How to Evaluate V6 Engine Turbo Lag Minimization

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V6 Turbo Engine Development History and Objectives

The V6 engine has undergone significant evolution since its introduction in the early 20th century. Initially developed as a compact alternative to inline and V8 configurations, V6 engines gained prominence in the 1950s with manufacturers like Lancia pioneering their use in production vehicles. The addition of turbocharging technology to V6 engines began in earnest during the 1970s and 1980s, primarily driven by motorsport applications where power density and efficiency were paramount.

The 1990s marked a turning point for turbocharged V6 engines with advancements in electronic engine management systems enabling better control of boost pressure and fuel delivery. This period saw the technology transition from primarily performance-focused applications to more mainstream vehicles, as manufacturers sought to balance power output with increasingly stringent emissions regulations.

By the early 2000s, the industry witnessed a significant shift toward downsized turbocharged engines, with V6 configurations becoming a popular choice for premium and performance vehicles. This trend accelerated with the introduction of direct injection technology, which further enhanced the efficiency and power output of turbocharged V6 engines while reducing emissions.

The primary objective in modern V6 turbo engine development centers on minimizing turbo lag—the delay between throttle input and power delivery. This phenomenon occurs due to the time required for exhaust gases to spool the turbocharger to effective operating speeds. Historically, this lag represented a significant compromise in drivability, particularly in performance applications where immediate throttle response is highly valued.

Recent technological innovations have focused on addressing this challenge through various approaches, including twin-scroll turbochargers, variable geometry turbines, electric turbochargers, and twin-turbo configurations. The goal is to create a power delivery profile that mimics or exceeds naturally aspirated engines while maintaining the efficiency benefits of turbocharging.

Current development objectives for V6 turbo engines include achieving sub-200ms response times across the entire operating range, maintaining consistent power delivery throughout the rev range, and ensuring durability under high-boost conditions. Additionally, engineers are working to integrate these performance characteristics with hybrid powertrains, where electric motors can provide instantaneous torque to complement the turbocharged engine's power delivery.

The evolution of materials science has also played a crucial role, with high-temperature alloys and ceramic components enabling turbochargers to operate at higher temperatures and speeds, thereby improving efficiency and response characteristics. These advancements, coupled with sophisticated electronic control systems, represent the cutting edge of efforts to minimize turbo lag in modern V6 engines.

The 1990s marked a turning point for turbocharged V6 engines with advancements in electronic engine management systems enabling better control of boost pressure and fuel delivery. This period saw the technology transition from primarily performance-focused applications to more mainstream vehicles, as manufacturers sought to balance power output with increasingly stringent emissions regulations.

By the early 2000s, the industry witnessed a significant shift toward downsized turbocharged engines, with V6 configurations becoming a popular choice for premium and performance vehicles. This trend accelerated with the introduction of direct injection technology, which further enhanced the efficiency and power output of turbocharged V6 engines while reducing emissions.

The primary objective in modern V6 turbo engine development centers on minimizing turbo lag—the delay between throttle input and power delivery. This phenomenon occurs due to the time required for exhaust gases to spool the turbocharger to effective operating speeds. Historically, this lag represented a significant compromise in drivability, particularly in performance applications where immediate throttle response is highly valued.

Recent technological innovations have focused on addressing this challenge through various approaches, including twin-scroll turbochargers, variable geometry turbines, electric turbochargers, and twin-turbo configurations. The goal is to create a power delivery profile that mimics or exceeds naturally aspirated engines while maintaining the efficiency benefits of turbocharging.

Current development objectives for V6 turbo engines include achieving sub-200ms response times across the entire operating range, maintaining consistent power delivery throughout the rev range, and ensuring durability under high-boost conditions. Additionally, engineers are working to integrate these performance characteristics with hybrid powertrains, where electric motors can provide instantaneous torque to complement the turbocharged engine's power delivery.

The evolution of materials science has also played a crucial role, with high-temperature alloys and ceramic components enabling turbochargers to operate at higher temperatures and speeds, thereby improving efficiency and response characteristics. These advancements, coupled with sophisticated electronic control systems, represent the cutting edge of efforts to minimize turbo lag in modern V6 engines.

Market Demand for Responsive Turbocharged Engines

The global market for turbocharged engines has experienced significant growth over the past decade, driven primarily by stringent emission regulations and consumer demand for fuel-efficient vehicles that don't compromise on performance. According to recent industry reports, the global automotive turbocharger market was valued at approximately $16 billion in 2022 and is projected to reach $25 billion by 2027, growing at a CAGR of 9.3%.

