How to Improve GDI Engine Turbocharging Potential

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

GDI Turbocharging Evolution and Objectives

Gasoline Direct Injection (GDI) technology has evolved significantly since its commercial introduction in the late 1990s. The journey began with first-generation systems focused primarily on stratified charge combustion for improved fuel economy. These early systems operated at relatively low injection pressures (50-120 bar) and faced challenges with particulate emissions and carbon deposits. The second generation, emerging in the mid-2000s, introduced higher injection pressures (150-200 bar) and improved injector designs, enabling better atomization and more precise fuel delivery.

The third generation of GDI systems, prevalent since the 2010s, has been characterized by even higher injection pressures (250-350 bar) and sophisticated multi-hole injectors capable of multiple injection events per cycle. This evolution has been largely driven by increasingly stringent emissions regulations and the demand for improved fuel efficiency without sacrificing performance.

Turbocharging technology has undergone parallel development, transitioning from simple fixed-geometry turbochargers to variable geometry systems, twin-scroll designs, and electric-assist technologies. The integration of advanced turbocharging with GDI has been a key enabler for engine downsizing strategies across the automotive industry.

The primary objective in improving GDI engine turbocharging potential is to overcome the inherent limitations of forced induction in gasoline engines, particularly knock resistance and thermal management challenges. By enhancing the synergy between direct injection and turbocharging, manufacturers aim to extract maximum power density while maintaining reliability, emissions compliance, and fuel efficiency.

Specific technical objectives include increasing the effective compression ratio without inducing knock, optimizing charge cooling effects through strategic injection timing, minimizing turbo lag through improved transient response, and ensuring combustion stability across a wider operating range. Additionally, there is a focus on mitigating particulate emissions that tend to increase with higher boost pressures in GDI engines.

The evolution trajectory points toward fully integrated systems where injection parameters, boost pressure, valve timing, and ignition are dynamically optimized in real-time based on sophisticated control algorithms. Future objectives include enabling higher levels of boost (beyond 2.5 bar absolute) while maintaining stoichiometric operation for emissions control, and facilitating ultra-lean combustion modes under specific operating conditions.

Industry benchmarks suggest that next-generation GDI turbocharged engines will target specific power outputs exceeding 150 kW/L while meeting Euro 7 and equivalent global emissions standards, representing a significant advancement over current production engines typically delivering 95-120 kW/L.

The third generation of GDI systems, prevalent since the 2010s, has been characterized by even higher injection pressures (250-350 bar) and sophisticated multi-hole injectors capable of multiple injection events per cycle. This evolution has been largely driven by increasingly stringent emissions regulations and the demand for improved fuel efficiency without sacrificing performance.

Turbocharging technology has undergone parallel development, transitioning from simple fixed-geometry turbochargers to variable geometry systems, twin-scroll designs, and electric-assist technologies. The integration of advanced turbocharging with GDI has been a key enabler for engine downsizing strategies across the automotive industry.

The primary objective in improving GDI engine turbocharging potential is to overcome the inherent limitations of forced induction in gasoline engines, particularly knock resistance and thermal management challenges. By enhancing the synergy between direct injection and turbocharging, manufacturers aim to extract maximum power density while maintaining reliability, emissions compliance, and fuel efficiency.

Specific technical objectives include increasing the effective compression ratio without inducing knock, optimizing charge cooling effects through strategic injection timing, minimizing turbo lag through improved transient response, and ensuring combustion stability across a wider operating range. Additionally, there is a focus on mitigating particulate emissions that tend to increase with higher boost pressures in GDI engines.

The evolution trajectory points toward fully integrated systems where injection parameters, boost pressure, valve timing, and ignition are dynamically optimized in real-time based on sophisticated control algorithms. Future objectives include enabling higher levels of boost (beyond 2.5 bar absolute) while maintaining stoichiometric operation for emissions control, and facilitating ultra-lean combustion modes under specific operating conditions.

Industry benchmarks suggest that next-generation GDI turbocharged engines will target specific power outputs exceeding 150 kW/L while meeting Euro 7 and equivalent global emissions standards, representing a significant advancement over current production engines typically delivering 95-120 kW/L.

