How to Improve V6 Engine Fuel Injector Longevity

SEP 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V6 Fuel Injector Evolution and Longevity Goals

Fuel injection systems have undergone significant evolution since their introduction in automotive applications. The journey from mechanical to electronic fuel injection marked a pivotal shift in engine technology, with V6 engines benefiting tremendously from these advancements. Early V6 engines utilized basic mechanical fuel injection systems that offered limited precision and durability, often requiring replacement after relatively short service intervals of 50,000-70,000 miles.

The transition to electronic fuel injection (EFI) in the 1980s represented a quantum leap in both performance and longevity. These systems incorporated electronic control units that could precisely regulate fuel delivery based on multiple sensor inputs, dramatically improving combustion efficiency and reducing injector wear. By the 1990s, multi-port injection systems became standard in V6 engines, with each cylinder receiving its dedicated injector, further enhancing performance and reliability.

The early 2000s witnessed the emergence of direct injection technology in V6 engines, where fuel is sprayed directly into the combustion chamber rather than the intake port. This innovation significantly improved fuel atomization and combustion efficiency but introduced new challenges for injector longevity due to exposure to higher temperatures and pressures. Modern direct injection systems operate at pressures exceeding 2,000 bar, creating substantial mechanical stress on injector components.

Current industry benchmarks for V6 fuel injector longevity typically range from 100,000 to 150,000 miles for port injection systems and 80,000 to 120,000 miles for direct injection systems. However, premium manufacturers have established more ambitious targets, aiming for 200,000+ miles without significant performance degradation. These targets reflect growing consumer expectations for reduced maintenance costs and environmental considerations regarding resource conservation.

The technological evolution continues with the development of piezoelectric injectors, which offer faster response times and more precise fuel metering compared to traditional solenoid-actuated injectors. These advanced systems can perform multiple injection events per combustion cycle, further optimizing the combustion process and potentially extending service life through more controlled operation.

Looking forward, the industry is targeting several specific longevity goals for V6 fuel injectors: increasing service life to match or exceed overall engine lifespan (typically 250,000+ miles), maintaining consistent spray patterns throughout the operational lifetime, reducing deposit formation that compromises performance, and ensuring compatibility with alternative fuels including higher ethanol blends and synthetic fuels.

Achieving these ambitious longevity targets requires addressing multiple technical challenges, including material degradation from fuel contaminants, thermal stress management, and mitigating the effects of carbon buildup. The trajectory of fuel injector technology suggests a continued focus on materials science innovations, advanced coating technologies, and more sophisticated electronic control strategies to extend service intervals while maintaining optimal engine performance.

The transition to electronic fuel injection (EFI) in the 1980s represented a quantum leap in both performance and longevity. These systems incorporated electronic control units that could precisely regulate fuel delivery based on multiple sensor inputs, dramatically improving combustion efficiency and reducing injector wear. By the 1990s, multi-port injection systems became standard in V6 engines, with each cylinder receiving its dedicated injector, further enhancing performance and reliability.

The early 2000s witnessed the emergence of direct injection technology in V6 engines, where fuel is sprayed directly into the combustion chamber rather than the intake port. This innovation significantly improved fuel atomization and combustion efficiency but introduced new challenges for injector longevity due to exposure to higher temperatures and pressures. Modern direct injection systems operate at pressures exceeding 2,000 bar, creating substantial mechanical stress on injector components.

Current industry benchmarks for V6 fuel injector longevity typically range from 100,000 to 150,000 miles for port injection systems and 80,000 to 120,000 miles for direct injection systems. However, premium manufacturers have established more ambitious targets, aiming for 200,000+ miles without significant performance degradation. These targets reflect growing consumer expectations for reduced maintenance costs and environmental considerations regarding resource conservation.

The technological evolution continues with the development of piezoelectric injectors, which offer faster response times and more precise fuel metering compared to traditional solenoid-actuated injectors. These advanced systems can perform multiple injection events per combustion cycle, further optimizing the combustion process and potentially extending service life through more controlled operation.

Looking forward, the industry is targeting several specific longevity goals for V6 fuel injectors: increasing service life to match or exceed overall engine lifespan (typically 250,000+ miles), maintaining consistent spray patterns throughout the operational lifetime, reducing deposit formation that compromises performance, and ensuring compatibility with alternative fuels including higher ethanol blends and synthetic fuels.