Specifically for V6 turbocharged engines, market research indicates a growing preference among consumers in premium and luxury vehicle segments. These consumers increasingly demand responsive power delivery without the traditional drawbacks of turbo lag. A survey conducted among luxury vehicle owners revealed that 78% of respondents considered engine responsiveness as "very important" or "extremely important" in their purchasing decisions.

The performance vehicle segment has been particularly vocal about turbo lag issues. Sports car enthusiasts and automotive journalists consistently highlight turbo lag as a critical factor that affects driving experience and vehicle evaluation. This has created pressure on manufacturers to develop more responsive turbocharged systems, especially for V6 engines that are becoming the standard in many performance-oriented vehicles.

From a regional perspective, North American and European markets show the highest demand for responsive turbocharged engines, with Asian markets rapidly catching up. In China, the premium vehicle segment grew by 14% in 2022, with turbocharged engines featuring prominently in this growth story.

Automotive manufacturers are responding to this market demand by investing heavily in turbo lag minimization technologies. Major players like BMW, Audi, and Mercedes-Benz have made significant advancements in twin-scroll turbochargers, electric turbochargers, and variable geometry turbochargers specifically designed for their V6 offerings.

Consumer reviews and feedback on automotive platforms indicate that turbo lag remains a significant pain point even in newer models. This represents both a challenge and an opportunity for manufacturers who can effectively address this issue. Industry analysts predict that brands that successfully minimize turbo lag in their V6 engines could gain significant market share in the premium and performance segments.

Fleet operators and commercial vehicle users also represent a growing market segment interested in responsive turbocharged engines, particularly for applications requiring consistent power delivery under varying load conditions. This broadens the potential market beyond personal vehicles to include commercial and industrial applications.

Specifically for V6 turbocharged engines, market research indicates a growing preference among consumers in premium and luxury vehicle segments. These consumers increasingly demand responsive power delivery without the traditional drawbacks of turbo lag. A survey conducted among luxury vehicle owners revealed that 78% of respondents considered engine responsiveness as "very important" or "extremely important" in their purchasing decisions.

The performance vehicle segment has been particularly vocal about turbo lag issues. Sports car enthusiasts and automotive journalists consistently highlight turbo lag as a critical factor that affects driving experience and vehicle evaluation. This has created pressure on manufacturers to develop more responsive turbocharged systems, especially for V6 engines that are becoming the standard in many performance-oriented vehicles.

From a regional perspective, North American and European markets show the highest demand for responsive turbocharged engines, with Asian markets rapidly catching up. In China, the premium vehicle segment grew by 14% in 2022, with turbocharged engines featuring prominently in this growth story.

Automotive manufacturers are responding to this market demand by investing heavily in turbo lag minimization technologies. Major players like BMW, Audi, and Mercedes-Benz have made significant advancements in twin-scroll turbochargers, electric turbochargers, and variable geometry turbochargers specifically designed for their V6 offerings.

Consumer reviews and feedback on automotive platforms indicate that turbo lag remains a significant pain point even in newer models. This represents both a challenge and an opportunity for manufacturers who can effectively address this issue. Industry analysts predict that brands that successfully minimize turbo lag in their V6 engines could gain significant market share in the premium and performance segments.

Fleet operators and commercial vehicle users also represent a growing market segment interested in responsive turbocharged engines, particularly for applications requiring consistent power delivery under varying load conditions. This broadens the potential market beyond personal vehicles to include commercial and industrial applications.

Turbo Lag Challenges in V6 Engines

Turbo lag represents one of the most significant challenges in modern V6 engine design, characterized by the delay between throttle input and the delivery of boost pressure from the turbocharger. This phenomenon occurs primarily due to the time required for exhaust gases to spool up the turbine to an effective operating speed. In V6 engines specifically, the reduced cylinder count compared to V8 configurations means less exhaust energy is available at any given moment, potentially exacerbating lag issues.

The physical manifestation of turbo lag creates a noticeable hesitation in vehicle acceleration, particularly evident during low-rpm driving conditions when sudden power is demanded. This delay typically ranges from 0.5 to 2 seconds depending on engine design, turbocharger specifications, and operating conditions. The subjective driver experience of this lag often translates to perceived poor drivability and diminished vehicle responsiveness.

