How to Enhance CFRP Aerodynamic Efficiency in Race Cars

SEP 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CFRP Aerodynamics Evolution and Objectives

Carbon Fiber Reinforced Polymer (CFRP) has revolutionized motorsport aerodynamics since its introduction in Formula 1 during the 1980s. Initially utilized for structural components, CFRP's exceptional strength-to-weight ratio quickly made it indispensable for aerodynamic applications. The evolution of CFRP in race car aerodynamics has been marked by continuous innovation, moving from simple wings and spoilers to complex multi-element systems that generate substantial downforce while minimizing drag.

The historical progression of CFRP aerodynamic applications reveals a clear trajectory toward increasingly sophisticated designs. Early implementations focused primarily on weight reduction, replacing metal components with carbon fiber equivalents. By the 1990s, teams began exploiting CFRP's formability to create more complex aerodynamic profiles that would have been impossible with traditional materials. The 2000s saw the integration of computational fluid dynamics (CFD) with advanced CFRP manufacturing techniques, enabling highly optimized aerodynamic solutions.

Current CFRP aerodynamic technology in motorsport represents a convergence of materials science, aerodynamic theory, and manufacturing innovation. Teams now utilize variable-thickness laminates, selective reinforcement, and hybrid material systems to tune the mechanical properties of aerodynamic components for specific track conditions. The flexibility in design afforded by CFRP allows engineers to create adaptive aerodynamic elements that respond to changing airflow conditions.

The primary objective in enhancing CFRP aerodynamic efficiency is to maximize downforce generation while minimizing drag penalties. This involves optimizing the material composition, manufacturing processes, and geometric design of aerodynamic components. Secondary objectives include improving durability under high aerodynamic loads, reducing weight without compromising structural integrity, and developing cost-effective production methods for complex geometries.

Future development goals center on several key areas: the integration of active aerodynamic systems using shape-memory CFRP composites; the implementation of nano-engineered carbon fibers with enhanced surface properties for improved airflow characteristics; and the development of computational models that can accurately predict the aeroelastic behavior of thin-walled CFRP structures under varying aerodynamic loads.

The technological trajectory suggests that next-generation CFRP aerodynamic solutions will likely incorporate multi-functional capabilities, such as embedded sensors for real-time performance monitoring, self-healing matrices to extend component lifespan, and surface treatments that can dynamically alter boundary layer behavior to reduce drag in specific racing conditions.

The historical progression of CFRP aerodynamic applications reveals a clear trajectory toward increasingly sophisticated designs. Early implementations focused primarily on weight reduction, replacing metal components with carbon fiber equivalents. By the 1990s, teams began exploiting CFRP's formability to create more complex aerodynamic profiles that would have been impossible with traditional materials. The 2000s saw the integration of computational fluid dynamics (CFD) with advanced CFRP manufacturing techniques, enabling highly optimized aerodynamic solutions.

Current CFRP aerodynamic technology in motorsport represents a convergence of materials science, aerodynamic theory, and manufacturing innovation. Teams now utilize variable-thickness laminates, selective reinforcement, and hybrid material systems to tune the mechanical properties of aerodynamic components for specific track conditions. The flexibility in design afforded by CFRP allows engineers to create adaptive aerodynamic elements that respond to changing airflow conditions.

The primary objective in enhancing CFRP aerodynamic efficiency is to maximize downforce generation while minimizing drag penalties. This involves optimizing the material composition, manufacturing processes, and geometric design of aerodynamic components. Secondary objectives include improving durability under high aerodynamic loads, reducing weight without compromising structural integrity, and developing cost-effective production methods for complex geometries.

Future development goals center on several key areas: the integration of active aerodynamic systems using shape-memory CFRP composites; the implementation of nano-engineered carbon fibers with enhanced surface properties for improved airflow characteristics; and the development of computational models that can accurately predict the aeroelastic behavior of thin-walled CFRP structures under varying aerodynamic loads.

The technological trajectory suggests that next-generation CFRP aerodynamic solutions will likely incorporate multi-functional capabilities, such as embedded sensors for real-time performance monitoring, self-healing matrices to extend component lifespan, and surface treatments that can dynamically alter boundary layer behavior to reduce drag in specific racing conditions.