Achieving these ambitious longevity targets requires addressing multiple technical challenges, including material degradation from fuel contaminants, thermal stress management, and mitigating the effects of carbon buildup. The trajectory of fuel injector technology suggests a continued focus on materials science innovations, advanced coating technologies, and more sophisticated electronic control strategies to extend service intervals while maintaining optimal engine performance.

Market Demand for Durable Fuel Injection Systems

The global market for durable fuel injection systems has witnessed substantial growth over the past decade, primarily driven by stringent emission regulations and increasing consumer demand for fuel-efficient vehicles. The V6 engine segment, particularly in mid-size to luxury vehicles, represents a significant portion of this market, with fuel injector longevity becoming a critical factor in consumer satisfaction and manufacturer reputation.

Industry reports indicate that the automotive fuel injection system market is projected to reach $92 billion by 2027, growing at a CAGR of approximately 6.3% from 2022. Within this market, the demand for durable fuel injectors specifically for V6 engines has shown stronger growth rates, reflecting the premium nature of these powertrains and higher consumer expectations for reliability.

Vehicle manufacturers are increasingly facing pressure from consumers regarding the total cost of ownership, with fuel injector replacement representing a significant maintenance expense. Market research shows that consumers are willing to pay a premium of 15-20% for vehicles with demonstrably longer-lasting fuel injection systems, particularly in regions with higher fuel prices such as Europe and parts of Asia.

Fleet operators and commercial vehicle owners constitute another significant market segment demanding improved fuel injector longevity. For these customers, vehicle downtime directly impacts operational costs, making the reliability of fuel injection systems a key purchasing criterion. Data from fleet management companies indicates that fuel system failures account for approximately 17% of unscheduled maintenance events in V6-equipped commercial vehicles.

The aftermarket for replacement fuel injectors represents another substantial market opportunity. Currently valued at approximately $4.8 billion globally, this segment is experiencing increased demand for higher-quality, longer-lasting replacement parts. Consumers are increasingly educated about the impact of fuel injector quality on engine performance and are willing to invest in premium solutions.

Regional analysis reveals varying market demands. North American consumers prioritize long-term reliability and warranty coverage, while European markets show stronger interest in fuel efficiency benefits of advanced injection systems. Emerging markets in Asia and Latin America demonstrate growing demand for cost-effective solutions that balance initial price with longevity.

Market forecasts suggest that as electric vehicles gain market share, the remaining internal combustion engine market will increasingly shift toward premium segments where V6 engines are common. This trend is expected to further intensify the demand for high-quality, durable fuel injection systems as manufacturers compete for a shrinking but more discerning customer base in the traditional powertrain market.

Industry reports indicate that the automotive fuel injection system market is projected to reach $92 billion by 2027, growing at a CAGR of approximately 6.3% from 2022. Within this market, the demand for durable fuel injectors specifically for V6 engines has shown stronger growth rates, reflecting the premium nature of these powertrains and higher consumer expectations for reliability.

Vehicle manufacturers are increasingly facing pressure from consumers regarding the total cost of ownership, with fuel injector replacement representing a significant maintenance expense. Market research shows that consumers are willing to pay a premium of 15-20% for vehicles with demonstrably longer-lasting fuel injection systems, particularly in regions with higher fuel prices such as Europe and parts of Asia.

Fleet operators and commercial vehicle owners constitute another significant market segment demanding improved fuel injector longevity. For these customers, vehicle downtime directly impacts operational costs, making the reliability of fuel injection systems a key purchasing criterion. Data from fleet management companies indicates that fuel system failures account for approximately 17% of unscheduled maintenance events in V6-equipped commercial vehicles.

The aftermarket for replacement fuel injectors represents another substantial market opportunity. Currently valued at approximately $4.8 billion globally, this segment is experiencing increased demand for higher-quality, longer-lasting replacement parts. Consumers are increasingly educated about the impact of fuel injector quality on engine performance and are willing to invest in premium solutions.

Regional analysis reveals varying market demands. North American consumers prioritize long-term reliability and warranty coverage, while European markets show stronger interest in fuel efficiency benefits of advanced injection systems. Emerging markets in Asia and Latin America demonstrate growing demand for cost-effective solutions that balance initial price with longevity.