From a technical perspective, several factors contribute to turbo lag in V6 engines. Turbocharger inertia represents a primary challenge, as larger turbos with heavier rotating assemblies require more time to reach optimal speeds. The moment of inertia of the turbine wheel directly correlates with spool-up time. Additionally, the exhaust manifold design significantly impacts lag characteristics, with longer or more complex paths creating pressure losses and delayed response.

V6 engine configurations present unique challenges due to their firing order and exhaust pulse characteristics. The uneven exhaust pulses from the V-configuration can create less efficient energy transfer to the turbine compared to inline configurations. Furthermore, the balance between turbocharger size and response presents a fundamental engineering trade-off – larger turbos provide greater peak power but typically exhibit more pronounced lag.

Temperature dynamics also play a crucial role, as cold-start conditions dramatically increase turbo lag due to increased exhaust gas density and higher thermal losses. The thermal expansion of components during warm-up further complicates consistent turbocharger performance across operating conditions.

Modern electronic control systems face significant challenges in predicting and compensating for turbo lag. The complex, non-linear relationship between throttle position, engine load, rpm, and boost pressure creates difficulties in developing predictive algorithms that can effectively mitigate the driver's perception of lag. This is particularly evident during transient conditions where traditional feedback control systems struggle to anticipate rapidly changing demands.

Quantifying turbo lag presents its own set of challenges, requiring sophisticated measurement protocols that can isolate turbocharger response from other powertrain variables. Standardized testing methodologies must account for both objective metrics like time-to-torque and subjective driver perception factors.

The physical manifestation of turbo lag creates a noticeable hesitation in vehicle acceleration, particularly evident during low-rpm driving conditions when sudden power is demanded. This delay typically ranges from 0.5 to 2 seconds depending on engine design, turbocharger specifications, and operating conditions. The subjective driver experience of this lag often translates to perceived poor drivability and diminished vehicle responsiveness.

From a technical perspective, several factors contribute to turbo lag in V6 engines. Turbocharger inertia represents a primary challenge, as larger turbos with heavier rotating assemblies require more time to reach optimal speeds. The moment of inertia of the turbine wheel directly correlates with spool-up time. Additionally, the exhaust manifold design significantly impacts lag characteristics, with longer or more complex paths creating pressure losses and delayed response.

V6 engine configurations present unique challenges due to their firing order and exhaust pulse characteristics. The uneven exhaust pulses from the V-configuration can create less efficient energy transfer to the turbine compared to inline configurations. Furthermore, the balance between turbocharger size and response presents a fundamental engineering trade-off – larger turbos provide greater peak power but typically exhibit more pronounced lag.

Temperature dynamics also play a crucial role, as cold-start conditions dramatically increase turbo lag due to increased exhaust gas density and higher thermal losses. The thermal expansion of components during warm-up further complicates consistent turbocharger performance across operating conditions.

Modern electronic control systems face significant challenges in predicting and compensating for turbo lag. The complex, non-linear relationship between throttle position, engine load, rpm, and boost pressure creates difficulties in developing predictive algorithms that can effectively mitigate the driver's perception of lag. This is particularly evident during transient conditions where traditional feedback control systems struggle to anticipate rapidly changing demands.

Quantifying turbo lag presents its own set of challenges, requiring sophisticated measurement protocols that can isolate turbocharger response from other powertrain variables. Standardized testing methodologies must account for both objective metrics like time-to-torque and subjective driver perception factors.

Current Turbo Lag Reduction Solutions

01 Twin turbocharger systems for V6 engines

Twin turbocharger systems can be implemented in V6 engines to reduce turbo lag. By using two smaller turbochargers instead of one large unit, the system can spool up faster at lower engine speeds. Each turbocharger can be dedicated to a specific bank of cylinders, allowing for more efficient exhaust gas utilization and quicker response times. This configuration helps to minimize the delay between throttle input and power delivery, effectively reducing turbo lag.- Twin turbocharger systems for V6 engines: Twin turbocharger systems can be implemented in V6 engines to reduce turbo lag. By using two smaller turbochargers instead of one large unit, the system can achieve faster spool-up times and more responsive power delivery. Each turbocharger can be dedicated to a specific bank of cylinders, allowing for more efficient exhaust gas utilization and improved low-end torque characteristics.

