How To Improve Tungsten’s Machinability?

Tungsten Machinability Background and Objectives

Tungsten, known for its exceptional strength and high melting point, has been a crucial material in various industrial applications for decades. However, its inherent hardness and brittleness pose significant challenges in machining processes, limiting its widespread use in complex manufacturing scenarios. The evolution of tungsten machining techniques has been a continuous journey of innovation and technological advancement.

The primary objective in improving tungsten's machinability is to enhance its formability and reduce tool wear during cutting operations. This goal aligns with the broader industrial trend towards more efficient and cost-effective manufacturing processes, especially in sectors such as aerospace, defense, and electronics where tungsten's unique properties are highly valued.

Historically, tungsten machining has relied on traditional methods such as grinding and electrical discharge machining (EDM). These techniques, while effective, often result in slow production rates and high tooling costs. The industry has long sought more efficient alternatives that can maintain the material's integrity while improving processing speed and reducing overall manufacturing expenses.

Recent technological advancements have opened new avenues for enhancing tungsten's machinability. Innovations in cutting tool materials, such as the development of ultra-hard coatings and novel carbide compositions, have shown promise in extending tool life and improving cutting performance. Additionally, the integration of advanced cooling techniques and high-precision CNC systems has contributed to more controlled and efficient machining processes.

The pursuit of improved tungsten machinability is driven by several key factors. First, there is a growing demand for complex tungsten components in emerging technologies, particularly in the fields of nuclear fusion and high-energy physics. Second, the push for sustainable manufacturing practices necessitates more efficient material utilization and reduced energy consumption during machining operations.

Looking ahead, the trajectory of tungsten machining technology is expected to focus on several key areas. These include the development of hybrid machining processes that combine traditional and non-traditional techniques, the exploration of novel alloying elements to enhance tungsten's ductility without compromising its core properties, and the application of advanced simulation and modeling tools to optimize machining parameters.

As we delve deeper into the challenges and potential solutions for improving tungsten's machinability, it is crucial to consider the interdisciplinary nature of this endeavor. Success in this field will likely require collaboration across materials science, mechanical engineering, and advanced manufacturing disciplines, paving the way for innovative approaches that could revolutionize tungsten processing and expand its applications in cutting-edge technologies.

Market Demand for Improved Tungsten Machining

The demand for improved tungsten machining has been steadily increasing across various industries, driven by the unique properties of tungsten and its alloys. Tungsten's high melting point, excellent thermal and electrical conductivity, and superior strength make it invaluable in applications ranging from aerospace and defense to electronics and medical equipment. However, its inherent hardness and brittleness pose significant challenges in machining processes, leading to a growing market need for enhanced machinability solutions.

In the aerospace sector, the demand for improved tungsten machining is particularly pronounced. Aircraft engines require precision-machined tungsten components for their high-temperature resistance and strength-to-weight ratio. As the aviation industry continues to push for more efficient and powerful engines, the need for complex tungsten parts with tighter tolerances has intensified. This trend is expected to drive substantial growth in the market for advanced tungsten machining technologies.

The electronics industry represents another significant driver of demand. With the ongoing miniaturization of electronic devices, manufacturers require increasingly precise machining of tungsten components for applications such as heat sinks, electrical contacts, and microwave tubes. The ability to produce intricate tungsten parts with high accuracy and surface finish is crucial for maintaining the performance and reliability of modern electronic systems.

In the medical field, tungsten's biocompatibility and radiopacity have led to its increased use in surgical instruments, radiation shielding, and implants. The growing adoption of minimally invasive surgical techniques has created a demand for finely machined tungsten tools and components. Improved machinability would enable the production of more complex and precise medical devices, potentially expanding tungsten's applications in healthcare.

The energy sector, particularly in nuclear and renewable energy applications, also contributes to the market demand for enhanced tungsten machining. Tungsten's resistance to corrosion and high temperatures makes it ideal for use in nuclear reactors and solar energy systems. As these industries expand and evolve, the need for efficiently machined tungsten parts is expected to grow, driving innovation in machining technologies.

