How To Improve Thermal Conductivity In Tungsten?

Tungsten Thermal Conductivity Background and Objectives

Tungsten, known for its exceptional strength and high melting point, has been a critical material in various high-temperature applications. However, its thermal conductivity, while relatively high compared to many metals, still presents opportunities for improvement. The evolution of tungsten's thermal properties has been closely tied to advancements in materials science and engineering over the past century.

The primary objective in enhancing tungsten's thermal conductivity is to expand its utility in extreme thermal environments, particularly in aerospace, nuclear energy, and advanced manufacturing sectors. Improving heat dissipation capabilities could lead to more efficient and durable components in these industries, potentially revolutionizing thermal management systems.

Historically, tungsten's thermal conductivity has been a subject of extensive research, with early studies focusing on understanding its intrinsic properties. As technology progressed, the focus shifted towards manipulating its microstructure and composition to achieve better thermal performance. This transition marked a significant milestone in the field, opening new avenues for tailoring tungsten's properties to specific applications.

Recent technological trends have emphasized the development of tungsten-based composites and alloys, aiming to synergistically combine tungsten's inherent properties with those of other materials. These efforts have led to promising results, showcasing the potential for substantial improvements in thermal conductivity without compromising other desirable characteristics of tungsten.

The current technological landscape presents both challenges and opportunities. While traditional methods of enhancing thermal conductivity have reached certain limitations, emerging technologies such as nanotechnology and advanced manufacturing techniques offer new possibilities. These innovations provide pathways to engineer tungsten at the atomic and molecular levels, potentially unlocking unprecedented levels of thermal performance.

Looking ahead, the goals for improving tungsten's thermal conductivity are multifaceted. They include not only achieving higher absolute conductivity values but also enhancing thermal stability across a wider temperature range, improving isotropy in thermal properties, and developing more cost-effective production methods for high-performance tungsten materials.

As we delve deeper into this technological frontier, it becomes evident that improving tungsten's thermal conductivity is not just about enhancing a single material property. It represents a broader quest to push the boundaries of material science, with far-reaching implications for energy efficiency, technological advancement, and sustainable industrial practices in the coming decades.

Market Demand Analysis for High Thermal Conductivity Tungsten

The market demand for high thermal conductivity tungsten is experiencing significant growth, driven by several key factors across multiple industries. In the electronics sector, the miniaturization of devices and the increasing power density of integrated circuits have created a pressing need for materials that can efficiently dissipate heat. Tungsten, with its high melting point and potential for improved thermal conductivity, is becoming an attractive option for thermal management solutions in advanced electronic systems.

The aerospace and defense industries are also major contributors to the rising demand for thermally enhanced tungsten. As aircraft and spacecraft designs push the boundaries of performance, the need for materials that can withstand extreme temperatures while efficiently conducting heat away from critical components has become paramount. High thermal conductivity tungsten alloys are being explored for use in rocket nozzles, heat shields, and other high-temperature applications where traditional materials fall short.

In the energy sector, particularly in nuclear power and fusion research, the demand for high thermal conductivity tungsten is growing. The material's ability to handle high heat loads makes it a candidate for plasma-facing components in fusion reactors and for various applications in fission reactors where heat management is crucial.

The automotive industry, especially in the realm of electric vehicles (EVs), is another significant market driver. As EV manufacturers strive to improve battery performance and longevity, efficient thermal management systems become essential. High thermal conductivity tungsten components are being considered for use in battery cooling systems and power electronics, where heat dissipation is critical for maintaining optimal performance and safety.

Market analysis indicates that the global demand for high-performance thermal management materials, including enhanced tungsten, is projected to grow steadily over the next decade. This growth is fueled by the increasing adoption of 5G technology, the expansion of data centers, and the ongoing development of high-performance computing systems, all of which require advanced heat dissipation solutions.

The medical technology sector is also showing interest in high thermal conductivity tungsten for applications in imaging equipment and radiation therapy devices. The material's combination of high density and improved thermal properties makes it valuable for shielding and heat management in these sophisticated medical systems.