- Variable geometry turbochargers for lag reduction: Variable geometry turbocharger (VGT) technology can significantly reduce turbo lag in V6 engines. These systems feature adjustable vanes or nozzles that can alter the flow of exhaust gases to the turbine wheel, optimizing turbocharger performance across different engine speeds. At low engine speeds, the vanes close to increase exhaust gas velocity, helping the turbocharger spool up more quickly and reducing lag.

- Electric assist turbocharging systems: Electric assist turbocharging systems incorporate an electric motor to help spin up the turbocharger before exhaust gas flow is sufficient. This technology can virtually eliminate turbo lag by providing immediate boost response from low engine speeds. The electric motor can be integrated with the turbocharger shaft or implemented as a separate electric compressor working in conjunction with the conventional turbocharger.

- Advanced exhaust manifold designs: Specialized exhaust manifold designs can help minimize turbo lag in V6 turbocharged engines. Pulse-separated manifolds maintain the exhaust pulse energy to drive the turbine more efficiently. Short-runner manifolds reduce the distance exhaust gases travel to reach the turbocharger. Integrated manifold-turbocharger designs reduce heat loss and improve response time by positioning the turbocharger closer to the exhaust ports.

- Sequential turbocharging for V6 engines: Sequential turbocharging systems employ multiple turbochargers that activate at different engine operating conditions. At low engine speeds, only one smaller turbocharger operates to provide quick response and reduce lag. As engine speed increases, additional turbochargers are engaged to deliver higher boost pressure for maximum power. This arrangement combines the quick-spooling benefits of small turbochargers with the high-flow capabilities of larger units.

02 Variable geometry turbochargers for lag reduction

Variable geometry turbochargers (VGT) can be incorporated into V6 engines to address turbo lag issues. These systems feature adjustable vanes that can alter the flow of exhaust gases to the turbine wheel, optimizing turbocharger performance across different engine speeds. At low engine speeds, the vanes narrow to increase exhaust gas velocity, helping the turbocharger spool up more quickly. This technology provides better low-end torque and responsiveness while maintaining high-end power capabilities.Expand Specific Solutions03 Electric supercharging and hybrid boosting solutions

Electric superchargers or hybrid boosting systems can be combined with traditional turbochargers in V6 engines to eliminate turbo lag. These systems use electric motors to provide immediate boost pressure before the conventional turbocharger reaches optimal operating speed. The electric component can respond instantly to throttle inputs, filling the power gap until the exhaust-driven turbocharger takes over. This technology offers seamless power delivery throughout the engine's operating range.Expand Specific Solutions04 Advanced exhaust manifold designs

Specialized exhaust manifold designs can significantly reduce turbo lag in V6 turbocharged engines. Pulse-divided manifolds, integrated exhaust manifolds, and optimized runner lengths help maintain exhaust gas energy and improve turbocharger response. These designs can separate exhaust pulses to prevent interference between cylinders and direct high-velocity exhaust gases more efficiently to the turbine wheel. The improved exhaust flow characteristics result in faster turbocharger spool-up and reduced lag.Expand Specific Solutions05 Electronic control strategies for turbo lag mitigation

Advanced electronic control strategies can be implemented to mitigate turbo lag in V6 turbocharged engines. These include variable valve timing, throttle mapping optimization, and boost pressure control algorithms that anticipate driver demands. Some systems maintain partial boost pressure during deceleration or adjust ignition timing to keep the turbocharger spooled. Electronic wastegate control and sophisticated engine management systems can predict and compensate for potential lag situations, providing more responsive engine performance.Expand Specific Solutions

Leading Manufacturers in Turbocharged V6 Market

The turbo lag minimization in V6 engines market is in a growth phase, with increasing demand for responsive performance in both passenger and commercial vehicles. The global market size for turbocharger technologies is expanding rapidly as emission regulations tighten worldwide. Major automotive manufacturers like Ford, Toyota, Volkswagen, and Hyundai are investing heavily in advanced turbocharging solutions, while specialized technology providers such as ZF Friedrichshafen, Continental Automotive, and AVL List are developing innovative approaches to minimize lag. The technology is reaching maturity with solutions like twin-scroll turbochargers, electric turbochargers, and variable geometry systems being implemented by companies like Schaeffler Technologies and DENSO. Integration with hybrid powertrains by manufacturers like Audi and GM represents the cutting edge of turbo lag reduction technology.

