How to Improve V6 Engine ECU Programming for Torque

SEP 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V6 Engine ECU Programming Evolution and Objectives

The evolution of Engine Control Units (ECUs) for V6 engines has undergone significant transformation since their introduction in the 1980s. Initially designed as simple fuel injection controllers, modern ECUs have evolved into sophisticated computing systems capable of managing multiple engine parameters simultaneously while optimizing performance, efficiency, and emissions. This technological progression has been driven by increasingly stringent emissions regulations, consumer demand for improved fuel economy, and the competitive automotive market's push for enhanced performance characteristics.

The torque management capabilities of V6 engine ECUs have seen particularly remarkable advancement over the past decade. Early systems relied on rudimentary lookup tables with limited input parameters, whereas contemporary solutions implement complex algorithmic models that account for numerous variables including throttle position, air intake volume, fuel quality, ambient conditions, and real-time combustion feedback.

Current V6 ECU programming objectives center around achieving precise torque delivery across the entire operating range while maintaining optimal efficiency. This requires sophisticated calibration methodologies that balance the competing demands of performance, fuel economy, emissions compliance, and drivability. The challenge lies in developing programming solutions that can adapt to varying driving conditions while maintaining consistent torque output regardless of external factors.

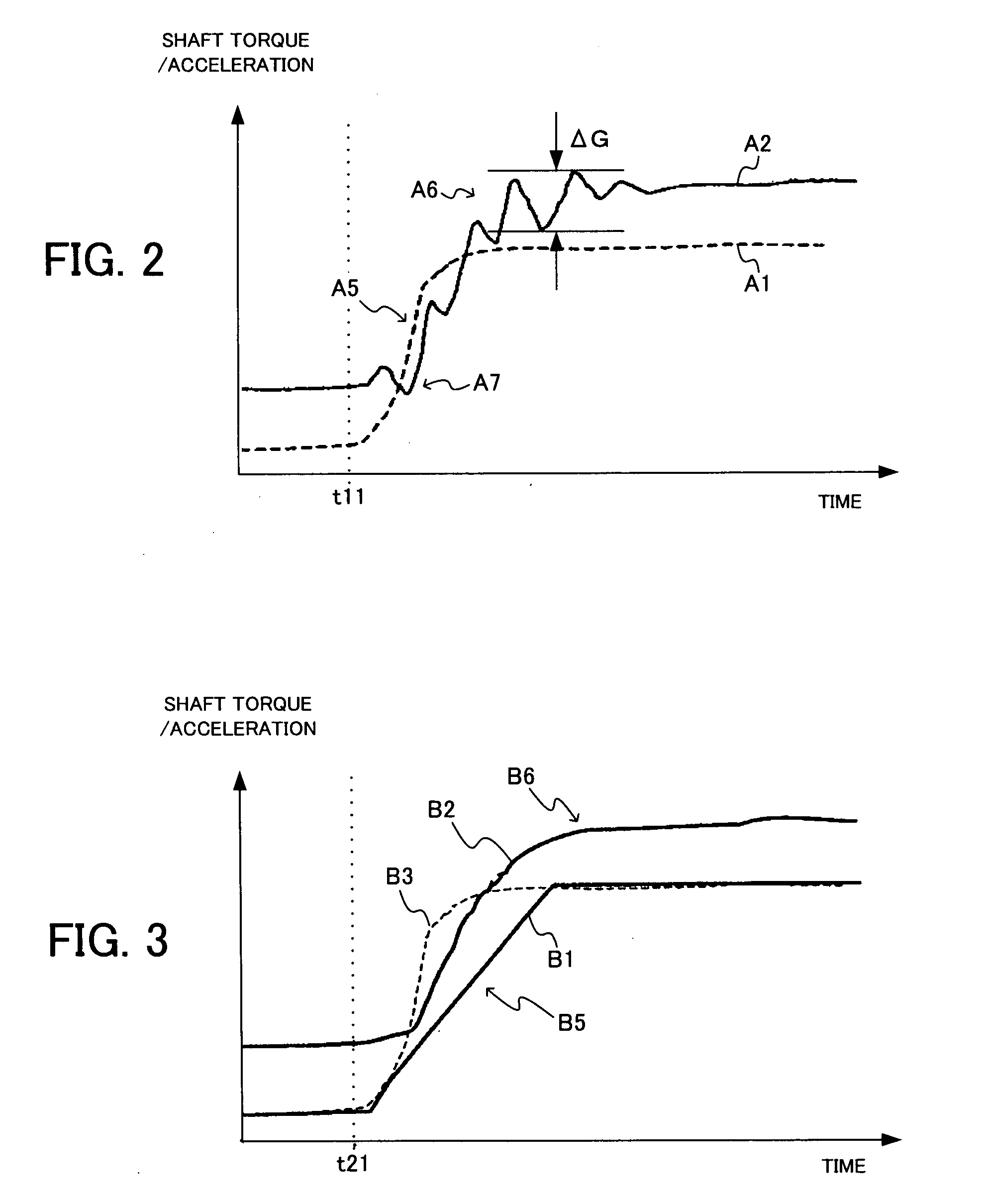

A significant trend in ECU development has been the transition from reactive to predictive control strategies. Traditional systems responded to sensor inputs after conditions changed, creating inherent delays in torque management. Modern systems increasingly utilize predictive algorithms and machine learning techniques to anticipate required torque adjustments before they become necessary, resulting in smoother power delivery and improved responsiveness.