Furthermore, the defense industry's reliance on tungsten for armor-piercing projectiles, counterweights, and radiation shielding continues to fuel demand for improved machining capabilities. The ability to produce tungsten components with complex geometries and tight tolerances is essential for developing advanced defense systems and equipment.

As industries push the boundaries of material performance, the market for improved tungsten machining is poised for significant growth. Manufacturers and researchers are actively seeking solutions to overcome the challenges associated with tungsten's hardness and brittleness, aiming to develop more efficient and cost-effective machining processes. This market demand is likely to drive investments in research and development, fostering innovations in cutting tools, machining strategies, and surface treatment technologies specifically tailored for tungsten and its alloys.

Current Challenges in Tungsten Machining

Tungsten, known for its exceptional hardness and high melting point, presents significant challenges in machining processes. The primary difficulty lies in its inherent brittleness and low thermal conductivity, which lead to rapid tool wear and poor surface finish. These properties make conventional machining techniques less effective and often result in increased production costs and reduced productivity.

One of the major challenges in tungsten machining is tool wear. The material's hardness causes rapid degradation of cutting tools, necessitating frequent replacements and increasing downtime. This issue is exacerbated by tungsten's low thermal conductivity, which concentrates heat at the cutting edge, further accelerating tool wear. The combination of these factors results in reduced tool life and increased machining costs.

Surface finish quality is another critical challenge. Tungsten's brittleness leads to the formation of micro-cracks and surface defects during machining, compromising the integrity and performance of the final product. Achieving a smooth surface finish often requires additional post-processing steps, further increasing production time and costs.

The material's high strength-to-weight ratio also poses difficulties in maintaining dimensional accuracy during machining. Tungsten's resistance to deformation can cause deflection of cutting tools, leading to inaccuracies in the final product. This challenge is particularly pronounced in precision machining applications where tight tolerances are required.

Chip formation and removal present additional obstacles. Tungsten's toughness and work-hardening characteristics often result in the formation of long, continuous chips that are difficult to break and remove from the cutting zone. This can lead to poor chip evacuation, increased cutting forces, and potential damage to both the workpiece and the cutting tool.

The limited availability of specialized cutting tools and optimized machining parameters for tungsten further compounds these challenges. Unlike more common materials, there is a scarcity of comprehensive research and industry-standard best practices for tungsten machining. This lack of established guidelines often leads to a trial-and-error approach, resulting in inefficiencies and inconsistent results.

Environmental and health concerns also play a role in the challenges of tungsten machining. The fine dust produced during machining operations can pose health risks to operators and require specialized containment and disposal procedures. This adds complexity to the machining process and necessitates additional safety measures and equipment.

Addressing these challenges requires a multifaceted approach, combining advances in cutting tool materials, innovative cooling techniques, and optimized machining strategies. The development of new cutting tool coatings, such as diamond-like carbon (DLC) or cubic boron nitride (CBN), shows promise in improving tool life and surface finish quality. Additionally, the implementation of high-pressure coolant systems and cryogenic cooling techniques may help mitigate the heat-related issues in tungsten machining.

Existing Solutions for Enhancing Tungsten Machinability

01 Alloying elements for improved machinability

Adding specific alloying elements to tungsten can significantly improve its machinability. These elements can modify the microstructure, reduce hardness, or act as lubricants during machining. Common alloying elements include rhenium, molybdenum, and nickel, which can enhance ductility and reduce tool wear during machining processes.- Alloying elements for improved machinability: Adding specific alloying elements to tungsten can significantly improve its machinability. These elements can modify the microstructure, reduce hardness, or act as lubricants during machining, making the tungsten easier to cut and shape. Common alloying elements used for this purpose include rhenium, molybdenum, and nickel.

- Heat treatment processes: Various heat treatment processes can be applied to tungsten to enhance its machinability. These processes may include annealing, stress-relieving, or controlled cooling, which can alter the material's grain structure and reduce internal stresses, making it more amenable to machining operations.