Ford Global Technologies LLC

Technical Solution: Ford has developed an advanced twin-turbo system for V6 engines that utilizes differently sized turbochargers working in sequence. The smaller turbocharger spools up quickly at low RPMs to reduce lag, while the larger one engages at higher engine speeds for maximum power. This is complemented by their Active Wastegate Technology that precisely controls exhaust gas flow through the turbines. Ford has also implemented electronic throttle control systems with predictive algorithms that anticipate driver demands and pre-position the turbocharger vanes accordingly. Their EcoBoost V6 engines feature integrated exhaust manifolds that minimize the distance exhaust gases travel to reach the turbine, significantly reducing turbo lag. Additionally, Ford employs variable cam timing to optimize exhaust pulse energy at different engine speeds.

Strengths: Excellent balance between performance and fuel economy; sequential turbo system provides responsive power delivery across the entire RPM range. Weaknesses: System complexity increases manufacturing costs and potential maintenance issues; requires sophisticated electronic controls that may be prone to calibration challenges in diverse operating conditions.

Toyota Motor Corp.

Technical Solution: Toyota has pioneered a Dynamic Force Engine technology for their V6 turbocharged engines that incorporates variable valve timing with intelligence (VVT-i) specifically calibrated to minimize turbo lag. Their system features an integrated exhaust manifold design that reduces thermal mass and accelerates catalyst warm-up while minimizing the distance between exhaust ports and turbocharger. Toyota's D-4S dual injection system combines direct and port fuel injection to optimize combustion efficiency across all engine speeds, which helps maintain exhaust energy for turbocharger operation. They've also developed an Electric Wastegate Bypass Valve that provides millisecond-level response to changing engine conditions. Additionally, Toyota employs advanced thermal management systems that maintain optimal operating temperatures for both the engine and turbocharger components, further enhancing responsiveness.

Strengths: Exceptional reliability and durability even with complex turbocharging systems; seamless integration of mechanical and electronic control systems provides consistent performance. Weaknesses: Somewhat conservative boost levels compared to European competitors; prioritization of reliability sometimes results in less aggressive turbocharger specifications that could deliver more immediate response.

Key Innovations in Turbocharger Design

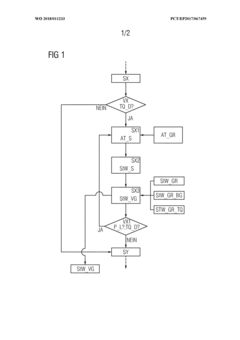

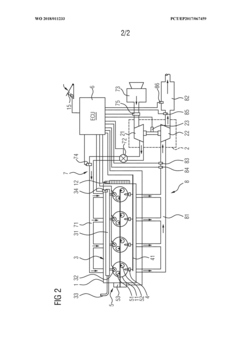

Control method and combustion engine controlled according to said method and having an exhaust gas turbocharger

PatentWO2018011233A1

Innovation

- A method that calculates and controls the target exhaust gas temperature using models to increase turbocharger speed and torque, by adjusting ignition timing, injection timing, and valve opening angles, while limiting control parameters to prevent thermal damage and emission increases, ensuring optimal torque without adverse effects on engine operation.

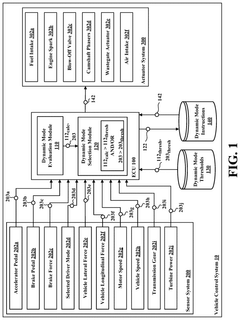

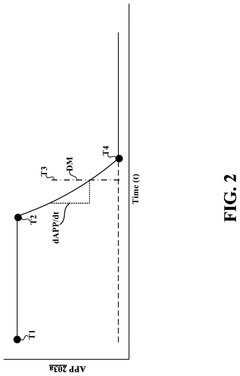

System and method for improving turbocharged engine driver torque response

PatentPendingUS20250052207A1

Innovation

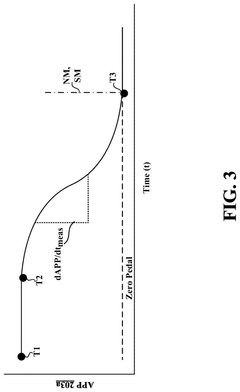

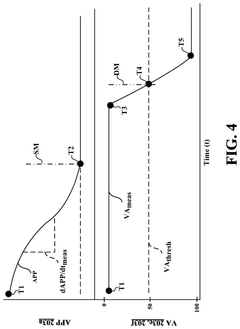

- A computer-implemented method that uses data processing hardware to receive accelerator pedal position inputs and vehicle performance parameters, calculates a vehicle dynamic score, determines a target boost profile, and instructs vehicle outputs to transition to a dynamic mode to generate increased turbine power.