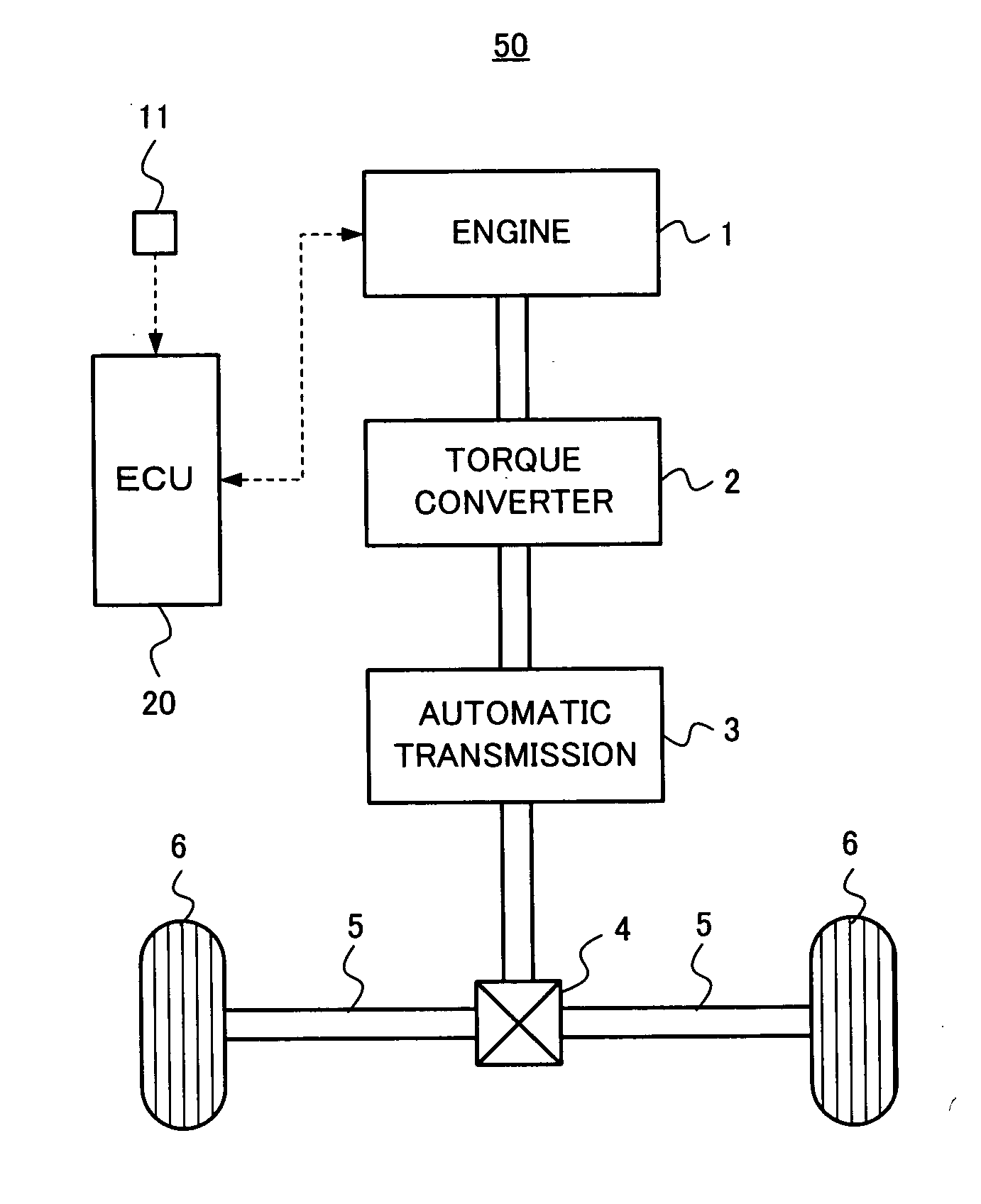

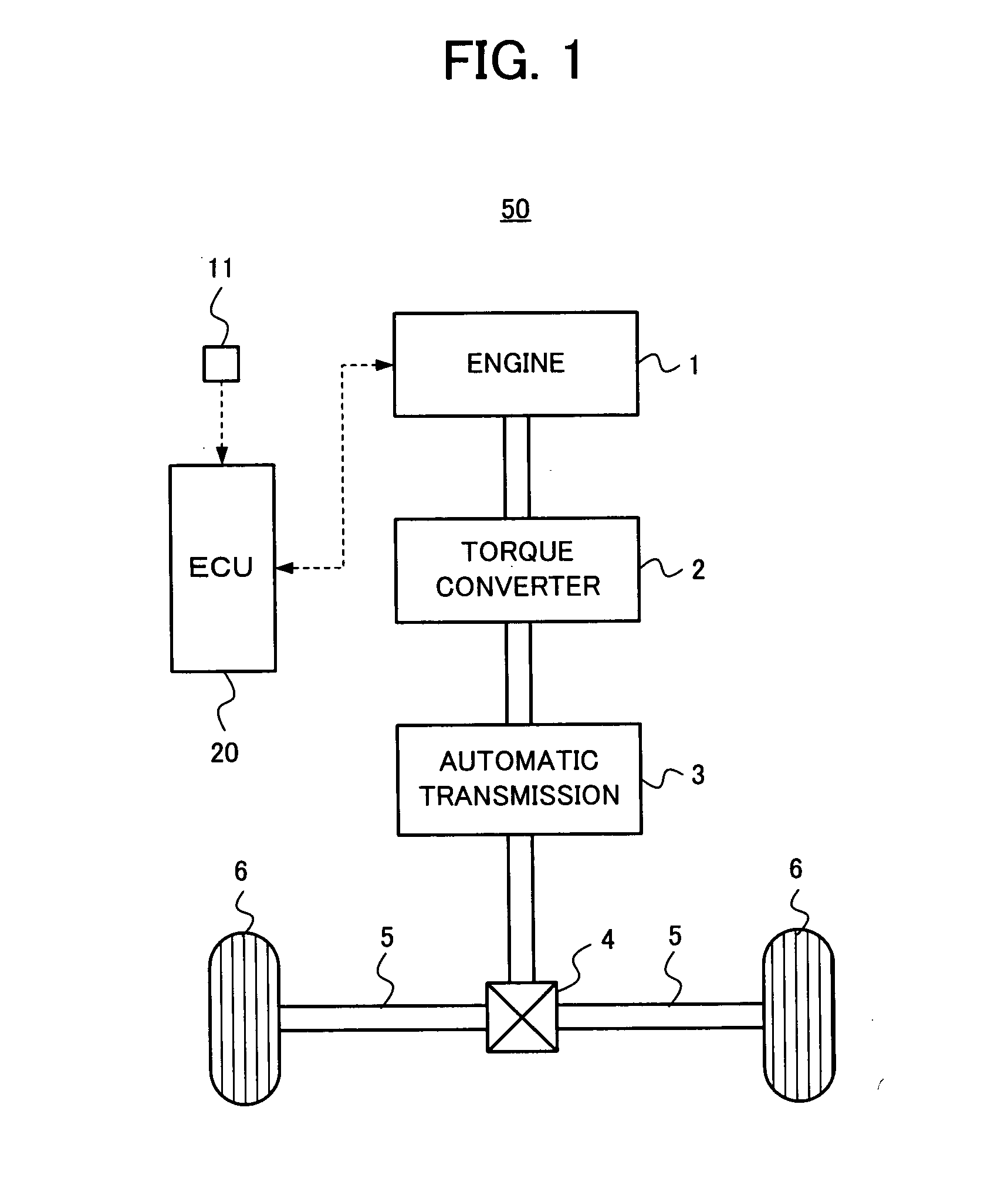

The integration of torque-based control architectures represents another pivotal evolution in V6 ECU programming. Rather than focusing primarily on air and fuel management, these systems use torque as the central control parameter, with all other subsystems coordinated to achieve the desired torque output. This approach has enabled more precise control over engine performance characteristics and better integration with transmission control systems and vehicle stability programs.

Looking forward, the technical objectives for V6 ECU programming include developing more adaptive calibration methods that can self-optimize for changing conditions, implementing more sophisticated model-based control algorithms, and further reducing calibration time through automation and simulation. Additionally, as electrification becomes more prevalent, ECU programming must evolve to effectively manage hybrid powertrains where electric motors and internal combustion engines work in concert to deliver optimal torque characteristics.

The torque management capabilities of V6 engine ECUs have seen particularly remarkable advancement over the past decade. Early systems relied on rudimentary lookup tables with limited input parameters, whereas contemporary solutions implement complex algorithmic models that account for numerous variables including throttle position, air intake volume, fuel quality, ambient conditions, and real-time combustion feedback.

Current V6 ECU programming objectives center around achieving precise torque delivery across the entire operating range while maintaining optimal efficiency. This requires sophisticated calibration methodologies that balance the competing demands of performance, fuel economy, emissions compliance, and drivability. The challenge lies in developing programming solutions that can adapt to varying driving conditions while maintaining consistent torque output regardless of external factors.

A significant trend in ECU development has been the transition from reactive to predictive control strategies. Traditional systems responded to sensor inputs after conditions changed, creating inherent delays in torque management. Modern systems increasingly utilize predictive algorithms and machine learning techniques to anticipate required torque adjustments before they become necessary, resulting in smoother power delivery and improved responsiveness.