As industries continue to push the limits of material performance, the market for high thermal conductivity tungsten is expected to expand. However, the realization of this market potential hinges on successful research and development efforts to significantly enhance tungsten's thermal conductivity while maintaining its other desirable properties. The ability to produce such enhanced tungsten at scale and at competitive prices will be crucial in meeting the growing market demand across these diverse industrial sectors.

Current State and Challenges in Tungsten Thermal Enhancement

Tungsten, known for its high melting point and excellent mechanical properties, has been widely used in various high-temperature applications. However, its relatively low thermal conductivity has been a significant limitation in many advanced technological fields. The current state of thermal conductivity enhancement in tungsten presents both promising advancements and formidable challenges.

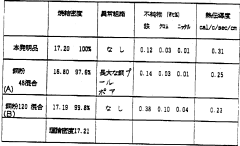

Recent research has shown that the thermal conductivity of tungsten can be improved through various methods, including alloying, nanostructuring, and composite formation. One of the most successful approaches has been the development of tungsten-based composites, particularly those incorporating high thermal conductivity materials such as copper or diamond. These composites have demonstrated significant improvements in thermal conductivity while maintaining many of tungsten's desirable properties.

Despite these advancements, several challenges persist in the field of tungsten thermal enhancement. One of the primary obstacles is the trade-off between improved thermal conductivity and other critical properties such as mechanical strength and radiation resistance. Enhancing thermal conductivity often comes at the cost of compromising these other essential characteristics, making it difficult to achieve an optimal balance for specific applications.

Another significant challenge lies in the scalability and cost-effectiveness of thermal enhancement techniques. While laboratory-scale experiments have shown promising results, translating these improvements to large-scale industrial production remains problematic. The complex processing techniques required for nanostructuring or composite formation often involve high costs and technical difficulties, limiting their widespread adoption.

The geographical distribution of tungsten thermal conductivity research and development is primarily concentrated in countries with advanced materials science capabilities, such as the United States, Germany, China, and Japan. This concentration of expertise has led to rapid advancements but also highlights the need for broader international collaboration to address global challenges in this field.

Current research efforts are focused on overcoming these challenges through innovative approaches. These include exploring novel alloying elements, developing advanced manufacturing techniques for nanostructured tungsten, and investigating the potential of two-dimensional tungsten-based materials. Additionally, computational modeling and simulation are playing an increasingly important role in predicting and optimizing the thermal properties of tungsten-based materials.

In conclusion, while significant progress has been made in enhancing the thermal conductivity of tungsten, substantial challenges remain. The field continues to evolve, driven by the growing demand for high-performance materials in extreme environments. Overcoming these obstacles will require continued investment in research and development, as well as interdisciplinary collaboration between materials scientists, engineers, and industry partners.

Existing Solutions for Enhancing Tungsten Thermal Conductivity

01 Tungsten-based composites for improved thermal conductivity

Composites incorporating tungsten and other materials are developed to enhance thermal conductivity. These composites often combine tungsten with copper, silver, or other metals to create materials with superior heat transfer properties. The resulting materials find applications in various industries where efficient heat dissipation is crucial.- Tungsten-based composites for improved thermal conductivity: Composites incorporating tungsten and other materials are developed to enhance thermal conductivity. These composites often combine tungsten with copper, silver, or other metals to create materials with superior heat transfer properties. The resulting materials find applications in various industries where efficient heat dissipation is crucial.

- Tungsten thermal management in electronic devices: Tungsten's high thermal conductivity is utilized in electronic devices for effective heat dissipation. It is incorporated into heat sinks, thermal interfaces, and other components to manage temperature in high-performance electronics. This application of tungsten helps improve device reliability and performance by preventing overheating.

- Measurement and characterization of tungsten's thermal properties: Various methods and apparatus are developed to accurately measure and characterize the thermal conductivity of tungsten and tungsten-based materials. These techniques include laser flash methods, steady-state heat flow measurements, and thermal diffusivity analysis. Precise measurement is crucial for material development and quality control in applications relying on tungsten's thermal properties.