Market forecasts suggest that as electric vehicles gain market share, the remaining internal combustion engine market will increasingly shift toward premium segments where V6 engines are common. This trend is expected to further intensify the demand for high-quality, durable fuel injection systems as manufacturers compete for a shrinking but more discerning customer base in the traditional powertrain market.

Current Challenges in V6 Injector Technology

V6 engine fuel injector systems face significant challenges that impact their longevity and performance. The primary issue stems from carbon deposit formation, which occurs when fuel residue accumulates on injector tips during incomplete combustion cycles. These deposits gradually restrict fuel flow, creating irregular spray patterns that compromise engine efficiency and increase emissions. Modern high-pressure direct injection systems, while offering improved fuel atomization, are particularly susceptible to this issue due to their precise engineering tolerances.

Thermal stress represents another critical challenge, as injectors operate in extreme temperature environments, cycling between combustion heat and cooling fuel flow. This thermal cycling causes material fatigue and can lead to premature component failure, particularly affecting the solenoid valves and internal seals. The problem is exacerbated in V6 engines where cylinder arrangement creates uneven heat distribution across the injector array.

Fuel quality variations introduce significant complications for injector longevity. Modern fuels containing ethanol and various additives can accelerate corrosion of internal injector components and contribute to deposit formation. Regional fuel standard differences further complicate this issue, as injectors designed for specific markets may encounter unexpected degradation when vehicles operate in areas with different fuel compositions.

Electrical component reliability presents ongoing challenges, with solenoid failures and wiring harness degradation accounting for approximately 15% of injector failures. The high-frequency operation of modern injectors—often exceeding 100 million cycles during a vehicle's lifetime—places extreme demands on electrical components, while exposure to engine bay heat and vibration accelerates insulation breakdown and connector corrosion.

Manufacturing precision limitations continue to constrain injector development. Current production technologies struggle to consistently achieve the sub-micron tolerances required for optimal injector performance across high production volumes. Even minor variations in nozzle geometry can significantly impact spray patterns and fuel atomization quality, leading to performance inconsistencies between individual injectors.

Diagnostic limitations compound these challenges, as current onboard diagnostic systems can typically only detect complete injector failure rather than gradual performance degradation. This diagnostic gap means many vehicles operate with sub-optimal injector performance for extended periods before problems become apparent, accelerating wear on other engine components and reducing overall efficiency.

Thermal stress represents another critical challenge, as injectors operate in extreme temperature environments, cycling between combustion heat and cooling fuel flow. This thermal cycling causes material fatigue and can lead to premature component failure, particularly affecting the solenoid valves and internal seals. The problem is exacerbated in V6 engines where cylinder arrangement creates uneven heat distribution across the injector array.

Fuel quality variations introduce significant complications for injector longevity. Modern fuels containing ethanol and various additives can accelerate corrosion of internal injector components and contribute to deposit formation. Regional fuel standard differences further complicate this issue, as injectors designed for specific markets may encounter unexpected degradation when vehicles operate in areas with different fuel compositions.

Electrical component reliability presents ongoing challenges, with solenoid failures and wiring harness degradation accounting for approximately 15% of injector failures. The high-frequency operation of modern injectors—often exceeding 100 million cycles during a vehicle's lifetime—places extreme demands on electrical components, while exposure to engine bay heat and vibration accelerates insulation breakdown and connector corrosion.

Manufacturing precision limitations continue to constrain injector development. Current production technologies struggle to consistently achieve the sub-micron tolerances required for optimal injector performance across high production volumes. Even minor variations in nozzle geometry can significantly impact spray patterns and fuel atomization quality, leading to performance inconsistencies between individual injectors.

Diagnostic limitations compound these challenges, as current onboard diagnostic systems can typically only detect complete injector failure rather than gradual performance degradation. This diagnostic gap means many vehicles operate with sub-optimal injector performance for extended periods before problems become apparent, accelerating wear on other engine components and reducing overall efficiency.

Current Solutions for Extending Injector Lifespan

01 Material selection for fuel injector components

The choice of materials for fuel injector components significantly impacts their longevity in V6 engines. Advanced materials such as ceramic coatings, stainless steel alloys, and specialized polymers can resist corrosion, wear, and high-temperature degradation. These materials help maintain precise fuel delivery over extended periods and reduce the formation of deposits that can impair injector performance. Proper material selection can extend the service life of fuel injectors in demanding V6 engine environments.- Material selection for fuel injector components: The choice of materials for fuel injector components significantly impacts their longevity in V6 engines. Advanced materials such as ceramic coatings, stainless steel alloys, and specialized polymers can resist wear, corrosion, and high-temperature degradation. These materials help maintain proper spray patterns and flow rates over extended periods, reducing the need for replacement and ensuring consistent engine performance.