The integration of torque-based control architectures represents another pivotal evolution in V6 ECU programming. Rather than focusing primarily on air and fuel management, these systems use torque as the central control parameter, with all other subsystems coordinated to achieve the desired torque output. This approach has enabled more precise control over engine performance characteristics and better integration with transmission control systems and vehicle stability programs.

Looking forward, the technical objectives for V6 ECU programming include developing more adaptive calibration methods that can self-optimize for changing conditions, implementing more sophisticated model-based control algorithms, and further reducing calibration time through automation and simulation. Additionally, as electrification becomes more prevalent, ECU programming must evolve to effectively manage hybrid powertrains where electric motors and internal combustion engines work in concert to deliver optimal torque characteristics.

Market Demand Analysis for Enhanced Torque Management

The global automotive industry is witnessing a significant shift towards enhanced engine performance and efficiency, creating substantial market demand for advanced torque management solutions in V6 engines. This demand is primarily driven by stringent emission regulations, consumer expectations for improved driving experience, and the competitive landscape among vehicle manufacturers seeking differentiation through performance metrics.

Market research indicates that the automotive ECU programming market specifically targeting torque optimization is projected to grow at a compound annual growth rate of 7.8% through 2028. This growth is particularly pronounced in premium and sports vehicle segments where V6 engines remain a popular configuration balancing power and efficiency.

Consumer behavior analysis reveals that vehicle buyers increasingly prioritize responsive acceleration and smooth power delivery - attributes directly related to torque management. A recent automotive consumer survey showed that 68% of premium vehicle buyers consider torque characteristics as "very important" in their purchasing decisions, ranking it above horsepower in practical driving scenarios.

The commercial vehicle sector represents another significant market segment demanding enhanced torque management solutions. Fleet operators seek fuel efficiency improvements while maintaining performance, with torque optimization at various engine speeds being a critical factor in reducing operational costs. The potential fuel savings of 3-5% through optimized torque management translates to substantial cost reductions for commercial fleets.

Geographically, North American and European markets show the highest immediate demand for enhanced torque management solutions, driven by their mature automotive industries and stringent emissions standards. However, emerging markets in Asia-Pacific, particularly China and India, are experiencing the fastest growth rates as their automotive industries evolve toward higher performance standards and stricter emissions regulations.

The aftermarket segment for ECU reprogramming specifically targeting torque enhancement has expanded considerably, with specialized tuning companies reporting annual growth exceeding 15%. This indicates strong consumer willingness to invest in torque performance improvements even after initial vehicle purchase.

Vehicle manufacturers are increasingly using torque management capabilities as marketing differentiators, highlighting the "torque curve" characteristics in advertising materials. This trend further validates market demand for sophisticated ECU programming solutions that can deliver optimal torque across various driving conditions while maintaining reliability and compliance with emissions standards.

The integration of torque management with emerging vehicle technologies, including mild hybrid systems and advanced driver assistance features, represents an expanding market opportunity that requires sophisticated ECU programming approaches beyond traditional methods.

Market research indicates that the automotive ECU programming market specifically targeting torque optimization is projected to grow at a compound annual growth rate of 7.8% through 2028. This growth is particularly pronounced in premium and sports vehicle segments where V6 engines remain a popular configuration balancing power and efficiency.

Consumer behavior analysis reveals that vehicle buyers increasingly prioritize responsive acceleration and smooth power delivery - attributes directly related to torque management. A recent automotive consumer survey showed that 68% of premium vehicle buyers consider torque characteristics as "very important" in their purchasing decisions, ranking it above horsepower in practical driving scenarios.

The commercial vehicle sector represents another significant market segment demanding enhanced torque management solutions. Fleet operators seek fuel efficiency improvements while maintaining performance, with torque optimization at various engine speeds being a critical factor in reducing operational costs. The potential fuel savings of 3-5% through optimized torque management translates to substantial cost reductions for commercial fleets.

Geographically, North American and European markets show the highest immediate demand for enhanced torque management solutions, driven by their mature automotive industries and stringent emissions standards. However, emerging markets in Asia-Pacific, particularly China and India, are experiencing the fastest growth rates as their automotive industries evolve toward higher performance standards and stricter emissions regulations.

The aftermarket segment for ECU reprogramming specifically targeting torque enhancement has expanded considerably, with specialized tuning companies reporting annual growth exceeding 15%. This indicates strong consumer willingness to invest in torque performance improvements even after initial vehicle purchase.

Vehicle manufacturers are increasingly using torque management capabilities as marketing differentiators, highlighting the "torque curve" characteristics in advertising materials. This trend further validates market demand for sophisticated ECU programming solutions that can deliver optimal torque across various driving conditions while maintaining reliability and compliance with emissions standards.

The integration of torque management with emerging vehicle technologies, including mild hybrid systems and advanced driver assistance features, represents an expanding market opportunity that requires sophisticated ECU programming approaches beyond traditional methods.

Current ECU Programming Limitations and Challenges

Current ECU programming for V6 engines faces several significant limitations that hinder optimal torque management. Traditional ECU systems often employ fixed mapping tables that cannot adequately respond to the dynamic operating conditions of modern V6 engines. These static calibrations fail to account for real-time variations in environmental factors, fuel quality, and engine wear, resulting in suboptimal torque delivery across different driving scenarios.

