How To Enhance The Efficiency Of Tungsten Drill Bits?

Tungsten Drill Bit Evolution and Objectives

Tungsten drill bits have been a cornerstone in drilling technology for decades, evolving significantly since their inception. The journey of these drill bits began in the early 20th century when the exceptional hardness and heat resistance of tungsten carbide were first harnessed for drilling applications. Initially used in mining and construction, tungsten drill bits quickly found their way into various industries, including oil and gas exploration, where their durability and performance under extreme conditions proved invaluable.

The evolution of tungsten drill bits has been driven by the ever-increasing demands of drilling operations, particularly in challenging environments such as deep-sea drilling and hard rock formations. Over time, manufacturers have focused on improving the composition of tungsten carbide, optimizing the balance between hardness and toughness to enhance overall performance and longevity. This has led to the development of advanced tungsten carbide grades and innovative binding materials that significantly extend the life of drill bits.

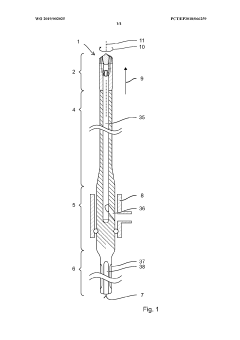

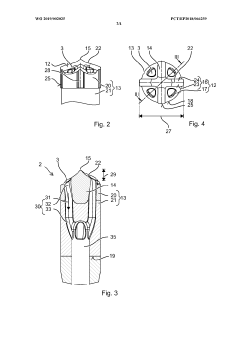

In recent years, the integration of cutting-edge technologies has further propelled the advancement of tungsten drill bits. Computer-aided design and simulation tools have enabled engineers to create more efficient bit geometries, optimizing cutting angles and fluid dynamics to improve drilling speed and reduce wear. Additionally, the introduction of polycrystalline diamond compact (PDC) cutters in combination with tungsten carbide has revolutionized bit design, offering superior cutting efficiency and durability in various drilling conditions.

The primary objective in enhancing the efficiency of tungsten drill bits is to increase the rate of penetration (ROP) while simultaneously extending bit life. This dual goal presents a significant challenge, as higher drilling speeds often lead to accelerated wear. To address this, research efforts are focused on developing novel materials and coatings that can withstand higher temperatures and abrasive forces without compromising structural integrity.

Another critical objective is to improve the stability and directional control of tungsten drill bits, particularly in directional and horizontal drilling applications. This involves refining bit designs to minimize vibration and enhance steerability, allowing for more precise well trajectories and reduced drilling time. Furthermore, there is a growing emphasis on creating "smart" drill bits equipped with sensors and real-time data transmission capabilities, enabling operators to optimize drilling parameters on the fly and respond quickly to changing formation characteristics.

As the drilling industry continues to push the boundaries of what is possible, the evolution of tungsten drill bits remains a key focus area. Future objectives include the development of self-sharpening bits, advanced wear-resistant coatings, and the integration of artificial intelligence for predictive maintenance and performance optimization. These advancements aim to not only enhance drilling efficiency but also contribute to more sustainable and environmentally friendly drilling practices.

Market Demand Analysis for High-Efficiency Drilling

The global drilling industry has witnessed a significant surge in demand for high-efficiency drilling solutions, particularly in the oil and gas sector, mining, and construction. This growing market need is driven by several factors, including the increasing complexity of drilling operations, the push for cost reduction, and the emphasis on environmental sustainability.

In the oil and gas industry, the demand for enhanced drilling efficiency is particularly pronounced. As easily accessible reserves become depleted, companies are forced to explore more challenging environments, such as deep-water offshore locations and unconventional reservoirs. These complex drilling scenarios require advanced technologies that can improve penetration rates, extend bit life, and reduce overall drilling time. The market for high-efficiency drilling solutions in this sector is expected to grow substantially over the next decade.

The mining industry also presents a significant market opportunity for improved drilling technologies. As surface deposits become scarce, mining operations are moving deeper underground, necessitating more efficient drilling methods. The demand for high-performance drill bits that can withstand extreme conditions while maintaining productivity is on the rise.

In the construction sector, the increasing number of large-scale infrastructure projects worldwide is driving the need for more efficient drilling solutions. Tunnel boring, foundation work, and geothermal drilling all require advanced drill bits that can operate effectively in diverse geological conditions.

