ceramics segment within cutting tools is growing at a compound annual growth rate exceeding that of traditional carbide tools, reflecting increasing industry recognition of ceramic-enhanced durability benefits.

Manufacturing industries are increasingly demanding cutting tools that can maintain performance under extreme conditions, particularly when machining difficult materials such as superalloys, hardened steels, and composite materials. This demand is especially pronounced in aerospace manufacturing, where the adoption of heat-resistant superalloys has created significant challenges for traditional cutting tools. Market research shows that companies are willing to pay premium prices for cutting tools that demonstrably reduce downtime and increase productivity through extended tool life.

The automotive industry represents another substantial market segment, where high-volume production necessitates cutting tools with exceptional wear resistance and reliability. As automotive manufacturers transition toward harder, lighter materials for fuel efficiency, the limitations of conventional cutting tools become more apparent, creating market opportunities for ceramic-enhanced alternatives.

Economic factors are also driving market demand, with manufacturers increasingly focused on total cost of ownership rather than initial purchase price. Analysis of production economics reveals that cutting tool costs typically represent only 3-5% of total machining costs, while tool failure and replacement can account for significant production losses through downtime. This economic reality has shifted procurement priorities toward performance longevity rather than acquisition cost.

Regional market analysis shows varying adoption rates, with developed manufacturing economies in North America, Europe, and East Asia leading in ceramic cutting tool implementation. Emerging manufacturing hubs in Southeast Asia and Eastern Europe represent high-growth potential markets as their industrial bases mature and production sophistication increases.

Industry surveys indicate that end-users prioritize three key performance attributes in cutting tools: predictable tool life, consistent surface finish quality, and ability to maintain dimensional accuracy throughout the tool's service life. Structural ceramics address these requirements through their inherent hardness, thermal stability, and wear resistance properties.

Market forecasts suggest that as advanced manufacturing processes become more widespread, particularly in high-precision industries, the demand for ceramic-enhanced cutting tools will continue to accelerate, potentially reshaping the competitive landscape of the cutting tool industry over the next decade.

Manufacturing industries are increasingly demanding cutting tools that can maintain performance under extreme conditions, particularly when machining difficult materials such as superalloys, hardened steels, and composite materials. This demand is especially pronounced in aerospace manufacturing, where the adoption of heat-resistant superalloys has created significant challenges for traditional cutting tools. Market research shows that companies are willing to pay premium prices for cutting tools that demonstrably reduce downtime and increase productivity through extended tool life.

The automotive industry represents another substantial market segment, where high-volume production necessitates cutting tools with exceptional wear resistance and reliability. As automotive manufacturers transition toward harder, lighter materials for fuel efficiency, the limitations of conventional cutting tools become more apparent, creating market opportunities for ceramic-enhanced alternatives.

Economic factors are also driving market demand, with manufacturers increasingly focused on total cost of ownership rather than initial purchase price. Analysis of production economics reveals that cutting tool costs typically represent only 3-5% of total machining costs, while tool failure and replacement can account for significant production losses through downtime. This economic reality has shifted procurement priorities toward performance longevity rather than acquisition cost.

Regional market analysis shows varying adoption rates, with developed manufacturing economies in North America, Europe, and East Asia leading in ceramic cutting tool implementation. Emerging manufacturing hubs in Southeast Asia and Eastern Europe represent high-growth potential markets as their industrial bases mature and production sophistication increases.

Industry surveys indicate that end-users prioritize three key performance attributes in cutting tools: predictable tool life, consistent surface finish quality, and ability to maintain dimensional accuracy throughout the tool's service life. Structural ceramics address these requirements through their inherent hardness, thermal stability, and wear resistance properties.

Market forecasts suggest that as advanced manufacturing processes become more widespread, particularly in high-precision industries, the demand for ceramic-enhanced cutting tools will continue to accelerate, potentially reshaping the competitive landscape of the cutting tool industry over the next decade.

Current State and Challenges in Ceramic Cutting Technologies

The global ceramic cutting tool market has witnessed significant growth in recent years, reaching approximately $1.8 billion in 2022 with a projected CAGR of 7.2% through 2030. This expansion is primarily driven by increasing demands in aerospace, automotive, and medical device manufacturing sectors where precision and durability are paramount.