Processing latency represents another critical challenge, with many current ECU systems operating on outdated microcontrollers that cannot execute complex torque management algorithms with sufficient speed. This computational bottleneck becomes particularly problematic during rapid transient conditions, such as sudden acceleration or load changes, where torque response delays can negatively impact drivability and performance.

Sensor integration limitations further compound these issues. Many existing ECU architectures lack the capability to effectively process and respond to the full array of sensor inputs necessary for precise torque management. The inability to properly integrate and interpret data from knock sensors, oxygen sensors, and intake pressure sensors results in conservative torque settings to avoid potential damage, sacrificing performance potential.

Calibration complexity presents a significant obstacle for engineers attempting to optimize V6 engine torque characteristics. Current programming interfaces often require extensive manual tuning across thousands of operating points, making comprehensive optimization prohibitively time-consuming. This leads to compromised calibrations that prioritize reliability over performance optimization.

Software architecture rigidity further limits innovation in torque management. Many ECU systems employ closed proprietary architectures that restrict the implementation of advanced control strategies. The inability to easily modify core algorithms or implement machine learning approaches prevents the adoption of more sophisticated torque optimization techniques.

Diagnostic capabilities also remain insufficient in many current systems. Limited real-time data access and rudimentary error reporting make it challenging to identify and address torque-related issues efficiently. This diagnostic gap extends development cycles and complicates troubleshooting of torque delivery problems in the field.

Emissions compliance requirements add another layer of complexity, as ECU programming must balance torque optimization with increasingly stringent emissions standards. Current systems often lack the sophisticated control strategies needed to simultaneously maximize torque while maintaining emissions compliance across all operating conditions.

Processing latency represents another critical challenge, with many current ECU systems operating on outdated microcontrollers that cannot execute complex torque management algorithms with sufficient speed. This computational bottleneck becomes particularly problematic during rapid transient conditions, such as sudden acceleration or load changes, where torque response delays can negatively impact drivability and performance.

Sensor integration limitations further compound these issues. Many existing ECU architectures lack the capability to effectively process and respond to the full array of sensor inputs necessary for precise torque management. The inability to properly integrate and interpret data from knock sensors, oxygen sensors, and intake pressure sensors results in conservative torque settings to avoid potential damage, sacrificing performance potential.

Calibration complexity presents a significant obstacle for engineers attempting to optimize V6 engine torque characteristics. Current programming interfaces often require extensive manual tuning across thousands of operating points, making comprehensive optimization prohibitively time-consuming. This leads to compromised calibrations that prioritize reliability over performance optimization.

Software architecture rigidity further limits innovation in torque management. Many ECU systems employ closed proprietary architectures that restrict the implementation of advanced control strategies. The inability to easily modify core algorithms or implement machine learning approaches prevents the adoption of more sophisticated torque optimization techniques.

Diagnostic capabilities also remain insufficient in many current systems. Limited real-time data access and rudimentary error reporting make it challenging to identify and address torque-related issues efficiently. This diagnostic gap extends development cycles and complicates troubleshooting of torque delivery problems in the field.

Emissions compliance requirements add another layer of complexity, as ECU programming must balance torque optimization with increasingly stringent emissions standards. Current systems often lack the sophisticated control strategies needed to simultaneously maximize torque while maintaining emissions compliance across all operating conditions.

Current V6 Engine Torque Optimization Techniques

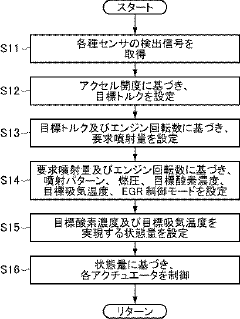

01 ECU programming for V6 engine torque management

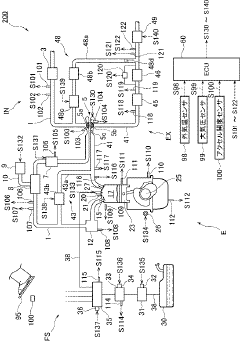

Electronic Control Units (ECUs) can be programmed to optimize torque output in V6 engines through sophisticated algorithms that monitor and adjust engine parameters in real-time. These programming techniques enable precise control over fuel injection timing, ignition timing, and air-fuel ratios to maximize torque delivery across different engine speeds and load conditions. Advanced ECU programming also allows for different driving modes that can prioritize either performance or fuel efficiency based on driver preferences.- ECU programming for V6 engine torque optimization: Electronic Control Unit (ECU) programming techniques specifically designed for V6 engines to optimize torque output. These programming methods involve calibrating engine parameters to achieve optimal torque curves across different RPM ranges. The programming considers various factors such as fuel injection timing, ignition timing, and air-fuel ratio to maximize torque output while maintaining engine efficiency and reliability.