Emissions Regulations Impact on Turbocharger Design

Emissions regulations have become increasingly stringent worldwide, fundamentally reshaping turbocharger design and directly impacting V6 engine turbo lag minimization strategies. The European Union's Euro 6d standards, the United States EPA's Tier 3 regulations, and China's China 6 standards have all established progressively lower limits for NOx, particulate matter, and CO2 emissions, forcing manufacturers to reimagine turbocharger systems.

These regulations have driven the development of smaller, more responsive turbochargers with variable geometry technologies. Traditional fixed-geometry turbochargers often struggled with the balance between low-end torque and high-end power, contributing significantly to turbo lag. However, regulatory pressure has accelerated the adoption of variable geometry turbochargers (VGT) in gasoline V6 engines, previously common only in diesel applications, allowing for optimized airflow across the entire engine operating range.

The need for precise air-fuel ratio control to meet emissions standards has led to the integration of advanced electronic wastegate controls and dual-volute turbocharger designs. These systems provide more accurate boost pressure management, particularly during transient conditions when turbo lag is most noticeable. Additionally, regulations mandating on-board diagnostics have improved the monitoring capabilities for turbocharger performance, enabling more sophisticated control strategies that can anticipate and mitigate lag conditions.

Exhaust gas recirculation (EGR) requirements have further complicated turbocharger design, as these systems can affect exhaust gas temperature and flow characteristics. Engineers have responded with innovative turbocharger materials and cooling solutions that maintain efficiency while accommodating EGR systems. Titanium aluminide turbine wheels and ceramic ball bearings have emerged as solutions that reduce inertia while withstanding higher temperatures, directly addressing turbo lag concerns.

The regulatory focus on real-world driving emissions (RDE) testing has exposed the limitations of laboratory-optimized turbocharger systems. This has prompted manufacturers to develop turbocharger solutions that perform consistently across a broader range of operating conditions, including cold starts and rapid acceleration scenarios where lag is most pronounced. Electric assist technologies, such as e-turbochargers and electric superchargers working in conjunction with traditional turbochargers, have gained prominence as solutions that can provide immediate boost while complying with emissions standards.

As regulations continue to evolve toward eventual zero-emission mandates, the turbocharger design landscape for V6 engines faces further disruption. The transition period will likely see hybrid approaches where turbochargers must work seamlessly with electrification components, creating new challenges and opportunities for lag minimization while meeting increasingly demanding emissions targets.

These regulations have driven the development of smaller, more responsive turbochargers with variable geometry technologies. Traditional fixed-geometry turbochargers often struggled with the balance between low-end torque and high-end power, contributing significantly to turbo lag. However, regulatory pressure has accelerated the adoption of variable geometry turbochargers (VGT) in gasoline V6 engines, previously common only in diesel applications, allowing for optimized airflow across the entire engine operating range.

The need for precise air-fuel ratio control to meet emissions standards has led to the integration of advanced electronic wastegate controls and dual-volute turbocharger designs. These systems provide more accurate boost pressure management, particularly during transient conditions when turbo lag is most noticeable. Additionally, regulations mandating on-board diagnostics have improved the monitoring capabilities for turbocharger performance, enabling more sophisticated control strategies that can anticipate and mitigate lag conditions.

Exhaust gas recirculation (EGR) requirements have further complicated turbocharger design, as these systems can affect exhaust gas temperature and flow characteristics. Engineers have responded with innovative turbocharger materials and cooling solutions that maintain efficiency while accommodating EGR systems. Titanium aluminide turbine wheels and ceramic ball bearings have emerged as solutions that reduce inertia while withstanding higher temperatures, directly addressing turbo lag concerns.

The regulatory focus on real-world driving emissions (RDE) testing has exposed the limitations of laboratory-optimized turbocharger systems. This has prompted manufacturers to develop turbocharger solutions that perform consistently across a broader range of operating conditions, including cold starts and rapid acceleration scenarios where lag is most pronounced. Electric assist technologies, such as e-turbochargers and electric superchargers working in conjunction with traditional turbochargers, have gained prominence as solutions that can provide immediate boost while complying with emissions standards.