- Tungsten in high-temperature applications: Tungsten's high melting point and good thermal conductivity make it suitable for high-temperature applications. It is used in furnace components, rocket nozzles, and other environments where materials must withstand extreme heat while efficiently conducting thermal energy. The development of tungsten alloys and coatings further enhances its performance in these demanding conditions.

- Nanostructured tungsten for enhanced thermal properties: Research focuses on developing nanostructured tungsten materials to further improve thermal conductivity. This includes creating tungsten nanowires, nanoparticles, and nanocomposites. These nanostructured forms of tungsten often exhibit unique thermal properties that can be advantageous in various applications, from microelectronics to energy systems.

02 Tungsten thermal management in electronic devices

Tungsten's high thermal conductivity is utilized in electronic devices for effective heat dissipation. It is incorporated into heat sinks, thermal interfaces, and other components to manage temperature in high-performance electronics. This application of tungsten helps improve device reliability and performance by preventing overheating.Expand Specific Solutions03 Measurement and characterization of tungsten's thermal properties

Various methods and apparatus are developed to accurately measure and characterize the thermal conductivity of tungsten and tungsten-based materials. These techniques include laser flash methods, steady-state heat flow measurements, and thermal diffusivity analysis. Precise measurement is crucial for material development and quality control in applications relying on tungsten's thermal properties.Expand Specific Solutions04 Tungsten in high-temperature applications

Tungsten's high melting point and good thermal conductivity make it suitable for high-temperature applications. It is used in furnace elements, rocket nozzles, and other components exposed to extreme heat. The material's ability to maintain its properties at elevated temperatures while efficiently conducting heat is crucial in these demanding environments.Expand Specific Solutions05 Nanostructured tungsten for enhanced thermal properties

Research focuses on developing nanostructured tungsten materials to further improve thermal conductivity. This includes creating tungsten nanowires, nanoparticles, and nanocomposites. These nanostructured forms of tungsten often exhibit unique thermal properties that can be advantageous in various applications, from microelectronics to energy systems.Expand Specific Solutions

Key Players in Tungsten Thermal Conductivity Research

The thermal conductivity improvement in tungsten is a critical area of research in advanced materials science, currently in a growth phase. The market for high-performance tungsten materials is expanding, driven by demands in aerospace, electronics, and energy sectors. Technologically, the field is progressing rapidly, with companies like Applied Materials, Inc., Plansee SE, and Xiamen Tungsten Co., Ltd. leading innovations. These firms are exploring various approaches, including nanostructuring, alloying, and composite development, to enhance tungsten's thermal properties. The involvement of research institutions like the Southwestern Institute of Physics and universities indicates ongoing fundamental research, suggesting that while advancements are being made, there's still room for significant breakthroughs in optimizing tungsten's thermal conductivity.

Applied Materials, Inc.

VACUUMSCHMELZE GmbH & Co. KG

Core Innovations in Tungsten Thermal Property Modification

- A hot-work steel composition with reduced carbon and chromium content, utilizing molybdenum and tungsten carbides to enhance thermal conductivity, achieving thermal conductivity of approximately 55 to 60 W/mK, nearly twice that of prior art, while maintaining or improving mechanical properties.

- The introduction of phosphorus to enhance wettability and deoxidize copper powder, combined with the use of cobalt, nickel, or iron to promote sintering, and the reduction of copper oxide powder in a controlled atmosphere to produce a homogeneous and high-density copper-tungsten alloy with uniform copper dispersion.

Material Processing Techniques for Improved Thermal Properties

Material processing techniques play a crucial role in enhancing the thermal conductivity of tungsten. One of the most effective methods is grain refinement through severe plastic deformation (SPD). This process involves subjecting the material to intense mechanical stress, resulting in a significant reduction in grain size. The increased number of grain boundaries acts as efficient phonon scatterers, thereby improving thermal conductivity. Equal Channel Angular Pressing (ECAP) and High-Pressure Torsion (HPT) are two prominent SPD techniques used for tungsten processing.