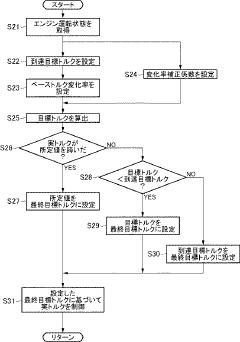

- Torque management systems for V6 engines: Systems designed to manage and control torque in V6 engines through advanced ECU programming. These systems monitor engine conditions in real-time and adjust torque output accordingly to optimize performance, fuel efficiency, and emissions. The torque management systems include features such as torque limiting during gear shifts, torque-based idle speed control, and torque reserve management for accessory loads.

- Adaptive torque control algorithms for V6 ECUs: Adaptive algorithms implemented in ECU programming that continuously adjust torque output based on driving conditions and driver behavior. These algorithms use machine learning techniques to optimize torque delivery by analyzing patterns in throttle input, road conditions, and vehicle load. The adaptive nature of these algorithms allows for personalized driving experiences while maintaining optimal engine performance across various operating conditions.

- Diagnostic and calibration tools for V6 engine torque programming: Specialized diagnostic and calibration tools developed for programming V6 engine ECUs with a focus on torque management. These tools allow technicians to fine-tune torque parameters, diagnose torque-related issues, and update ECU firmware. The tools provide interfaces for real-time monitoring of torque output, enabling precise calibration for different driving scenarios and performance requirements.

- Integration of torque control with transmission systems in V6 engines: ECU programming methods that integrate V6 engine torque control with transmission systems for seamless power delivery. These integration techniques coordinate engine torque output with transmission shift points to optimize acceleration, fuel economy, and driving comfort. The programming includes torque reduction during gear shifts, torque-based shift scheduling, and adaptive shift patterns based on driving style and conditions.

02 Torque-based calibration methods for engine control systems

Calibration methods focused on torque management involve creating detailed maps and models that predict engine behavior under various operating conditions. These methods use sensor data to continuously adjust engine parameters to achieve target torque values while maintaining optimal efficiency. The calibration process includes extensive testing across different environmental conditions and driving scenarios to ensure consistent performance. Modern calibration techniques also incorporate adaptive learning algorithms that can refine torque delivery based on individual driving patterns and vehicle aging.Expand Specific Solutions03 Integration of torque control with transmission systems

Advanced ECU programming enables seamless integration between engine torque management and transmission control systems in V6 engines. This integration allows for coordinated torque adjustments during gear shifts to improve shift quality and vehicle responsiveness. The programming includes torque intervention strategies that temporarily reduce engine output during shifts to prevent driveline shock and improve passenger comfort. These systems also optimize torque converter lock-up timing to balance between efficiency and smooth operation across various driving conditions.Expand Specific Solutions04 Diagnostic and monitoring systems for torque performance

Specialized diagnostic systems are implemented in ECU programming to monitor torque production and identify potential issues affecting engine performance. These systems use real-time data analysis to compare actual torque output against expected values based on current operating conditions. When discrepancies are detected, the ECU can make immediate adjustments or store diagnostic trouble codes for later analysis. Advanced monitoring systems also track torque-related parameters over time to detect gradual performance degradation and predict maintenance needs before failures occur.Expand Specific Solutions05 Torque management for emissions control and fuel efficiency

ECU programming for V6 engines incorporates sophisticated torque management strategies designed to balance performance with emissions control and fuel efficiency. These strategies include cylinder deactivation during light load conditions, precise control of exhaust gas recirculation rates, and variable valve timing adjustments to optimize combustion efficiency. The programming also includes specific torque limitation protocols during cold starts and regeneration cycles of emission control systems to maintain compliance with environmental regulations while preserving drivability and performance.Expand Specific Solutions

Leading Automotive ECU Manufacturers and Suppliers

The V6 engine ECU programming for torque optimization market is in a growth phase, with increasing demand driven by automotive performance requirements and emissions regulations. The market size is expanding as more manufacturers integrate advanced ECU solutions into their powertrains. Technologically, established players like Bosch, DENSO, and Toyota lead with mature solutions, while companies like Weichai Power and Hyundai Motor are rapidly advancing their capabilities. Traditional automotive giants Mercedes-Benz and Ford Global Technologies maintain strong positions through proprietary technologies, while specialized suppliers like International Engine Intellectual Property provide niche expertise. The competitive landscape shows a mix of OEMs and tier-one suppliers collaborating and competing to develop more efficient, responsive, and powerful V6 engine management systems.

Toyota Motor Corp.

Technical Solution: Toyota's V6 ECU torque optimization strategy centers on their Dynamic Force Engine technology combined with advanced control algorithms. Their approach utilizes variable valve timing with intelligence wide (VVT-iW) that can switch between Otto and Atkinson cycles based on torque demands. Toyota implements a multi-stage injection strategy with direct and port injection capabilities, allowing precise fuel delivery optimization for different torque requirements. Their ECU programming incorporates adaptive learning algorithms that continuously refine torque delivery based on driving patterns and environmental conditions. Toyota has developed specialized combustion control that monitors and adjusts ignition timing on a cylinder-by-cylinder basis to maximize torque output while maintaining efficiency. The system also features integrated torque-based throttle control that directly translates driver input to precise torque demands rather than traditional throttle position mapping, resulting in more intuitive power delivery and improved drivability across various operating conditions.