Market Demand for Enhanced GDI Turbo Systems

The global market for enhanced GDI (Gasoline Direct Injection) turbocharging systems has experienced significant growth in recent years, driven primarily by stringent emission regulations and increasing consumer demand for fuel-efficient vehicles with improved performance. According to industry reports, the automotive turbocharger market reached approximately $16 billion in 2022 and is projected to grow at a CAGR of 6.5% through 2028, with GDI turbo systems representing a substantial portion of this growth.

Vehicle manufacturers are facing mounting pressure to meet increasingly strict CO2 emission targets while simultaneously satisfying consumer expectations for responsive performance. This has created a robust demand for advanced GDI turbocharging solutions that can deliver both efficiency and power. The European market has been particularly aggressive in this transition due to Euro 7 standards, with manufacturers investing heavily in turbocharging technology to meet the 95g/km fleet average CO2 target.

The premium automotive segment demonstrates the strongest demand for enhanced GDI turbo systems, with luxury brands implementing sophisticated twin-scroll and variable geometry turbochargers to maintain brand performance characteristics while meeting efficiency requirements. However, the technology is rapidly penetrating mid-range vehicle segments as production costs decrease and consumer awareness of turbocharged benefits increases.

Asian markets, particularly China and India, represent the fastest-growing regions for GDI turbo system adoption. China's implementation of China 6 emission standards has accelerated the shift toward turbocharged engines, with domestic market penetration increasing from 28% in 2018 to over 40% in 2022. Industry forecasts suggest this figure could reach 60% by 2026 as manufacturers continue to phase out naturally aspirated engines.

Commercial vehicle manufacturers are also showing increased interest in enhanced GDI turbo systems, particularly for light commercial vehicles where the balance between load capacity and fuel economy is critical. Fleet operators cite fuel savings of 12-15% when comparing modern turbocharged GDI engines to their naturally aspirated predecessors.

Consumer surveys indicate that vehicle buyers increasingly recognize and value turbocharging as a desirable feature, with 68% of new car buyers in developed markets expressing preference for turbocharged engines over naturally aspirated alternatives when presented with comparable price points. This consumer pull factor complements the regulatory push, creating a favorable market environment for continued innovation in GDI turbocharging technology.

The aftermarket segment for performance turbocharging upgrades continues to show resilience, with specialized tuning companies reporting steady demand for enhanced turbocharging solutions that can extract additional performance from factory GDI systems while maintaining reliability.

Vehicle manufacturers are facing mounting pressure to meet increasingly strict CO2 emission targets while simultaneously satisfying consumer expectations for responsive performance. This has created a robust demand for advanced GDI turbocharging solutions that can deliver both efficiency and power. The European market has been particularly aggressive in this transition due to Euro 7 standards, with manufacturers investing heavily in turbocharging technology to meet the 95g/km fleet average CO2 target.

The premium automotive segment demonstrates the strongest demand for enhanced GDI turbo systems, with luxury brands implementing sophisticated twin-scroll and variable geometry turbochargers to maintain brand performance characteristics while meeting efficiency requirements. However, the technology is rapidly penetrating mid-range vehicle segments as production costs decrease and consumer awareness of turbocharged benefits increases.

Asian markets, particularly China and India, represent the fastest-growing regions for GDI turbo system adoption. China's implementation of China 6 emission standards has accelerated the shift toward turbocharged engines, with domestic market penetration increasing from 28% in 2018 to over 40% in 2022. Industry forecasts suggest this figure could reach 60% by 2026 as manufacturers continue to phase out naturally aspirated engines.

Commercial vehicle manufacturers are also showing increased interest in enhanced GDI turbo systems, particularly for light commercial vehicles where the balance between load capacity and fuel economy is critical. Fleet operators cite fuel savings of 12-15% when comparing modern turbocharged GDI engines to their naturally aspirated predecessors.

Consumer surveys indicate that vehicle buyers increasingly recognize and value turbocharging as a desirable feature, with 68% of new car buyers in developed markets expressing preference for turbocharged engines over naturally aspirated alternatives when presented with comparable price points. This consumer pull factor complements the regulatory push, creating a favorable market environment for continued innovation in GDI turbocharging technology.

The aftermarket segment for performance turbocharging upgrades continues to show resilience, with specialized tuning companies reporting steady demand for enhanced turbocharging solutions that can extract additional performance from factory GDI systems while maintaining reliability.