Another approach to improve thermal properties is the introduction of alloying elements. Carefully selected additives can modify the electronic structure and phonon scattering mechanisms within tungsten. For instance, the addition of rhenium has been shown to enhance thermal conductivity by reducing electron-phonon scattering. However, the concentration of alloying elements must be optimized to balance the benefits of improved thermal properties against potential drawbacks in other material characteristics.

Surface modification techniques also offer promising avenues for enhancing thermal conductivity. Plasma spraying and physical vapor deposition (PVD) can be used to create thin coatings or layers on tungsten surfaces, which can significantly alter heat transfer properties. These coatings can be designed to minimize thermal resistance at interfaces and promote efficient heat dissipation.

Heat treatment processes, such as annealing and quenching, can be employed to manipulate the microstructure of tungsten. Controlled heating and cooling cycles can reduce defects, optimize grain size, and improve overall crystallinity. This results in enhanced phonon transport and, consequently, improved thermal conductivity. The precise temperature and duration of heat treatment must be carefully controlled to achieve the desired microstructural changes without compromising other material properties.

Powder metallurgy techniques offer unique opportunities for tailoring the thermal properties of tungsten. By controlling the particle size distribution, compaction pressure, and sintering parameters, it is possible to create tungsten components with optimized thermal conductivity. Advanced sintering methods, such as spark plasma sintering (SPS), allow for rapid consolidation of tungsten powders while maintaining fine grain structures, which can lead to improved thermal performance.

Lastly, the development of tungsten-based composites presents a promising approach to enhance thermal conductivity. By incorporating high thermal conductivity materials such as diamond or carbon nanotubes into a tungsten matrix, it is possible to create composites with superior heat transfer capabilities. The challenge lies in ensuring proper dispersion of the reinforcing phase and maintaining strong interfacial bonding to maximize thermal conductivity improvements.

Environmental Impact of Enhanced Thermal Conductivity Tungsten

The enhancement of thermal conductivity in tungsten has significant environmental implications that warrant careful consideration. As tungsten's thermal properties improve, its applications in various industries expand, potentially leading to both positive and negative environmental impacts.

One of the primary environmental benefits of enhanced thermal conductivity tungsten is its potential to improve energy efficiency in high-temperature applications. By conducting heat more effectively, tungsten components can reduce energy losses and minimize the overall energy consumption of systems they are used in. This can lead to decreased greenhouse gas emissions and a reduced carbon footprint across multiple industries, including aerospace, electronics, and energy production.

However, the increased demand for tungsten with improved thermal properties may lead to intensified mining activities. Tungsten mining can have substantial environmental consequences, including habitat destruction, soil erosion, and water pollution. The extraction process often involves the use of chemicals that can contaminate local water sources if not properly managed. Additionally, the energy-intensive nature of tungsten processing contributes to carbon emissions, potentially offsetting some of the environmental gains achieved through its improved thermal properties.

The production of enhanced thermal conductivity tungsten may also require additional processing steps or the incorporation of other materials, which could introduce new environmental challenges. For instance, the use of certain dopants or nanostructures to improve thermal conductivity might involve materials with their own environmental concerns, such as rare earth elements or engineered nanoparticles.

On the other hand, the improved durability and longevity of tungsten components with enhanced thermal conductivity could lead to reduced material consumption over time. This could result in less frequent replacements and, consequently, a decrease in the overall environmental impact associated with manufacturing and disposal of tungsten products.

The recycling and end-of-life management of enhanced thermal conductivity tungsten products also present environmental considerations. While tungsten is highly recyclable, the presence of additional materials or complex structures used to improve its thermal properties may complicate recycling processes. Developing effective recycling methods for these advanced tungsten materials will be crucial to minimizing their long-term environmental impact and promoting a circular economy approach.

In conclusion, while the improvement of thermal conductivity in tungsten offers potential environmental benefits through increased energy efficiency, it also presents challenges related to resource extraction, production processes, and end-of-life management. Balancing these factors and developing sustainable practices throughout the lifecycle of enhanced thermal conductivity tungsten products will be essential to maximizing their positive environmental impact while mitigating potential drawbacks.