Market Demand for High-Performance Racing Components

The motorsport industry has witnessed a significant surge in demand for high-performance racing components, particularly those utilizing Carbon Fiber Reinforced Polymers (CFRP). Market research indicates that the global racing components market exceeded $4.5 billion in 2022, with CFRP components representing approximately 30% of this value. This growth trajectory is expected to continue at a compound annual growth rate of 8.7% through 2028, driven primarily by Formula 1, NASCAR, WEC, and other premier racing series.

Consumer demand for CFRP aerodynamic components stems from their exceptional strength-to-weight ratio, which directly translates to improved vehicle performance. Racing teams are increasingly willing to invest substantial resources in aerodynamic efficiency improvements, as even marginal gains of 0.1 seconds per lap can significantly impact race outcomes. This performance-driven market has created a premium segment where cost considerations are secondary to competitive advantage.

Regulatory changes across racing categories have further stimulated market demand. Formula 1's cost cap regulations, implemented in 2021, have paradoxically increased focus on aerodynamic efficiency as teams seek performance advantages within budgetary constraints. Similarly, GT racing categories have adopted regulations permitting greater use of composite materials in aerodynamic packages, expanding the addressable market.

The aftermarket segment for high-performance vehicles represents another substantial growth area. Wealthy enthusiasts and track-day participants increasingly demand racing-derived aerodynamic solutions for their vehicles, with this segment growing at 12.3% annually. This has created a trickle-down effect where technologies initially developed for professional racing find commercial applications in premium road vehicles.

Regional analysis reveals that Europe dominates the market with 45% share, followed by North America at 32% and Asia-Pacific at 18%. However, emerging markets in the Middle East and Asia are showing the fastest growth rates, particularly as motorsport events gain popularity in these regions and local racing series adopt international technical standards.

Customer requirements have evolved beyond pure performance metrics to include considerations of manufacturing efficiency, repairability, and sustainability. Racing teams increasingly demand components that can be rapidly produced, modified between race weekends, and repaired trackside. Additionally, there is growing interest in sustainable manufacturing processes and recyclable composites, driven by motorsport's broader sustainability initiatives.

Consumer demand for CFRP aerodynamic components stems from their exceptional strength-to-weight ratio, which directly translates to improved vehicle performance. Racing teams are increasingly willing to invest substantial resources in aerodynamic efficiency improvements, as even marginal gains of 0.1 seconds per lap can significantly impact race outcomes. This performance-driven market has created a premium segment where cost considerations are secondary to competitive advantage.

Regulatory changes across racing categories have further stimulated market demand. Formula 1's cost cap regulations, implemented in 2021, have paradoxically increased focus on aerodynamic efficiency as teams seek performance advantages within budgetary constraints. Similarly, GT racing categories have adopted regulations permitting greater use of composite materials in aerodynamic packages, expanding the addressable market.

The aftermarket segment for high-performance vehicles represents another substantial growth area. Wealthy enthusiasts and track-day participants increasingly demand racing-derived aerodynamic solutions for their vehicles, with this segment growing at 12.3% annually. This has created a trickle-down effect where technologies initially developed for professional racing find commercial applications in premium road vehicles.

Regional analysis reveals that Europe dominates the market with 45% share, followed by North America at 32% and Asia-Pacific at 18%. However, emerging markets in the Middle East and Asia are showing the fastest growth rates, particularly as motorsport events gain popularity in these regions and local racing series adopt international technical standards.

Customer requirements have evolved beyond pure performance metrics to include considerations of manufacturing efficiency, repairability, and sustainability. Racing teams increasingly demand components that can be rapidly produced, modified between race weekends, and repaired trackside. Additionally, there is growing interest in sustainable manufacturing processes and recyclable composites, driven by motorsport's broader sustainability initiatives.

Current CFRP Implementation Challenges in Motorsport

Carbon Fiber Reinforced Polymer (CFRP) implementation in motorsport faces several significant challenges despite its widespread adoption. The primary obstacle remains the high manufacturing costs associated with CFRP components. The material itself is expensive, and the production processes—including autoclave curing, vacuum infusion, and prepreg layup—require specialized equipment and skilled labor. This cost factor limits the extent to which racing teams, particularly those with modest budgets, can utilize CFRP in their aerodynamic packages.