- Fuel injector cleaning and maintenance systems: Integrated cleaning and maintenance systems can significantly extend fuel injector life in V6 engines. These systems include self-cleaning mechanisms, filtration improvements, and detergent additives that prevent carbon buildup and deposit formation. Regular cleaning cycles and maintenance protocols help maintain optimal spray patterns and prevent clogging, ensuring consistent fuel delivery and combustion efficiency throughout the injector's service life.

- Electronic control and monitoring systems: Advanced electronic control systems can optimize fuel injector operation and extend longevity in V6 engines. These systems include precise timing controls, adaptive fuel mapping, and real-time monitoring of injector performance parameters. By adjusting injection timing and duration based on operating conditions, these systems reduce stress on injector components and provide early detection of potential failures, allowing for preventive maintenance before catastrophic failure occurs.

- Thermal management for fuel injectors: Effective thermal management systems can significantly extend fuel injector life in V6 engines. These include cooling channels, heat shields, and thermal insulators that protect injectors from extreme temperature fluctuations. By maintaining optimal operating temperatures, these systems prevent thermal stress, reduce coking of fuel deposits, and minimize thermal expansion issues that can lead to premature wear or failure of injector components.

- Pressure regulation and pulsation dampening: Advanced pressure regulation and pulsation dampening systems help extend fuel injector longevity in V6 engines. These systems include pressure regulators, accumulators, and dampeners that maintain consistent fuel pressure and minimize pressure spikes. By reducing mechanical stress from pressure fluctuations, these systems prevent premature wear of injector components, seal failures, and inconsistent spray patterns, thereby extending service life and maintaining optimal engine performance.

02 Fuel quality and filtration systems

Fuel quality and effective filtration systems play crucial roles in extending fuel injector longevity in V6 engines. Advanced filtration technologies can remove contaminants and particulates that would otherwise cause injector clogging or premature wear. Systems that maintain consistent fuel pressure and quality help prevent deposit formation on injector nozzles. Implementing multi-stage filtration and fuel conditioning can significantly extend the operational life of fuel injectors by ensuring only clean fuel reaches the injection system.Expand Specific Solutions03 Electronic control and diagnostic systems

Sophisticated electronic control and diagnostic systems can optimize fuel injector performance and extend longevity in V6 engines. These systems continuously monitor injector operation, making real-time adjustments to fuel delivery parameters based on engine conditions. Advanced diagnostics can detect early signs of injector degradation, allowing for preventive maintenance before catastrophic failure occurs. Adaptive learning algorithms can compensate for gradual changes in injector performance, maintaining optimal engine operation while extending component life.Expand Specific Solutions04 Thermal management techniques

Effective thermal management is essential for maximizing fuel injector longevity in V6 engines. Innovations in cooling systems and heat dissipation techniques help maintain injectors within optimal temperature ranges during operation. Thermal barriers and strategic component placement can protect injectors from excessive heat exposure. Advanced cooling channels and heat-resistant designs prevent thermal stress and degradation of injector components, particularly in high-performance V6 applications where operating temperatures are elevated.Expand Specific Solutions05 Pulse modulation and injection timing strategies

Sophisticated pulse modulation and injection timing strategies can significantly extend fuel injector life in V6 engines. Precise control of injector opening and closing events reduces mechanical stress and wear on injector components. Multiple injection events per cycle, rather than single large injections, can decrease thermal loading and coking formation on injector tips. Adaptive injection timing based on engine load and temperature conditions helps maintain optimal combustion while minimizing the stresses that contribute to injector degradation over time.Expand Specific Solutions

Leading Manufacturers and Competitive Landscape

The V6 engine fuel injector longevity market is currently in a growth phase, with increasing demand for durable solutions driven by stringent emission regulations and consumer expectations for engine reliability. The global market size for advanced fuel injection systems is expanding at approximately 6-7% annually, reaching nearly $80 billion. Technologically, the field shows varying maturity levels, with established players like Robert Bosch GmbH, Continental Automotive, and DENSO Corp leading innovation through advanced materials and electronic control systems. Toyota, Ford, and Honda have integrated proprietary injector technologies, while emerging competitors like BYD and Chery are rapidly advancing their capabilities. The competitive landscape features traditional automotive suppliers collaborating with OEMs to develop next-generation solutions that balance performance, durability, and environmental compliance.