Technical Barriers in GDI Turbocharging

Despite significant advancements in Gasoline Direct Injection (GDI) engine technology, several technical barriers continue to limit the full potential of turbocharging implementation. One primary challenge is the increased likelihood of knock phenomena under boosted conditions. The higher cylinder pressures and temperatures created by turbocharging exacerbate the risk of abnormal combustion, particularly at high load conditions where GDI engines are expected to deliver performance advantages.

Thermal management presents another significant barrier. Turbochargers generate substantial heat, which can lead to fuel vaporization issues in the direct injection system. This thermal stress affects not only component durability but also compromises the precise fuel delivery timing that GDI systems rely on for optimal performance. The integration of effective cooling systems without adding excessive weight or complexity remains problematic.

Particulate emissions represent a growing technical challenge for turbocharged GDI engines. The combination of direct injection and increased cylinder pressures can lead to incomplete fuel atomization and mixing, resulting in higher particulate matter formation. This issue has become more critical with increasingly stringent emissions regulations worldwide, requiring sophisticated and costly aftertreatment systems.

Transient response limitations continue to plague turbocharged GDI systems. The inherent lag between throttle input and turbocharger response (turbo lag) compromises drivability and real-world performance. While various technologies like twin-scroll turbochargers and electric compressors offer partial solutions, they add cost and complexity to the powertrain system.

Fuel system limitations also constrain turbocharging potential. GDI systems require extremely high fuel pressures (up to 350 bar in modern systems) to achieve proper atomization under boosted conditions. These high pressures create significant engineering challenges for fuel pump durability, injector design, and system sealing, particularly as manufacturers push for even higher boost levels.

Control system complexity represents another barrier. The precise management of boost pressure, ignition timing, and fuel delivery requires sophisticated algorithms and sensors. The interaction between these parameters becomes exponentially more complex under varying operating conditions, making calibration extremely time-consuming and challenging.

Material limitations also restrict turbocharging potential. Components must withstand higher thermal and mechanical stresses, requiring advanced materials that add cost. The turbine housing and exhaust manifold must resist temperatures exceeding 1000°C while maintaining dimensional stability, presenting significant metallurgical challenges that limit boost capability.

Thermal management presents another significant barrier. Turbochargers generate substantial heat, which can lead to fuel vaporization issues in the direct injection system. This thermal stress affects not only component durability but also compromises the precise fuel delivery timing that GDI systems rely on for optimal performance. The integration of effective cooling systems without adding excessive weight or complexity remains problematic.

Particulate emissions represent a growing technical challenge for turbocharged GDI engines. The combination of direct injection and increased cylinder pressures can lead to incomplete fuel atomization and mixing, resulting in higher particulate matter formation. This issue has become more critical with increasingly stringent emissions regulations worldwide, requiring sophisticated and costly aftertreatment systems.

Transient response limitations continue to plague turbocharged GDI systems. The inherent lag between throttle input and turbocharger response (turbo lag) compromises drivability and real-world performance. While various technologies like twin-scroll turbochargers and electric compressors offer partial solutions, they add cost and complexity to the powertrain system.

Fuel system limitations also constrain turbocharging potential. GDI systems require extremely high fuel pressures (up to 350 bar in modern systems) to achieve proper atomization under boosted conditions. These high pressures create significant engineering challenges for fuel pump durability, injector design, and system sealing, particularly as manufacturers push for even higher boost levels.

Control system complexity represents another barrier. The precise management of boost pressure, ignition timing, and fuel delivery requires sophisticated algorithms and sensors. The interaction between these parameters becomes exponentially more complex under varying operating conditions, making calibration extremely time-consuming and challenging.

Material limitations also restrict turbocharging potential. Components must withstand higher thermal and mechanical stresses, requiring advanced materials that add cost. The turbine housing and exhaust manifold must resist temperatures exceeding 1000°C while maintaining dimensional stability, presenting significant metallurgical challenges that limit boost capability.

Current GDI Turbocharging Solutions

01 Turbocharger design optimization for GDI engines

Optimizing turbocharger design specifically for gasoline direct injection (GDI) engines can significantly enhance performance. This includes developing specialized turbine geometries, compressor wheel designs, and housing configurations that better match the unique airflow characteristics and combustion requirements of GDI systems. These optimizations help improve boost response, reduce turbo lag, and increase overall efficiency while maintaining reliability under the high-temperature conditions typical of GDI operation.- Turbocharger design optimization for GDI engines: Specific turbocharger designs can significantly enhance the performance of gasoline direct injection (GDI) engines. These optimizations include variable geometry turbochargers, twin-scroll designs, and advanced bearing systems that reduce lag and improve boost response. Such designs are particularly effective for GDI engines as they can be tailored to match the unique combustion characteristics and flow dynamics of direct injection technology, resulting in improved power output and efficiency across a wider operating range.