The market for high-efficiency drilling is not limited to these sectors alone. Emerging applications in geothermal energy exploration, water well drilling, and scientific research drilling are also contributing to the growing demand for advanced drilling technologies.

From a geographical perspective, regions with significant oil and gas activities, such as North America, the Middle East, and parts of Asia-Pacific, are expected to be major markets for high-efficiency drilling solutions. Additionally, countries with booming construction sectors and expanding mining operations, particularly in developing economies, are likely to see increased demand for these technologies.

The economic benefits of enhanced drilling efficiency are substantial. Improved drill bit performance can lead to significant reductions in overall project costs by minimizing downtime, reducing the number of bit trips, and increasing the rate of penetration. These factors are particularly crucial in high-cost environments such as offshore drilling, where rig time is extremely expensive.

As environmental regulations become more stringent, there is also a growing market demand for drilling technologies that can minimize environmental impact. This includes solutions that reduce energy consumption, decrease waste generation, and limit the footprint of drilling operations.

Current Challenges in Tungsten Drill Bit Technology

Tungsten drill bits, renowned for their hardness and durability, face several challenges in maintaining and enhancing their efficiency. One of the primary issues is wear resistance. Despite tungsten carbide's inherent hardness, the extreme conditions encountered during drilling operations, including high temperatures and abrasive materials, can lead to accelerated wear. This wear not only reduces the lifespan of the drill bit but also compromises its cutting efficiency over time.

Another significant challenge is heat dissipation. The high-speed rotation and friction generated during drilling operations produce substantial heat. Ineffective heat management can lead to thermal degradation of the bit's structure, potentially causing premature failure or reduced performance. Developing innovative cooling mechanisms or materials with superior thermal conductivity is crucial for addressing this issue.

The geometry of tungsten drill bits also presents a challenge in terms of optimizing cutting efficiency. The design of the cutting edges, flute shape, and point angle significantly influences the bit's performance. Achieving the ideal balance between aggressive cutting action and stability remains a complex task, especially when drilling through varied geological formations.

Furthermore, the brittleness of tungsten carbide poses a challenge in high-impact drilling scenarios. While extremely hard, tungsten carbide can be prone to chipping or fracturing under sudden loads or when encountering heterogeneous materials. Enhancing the toughness of the material without compromising its hardness is a key area of research and development.

The manufacturing process of tungsten drill bits also faces challenges in terms of precision and consistency. Achieving uniform grain size and distribution in the tungsten carbide matrix is critical for optimal performance. Any inconsistencies can lead to weak points in the bit structure, potentially causing premature failure or uneven wear.

Lastly, the environmental impact and cost of tungsten drill bit production and disposal present ongoing challenges. The mining and processing of tungsten have significant environmental implications, and the recycling of used drill bits is not always economically viable. Developing more sustainable production methods and improving recycling technologies are important considerations for the future of tungsten drill bit technology.

Addressing these challenges requires a multidisciplinary approach, combining materials science, engineering, and advanced manufacturing techniques. Innovations in nanotechnology, composite materials, and surface treatments offer promising avenues for enhancing the efficiency and longevity of tungsten drill bits. As the demand for more efficient drilling operations continues to grow across various industries, overcoming these challenges will be crucial for advancing tungsten drill bit technology.

Existing Solutions for Drill Bit Efficiency Enhancement

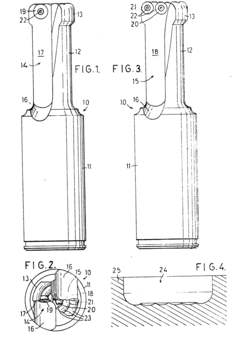

01 Tungsten carbide inserts for improved drilling efficiency

Drill bits incorporating tungsten carbide inserts can significantly enhance drilling efficiency. These inserts provide superior wear resistance and durability, allowing for longer operational life and improved penetration rates in various formations. The strategic placement of these inserts on the drill bit body optimizes cutting action and reduces overall drilling time.- Tungsten carbide inserts for improved drill bit efficiency: Drill bits incorporating tungsten carbide inserts demonstrate enhanced efficiency and durability. These inserts are strategically placed on the cutting surface to improve penetration rates and extend the bit's lifespan. The hardness and wear resistance of tungsten carbide contribute to maintaining cutting efficiency over prolonged periods of drilling.