As regulations continue to evolve toward eventual zero-emission mandates, the turbocharger design landscape for V6 engines faces further disruption. The transition period will likely see hybrid approaches where turbochargers must work seamlessly with electrification components, creating new challenges and opportunities for lag minimization while meeting increasingly demanding emissions targets.

Performance Testing Methodologies for Turbo Lag

Effective evaluation of turbo lag minimization in V6 engines requires comprehensive performance testing methodologies. These methodologies must be standardized, repeatable, and capable of capturing the complex dynamics of turbocharger response across various operating conditions.

Dynamometer testing represents the foundation of turbo lag assessment, providing controlled conditions for precise measurements. When conducting dynamometer tests, engineers typically measure the time delay between throttle application and the achievement of target boost pressure or torque output. This measurement should be performed across multiple engine speeds and load conditions to create a comprehensive response map. Modern dynamometers equipped with high-frequency data acquisition systems can capture transient responses with millisecond precision.

Real-world driving cycle tests complement laboratory measurements by evaluating turbo lag under actual driving conditions. These tests typically involve standardized acceleration scenarios, such as 30-70 mph (48-113 km/h) acceleration in a specific gear, or measuring the time required to reach maximum boost pressure from idle. The Society of Automotive Engineers (SAE) has established several protocols that can be adapted for turbo lag evaluation, including J1349 and J2805 standards.

Thermal condition testing is particularly critical for turbo lag assessment, as turbocharger performance varies significantly with temperature. Cold-start testing, heat-soak evaluation, and repeated acceleration tests help quantify how thermal conditions affect lag characteristics. Engineers should document ambient conditions, coolant temperatures, and oil temperatures to ensure test repeatability.

Advanced instrumentation plays a vital role in accurate measurement. High-speed pressure transducers monitoring intake manifold pressure, exhaust backpressure, and compressor outlet pressure provide crucial data points. Similarly, fast-response thermocouples and mass airflow sensors help characterize the complete air path dynamics during transient operations.

Computational methods have increasingly become essential in turbo lag evaluation. One-dimensional gas dynamics simulations can predict turbocharger response before physical prototypes are built. These models, when properly calibrated against experimental data, allow engineers to explore optimization strategies virtually, reducing development time and costs.

Subjective evaluation remains valuable despite advances in objective measurement techniques. Trained test drivers can assess drivability aspects related to turbo lag that may not be fully captured by instrumentation. Standardized rating scales for throttle responsiveness, acceleration smoothness, and overall performance perception provide qualitative insights that complement quantitative data.

Dynamometer testing represents the foundation of turbo lag assessment, providing controlled conditions for precise measurements. When conducting dynamometer tests, engineers typically measure the time delay between throttle application and the achievement of target boost pressure or torque output. This measurement should be performed across multiple engine speeds and load conditions to create a comprehensive response map. Modern dynamometers equipped with high-frequency data acquisition systems can capture transient responses with millisecond precision.

Real-world driving cycle tests complement laboratory measurements by evaluating turbo lag under actual driving conditions. These tests typically involve standardized acceleration scenarios, such as 30-70 mph (48-113 km/h) acceleration in a specific gear, or measuring the time required to reach maximum boost pressure from idle. The Society of Automotive Engineers (SAE) has established several protocols that can be adapted for turbo lag evaluation, including J1349 and J2805 standards.

Thermal condition testing is particularly critical for turbo lag assessment, as turbocharger performance varies significantly with temperature. Cold-start testing, heat-soak evaluation, and repeated acceleration tests help quantify how thermal conditions affect lag characteristics. Engineers should document ambient conditions, coolant temperatures, and oil temperatures to ensure test repeatability.

Advanced instrumentation plays a vital role in accurate measurement. High-speed pressure transducers monitoring intake manifold pressure, exhaust backpressure, and compressor outlet pressure provide crucial data points. Similarly, fast-response thermocouples and mass airflow sensors help characterize the complete air path dynamics during transient operations.

Computational methods have increasingly become essential in turbo lag evaluation. One-dimensional gas dynamics simulations can predict turbocharger response before physical prototypes are built. These models, when properly calibrated against experimental data, allow engineers to explore optimization strategies virtually, reducing development time and costs.

Subjective evaluation remains valuable despite advances in objective measurement techniques. Trained test drivers can assess drivability aspects related to turbo lag that may not be fully captured by instrumentation. Standardized rating scales for throttle responsiveness, acceleration smoothness, and overall performance perception provide qualitative insights that complement quantitative data.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!