Manufacturing complexity presents another substantial challenge. Creating complex geometries with CFRP requires precise layup techniques and specialized tooling. The anisotropic nature of carbon fiber composites means that fiber orientation must be meticulously controlled to achieve desired mechanical properties. This complexity extends production timelines and increases the potential for manufacturing defects, which can compromise aerodynamic performance.

Durability concerns also plague CFRP implementation in high-performance racing environments. While carbon fiber offers excellent strength-to-weight characteristics, it exhibits vulnerability to impact damage and can fail catastrophically without warning. This brittleness is particularly problematic in racing scenarios where components frequently encounter debris, vibration, and occasional contact with other vehicles or barriers.

Design iteration limitations further complicate CFRP utilization. Unlike traditional materials that allow for quick modifications, CFRP components typically require complete remolding when design changes are needed. This constraint significantly slows the aerodynamic development cycle, which is crucial in the fast-paced world of motorsport where continuous improvement drives competitive advantage.

Thermal management represents another critical challenge. CFRP components can experience performance degradation under extreme temperature conditions common in racing environments. The material's thermal expansion characteristics differ from those of metals, creating potential issues at interface points and affecting aerodynamic precision during race conditions.

Regulatory compliance adds another layer of complexity. Racing series increasingly implement restrictions on aerodynamic development and testing, limiting the extent to which teams can exploit CFRP's advantages. These regulations aim to control costs and maintain competitive balance but can constrain innovation in CFRP aerodynamic applications.

Finally, sustainability concerns are emerging as a significant challenge. The carbon footprint associated with CFRP production and the limited recyclability of these composites conflict with motorsport's growing emphasis on environmental responsibility. As racing series implement sustainability initiatives, finding more environmentally friendly approaches to CFRP implementation becomes increasingly important.

Manufacturing complexity presents another substantial challenge. Creating complex geometries with CFRP requires precise layup techniques and specialized tooling. The anisotropic nature of carbon fiber composites means that fiber orientation must be meticulously controlled to achieve desired mechanical properties. This complexity extends production timelines and increases the potential for manufacturing defects, which can compromise aerodynamic performance.

Durability concerns also plague CFRP implementation in high-performance racing environments. While carbon fiber offers excellent strength-to-weight characteristics, it exhibits vulnerability to impact damage and can fail catastrophically without warning. This brittleness is particularly problematic in racing scenarios where components frequently encounter debris, vibration, and occasional contact with other vehicles or barriers.

Design iteration limitations further complicate CFRP utilization. Unlike traditional materials that allow for quick modifications, CFRP components typically require complete remolding when design changes are needed. This constraint significantly slows the aerodynamic development cycle, which is crucial in the fast-paced world of motorsport where continuous improvement drives competitive advantage.

Thermal management represents another critical challenge. CFRP components can experience performance degradation under extreme temperature conditions common in racing environments. The material's thermal expansion characteristics differ from those of metals, creating potential issues at interface points and affecting aerodynamic precision during race conditions.

Regulatory compliance adds another layer of complexity. Racing series increasingly implement restrictions on aerodynamic development and testing, limiting the extent to which teams can exploit CFRP's advantages. These regulations aim to control costs and maintain competitive balance but can constrain innovation in CFRP aerodynamic applications.

Finally, sustainability concerns are emerging as a significant challenge. The carbon footprint associated with CFRP production and the limited recyclability of these composites conflict with motorsport's growing emphasis on environmental responsibility. As racing series implement sustainability initiatives, finding more environmentally friendly approaches to CFRP implementation becomes increasingly important.

Existing CFRP Aerodynamic Enhancement Solutions

01 CFRP in aerodynamic components for vehicles

Carbon Fiber Reinforced Polymer (CFRP) is used in manufacturing aerodynamic components for vehicles such as spoilers, diffusers, and body panels. These components are designed to reduce drag and improve downforce, enhancing overall vehicle performance. The lightweight nature of CFRP allows for complex aerodynamic shapes while maintaining structural integrity, resulting in improved fuel efficiency and handling characteristics.- CFRP in aerodynamic components for vehicles: Carbon Fiber Reinforced Polymer (CFRP) is used in manufacturing aerodynamic components for vehicles such as spoilers, diffusers, and body panels. The lightweight nature of CFRP combined with its high strength allows for the creation of complex aerodynamic shapes that can significantly reduce drag and improve vehicle performance. These components can be designed to optimize airflow around the vehicle, increasing downforce while minimizing weight penalties.