Currently, structural ceramics employed in cutting tools predominantly include aluminum oxide (Al₂O₃), silicon nitride (Si₃N₄), silicon carbide (SiC), and zirconia (ZrO₂). Each material offers distinct advantages: alumina provides excellent wear resistance at moderate costs, silicon nitride delivers superior thermal shock resistance, silicon carbide exhibits exceptional hardness, while zirconia-based ceramics offer remarkable fracture toughness through transformation toughening mechanisms.

Despite these advancements, ceramic cutting technologies face several critical challenges. Brittleness remains the foremost limitation, with fracture toughness values typically ranging from 3-8 MPa·m½, significantly lower than conventional carbide tools (10-20 MPa·m½). This inherent brittleness results in unpredictable tool failure and limits application in interrupted cutting operations.

Manufacturing complexity presents another substantial hurdle. The production of ceramic cutting tools requires specialized sintering processes at temperatures exceeding 1600°C, with precise control of grain size and porosity. Current manufacturing yields average only 70-85%, substantially lower than carbide tool production (90-95%), driving up costs and limiting mass production capabilities.

Cost factors continue to impede widespread adoption, with ceramic inserts typically priced 30-50% higher than comparable carbide alternatives. This price premium, coupled with the perception of unpredictable tool life, creates significant market resistance, particularly in small and medium enterprises.

Technical integration challenges persist in implementing ceramic tools within existing machining systems. Most CNC machines and CAM software are optimized for traditional cutting tools, requiring significant parameter adjustments for ceramic tools. The lack of standardized cutting parameters across different ceramic compositions further complicates implementation.

Geographically, Japan and Germany lead in ceramic cutting tool innovation, holding approximately 60% of relevant patents. China has emerged as the fastest-growing market, with domestic production capacity increasing by 25% annually since 2018, though quality consistency remains variable. North American adoption has been slower, concentrated primarily in aerospace and defense applications.

Recent research has focused on developing ceramic-matrix composites (CMCs) and ceramic-metal (cermet) hybrid materials to address brittleness issues. Whisker-reinforced ceramics incorporating SiC whiskers have demonstrated 40-60% improvements in fracture toughness, though manufacturing complexities have limited commercial scaling.

Currently, structural ceramics employed in cutting tools predominantly include aluminum oxide (Al₂O₃), silicon nitride (Si₃N₄), silicon carbide (SiC), and zirconia (ZrO₂). Each material offers distinct advantages: alumina provides excellent wear resistance at moderate costs, silicon nitride delivers superior thermal shock resistance, silicon carbide exhibits exceptional hardness, while zirconia-based ceramics offer remarkable fracture toughness through transformation toughening mechanisms.

Despite these advancements, ceramic cutting technologies face several critical challenges. Brittleness remains the foremost limitation, with fracture toughness values typically ranging from 3-8 MPa·m½, significantly lower than conventional carbide tools (10-20 MPa·m½). This inherent brittleness results in unpredictable tool failure and limits application in interrupted cutting operations.

Manufacturing complexity presents another substantial hurdle. The production of ceramic cutting tools requires specialized sintering processes at temperatures exceeding 1600°C, with precise control of grain size and porosity. Current manufacturing yields average only 70-85%, substantially lower than carbide tool production (90-95%), driving up costs and limiting mass production capabilities.

Cost factors continue to impede widespread adoption, with ceramic inserts typically priced 30-50% higher than comparable carbide alternatives. This price premium, coupled with the perception of unpredictable tool life, creates significant market resistance, particularly in small and medium enterprises.

Technical integration challenges persist in implementing ceramic tools within existing machining systems. Most CNC machines and CAM software are optimized for traditional cutting tools, requiring significant parameter adjustments for ceramic tools. The lack of standardized cutting parameters across different ceramic compositions further complicates implementation.

Geographically, Japan and Germany lead in ceramic cutting tool innovation, holding approximately 60% of relevant patents. China has emerged as the fastest-growing market, with domestic production capacity increasing by 25% annually since 2018, though quality consistency remains variable. North American adoption has been slower, concentrated primarily in aerospace and defense applications.