- Integration of exhaust gas recirculation with turbocharging: Combining exhaust gas recirculation (EGR) systems with turbocharging technology in GDI engines offers significant benefits for emissions control and efficiency. This integration allows for better management of combustion temperatures, reducing NOx emissions while maintaining performance. Advanced control strategies enable precise balancing of EGR rates and boost pressure according to engine load conditions, which is particularly valuable for GDI engines where combustion control is critical for managing particulate emissions and fuel economy.

- Low-pressure and multi-stage turbocharging systems: Low-pressure and multi-stage turbocharging systems offer particular advantages for GDI engines. These configurations provide more flexible boost control across the engine operating range, with smaller turbochargers handling low-end response while larger units deliver high-end power. This approach addresses the specific challenges of GDI engines, including their sensitivity to intake pressure and air-fuel mixing requirements. Sequential and parallel turbocharging arrangements can be specifically optimized to enhance the direct injection process and combustion efficiency.

- Electronic control strategies for GDI turbocharging: Advanced electronic control strategies are essential for maximizing the potential of turbocharged GDI engines. These control systems manage boost pressure, injection timing, and ignition parameters in a coordinated manner to optimize performance while preventing knock and ensuring durability. Machine learning algorithms and model-based controls can predict optimal operating parameters based on driver demands and environmental conditions, allowing for more precise management of the complex interactions between direct injection and forced induction systems.

- Fuel system modifications for turbocharged GDI applications: Specialized fuel system modifications are required to fully exploit the potential of turbocharged GDI engines. These include high-pressure fuel pumps capable of delivering consistent pressure under boosted conditions, injectors designed to maintain optimal spray patterns at various boost levels, and advanced fuel cooling systems. The integration of these components with the turbocharging system requires careful calibration to ensure proper atomization and mixture formation under all operating conditions, which is critical for combustion stability and emissions control in high-performance GDI applications.

02 Integration of variable geometry turbocharging with GDI

Variable geometry turbocharging (VGT) systems offer particular advantages when paired with GDI engines. By dynamically adjusting turbine geometry based on engine operating conditions, these systems can provide optimal boost across a wider RPM range. This integration enables better low-end torque, improved transient response, and enhanced fuel efficiency. The variable geometry components can be specifically calibrated to complement the precise fuel delivery characteristics of direct injection, resulting in more consistent power delivery and reduced emissions.Expand Specific Solutions03 Dual-stage and sequential turbocharging for GDI applications

Implementing dual-stage or sequential turbocharging systems in GDI engines addresses the challenge of providing appropriate boost across the entire operating range. These configurations typically employ a smaller turbocharger for low-end response and a larger one for high-end power. When properly integrated with direct injection timing and pressure control, these systems can significantly increase volumetric efficiency, reduce turbo lag, and improve overall engine performance. Advanced control strategies coordinate the transition between turbochargers to ensure smooth power delivery.Expand Specific Solutions04 Thermal management innovations for turbocharged GDI engines

Thermal management is critical in turbocharged GDI engines due to higher operating temperatures and potential for pre-ignition. Innovative cooling solutions include advanced intercooler designs, integrated exhaust manifolds with water cooling, and specialized heat shields. These systems help maintain optimal intake air temperatures, protect turbocharger components from thermal stress, and prevent fuel vaporization issues in the direct injection system. Effective thermal management extends turbocharger lifespan while allowing for higher boost pressures and compression ratios.Expand Specific Solutions05 Electronic control strategies for turbocharged GDI systems

Advanced electronic control strategies are essential for maximizing the potential of turbocharged GDI engines. These include sophisticated algorithms for coordinating boost pressure, fuel injection timing, ignition timing, and valve events. Machine learning and model-based control approaches enable real-time optimization of turbocharger operation based on driving conditions and performance demands. These control systems can also implement knock prevention strategies specific to turbocharged GDI engines, allowing for higher compression ratios and boost levels without compromising reliability.Expand Specific Solutions

Leading Manufacturers in GDI Turbo Technology

The GDI engine turbocharging market is currently in a growth phase, with major automotive manufacturers and suppliers actively developing solutions to enhance performance and efficiency. The global market for turbocharged GDI engines is expanding rapidly, driven by stringent emissions regulations and consumer demand for fuel-efficient vehicles with higher power output. Leading players include established OEMs like Ford, Toyota, Hyundai-Kia, and Mazda, alongside specialized component suppliers such as BorgWarner, Continental Automotive, and Robert Bosch. These companies are investing heavily in advanced technologies including variable geometry turbochargers, electric turbochargers, and integrated exhaust manifold designs. Research institutions like Beijing Institute of Technology and University of Michigan are contributing significant innovations, while emerging players from China such as SAIC Motor and Geely are rapidly gaining technological competence in this field.