- Powder metallurgy techniques: Utilizing powder metallurgy techniques can produce tungsten components with improved machinability. By carefully controlling the powder composition, particle size distribution, and sintering conditions, it's possible to create tungsten parts with more favorable machining characteristics compared to conventionally produced tungsten.

- Surface treatment methods: Applying various surface treatment methods to tungsten can enhance its machinability. These treatments may include coatings, chemical etching, or mechanical surface modifications that can reduce friction, prevent tool wear, or create a more favorable surface for machining operations.

- Specialized machining techniques: Developing and employing specialized machining techniques can improve the machinability of tungsten. These may include optimized cutting parameters, use of specific cutting tools or coolants, or advanced machining processes such as electrical discharge machining (EDM) or ultrasonic machining, which can be particularly effective for hard-to-machine materials like tungsten.

02 Heat treatment techniques

Various heat treatment methods can be applied to tungsten to improve its machinability. These techniques may include annealing, stress-relieving, or controlled cooling processes. Heat treatments can help reduce internal stresses, modify grain structure, and increase ductility, making tungsten more amenable to machining operations.Expand Specific Solutions03 Powder metallurgy approaches

Powder metallurgy techniques can be used to produce tungsten components with improved machinability. By carefully controlling the powder composition, particle size distribution, and sintering conditions, it's possible to create tungsten parts with more favorable machining characteristics. This approach can result in more uniform microstructures and reduced tool wear during machining.Expand Specific Solutions04 Surface treatment methods

Various surface treatment methods can be applied to tungsten to enhance its machinability. These may include chemical etching, electrochemical machining, or the application of coatings. Such treatments can modify the surface properties of tungsten, reducing friction and tool wear during machining processes.Expand Specific Solutions05 Specialized cutting tools and techniques

Developing specialized cutting tools and machining techniques can improve the machinability of tungsten. This may involve the use of advanced tool materials, optimized cutting geometries, or novel machining strategies. High-speed machining, ultrasonic-assisted machining, or cryogenic cooling techniques can also be employed to enhance the machinability of tungsten and its alloys.Expand Specific Solutions

Key Players in Tungsten Processing Industry

The tungsten machinability improvement market is in a growth phase, driven by increasing demand for high-performance materials in various industries. The market size is expanding, with a focus on developing advanced manufacturing techniques and alloy compositions. Technologically, the field is moderately mature but still evolving, with ongoing research to enhance tungsten's properties. Companies like Plansee SE, Xiamen Tungsten Co., Ltd., and Toshiba Materials Co., Ltd. are at the forefront, investing in R&D to overcome tungsten's inherent brittleness and hardness. Universities such as Central South University and University of Science & Technology Beijing are contributing significant academic research, while industrial players like Applied Materials, Inc. and JFE Steel Corp. are developing practical applications and manufacturing processes to improve tungsten's machinability.

Plansee SE

Xiamen Tungsten Co., Ltd.

Innovative Approaches in Tungsten Machining

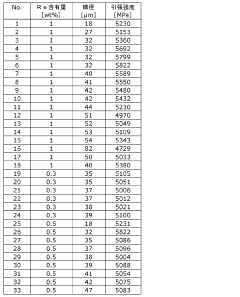

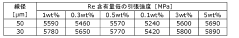

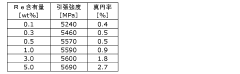

- A tungsten wire with a specific composition and manufacturing process that includes adding rhenium, potassium, or rare earth elements to achieve a tensile strength of 4800 MPa or more while maintaining a circularity of 2.0% or less, using a combination of heating wire drawing, room temperature drawing, and low-temperature hot drawing to refine crystal grains and improve workability.

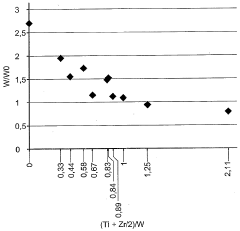

- Substituting part of the molybdenum with tungsten and adding titanium and/or zirconium to form large carbides that reduce segregation, maintaining hardness by adjusting carbon content, thereby minimizing the harmful effects of segregated veins.