Recent research has focused on developing ceramic-matrix composites (CMCs) and ceramic-metal (cermet) hybrid materials to address brittleness issues. Whisker-reinforced ceramics incorporating SiC whiskers have demonstrated 40-60% improvements in fracture toughness, though manufacturing complexities have limited commercial scaling.

Current Ceramic Formulations and Manufacturing Techniques

01 Composition modifications for enhanced durability

Various compositional modifications can be made to structural ceramics to enhance their durability. These include the addition of specific dopants, reinforcing agents, and phase stabilizers that improve mechanical properties and resistance to environmental degradation. By carefully controlling the chemical composition, manufacturers can develop ceramics with superior crack resistance, thermal shock resistance, and overall longevity under demanding conditions.- Composition modifications for enhanced durability: Structural ceramics can be made more durable by modifying their composition. This includes adding specific elements or compounds that improve mechanical properties, thermal shock resistance, and overall longevity. These modifications can involve incorporating reinforcing agents, stabilizers, or dopants that enhance grain boundary strength and prevent crack propagation, resulting in ceramics with superior durability under extreme conditions.

- Surface treatment and coating technologies: Various surface treatment and coating technologies can significantly improve the durability of structural ceramics. These include applying protective layers that shield the ceramic substrate from environmental degradation, thermal cycling, or chemical attack. Advanced coating methods create barriers against moisture, oxidation, and wear while maintaining the ceramic's inherent properties. These treatments often involve multi-layer systems designed to address specific durability challenges.

- Processing techniques for microstructural optimization: Specialized processing techniques can optimize the microstructure of structural ceramics to enhance durability. These methods control grain size, porosity, and phase distribution during manufacturing. Advanced sintering protocols, hot isostatic pressing, and controlled cooling regimes create more uniform and defect-free structures. By engineering the ceramic microstructure at the microscopic level, these techniques produce materials with superior resistance to thermal cycling, mechanical stress, and environmental factors.

- Composite and reinforcement strategies: Incorporating reinforcement materials into ceramic matrices creates composites with enhanced durability. These reinforcements can include fibers, whiskers, particles, or secondary phases that improve toughness and crack resistance. The strategic combination of ceramic matrices with reinforcing elements results in materials that maintain strength and integrity under mechanical stress, thermal shock, and cyclic loading. These composite approaches effectively overcome the inherent brittleness of conventional ceramics.

- Environmental resistance enhancements: Specific formulations and treatments can enhance the resistance of structural ceramics to harsh environmental conditions. These include modifications that improve performance in high-temperature, corrosive, or oxidizing environments. By incorporating specific compounds or creating protective surface layers, these ceramics maintain their structural integrity and functional properties when exposed to extreme conditions. These enhancements are particularly important for applications in aggressive industrial settings, aerospace, and energy production.

02 Surface treatments and coatings

Surface treatments and protective coatings can significantly improve the durability of structural ceramics. These treatments create barrier layers that protect against oxidation, corrosion, and wear while maintaining the base ceramic's desirable properties. Advanced coating technologies include plasma spraying, chemical vapor deposition, and sol-gel methods that deposit protective layers with strong adhesion to the ceramic substrate, extending component lifetime in harsh environments.Expand Specific Solutions03 Microstructural engineering for durability

Controlling the microstructure of structural ceramics through specialized processing techniques can significantly enhance durability. Methods such as grain size optimization, porosity control, and phase distribution management create ceramics with improved fracture toughness and resistance to crack propagation. Advanced sintering protocols and post-processing treatments help develop optimized microstructures that maintain structural integrity under mechanical stress and thermal cycling.Expand Specific Solutions04 Composite and multi-phase ceramic systems

Composite and multi-phase ceramic systems offer superior durability compared to monolithic ceramics. By combining different ceramic materials or incorporating ceramic matrices with reinforcing phases such as fibers, whiskers, or particles, these systems achieve enhanced mechanical properties and damage tolerance. The interfaces between different phases can deflect cracks and absorb energy, preventing catastrophic failure and extending the operational lifetime of ceramic components in demanding applications.Expand Specific Solutions05 Testing and evaluation methods for ceramic durability