Ford Global Technologies LLC

Technical Solution: Ford has developed EcoBoost technology as their flagship GDI turbocharging solution, combining direct injection with turbocharging and variable valve timing. Their latest advancements include dual-injection systems that utilize both port and direct injection to overcome carbon deposit issues while maintaining high boost potential. Ford employs twin-scroll turbochargers on many applications to separate exhaust pulses and reduce turbo lag, while their larger engines feature dual turbocharger configurations with sophisticated intercooling systems. Ford's patented Anti-Lag System (ALS) maintains turbocharger speed during throttle-off conditions by keeping the throttle open and adjusting fuel and spark to maintain exhaust energy. Their cylinder deactivation technology works in conjunction with turbocharging to optimize efficiency across the power band. Ford has also implemented advanced thermal management systems that specifically target turbocharger durability and efficiency under high-load conditions.

Strengths: Extensive real-world deployment across diverse vehicle platforms; proven durability in mass-market applications; excellent balance of performance and fuel economy. Weaknesses: Some earlier EcoBoost engines experienced carbon buildup issues; thermal management challenges under extreme conditions; complexity of dual-injection systems increases manufacturing costs.

Toyota Motor Corp.

Technical Solution: Toyota has developed a distinctive approach to GDI turbocharging with their D-4S (Direct injection 4-stroke gasoline engine Superior version) technology. Their system uniquely combines both direct and port fuel injection, allowing the engine management system to select optimal injection strategy based on operating conditions. Toyota's Dynamic Force Engine architecture incorporates high compression ratios (up to 13:1) even in turbocharged applications through sophisticated combustion chamber design and variable valve timing. Their turbocharging system features electric wastegate actuators that provide millisecond-level response times for precise boost control. Toyota has implemented advanced water-cooled intercooler systems positioned directly on the intake manifold to minimize lag and improve charge density. Their engines utilize variable oil pumps and advanced thermal management to reduce parasitic losses and improve efficiency. Toyota's ESTEC (Economy with Superior Thermal Efficient Combustion) technology optimizes combustion efficiency even under boosted conditions.

Strengths: Exceptional thermal efficiency; dual injection system effectively prevents carbon buildup; excellent reliability record; sophisticated combustion control. Weaknesses: More conservative boost levels compared to some competitors; higher manufacturing complexity due to dual injection systems; somewhat later adoption of turbocharging technology compared to European manufacturers.

Key Innovations in Turbo-GDI Integration

Method for maximizing the formation of deposits in injector nozzles of GDI engines

PatentWO2018002610A1

Innovation

- A method to maximize deposit formation in GDI engine injector nozzles by simulating severe conditions through controlled engine speed and load variations, high nozzle temperatures, and moderate fuel flow rates, allowing for automated and unsupervised testing to quickly assess fuel's deposit-forming tendencies.

Gasoline direct injection engine

PatentInactiveUS8251040B2

Innovation

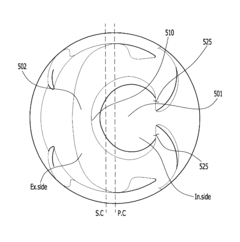

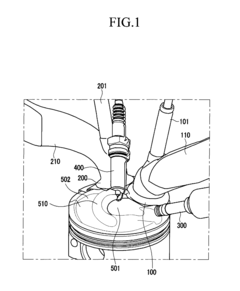

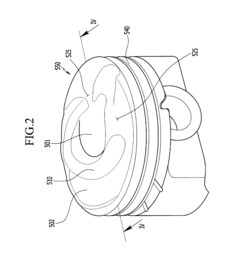

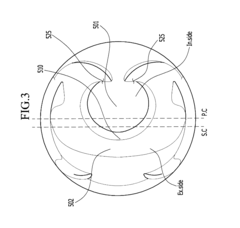

- The engine design includes a piston head with a first cavity for fuel return to the spark plug and a protrusion offset towards the exhaust valve, featuring a second cavity of a smaller height, allowing for differential control of intake and exhaust valve volumes to optimize the combustion chamber's volume ratio.