- CFRP manufacturing techniques for aerodynamic structures: Advanced manufacturing techniques for CFRP aerodynamic structures include automated fiber placement, resin transfer molding, and compression molding. These processes allow for precise control of fiber orientation and resin content, which directly impacts the aerodynamic efficiency of the final component. By optimizing manufacturing parameters, engineers can create CFRP structures with smooth surfaces and complex geometries that minimize turbulence and drag while maintaining structural integrity.

- Surface treatments and coatings for CFRP aerodynamic performance: Surface treatments and specialized coatings can significantly enhance the aerodynamic performance of CFRP components. These treatments can reduce surface roughness, create hydrophobic properties, or incorporate micro-textures that control boundary layer behavior. By manipulating the surface characteristics of CFRP structures, engineers can reduce skin friction drag and delay flow separation, resulting in improved aerodynamic efficiency without adding significant weight to the structure.

- CFRP in aircraft and aerospace applications: CFRP materials are extensively used in aircraft and aerospace applications to improve aerodynamic efficiency. Components such as wings, control surfaces, and fuselage sections benefit from the high stiffness-to-weight ratio of CFRP, allowing for optimized aerodynamic designs that would be impossible with traditional materials. The ability to tailor the material properties through fiber orientation enables engineers to design structures that maintain their aerodynamic shape under varying loads, further enhancing performance.

- Hybrid CFRP structures for optimized aerodynamic efficiency: Hybrid structures combining CFRP with other materials can provide optimized aerodynamic efficiency for specific applications. These hybrid designs may incorporate metal inserts, foam cores, or different composite materials to achieve the desired balance of weight, strength, and aerodynamic performance. By strategically placing materials based on local requirements, engineers can create structures that maintain excellent aerodynamic properties while addressing other design constraints such as impact resistance, cost, or manufacturing complexity.

02 Manufacturing techniques for CFRP aerodynamic structures

Advanced manufacturing techniques are employed to create CFRP aerodynamic structures with optimal efficiency. These include automated fiber placement, resin transfer molding, and vacuum-assisted processes that ensure precise fiber orientation and minimal voids. These techniques allow for the creation of complex geometries with smooth surfaces that minimize turbulence and drag while maintaining structural strength, resulting in components with superior aerodynamic performance.Expand Specific Solutions03 Surface treatments and coatings for CFRP aerodynamic efficiency

Various surface treatments and coatings are applied to CFRP components to enhance their aerodynamic efficiency. These treatments can reduce surface roughness, create specific textures that control boundary layer behavior, or add hydrophobic properties. Specialized coatings can also protect the CFRP from environmental factors while maintaining the aerodynamic profile, ensuring long-term performance and durability under various operating conditions.Expand Specific Solutions04 Integration of CFRP in aircraft and aerospace applications

CFRP materials are extensively used in aircraft and aerospace applications to improve aerodynamic efficiency. Components such as wings, control surfaces, and fuselage sections benefit from the high strength-to-weight ratio of CFRP, allowing for more efficient aerodynamic designs. The material enables the creation of smoother surfaces and more precise airfoil shapes that reduce drag and improve lift characteristics, contributing to overall fuel efficiency and performance in aerospace vehicles.Expand Specific Solutions05 Hybrid and multi-material CFRP aerodynamic systems

Hybrid and multi-material systems combine CFRP with other materials to optimize aerodynamic efficiency for specific applications. These systems may integrate CFRP with metals, ceramics, or other composites to achieve the desired balance of properties. Such combinations allow designers to place materials strategically where their properties are most beneficial, resulting in aerodynamic structures that offer improved performance characteristics while addressing challenges related to cost, manufacturing complexity, and specific operational requirements.Expand Specific Solutions

Leading Manufacturers and Racing Teams in CFRP Innovation

The carbon fiber reinforced polymer (CFRP) aerodynamic efficiency market in race cars is currently in a growth phase, with increasing adoption driven by performance demands and sustainability concerns. The market is expanding as racing teams seek competitive advantages through lightweight, high-strength materials that enhance vehicle performance. Leading automotive manufacturers like BMW, Honda, Toyota, and Hyundai are actively developing CFRP aerodynamic solutions, while specialized materials companies such as Toray Industries, BASF, and Resonac provide advanced composite technologies. Research institutions including NASA, JAXA, and universities like Jiangsu University and Harbin Institute of Technology are advancing fundamental knowledge in this field. The technology is approaching maturity in high-end racing applications but continues to evolve with innovations in manufacturing processes, material formulations, and computational design methods.