Specialized testing and evaluation methods have been developed to assess and predict the durability of structural ceramics. These include accelerated aging tests, thermal cycling protocols, and advanced non-destructive evaluation techniques that can identify potential failure mechanisms before they occur in service. Computational modeling approaches also help predict long-term performance under various environmental conditions, enabling the development of ceramics with optimized durability for specific applications.Expand Specific Solutions

Leading Manufacturers and Competitive Landscape

The structural ceramics market for cutting tools is in a growth phase, characterized by increasing adoption across manufacturing sectors due to superior durability and performance at high temperatures. The global market is expanding steadily, driven by demands in aerospace, automotive, and general manufacturing industries. Technologically, companies like Kyocera, Kennametal, and Sumitomo Electric are leading innovation with advanced ceramic composites that significantly enhance tool life and cutting efficiency. Mitsubishi Materials and Tungaloy are developing specialized ceramic formulations for extreme cutting conditions, while 3M and Sandvik focus on ceramic-metal hybrid solutions. Research partnerships between manufacturers and institutions like Nagoya University are accelerating material science breakthroughs, positioning structural ceramics as a critical technology for next-generation cutting applications.

Kyocera Corp.

Technical Solution: Kyocera has developed advanced silicon nitride (Si3N4) and silicon carbide (SiC) ceramic cutting tools with proprietary microstructure control technology. Their Fine Ceramics solutions incorporate nano-scale grain refinement processes that create ultra-fine ceramic microstructures with enhanced fracture toughness. Kyocera's structural ceramics feature self-reinforcing mechanisms where elongated β-Si3N4 crystals interlock to prevent crack propagation. The company employs hot isostatic pressing (HIP) technology to achieve near 100% density in their ceramic cutting tools, significantly reducing porosity-related failures. Their latest ceramic matrix composites (CMCs) incorporate whisker reinforcements that increase fracture toughness by up to 40% compared to conventional ceramics, enabling machining of hardened steels at cutting speeds exceeding 1000 m/min while maintaining tool life 3-5 times longer than traditional carbide tools.

Strengths: Superior thermal shock resistance and chemical stability allow for dry high-speed machining of hardened materials. Exceptional wear resistance at elevated temperatures (up to 1200°C). Weaknesses: Higher production costs compared to conventional carbide tools. More brittle than carbide tools, requiring careful handling and precise cutting parameters.

Kennametal, Inc.

Technical Solution: Kennametal has pioneered the KYS40 silicon nitride-based ceramic cutting tool system specifically engineered for high-temperature alloy machining. Their proprietary ceramic formulation incorporates whisker reinforcement technology where silicon carbide whiskers (10-20% by volume) are uniformly dispersed throughout the ceramic matrix, creating a multi-directional reinforcement network. This microstructural design significantly improves fracture toughness by deflecting crack propagation paths. Kennametal's advanced sintering process utilizes spark plasma sintering (SPS) technology that achieves full densification at lower temperatures, preserving the nanoscale features of the ceramic structure. Their KYS40 grade demonstrates exceptional thermal shock resistance with thermal conductivity values 45% higher than conventional alumina ceramics, allowing cutting speeds of 200-300 m/min when machining nickel-based superalloys - approximately 5-7 times faster than carbide tools. The ceramic tools maintain their hardness (94 HRA) at temperatures exceeding 1000°C, where conventional carbide tools begin to soften significantly.

Strengths: Exceptional performance in high-temperature alloy machining with significantly higher removal rates than carbide tools. Superior thermal stability allows for dry machining applications, reducing coolant costs. Weaknesses: Limited application range compared to more versatile carbide tools. Higher initial tool cost requires optimization of cutting parameters to achieve cost-effectiveness.