Emissions Compliance Strategies for Turbocharged GDI

Meeting stringent emissions regulations while enhancing turbocharging potential in GDI engines requires sophisticated compliance strategies. Modern turbocharged GDI engines face increasingly strict emissions standards worldwide, including Euro 7, China 7, and EPA Tier 3 regulations, which demand significant reductions in particulate matter (PM), NOx, and CO2 emissions.

Advanced aftertreatment systems represent the primary compliance approach. Three-way catalytic converters (TWC) remain fundamental but require optimization for high-temperature operation under boosted conditions. Gasoline particulate filters (GPF) have become essential for meeting PM limits, with coated versions (cGPF) combining filtration with catalytic functions to save packaging space in turbocharged applications.

Selective Catalytic Reduction (SCR) systems, traditionally used in diesel engines, are increasingly adopted in high-performance turbocharged GDI engines to address NOx emissions under high boost conditions. These systems require careful integration with turbocharger placement to ensure optimal thermal management.

Combustion optimization strategies complement aftertreatment solutions. Advanced fuel injection strategies, including multiple injections per cycle and optimized spray patterns, significantly reduce particulate formation while maintaining boost compatibility. Variable valve timing systems adjusted specifically for turbocharged operation help minimize overlap during high-load conditions, reducing raw emissions.

Cooled Exhaust Gas Recirculation (EGR) systems offer dual benefits by lowering combustion temperatures to reduce NOx formation while mitigating knock, enabling higher boost pressures without compromising emissions compliance. Low-pressure EGR systems are particularly effective for turbocharged applications as they provide cooler recirculated exhaust.

Electronic control strategies play a crucial role in emissions management. Model-based control algorithms continuously adjust boost pressure, injection timing, and EGR rates based on real-time emissions feedback. Transient control strategies specifically address emissions spikes during rapid boost changes, a common challenge in turbocharged GDI engines.

Water injection technology is emerging as a promising solution for emissions compliance in highly boosted engines. By introducing atomized water into the intake manifold or directly into the cylinder, combustion temperatures are reduced, allowing higher boost pressures while maintaining NOx compliance and improving knock resistance.

Cylinder deactivation, when implemented with sophisticated control algorithms, can maintain optimal catalyst temperatures during low-load operation while providing full power availability when boost is demanded, ensuring emissions systems remain effective across the entire operating range.

Advanced aftertreatment systems represent the primary compliance approach. Three-way catalytic converters (TWC) remain fundamental but require optimization for high-temperature operation under boosted conditions. Gasoline particulate filters (GPF) have become essential for meeting PM limits, with coated versions (cGPF) combining filtration with catalytic functions to save packaging space in turbocharged applications.

Selective Catalytic Reduction (SCR) systems, traditionally used in diesel engines, are increasingly adopted in high-performance turbocharged GDI engines to address NOx emissions under high boost conditions. These systems require careful integration with turbocharger placement to ensure optimal thermal management.

Combustion optimization strategies complement aftertreatment solutions. Advanced fuel injection strategies, including multiple injections per cycle and optimized spray patterns, significantly reduce particulate formation while maintaining boost compatibility. Variable valve timing systems adjusted specifically for turbocharged operation help minimize overlap during high-load conditions, reducing raw emissions.

Cooled Exhaust Gas Recirculation (EGR) systems offer dual benefits by lowering combustion temperatures to reduce NOx formation while mitigating knock, enabling higher boost pressures without compromising emissions compliance. Low-pressure EGR systems are particularly effective for turbocharged applications as they provide cooler recirculated exhaust.

Electronic control strategies play a crucial role in emissions management. Model-based control algorithms continuously adjust boost pressure, injection timing, and EGR rates based on real-time emissions feedback. Transient control strategies specifically address emissions spikes during rapid boost changes, a common challenge in turbocharged GDI engines.

Water injection technology is emerging as a promising solution for emissions compliance in highly boosted engines. By introducing atomized water into the intake manifold or directly into the cylinder, combustion temperatures are reduced, allowing higher boost pressures while maintaining NOx compliance and improving knock resistance.