Toray Industries, Inc.

Technical Solution: Toray has developed advanced CFRP materials specifically engineered for race car aerodynamic applications through their "T1100G" carbon fiber technology. Their approach focuses on creating ultra-high modulus carbon fibers that enable thinner, lighter aerodynamic components without sacrificing structural integrity. Toray's proprietary resin systems feature improved impact resistance and temperature stability, critical for maintaining aerodynamic performance under race conditions. Their technology includes specialized surface treatments that enhance bonding between carbon fibers and resin matrices, resulting in components with exceptional fatigue resistance even under high-frequency vibrations experienced in racing. Toray has also pioneered nano-modified resin systems that improve the interlaminar shear strength of CFRP components by up to 30%, allowing for more aggressive aerodynamic designs that can withstand higher downforce loads. Recent innovations include hybrid carbon fiber fabrics that combine different fiber types to optimize both stiffness and impact resistance in critical aerodynamic components.

Strengths: World-leading expertise in carbon fiber manufacturing; vertical integration from raw material production to finished components; extensive R&D capabilities with dedicated motorsport division. Weaknesses: Higher material costs compared to standard CFRP solutions; complex manufacturing processes requiring specialized equipment; challenges in scaling production for smaller racing teams with limited budgets.

Bayerische Motoren Werke AG

Technical Solution: BMW has developed advanced CFRP aerodynamic solutions for their race cars through their proprietary "EfficientDynamics" technology. Their approach integrates carbon fiber reinforced polymers into critical aerodynamic components such as front splitters, rear diffusers, and side skirts. BMW's technology involves a specialized resin transfer molding process that creates CFRP components with optimized fiber orientation to maximize strength while minimizing weight. Their latest innovations include active aerodynamic elements made from CFRP that can adjust in real-time based on driving conditions, effectively reducing drag by up to 15% at high speeds. BMW has also pioneered computational fluid dynamics simulations specifically calibrated for CFRP material properties, allowing them to predict and optimize airflow patterns around their race vehicles with exceptional precision.

Strengths: Industry-leading expertise in CFRP manufacturing; proprietary production methods that reduce weight while maintaining structural integrity; extensive motorsport experience providing real-world validation. Weaknesses: Higher production costs compared to traditional materials; longer manufacturing cycle times; challenges in recycling CFRP components at end-of-life.

Key Patents and Research in CFRP Aerodynamic Optimization

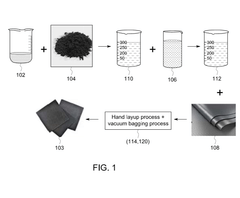

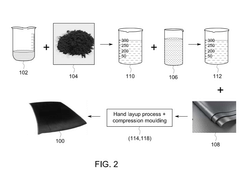

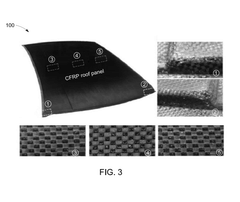

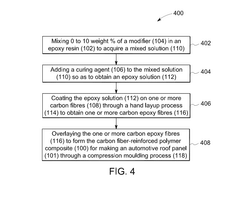

Material selection and manufacture of automotive roof panel using CFRP hybrid composite

PatentActiveIN202341035232A

Innovation

- A carbon fiber reinforced polymer composite for automotive roof panels using industrial waste carbon fiber powder, combined with epoxy resin and a curing agent, is fabricated through a hand layup and compression moulding process to reduce weight and enhance bending stiffness and impact strength.

Bio-inspired composite laminate design with high out-of-plane strength and ductility

PatentActiveUS11207867B1

Innovation

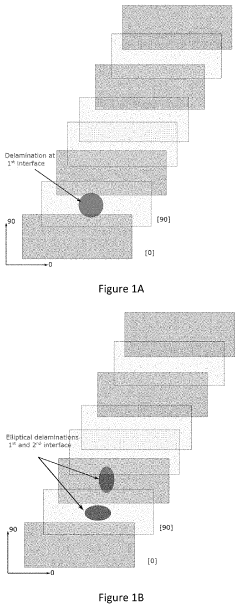

- Bio-inspired CFRP composite laminates are designed with intentionally introduced delaminations at specific positions and sizes during the lamination process to control crack propagation and enhance ductility, featuring a pseudo-ductile response with increased failure strain and energy absorption.