Key Innovations in Ceramic Cutting Tool Materials

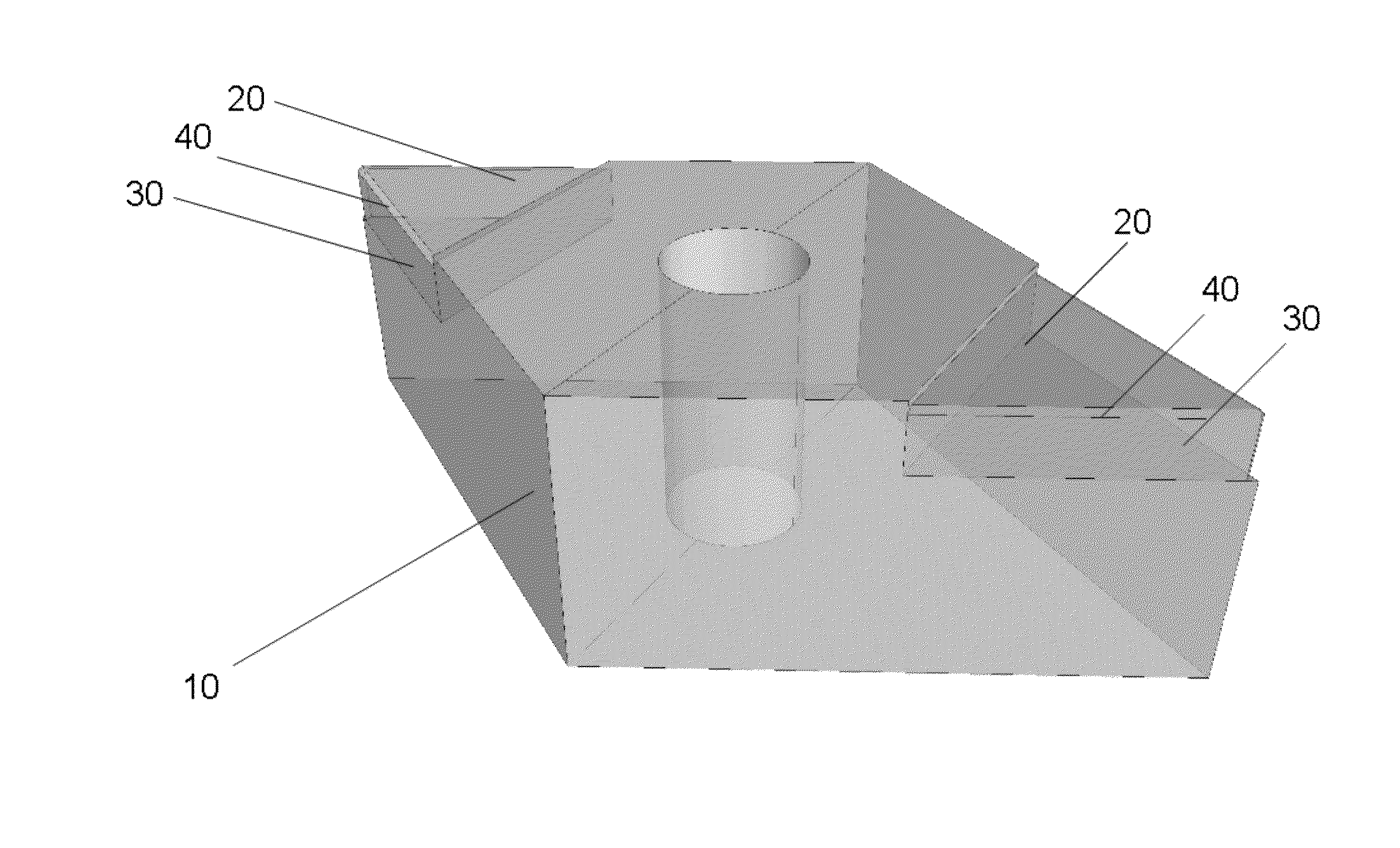

Method for toughening surface of sintered material cutting tool and sintered material cutting tool having long life

PatentWO2004103615A1

Innovation

- A surface toughening method using shot blasting to create a uniformly distributed linear dislocation structure on ceramic sintered cutting tools, enhancing fracture toughness, thermal shock resistance, and chipping resistance by applying an injection material with fine particles and controlled jet pressure and speed.

Wear-Resistant, High Durability Industrial Ceramic Cutting Edges and Tools made from Sintered Polycrystalline Composites Based on Aluminum Nitride

PatentInactiveUS20140349117A1

Innovation

- Development of sintered polycrystalline composites based on aluminum nitride with secondary phases such as silicon nitride, silicon carbide, or carbon nanotubes, which enhance toughness and thermal conductivity, allowing for efficient heat dissipation and reduced thermal stresses, enabling the use of coolants and higher cutting speeds.