Environmental Impact of Tungsten Machining Processes

The environmental impact of tungsten machining processes is a critical consideration in the quest to improve tungsten's machinability. Tungsten, known for its high melting point and exceptional strength, poses significant challenges during machining operations, often resulting in substantial environmental consequences.

One of the primary environmental concerns associated with tungsten machining is the generation of hazardous waste. The cutting fluids used in machining processes, which often contain harmful chemicals, can contaminate soil and water sources if not properly managed. These fluids, essential for reducing friction and heat during machining, require careful handling and disposal to minimize environmental risks.

Air pollution is another significant issue arising from tungsten machining. The process can release fine tungsten particles and other potentially harmful substances into the air. These airborne particles may pose health risks to workers and nearby communities if not adequately controlled through proper ventilation and filtration systems.

Energy consumption during tungsten machining is considerably high due to the material's hardness and resistance to deformation. This increased energy demand contributes to higher carbon emissions, especially in regions where electricity is primarily generated from fossil fuels. Improving machining efficiency can lead to reduced energy consumption and, consequently, a lower carbon footprint.

Water usage is also a concern in tungsten machining processes. Large volumes of water are often required for cooling and cleaning during machining operations. This high water consumption can strain local water resources, particularly in water-scarce regions. Implementing water recycling systems and more efficient cooling methods can help mitigate this impact.

The disposal of tungsten scrap and machining by-products presents another environmental challenge. While tungsten is recyclable, the process of reclaiming and recycling machining waste can be energy-intensive and may involve the use of chemicals that could harm the environment if not properly managed.

Improving tungsten's machinability can significantly reduce these environmental impacts. Developing new machining techniques that require less energy, produce fewer waste materials, and reduce the need for harmful cutting fluids can lead to more environmentally friendly processes. Additionally, advancements in tool materials and designs that allow for more efficient cutting of tungsten can decrease machining time and energy consumption.

Research into alternative cooling methods, such as cryogenic cooling or minimum quantity lubrication (MQL), shows promise in reducing the environmental impact of tungsten machining. These techniques can significantly decrease the use of traditional cutting fluids, thereby reducing waste generation and potential contamination.

Economic Implications of Advanced Tungsten Machining

The economic implications of advanced tungsten machining are far-reaching and multifaceted, impacting various sectors of the global economy. As tungsten's machinability improves, manufacturing processes become more efficient, leading to reduced production costs and increased productivity. This efficiency gain translates into lower prices for tungsten-based products, potentially expanding their market reach and applications.

In the aerospace and automotive industries, improved tungsten machining techniques enable the production of more complex and precise components. This advancement contributes to the development of lighter, more fuel-efficient vehicles and aircraft, resulting in significant cost savings for operators and reduced environmental impact. The energy sector also stands to benefit, as enhanced tungsten machining facilitates the production of more durable and efficient turbine blades for power generation.

The electronics industry, a major consumer of tungsten products, experiences substantial economic benefits from advanced machining techniques. Improved precision in tungsten processing allows for the creation of smaller, more intricate electronic components, driving innovation in consumer electronics, medical devices, and telecommunications equipment. This progress fuels market growth and stimulates job creation in high-tech manufacturing sectors.

From a global trade perspective, countries with advanced tungsten machining capabilities gain a competitive edge in the international market. This advantage can lead to increased exports, improved trade balances, and economic growth for nations at the forefront of tungsten technology. Additionally, the development of advanced machining techniques often spurs investment in research and development, fostering innovation ecosystems and attracting skilled talent.

The mining and raw materials sectors also experience significant economic impacts. As tungsten machining becomes more efficient, the demand for high-quality tungsten ore may increase, potentially leading to new mining operations and job creation in resource-rich regions. However, this could also intensify competition for limited tungsten resources, potentially affecting global pricing and supply chains.

In conclusion, the economic implications of advanced tungsten machining extend beyond immediate manufacturing benefits. They encompass broader effects on industrial competitiveness, technological innovation, global trade dynamics, and resource utilization. As this technology continues to evolve, it has the potential to reshape economic landscapes and drive sustainable growth across multiple industries.