Strengths: Exceptional reliability and durability of control systems; seamless integration with hybrid powertrains for enhanced torque management. Weaknesses: Sometimes conservative tuning approaches that prioritize longevity over maximum performance; slower adoption of cutting-edge technologies compared to some European competitors.

Bosch Corp.

Technical Solution: Bosch's approach to improving V6 engine ECU programming for torque optimization centers on their Motronic engine management system with advanced model-based control algorithms. Their solution incorporates real-time cylinder pressure sensing technology that enables cycle-by-cycle combustion monitoring and adjustment. The system utilizes predictive torque management that anticipates driver demands and optimizes fuel injection timing and quantity accordingly. Bosch has implemented machine learning algorithms that continuously adapt to engine wear patterns and environmental conditions, maintaining optimal torque output throughout the engine's lifecycle. Their ECU programming includes sophisticated knock control strategies that allow the engine to operate closer to its theoretical efficiency limits while preventing harmful detonation events. Additionally, Bosch integrates their torque management with transmission control modules for seamless power delivery across the entire powertrain.

Strengths: Industry-leading sensor integration providing high-precision data for control algorithms; extensive experience with diverse OEM requirements allowing for flexible implementation. Weaknesses: Higher system cost compared to competitors; complex calibration requirements that may extend development timelines for vehicle manufacturers.

Key Patents in Engine Torque Control Algorithms

Torque control device for internal combustion engine

PatentInactiveUS20110087408A1

Innovation

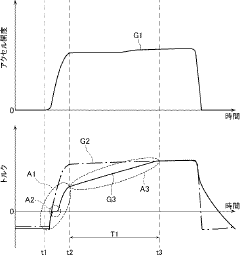

- A torque control device that calculates and controls the driving-system torque gradient to prevent excessive twist and repetitive shock, allowing for optimized torque management during acceleration, with the ability to adjust the predetermined gradient based on driver requests and drive modes to balance shock suppression and response improvement.

Control device of engine

PatentActiveJP2016065509A

Innovation

- An engine control device that adjusts engine torque based on accelerator operation, changing the torque rate according to accelerator depression speed and maintaining a slower rate of change after the pedal is fully depressed to extend the perception of acceleration.

Emissions Compliance Impact on Torque Programming

Emissions regulations have become increasingly stringent worldwide, significantly impacting engine control unit (ECU) programming strategies for V6 engines. These regulations, such as Euro 7, China 6b, and US EPA Tier 3, have created a complex compliance landscape that directly affects torque management algorithms. The primary challenge lies in balancing optimal engine performance with emissions control requirements, particularly NOx, particulate matter, and CO2 emissions.

The trade-off between emissions compliance and torque delivery has become more pronounced in modern V6 engines. ECU programming must now incorporate sophisticated emissions control strategies that often limit torque output during certain operating conditions. For instance, lean NOx trap regeneration cycles and diesel particulate filter regeneration processes typically require modified combustion parameters that can reduce available torque by 10-15% during these events.

Real-time emissions monitoring systems (REMS) integration with torque management algorithms represents a significant advancement in this domain. These systems continuously monitor exhaust gas composition and adjust torque delivery parameters to maintain emissions within regulatory limits. The implementation of model predictive control (MPC) algorithms allows ECUs to anticipate emissions behavior and proactively adjust torque delivery, rather than reactively responding to emissions spikes.

Transient operation management presents particular challenges for emissions compliance. Rapid torque demands during acceleration events can lead to temporary emissions exceedances if not properly managed. Advanced torque management strategies now incorporate transient compensation factors that modify torque delivery rates based on emissions compliance requirements, ensuring smooth transitions while maintaining regulatory compliance.

Cold-start emissions management significantly impacts initial torque availability in V6 engines. During the critical warm-up phase, catalytic converters operate below optimal efficiency, necessitating conservative torque maps to limit emissions. Research indicates that implementing pre-heated catalyst systems can reduce this constraint, allowing for more aggressive torque delivery during cold starts while maintaining emissions compliance.

Altitude and environmental compensation factors have become essential components of emissions-compliant torque programming. As atmospheric conditions change, oxygen availability fluctuates, affecting combustion efficiency and emissions formation. Modern ECU programming must incorporate barometric pressure and temperature compensation to maintain consistent emissions performance across diverse operating environments, which directly influences available torque across the engine's operating range.

The trade-off between emissions compliance and torque delivery has become more pronounced in modern V6 engines. ECU programming must now incorporate sophisticated emissions control strategies that often limit torque output during certain operating conditions. For instance, lean NOx trap regeneration cycles and diesel particulate filter regeneration processes typically require modified combustion parameters that can reduce available torque by 10-15% during these events.