Thermal and Mechanical Properties Optimization

The optimization of thermal and mechanical properties represents a critical frontier in structural ceramics research for cutting tool applications. Advanced ceramics such as silicon nitride (Si3N4), aluminum oxide (Al2O3), and zirconium oxide (ZrO2) demonstrate exceptional thermal stability, maintaining their mechanical integrity at temperatures exceeding 1000°C where conventional tool materials deteriorate rapidly. This thermal resistance directly translates to enhanced tool longevity in high-speed machining operations.

Material scientists have developed sophisticated multi-phase ceramic composites that strategically balance hardness and fracture toughness. By incorporating secondary phases such as silicon carbide whiskers into alumina matrices, researchers have achieved up to 40% improvement in fracture toughness while preserving the inherent hardness necessary for cutting applications. These composites effectively interrupt crack propagation pathways, significantly extending tool service life under cyclic loading conditions.

Thermal conductivity optimization presents another crucial parameter in cutting tool performance. While ceramics typically exhibit lower thermal conductivity than metals, recent innovations in ceramic matrix composites have yielded materials with enhanced thermal transport properties. The addition of graphene nanoplatelets to zirconia-based ceramics, for instance, has demonstrated a 35% increase in thermal conductivity, facilitating more efficient heat dissipation during machining processes.

Coefficient of thermal expansion (CTE) management has emerged as a key factor in preventing thermal shock failure. Advanced ceramic formulations with carefully controlled CTE values minimize internal stresses during rapid temperature fluctuations. Silicon nitride-based ceramics with tailored grain boundary phases have shown particular promise, exhibiting thermal shock resistance parameters up to three times higher than conventional ceramics.

Surface engineering techniques further enhance the thermal-mechanical performance envelope of ceramic cutting tools. Multilayer coatings combining aluminum titanium nitride (AlTiN) with nanostructured diamond-like carbon (DLC) create thermal barrier effects while simultaneously reducing friction coefficients by up to 60%. These surface modifications significantly reduce heat generation at the tool-workpiece interface, extending tool life in demanding applications.

Computational materials science has accelerated property optimization through predictive modeling of ceramic microstructures. Finite element simulations now enable precise tailoring of phase distributions and grain architectures to achieve optimal combinations of hardness, toughness, and thermal stability. These digital design approaches have reduced development cycles by approximately 40% while yielding ceramics with more precisely engineered property profiles.

Material scientists have developed sophisticated multi-phase ceramic composites that strategically balance hardness and fracture toughness. By incorporating secondary phases such as silicon carbide whiskers into alumina matrices, researchers have achieved up to 40% improvement in fracture toughness while preserving the inherent hardness necessary for cutting applications. These composites effectively interrupt crack propagation pathways, significantly extending tool service life under cyclic loading conditions.

Thermal conductivity optimization presents another crucial parameter in cutting tool performance. While ceramics typically exhibit lower thermal conductivity than metals, recent innovations in ceramic matrix composites have yielded materials with enhanced thermal transport properties. The addition of graphene nanoplatelets to zirconia-based ceramics, for instance, has demonstrated a 35% increase in thermal conductivity, facilitating more efficient heat dissipation during machining processes.

Coefficient of thermal expansion (CTE) management has emerged as a key factor in preventing thermal shock failure. Advanced ceramic formulations with carefully controlled CTE values minimize internal stresses during rapid temperature fluctuations. Silicon nitride-based ceramics with tailored grain boundary phases have shown particular promise, exhibiting thermal shock resistance parameters up to three times higher than conventional ceramics.

Surface engineering techniques further enhance the thermal-mechanical performance envelope of ceramic cutting tools. Multilayer coatings combining aluminum titanium nitride (AlTiN) with nanostructured diamond-like carbon (DLC) create thermal barrier effects while simultaneously reducing friction coefficients by up to 60%. These surface modifications significantly reduce heat generation at the tool-workpiece interface, extending tool life in demanding applications.