Robert Bosch GmbH

Technical Solution: Bosch has developed advanced high-precision fuel injectors for V6 engines featuring diamond-like carbon (DLC) coating technology that significantly reduces wear and extends service life. Their latest generation of direct injection systems incorporates multi-hole nozzles with optimized spray patterns that minimize carbon deposits. Bosch's proprietary XDI (eXtreme Direct Injection) technology operates at pressures up to 350 bar, enabling more precise fuel atomization while reducing mechanical stress on injector components. Their injectors utilize specialized heat-resistant polymers for internal seals that withstand aggressive modern fuels and high combustion temperatures. Bosch has also implemented advanced electronic control systems that optimize injection timing and duration based on real-time engine conditions, reducing unnecessary cycling and extending component life.

Strengths: Industry-leading precision manufacturing capabilities, extensive R&D resources, and global market presence. Weaknesses: Premium pricing compared to competitors, and some solutions may require specialized maintenance procedures.

DENSO Corp.

Technical Solution: DENSO has pioneered ceramic-based fuel injector components for V6 engines that offer superior thermal stability and resistance to fuel impurities. Their proprietary manufacturing process creates ultra-smooth internal surfaces that minimize flow turbulence and reduce erosion damage. DENSO's V6 injectors feature advanced solenoid designs with optimized magnetic circuits that ensure consistent performance over extended service intervals. The company has developed specialized metal alloys for injector bodies that resist corrosion from ethanol-blended fuels while maintaining dimensional stability under thermal cycling. DENSO's latest generation incorporates self-cleaning technology that uses controlled high-pressure pulses to remove deposits before they can accumulate and affect spray patterns or flow rates.

Strengths: Exceptional manufacturing precision, strong integration with OEM development cycles, and excellent reliability metrics. Weaknesses: Higher initial cost than some competitors and limited aftermarket support for older vehicle applications.

Key Patents and Innovations in Injector Materials

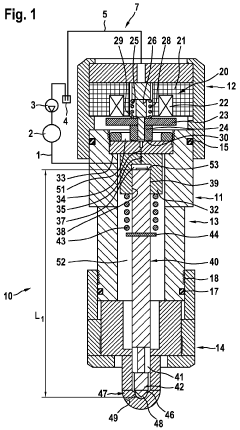

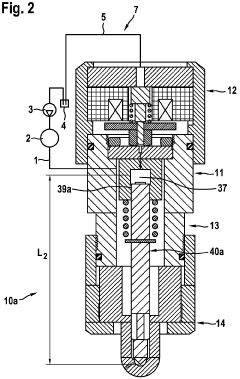

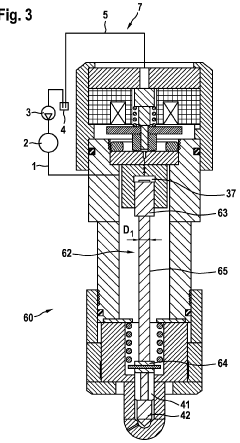

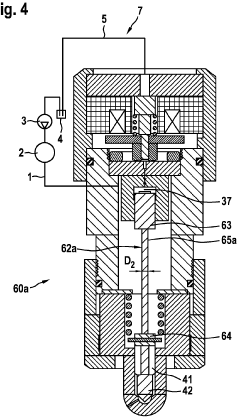

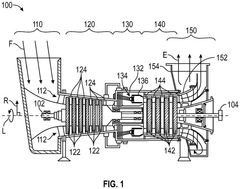

Method for producing a fuel injection valve, and fuel injection valve

PatentWO2011057863A1

Innovation

- The method involves varying the hydraulic rigidity of the control chamber connected to the valve needle by adjusting its volume, allowing for consistent response times across different injector lengths by using a cylindrical bore with a standardized diameter and varying the length of the valve needle, and optionally varying the diameter of the valve needle to fine-tune delay times.