- Optimized cutting structure design: Efficiency of tungsten drill bits is improved through optimized cutting structure designs. This includes strategic placement of cutters, varying cutter sizes, and customized blade configurations. These design optimizations enhance drilling performance by improving rock removal, reducing vibration, and increasing overall drilling efficiency.

- Advanced cooling and lubrication systems: Incorporating advanced cooling and lubrication systems in tungsten drill bits significantly enhances their efficiency. These systems help manage heat generation during drilling, reduce friction, and improve debris removal. By maintaining optimal operating temperatures and reducing wear, these features contribute to increased drilling speeds and extended bit life.

- Nanostructured tungsten materials: The use of nanostructured tungsten materials in drill bit manufacturing leads to improved efficiency. These advanced materials offer enhanced hardness, toughness, and wear resistance compared to conventional tungsten alloys. Drill bits made with nanostructured tungsten exhibit superior performance in challenging drilling conditions, resulting in increased penetration rates and longer operational life.

- Hybrid bit designs combining tungsten and other materials: Hybrid drill bit designs that combine tungsten components with other materials, such as diamond or steel, offer improved efficiency in various drilling applications. These designs leverage the strengths of different materials to optimize cutting action, durability, and overall performance. The synergistic effect of combining materials results in drill bits that can efficiently handle a wide range of formation types.

02 Optimized bit geometry for tungsten drill bits

Innovative designs in drill bit geometry can greatly improve the efficiency of tungsten drill bits. This includes optimizing the cutting structure, blade configuration, and nozzle placement. Such designs enhance fluid dynamics, improve cuttings removal, and reduce friction, resulting in faster penetration rates and extended bit life.Expand Specific Solutions03 Advanced cooling and lubrication systems

Implementing sophisticated cooling and lubrication systems in tungsten drill bits can significantly boost their efficiency. These systems help manage heat generation during drilling, reduce wear on the bit components, and improve overall performance. Enhanced fluid circulation and targeted cooling of critical areas contribute to increased drilling speeds and extended bit longevity.Expand Specific Solutions04 Integration of sensors and real-time monitoring

Incorporating sensors and real-time monitoring capabilities into tungsten drill bits can lead to improved efficiency. These technologies allow for continuous assessment of drilling parameters, formation characteristics, and bit performance. This data-driven approach enables operators to make informed decisions, optimize drilling processes, and prevent premature bit failure.Expand Specific Solutions05 Novel material compositions for tungsten drill bits

Developing new material compositions and manufacturing techniques for tungsten drill bits can enhance their efficiency. This includes creating advanced tungsten alloys, implementing novel coating technologies, and exploring composite materials. These innovations can result in bits with improved hardness, toughness, and wear resistance, leading to increased drilling efficiency and reduced downtime.Expand Specific Solutions

Key Players in Tungsten Drill Bit Manufacturing

The tungsten drill bit efficiency enhancement market is in a mature stage, with established players and ongoing innovation. The global market size for drill bits is substantial, driven by oil and gas, mining, and construction industries. Technologically, the field is advanced but still evolving, with companies like Baker Hughes Co., Hilti AG, and Schlumberger Technologies, Inc. leading in research and development. These firms, along with others like Kennametal, Inc. and Smith International, Inc., are focusing on improving bit designs, materials, and manufacturing processes to increase durability and cutting efficiency. Academic institutions such as Central South University and the University of Maryland are contributing to fundamental research, while specialized companies like Achemetal Tungsten & Molybdenum Co. Ltd. are advancing material science aspects.

Baker Hughes Co.

Hilti AG

Innovative Materials and Coatings for Drill Bits

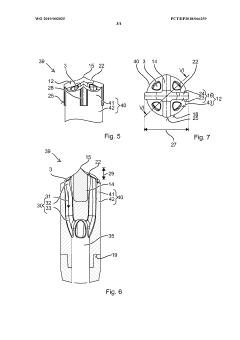

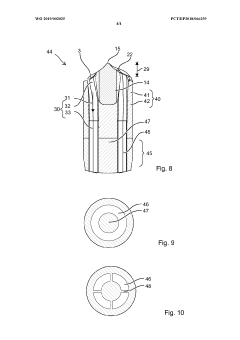

- A drilling bit design featuring segmental tungsten carbide cutters with different axes, arranged to form a flat-bottomed hole, allowing for quick replacement of worn cutting edges and enabling efficient drilling with reduced metal removal.