Computational materials science has accelerated property optimization through predictive modeling of ceramic microstructures. Finite element simulations now enable precise tailoring of phase distributions and grain architectures to achieve optimal combinations of hardness, toughness, and thermal stability. These digital design approaches have reduced development cycles by approximately 40% while yielding ceramics with more precisely engineered property profiles.

Sustainability Impact of Ceramic Cutting Tools

The adoption of ceramic cutting tools represents a significant advancement in sustainable manufacturing practices. These tools offer substantial environmental benefits compared to traditional carbide or high-speed steel alternatives, primarily through their extended service life and reduced resource consumption. Ceramic cutting tools typically last 2-5 times longer than conventional options when used in appropriate applications, directly reducing the frequency of tool replacement and associated material consumption.

This longevity translates into measurable sustainability improvements across the manufacturing value chain. The production of ceramic cutting tools, while energy-intensive initially, results in lower cumulative energy consumption when assessed over the complete lifecycle of the tool. Research indicates that the energy payback period for ceramic tools is achieved within approximately 30-40% of their operational lifespan, after which they represent a net positive energy investment compared to more frequently replaced alternatives.

Material efficiency gains are equally significant. The reduced replacement frequency decreases raw material extraction requirements, particularly for rare earth elements and strategic metals commonly used in conventional cutting tools. Life cycle assessments demonstrate that ceramic cutting tools can reduce overall material consumption by 35-60% depending on the specific application and operating conditions.

From an operational perspective, ceramic cutting tools contribute to manufacturing sustainability through reduced coolant requirements. Their superior thermal properties allow for dry or near-dry machining in many applications where traditional tools would require substantial cooling. This capability reduces water consumption and minimizes the environmental impact associated with coolant disposal and treatment.

The waste reduction benefits extend beyond the tools themselves. By enabling more precise cutting with tighter tolerances, ceramic tools can reduce material waste in the manufactured components. Additionally, the chemical stability of ceramics eliminates concerns about toxic leaching during disposal, unlike some coated carbide alternatives.

Economic sustainability is enhanced through reduced downtime for tool changes and more consistent part quality. Manufacturing operations utilizing ceramic cutting tools report productivity improvements of 15-25% in high-temperature applications, directly impacting energy efficiency per unit produced.

Looking forward, the sustainability profile of ceramic cutting tools continues to improve as manufacturing processes become more efficient and as hybrid ceramic composites enter the market. These next-generation materials promise to further extend tool life while reducing the energy requirements for their production, creating a virtuous cycle of sustainability improvements in precision manufacturing.

This longevity translates into measurable sustainability improvements across the manufacturing value chain. The production of ceramic cutting tools, while energy-intensive initially, results in lower cumulative energy consumption when assessed over the complete lifecycle of the tool. Research indicates that the energy payback period for ceramic tools is achieved within approximately 30-40% of their operational lifespan, after which they represent a net positive energy investment compared to more frequently replaced alternatives.

Material efficiency gains are equally significant. The reduced replacement frequency decreases raw material extraction requirements, particularly for rare earth elements and strategic metals commonly used in conventional cutting tools. Life cycle assessments demonstrate that ceramic cutting tools can reduce overall material consumption by 35-60% depending on the specific application and operating conditions.

From an operational perspective, ceramic cutting tools contribute to manufacturing sustainability through reduced coolant requirements. Their superior thermal properties allow for dry or near-dry machining in many applications where traditional tools would require substantial cooling. This capability reduces water consumption and minimizes the environmental impact associated with coolant disposal and treatment.

The waste reduction benefits extend beyond the tools themselves. By enabling more precise cutting with tighter tolerances, ceramic tools can reduce material waste in the manufactured components. Additionally, the chemical stability of ceramics eliminates concerns about toxic leaching during disposal, unlike some coated carbide alternatives.

Economic sustainability is enhanced through reduced downtime for tool changes and more consistent part quality. Manufacturing operations utilizing ceramic cutting tools report productivity improvements of 15-25% in high-temperature applications, directly impacting energy efficiency per unit produced.

Looking forward, the sustainability profile of ceramic cutting tools continues to improve as manufacturing processes become more efficient and as hybrid ceramic composites enter the market. These next-generation materials promise to further extend tool life while reducing the energy requirements for their production, creating a virtuous cycle of sustainability improvements in precision manufacturing.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!