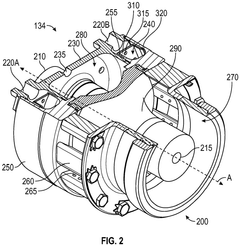

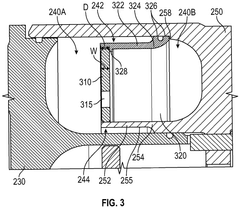

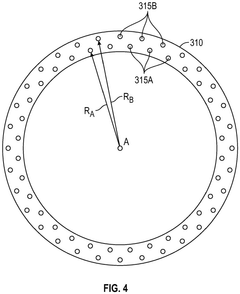

Fuel injector assembly for a gas turbine engine

PatentPendingEP4431717A1

Innovation

- The fuel injector design includes an annular distributor plate positioned between inner and outer arms within the fuel gallery, with the inner and outer arms creating spaces that allow the distributor plate to expand differently from the injector head, thereby isolating thermal expansion and reducing stress on the bonding areas.

Environmental Regulations Impact on Injector Design

Environmental regulations have become increasingly stringent worldwide, significantly influencing fuel injector design and development for V6 engines. The European Union's Euro 7 standards, expected to be implemented by 2025, will impose stricter limits on nitrogen oxide (NOx) and particulate matter emissions, directly affecting injector performance requirements. Similarly, the United States EPA's Tier 4 Final and upcoming Tier 5 regulations continue to push manufacturers toward more precise fuel delivery systems with enhanced durability.

These regulations have catalyzed a shift toward higher-pressure fuel injection systems, with common rail pressures now routinely exceeding 2,500 bar in modern diesel V6 engines. This pressure increase improves atomization and combustion efficiency but simultaneously accelerates wear on injector components, particularly the needle and seat assemblies. Manufacturers must now balance the competing demands of emissions compliance and component longevity.

Material selection for injectors has evolved significantly in response to regulatory pressures. Traditional stainless steel components are increasingly being replaced with advanced ceramics and diamond-like carbon (DLC) coatings that offer superior wear resistance under high-pressure conditions. These materials can withstand the corrosive effects of ultra-low sulfur diesel and biodiesel blends mandated by environmental regulations in many markets.

The introduction of Real Driving Emissions (RDE) testing in regulatory frameworks has further complicated injector design parameters. Injectors must now maintain precise operation across a wider range of operating conditions than previously required, including cold starts and variable load scenarios. This expanded performance envelope has necessitated more sophisticated electronic control systems and more robust mechanical components to ensure consistent operation throughout the injector's service life.

Biofuel compatibility requirements present another regulatory challenge affecting injector longevity. Many jurisdictions now mandate minimum biofuel content in diesel fuel, with proportions ranging from 5% to 20% depending on the region. These biofuels typically have different lubricity properties and can accelerate certain types of wear mechanisms in traditional injector designs, particularly in sealing surfaces and small orifices where deposits may form.

The regulatory push toward on-board diagnostics (OBD) has also influenced injector design, with requirements for self-monitoring capabilities that can detect degradation before emissions performance is compromised. These systems typically monitor injector electrical characteristics and fuel rail pressure to infer injector health, adding another layer of complexity to the design process but potentially extending service life through early intervention when performance begins to deteriorate.

These regulations have catalyzed a shift toward higher-pressure fuel injection systems, with common rail pressures now routinely exceeding 2,500 bar in modern diesel V6 engines. This pressure increase improves atomization and combustion efficiency but simultaneously accelerates wear on injector components, particularly the needle and seat assemblies. Manufacturers must now balance the competing demands of emissions compliance and component longevity.

Material selection for injectors has evolved significantly in response to regulatory pressures. Traditional stainless steel components are increasingly being replaced with advanced ceramics and diamond-like carbon (DLC) coatings that offer superior wear resistance under high-pressure conditions. These materials can withstand the corrosive effects of ultra-low sulfur diesel and biodiesel blends mandated by environmental regulations in many markets.

The introduction of Real Driving Emissions (RDE) testing in regulatory frameworks has further complicated injector design parameters. Injectors must now maintain precise operation across a wider range of operating conditions than previously required, including cold starts and variable load scenarios. This expanded performance envelope has necessitated more sophisticated electronic control systems and more robust mechanical components to ensure consistent operation throughout the injector's service life.

Biofuel compatibility requirements present another regulatory challenge affecting injector longevity. Many jurisdictions now mandate minimum biofuel content in diesel fuel, with proportions ranging from 5% to 20% depending on the region. These biofuels typically have different lubricity properties and can accelerate certain types of wear mechanisms in traditional injector designs, particularly in sealing surfaces and small orifices where deposits may form.