Computational Fluid Dynamics for CFRP Component Design

Computational Fluid Dynamics (CFD) has revolutionized the design and optimization of Carbon Fiber Reinforced Polymer (CFRP) components in race car aerodynamics. This advanced simulation technology enables engineers to predict airflow patterns around complex geometries without the need for extensive physical testing, significantly reducing development time and costs.

Modern CFD software packages specifically tailored for automotive applications offer high-fidelity simulations that can accurately model the interaction between air and CFRP surfaces. These tools incorporate sophisticated turbulence models, boundary layer analysis, and pressure distribution calculations that are essential for understanding the aerodynamic behavior of composite structures at racing speeds.

The integration of CFD with Computer-Aided Design (CAD) systems creates a powerful workflow for CFRP component development. Engineers can rapidly iterate through design variations, testing multiple configurations virtually before committing to expensive prototype fabrication. This digital approach allows for the exploration of innovative shapes and features that would be difficult to evaluate through traditional methods.

Mesh generation represents a critical aspect of CFD analysis for CFRP components. The complex curvatures and thin-walled structures typical of carbon fiber parts require specialized meshing techniques to ensure accurate simulation results. Adaptive meshing algorithms that concentrate computational resources in areas of high aerodynamic importance have proven particularly valuable for race car applications.

Multi-physics simulations that combine CFD with structural analysis provide comprehensive insights into CFRP component performance. These coupled analyses account for the deformation of flexible composite structures under aerodynamic loads, capturing the fluid-structure interaction effects that can significantly impact race car performance at high speeds.

Validation of CFD results against wind tunnel testing and track data remains essential for ensuring simulation accuracy. Correlation studies between computational predictions and physical measurements help refine simulation parameters and increase confidence in virtual testing outcomes. This validation process has established CFD as a reliable tool for CFRP aerodynamic development.

Recent advances in computational capabilities have enabled the implementation of optimization algorithms within the CFD workflow. These tools can automatically explore thousands of design variations to identify optimal CFRP component geometries that maximize downforce while minimizing drag. Such computational optimization approaches have led to breakthrough designs that would be difficult to discover through intuition alone.

Modern CFD software packages specifically tailored for automotive applications offer high-fidelity simulations that can accurately model the interaction between air and CFRP surfaces. These tools incorporate sophisticated turbulence models, boundary layer analysis, and pressure distribution calculations that are essential for understanding the aerodynamic behavior of composite structures at racing speeds.

The integration of CFD with Computer-Aided Design (CAD) systems creates a powerful workflow for CFRP component development. Engineers can rapidly iterate through design variations, testing multiple configurations virtually before committing to expensive prototype fabrication. This digital approach allows for the exploration of innovative shapes and features that would be difficult to evaluate through traditional methods.

Mesh generation represents a critical aspect of CFD analysis for CFRP components. The complex curvatures and thin-walled structures typical of carbon fiber parts require specialized meshing techniques to ensure accurate simulation results. Adaptive meshing algorithms that concentrate computational resources in areas of high aerodynamic importance have proven particularly valuable for race car applications.

Multi-physics simulations that combine CFD with structural analysis provide comprehensive insights into CFRP component performance. These coupled analyses account for the deformation of flexible composite structures under aerodynamic loads, capturing the fluid-structure interaction effects that can significantly impact race car performance at high speeds.

Validation of CFD results against wind tunnel testing and track data remains essential for ensuring simulation accuracy. Correlation studies between computational predictions and physical measurements help refine simulation parameters and increase confidence in virtual testing outcomes. This validation process has established CFD as a reliable tool for CFRP aerodynamic development.

Recent advances in computational capabilities have enabled the implementation of optimization algorithms within the CFD workflow. These tools can automatically explore thousands of design variations to identify optimal CFRP component geometries that maximize downforce while minimizing drag. Such computational optimization approaches have led to breakthrough designs that would be difficult to discover through intuition alone.

Sustainability Considerations in Racing CFRP Applications

The integration of sustainability principles into Carbon Fiber Reinforced Polymer (CFRP) applications for racing represents a critical evolution in motorsport engineering. As environmental concerns gain prominence globally, racing teams and manufacturers face increasing pressure to balance performance with ecological responsibility. This paradigm shift necessitates a comprehensive approach to CFRP utilization that considers the entire lifecycle of these materials.