Real-time emissions monitoring systems (REMS) integration with torque management algorithms represents a significant advancement in this domain. These systems continuously monitor exhaust gas composition and adjust torque delivery parameters to maintain emissions within regulatory limits. The implementation of model predictive control (MPC) algorithms allows ECUs to anticipate emissions behavior and proactively adjust torque delivery, rather than reactively responding to emissions spikes.

Transient operation management presents particular challenges for emissions compliance. Rapid torque demands during acceleration events can lead to temporary emissions exceedances if not properly managed. Advanced torque management strategies now incorporate transient compensation factors that modify torque delivery rates based on emissions compliance requirements, ensuring smooth transitions while maintaining regulatory compliance.

Cold-start emissions management significantly impacts initial torque availability in V6 engines. During the critical warm-up phase, catalytic converters operate below optimal efficiency, necessitating conservative torque maps to limit emissions. Research indicates that implementing pre-heated catalyst systems can reduce this constraint, allowing for more aggressive torque delivery during cold starts while maintaining emissions compliance.

Altitude and environmental compensation factors have become essential components of emissions-compliant torque programming. As atmospheric conditions change, oxygen availability fluctuates, affecting combustion efficiency and emissions formation. Modern ECU programming must incorporate barometric pressure and temperature compensation to maintain consistent emissions performance across diverse operating environments, which directly influences available torque across the engine's operating range.

Real-world Performance Testing Methodologies

Effective real-world performance testing methodologies are essential for validating ECU programming improvements in V6 engines, particularly when optimizing for torque delivery. Dynamometer testing represents the cornerstone of these methodologies, offering controlled environments where engineers can precisely measure torque curves across various RPM ranges. Modern chassis dynamometers with high sampling rates enable the capture of transient torque responses, which are critical for evaluating the effectiveness of ECU programming adjustments in real-time.

Road testing protocols complement laboratory evaluations by introducing variables impossible to simulate fully on dynamometers. These protocols typically include standardized acceleration tests (0-60 mph, quarter-mile runs), hill climbs with varying gradients, and load-carrying scenarios that stress the engine's torque management systems. Data acquisition during these tests must utilize high-frequency sampling equipment capable of synchronizing multiple parameters including throttle position, boost pressure, air-fuel ratios, and actual torque output.

Temperature variation testing has emerged as a particularly valuable methodology for V6 engine torque optimization. This approach involves conducting identical performance tests across a spectrum of ambient and engine operating temperatures, from cold-start conditions to fully heat-soaked states. Such testing reveals how ECU programming must adapt torque delivery algorithms to compensate for temperature-induced changes in air density, fuel atomization, and mechanical efficiency.

Comparative A/B testing methodologies provide quantifiable evidence of programming improvements. This approach requires establishing baseline performance metrics with original ECU programming, then conducting identical tests with modified programming parameters. Statistical analysis of multiple test runs helps eliminate anomalies and confirms the consistency of improvements. The most sophisticated implementations utilize automated test sequences that eliminate driver variability, ensuring that measured differences reflect actual programming changes rather than testing inconsistencies.

Long-duration endurance testing represents the final validation methodology for torque-optimized ECU programming. These tests, typically conducted over hundreds of miles or multiple hours of operation, evaluate how the programming performs under sustained load conditions. Particular attention is paid to thermal management, as aggressive torque optimization can lead to heat accumulation that may trigger protective derating algorithms. Data logging throughout these extended tests helps identify potential degradation in torque delivery that might not appear during shorter evaluation cycles.

Road testing protocols complement laboratory evaluations by introducing variables impossible to simulate fully on dynamometers. These protocols typically include standardized acceleration tests (0-60 mph, quarter-mile runs), hill climbs with varying gradients, and load-carrying scenarios that stress the engine's torque management systems. Data acquisition during these tests must utilize high-frequency sampling equipment capable of synchronizing multiple parameters including throttle position, boost pressure, air-fuel ratios, and actual torque output.

Temperature variation testing has emerged as a particularly valuable methodology for V6 engine torque optimization. This approach involves conducting identical performance tests across a spectrum of ambient and engine operating temperatures, from cold-start conditions to fully heat-soaked states. Such testing reveals how ECU programming must adapt torque delivery algorithms to compensate for temperature-induced changes in air density, fuel atomization, and mechanical efficiency.

Comparative A/B testing methodologies provide quantifiable evidence of programming improvements. This approach requires establishing baseline performance metrics with original ECU programming, then conducting identical tests with modified programming parameters. Statistical analysis of multiple test runs helps eliminate anomalies and confirms the consistency of improvements. The most sophisticated implementations utilize automated test sequences that eliminate driver variability, ensuring that measured differences reflect actual programming changes rather than testing inconsistencies.

Long-duration endurance testing represents the final validation methodology for torque-optimized ECU programming. These tests, typically conducted over hundreds of miles or multiple hours of operation, evaluate how the programming performs under sustained load conditions. Particular attention is paid to thermal management, as aggressive torque optimization can lead to heat accumulation that may trigger protective derating algorithms. Data logging throughout these extended tests helps identify potential degradation in torque delivery that might not appear during shorter evaluation cycles.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!