The regulatory push toward on-board diagnostics (OBD) has also influenced injector design, with requirements for self-monitoring capabilities that can detect degradation before emissions performance is compromised. These systems typically monitor injector electrical characteristics and fuel rail pressure to infer injector health, adding another layer of complexity to the design process but potentially extending service life through early intervention when performance begins to deteriorate.

Cost-Benefit Analysis of Advanced Injector Technologies

When evaluating advanced fuel injector technologies for V6 engines, a comprehensive cost-benefit analysis reveals significant economic considerations that influence implementation decisions. Initial acquisition costs for advanced injectors such as piezoelectric or direct injection systems typically range from $80-150 per unit, representing a 30-50% premium over conventional solenoid injectors. However, this higher upfront investment must be weighed against long-term operational savings.

Maintenance cost reduction presents a compelling economic advantage. Advanced injectors with improved materials like diamond-like carbon (DLC) coatings demonstrate 40-60% longer service intervals, reducing workshop labor costs by approximately $200-300 per maintenance cycle. Fleet operators particularly benefit from this extended service life, with potential savings of $1,200-1,800 per vehicle over a 150,000-mile operational period.

Fuel efficiency improvements deliver substantial economic returns. High-precision injectors with multiple injection events per cycle typically yield 3-7% better fuel economy. For a V6 engine consuming 12 liters/100km, this translates to annual savings of $180-420 per vehicle (assuming 20,000km annual mileage and $1.50/liter fuel costs). Commercial fleet operators with hundreds of vehicles can realize six-figure annual savings through this efficiency improvement alone.

Warranty claim reduction represents another significant economic benefit. Advanced injectors with enhanced durability reduce injector-related warranty claims by 25-35%, saving manufacturers approximately $75-120 per vehicle in warranty reserves. This benefit extends to reduced dealer service costs and improved brand reputation metrics.

Environmental compliance value must also be factored into the analysis. Advanced injectors enable engines to meet stringent emissions standards without requiring additional expensive after-treatment systems. This compliance advantage represents $200-350 per vehicle in avoided costs for supplementary emissions equipment, particularly relevant as regulations continue to tighten globally.

Total cost of ownership calculations reveal that despite higher initial costs, advanced injector technologies typically reach break-even within 40,000-60,000 miles of operation. The positive return on investment accelerates in high-utilization scenarios such as commercial fleets, where payback periods can shrink to 30,000 miles. For manufacturers, the ability to command premium pricing for vehicles with enhanced reliability and efficiency further improves the economic equation.

Maintenance cost reduction presents a compelling economic advantage. Advanced injectors with improved materials like diamond-like carbon (DLC) coatings demonstrate 40-60% longer service intervals, reducing workshop labor costs by approximately $200-300 per maintenance cycle. Fleet operators particularly benefit from this extended service life, with potential savings of $1,200-1,800 per vehicle over a 150,000-mile operational period.

Fuel efficiency improvements deliver substantial economic returns. High-precision injectors with multiple injection events per cycle typically yield 3-7% better fuel economy. For a V6 engine consuming 12 liters/100km, this translates to annual savings of $180-420 per vehicle (assuming 20,000km annual mileage and $1.50/liter fuel costs). Commercial fleet operators with hundreds of vehicles can realize six-figure annual savings through this efficiency improvement alone.

Warranty claim reduction represents another significant economic benefit. Advanced injectors with enhanced durability reduce injector-related warranty claims by 25-35%, saving manufacturers approximately $75-120 per vehicle in warranty reserves. This benefit extends to reduced dealer service costs and improved brand reputation metrics.

Environmental compliance value must also be factored into the analysis. Advanced injectors enable engines to meet stringent emissions standards without requiring additional expensive after-treatment systems. This compliance advantage represents $200-350 per vehicle in avoided costs for supplementary emissions equipment, particularly relevant as regulations continue to tighten globally.

Total cost of ownership calculations reveal that despite higher initial costs, advanced injector technologies typically reach break-even within 40,000-60,000 miles of operation. The positive return on investment accelerates in high-utilization scenarios such as commercial fleets, where payback periods can shrink to 30,000 miles. For manufacturers, the ability to command premium pricing for vehicles with enhanced reliability and efficiency further improves the economic equation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!