Cylinder deactivation, when implemented with sophisticated control algorithms, can maintain optimal catalyst temperatures during low-load operation while providing full power availability when boost is demanded, ensuring emissions systems remain effective across the entire operating range.

Thermal Management Advancements for GDI Turbo Systems

Thermal management has emerged as a critical factor in maximizing the performance and efficiency of turbocharged Gasoline Direct Injection (GDI) engines. As boost pressures increase to meet power demands, the thermal loads on engine components and intake charge air rise significantly, creating challenges that require innovative solutions.

Advanced intercooling systems represent a major breakthrough in GDI turbo thermal management. Traditional air-to-air intercoolers are increasingly being supplemented or replaced by water-to-air systems that offer more consistent cooling performance across varying operating conditions. These systems can reduce intake temperatures by up to 30°C compared to conventional designs, directly enhancing volumetric efficiency and reducing the risk of knock.

Integrated exhaust manifolds (IEM) have revolutionized thermal management by incorporating the exhaust manifold directly into the cylinder head. This design enables faster catalyst light-off during cold starts while improving heat rejection during high-load operation. The dual-mode capability optimizes emissions performance without compromising turbocharger response, representing a significant advancement in thermal design philosophy.

Electronic wastegate control systems with thermal compensation algorithms now dynamically adjust boost pressure based on real-time temperature monitoring. These systems utilize multiple temperature sensors throughout the intake and exhaust paths to create thermal maps that optimize turbocharger operation across the entire engine operating range, preventing thermal-induced performance degradation.

Turbocharger water cooling jackets have evolved substantially, with computational fluid dynamics enabling precise cooling channel designs that target critical bearing and shaft components. Modern water-cooled turbochargers can withstand exhaust gas temperatures exceeding 1050°C while maintaining bearing temperatures within safe operating ranges, extending turbocharger lifespan and reliability.

Heat-resistant materials and coatings represent another frontier in thermal management. Ceramic thermal barrier coatings on turbine housings can reduce heat transfer by up to 40%, while nickel-based superalloys in turbine wheels maintain structural integrity at extreme temperatures. These materials enable higher boost pressures without compromising component durability.

Split-cooling systems that independently manage cylinder head and block temperatures have demonstrated significant benefits for turbocharged GDI applications. By maintaining optimal temperatures in combustion chambers while ensuring adequate cooling for highly stressed components, these systems expand the engine's operating envelope and improve thermal efficiency across varying load conditions.

Advanced intercooling systems represent a major breakthrough in GDI turbo thermal management. Traditional air-to-air intercoolers are increasingly being supplemented or replaced by water-to-air systems that offer more consistent cooling performance across varying operating conditions. These systems can reduce intake temperatures by up to 30°C compared to conventional designs, directly enhancing volumetric efficiency and reducing the risk of knock.

Integrated exhaust manifolds (IEM) have revolutionized thermal management by incorporating the exhaust manifold directly into the cylinder head. This design enables faster catalyst light-off during cold starts while improving heat rejection during high-load operation. The dual-mode capability optimizes emissions performance without compromising turbocharger response, representing a significant advancement in thermal design philosophy.

Electronic wastegate control systems with thermal compensation algorithms now dynamically adjust boost pressure based on real-time temperature monitoring. These systems utilize multiple temperature sensors throughout the intake and exhaust paths to create thermal maps that optimize turbocharger operation across the entire engine operating range, preventing thermal-induced performance degradation.

Turbocharger water cooling jackets have evolved substantially, with computational fluid dynamics enabling precise cooling channel designs that target critical bearing and shaft components. Modern water-cooled turbochargers can withstand exhaust gas temperatures exceeding 1050°C while maintaining bearing temperatures within safe operating ranges, extending turbocharger lifespan and reliability.

Heat-resistant materials and coatings represent another frontier in thermal management. Ceramic thermal barrier coatings on turbine housings can reduce heat transfer by up to 40%, while nickel-based superalloys in turbine wheels maintain structural integrity at extreme temperatures. These materials enable higher boost pressures without compromising component durability.

Split-cooling systems that independently manage cylinder head and block temperatures have demonstrated significant benefits for turbocharged GDI applications. By maintaining optimal temperatures in combustion chambers while ensuring adequate cooling for highly stressed components, these systems expand the engine's operating envelope and improve thermal efficiency across varying load conditions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!