- A drill bit design featuring a hollow shank with suction openings and ducts that utilize inclined suction channels to facilitate the removal of cuttings, combined with cutting edges made of sintered tungsten carbide for enhanced chiseling performance, and a base that surrounds the cutting edges for structural support.

Environmental Impact of Drilling Operations

The environmental impact of drilling operations, particularly those involving tungsten drill bits, is a critical consideration in the quest to enhance drilling efficiency. As drilling activities intensify to meet growing energy demands, their ecological footprint becomes increasingly significant. Tungsten drill bits, while known for their durability and performance, contribute to various environmental concerns throughout their lifecycle.

During the manufacturing process of tungsten drill bits, the extraction and processing of tungsten ore can lead to habitat disruption, soil erosion, and water pollution. The energy-intensive production methods also result in substantial greenhouse gas emissions, contributing to climate change. Additionally, the use of chemical treatments and coatings on drill bits may introduce toxic substances into the environment if not properly managed.

In the operational phase, the use of tungsten drill bits in drilling activities can have direct environmental consequences. The drilling process itself generates significant amounts of waste, including drill cuttings and used drilling fluids. These materials may contain heavy metals, hydrocarbons, and other contaminants that can pose risks to soil and water quality if not properly disposed of or treated. The noise and vibrations associated with drilling operations can also disrupt local ecosystems and wildlife habitats.

Water consumption is another critical environmental concern in drilling operations. Large volumes of water are often required for cooling and lubricating drill bits, as well as for hydraulic fracturing in some cases. This can strain local water resources, particularly in water-scarce regions, and may lead to conflicts with other water users.

The disposal of worn-out tungsten drill bits presents additional environmental challenges. While tungsten is recyclable, the process is complex and energy-intensive. Improper disposal can lead to soil and groundwater contamination, as tungsten and associated materials slowly degrade and leach into the environment.

To mitigate these environmental impacts, the industry is exploring various strategies. These include developing more environmentally friendly drilling fluids, implementing closed-loop drilling systems to reduce waste, and improving recycling processes for tungsten drill bits. Advanced drilling techniques that minimize the number of wells required and reduce the overall environmental footprint are also being developed.

Furthermore, there is a growing focus on life cycle assessments of drilling equipment, including tungsten drill bits, to identify and address environmental hotspots throughout their production, use, and disposal phases. This holistic approach aims to optimize the environmental performance of drilling operations while maintaining or improving efficiency.

Cost-Benefit Analysis of Advanced Drill Bit Technologies

The cost-benefit analysis of advanced drill bit technologies is crucial for evaluating the potential return on investment in enhancing the efficiency of tungsten drill bits. This analysis encompasses both the financial implications and operational advantages of implementing cutting-edge technologies in drilling operations.

From a cost perspective, advanced drill bit technologies often require significant upfront investments. These costs include research and development expenses, manufacturing of new drill bit designs, and potential retooling of existing equipment to accommodate the advanced bits. Additionally, there may be costs associated with training personnel to effectively utilize and maintain these new technologies.

However, the benefits of implementing advanced drill bit technologies can be substantial. Improved drilling efficiency translates to reduced drilling time, which directly impacts operational costs. Advanced bits typically demonstrate enhanced durability, resulting in fewer bit replacements and decreased downtime for bit changes. This increased longevity can lead to significant savings in both equipment and labor costs over time.

Furthermore, advanced drill bits often exhibit superior performance in challenging geological formations. This capability allows for more effective penetration in hard rock environments, potentially opening up new drilling opportunities that were previously economically unfeasible. The ability to drill in diverse conditions can expand a company's operational range and market competitiveness.

Energy efficiency is another critical factor in the cost-benefit equation. Advanced drill bit technologies often require less energy input to achieve the same or better drilling results. This reduction in energy consumption not only lowers operational costs but also aligns with growing environmental concerns and regulatory pressures for more sustainable drilling practices.

The impact on overall project timelines is a significant benefit to consider. Faster drilling rates and reduced downtime can lead to earlier project completion, potentially allowing companies to capitalize on market opportunities more quickly. This acceleration of project schedules can have far-reaching financial implications, particularly in volatile commodity markets.

When evaluating the cost-benefit ratio, it's essential to consider the long-term perspective. While the initial investment in advanced drill bit technologies may be substantial, the cumulative benefits over multiple drilling projects can far outweigh the upfront costs. Companies must assess their specific operational needs, drilling environments, and long-term strategic goals to determine the most appropriate investment in advanced drill bit technologies.