Traditional CFRP production processes are notably energy-intensive, with carbon fiber manufacturing requiring approximately 25-30 times more energy than conventional steel production. The carbon footprint implications are substantial, particularly when considering the relatively short competitive lifespan of racing components. Addressing this challenge requires innovative approaches to material sourcing, manufacturing processes, and end-of-life management.

Emerging sustainable alternatives include bio-derived carbon fibers, which utilize precursors from renewable sources such as lignin or cellulose rather than petroleum-based polyacrylonitrile (PAN). These materials show promising mechanical properties while potentially reducing environmental impact by 30-40% compared to conventional carbon fibers. Additionally, natural fiber hybrid composites incorporating flax, hemp, or bamboo fibers can provide strategic reinforcement in less critical structural areas.

Manufacturing innovations are equally important in enhancing sustainability. Advanced out-of-autoclave (OOA) processing techniques reduce energy consumption by eliminating the need for high-pressure, high-temperature curing cycles. Microwave curing technologies have demonstrated energy savings of up to 60% compared to traditional autoclave methods while maintaining comparable mechanical properties in the finished components.

Circular economy principles are increasingly being applied to racing CFRP applications. Pyrolysis and solvolysis recycling methods can recover carbon fibers from end-of-life components with minimal degradation in fiber properties. These reclaimed fibers can be incorporated into non-primary structural components, creating a closed-loop material system that reduces waste and resource consumption.

The aerodynamic efficiency gains from CFRP must be evaluated against their environmental costs through comprehensive Life Cycle Assessment (LCA) methodologies. This holistic approach considers raw material extraction, manufacturing energy requirements, use-phase benefits, and end-of-life scenarios. Recent studies indicate that weight reduction through CFRP can offset initial production impacts if components achieve sufficient service life or are effectively recycled.

Regulatory frameworks are evolving to encourage sustainable practices in motorsport. Formula 1's commitment to carbon neutrality by 2030 and the FIA's environmental accreditation program exemplify this trend, creating incentives for teams to adopt more sustainable CFRP strategies while maintaining competitive performance.

Traditional CFRP production processes are notably energy-intensive, with carbon fiber manufacturing requiring approximately 25-30 times more energy than conventional steel production. The carbon footprint implications are substantial, particularly when considering the relatively short competitive lifespan of racing components. Addressing this challenge requires innovative approaches to material sourcing, manufacturing processes, and end-of-life management.

Emerging sustainable alternatives include bio-derived carbon fibers, which utilize precursors from renewable sources such as lignin or cellulose rather than petroleum-based polyacrylonitrile (PAN). These materials show promising mechanical properties while potentially reducing environmental impact by 30-40% compared to conventional carbon fibers. Additionally, natural fiber hybrid composites incorporating flax, hemp, or bamboo fibers can provide strategic reinforcement in less critical structural areas.

Manufacturing innovations are equally important in enhancing sustainability. Advanced out-of-autoclave (OOA) processing techniques reduce energy consumption by eliminating the need for high-pressure, high-temperature curing cycles. Microwave curing technologies have demonstrated energy savings of up to 60% compared to traditional autoclave methods while maintaining comparable mechanical properties in the finished components.

Circular economy principles are increasingly being applied to racing CFRP applications. Pyrolysis and solvolysis recycling methods can recover carbon fibers from end-of-life components with minimal degradation in fiber properties. These reclaimed fibers can be incorporated into non-primary structural components, creating a closed-loop material system that reduces waste and resource consumption.

The aerodynamic efficiency gains from CFRP must be evaluated against their environmental costs through comprehensive Life Cycle Assessment (LCA) methodologies. This holistic approach considers raw material extraction, manufacturing energy requirements, use-phase benefits, and end-of-life scenarios. Recent studies indicate that weight reduction through CFRP can offset initial production impacts if components achieve sufficient service life or are effectively recycled.

Regulatory frameworks are evolving to encourage sustainable practices in motorsport. Formula 1's commitment to carbon neutrality by 2030 and the FIA's environmental accreditation program exemplify this trend, creating incentives for teams to adopt more sustainable CFRP strategies while maintaining competitive performance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!