How To Innovate With Tungsten Composites?

Tungsten Composites Evolution and Objectives

Tungsten composites have evolved significantly over the past few decades, driven by the unique properties of tungsten and the growing demand for advanced materials in various industries. The journey of tungsten composites began with simple metal matrix composites and has progressed to sophisticated multi-component systems with tailored properties.

In the early stages, tungsten composites were primarily developed for military applications, particularly in armor and penetrators. The focus was on leveraging tungsten's high density and strength to create materials that could withstand extreme conditions. As manufacturing techniques improved, the application scope expanded to include aerospace, nuclear, and electronics industries.

The evolution of tungsten composites has been marked by several key milestones. The introduction of powder metallurgy techniques in the 1960s and 1970s allowed for better control over the microstructure and properties of these materials. The 1980s and 1990s saw the development of tungsten heavy alloys, which combined tungsten with other metals like nickel and iron to enhance ductility and machinability.

In recent years, the focus has shifted towards nanostructured tungsten composites, which offer unprecedented combinations of strength, ductility, and radiation resistance. This has opened up new possibilities in fusion reactor components and advanced nuclear systems. Additionally, the integration of tungsten composites with other advanced materials, such as ceramics and carbon fibers, has led to the creation of hybrid composites with exceptional performance characteristics.

The current objectives in tungsten composite innovation are multifaceted. One primary goal is to develop materials with improved ductility and toughness without sacrificing the high density and strength that make tungsten composites valuable. This is particularly crucial for applications in extreme environments, such as fusion reactors and hypersonic vehicles.

Another key objective is to enhance the radiation resistance of tungsten composites, making them more suitable for next-generation nuclear technologies. Researchers are exploring various strategies, including the incorporation of nano-dispersed oxides and the development of self-healing composites that can mitigate radiation-induced damage.

Sustainability is also becoming an increasingly important objective in tungsten composite innovation. Efforts are being made to develop more efficient recycling processes for tungsten composites and to explore alternative, more environmentally friendly production methods. This includes investigating bio-inspired manufacturing techniques and exploring the potential of additive manufacturing for creating complex tungsten composite structures with minimal waste.

As we look to the future, the objectives for tungsten composite innovation are likely to focus on pushing the boundaries of material performance, developing multi-functional composites that can serve multiple roles simultaneously, and creating smart tungsten composites that can adapt to their environment. These advancements will be crucial in meeting the demands of emerging technologies and addressing global challenges in energy, transportation, and defense sectors.

Market Demand Analysis for Tungsten Composites

The market demand for tungsten composites has been steadily growing, driven by their unique properties and diverse applications across multiple industries. These composites, which combine tungsten's high density and excellent thermal properties with other materials, are finding increasing use in aerospace, defense, automotive, and energy sectors.

In the aerospace industry, tungsten composites are highly sought after for their ability to withstand extreme temperatures and provide radiation shielding. As space exploration and satellite technology advance, the demand for these materials in spacecraft components and thermal management systems is expected to rise significantly. The global space industry, valued at over $400 billion, is projected to grow at a CAGR of 5.6% through 2026, indicating a strong potential market for tungsten composites.

The defense sector represents another major market for tungsten composites. Their high density and strength make them ideal for armor plating, kinetic energy penetrators, and other military applications. With global defense spending reaching $1.98 trillion in 2020 and continuing to grow, the demand for advanced materials like tungsten composites is likely to increase.

In the automotive industry, tungsten composites are gaining traction in high-performance vehicles and electric cars. Their use in brake rotors, for instance, offers improved heat dissipation and wear resistance. As the global electric vehicle market expands, projected to reach 26.8 million units by 2030, the demand for lightweight, heat-resistant materials like tungsten composites is expected to surge.

The energy sector, particularly nuclear power and oil & gas industries, presents significant opportunities for tungsten composites. Their radiation shielding properties make them valuable in nuclear reactor components, while their corrosion resistance is beneficial in oil and gas extraction equipment. With the global nuclear energy market expected to grow at a CAGR of 1.9% from 2020 to 2025, and ongoing investments in oil and gas infrastructure, these sectors will continue to drive demand for tungsten composites.

Emerging applications in additive manufacturing and medical devices are also contributing to market growth. The ability to 3D print complex tungsten composite structures is opening new possibilities in customized radiation shielding and medical imaging equipment. The global 3D printing market, growing at a CAGR of 21%, represents a promising avenue for tungsten composite innovations.

However, challenges such as high production costs and limited raw material availability may constrain market growth. Innovations in manufacturing processes and material formulations will be crucial to address these issues and fully capitalize on the market potential of tungsten composites.

Current State and Challenges in Tungsten Composite Technology

Tungsten composites have gained significant attention in recent years due to their exceptional properties and potential applications across various industries. The current state of tungsten composite technology is characterized by ongoing research and development efforts aimed at enhancing material performance and expanding its applications.

One of the primary challenges in tungsten composite technology is the optimization of material properties. Researchers are focusing on improving the strength-to-weight ratio, thermal conductivity, and wear resistance of tungsten composites. This involves exploring various matrix materials, reinforcement types, and processing techniques to achieve desired characteristics for specific applications.

The development of advanced manufacturing processes presents another significant challenge. Traditional powder metallurgy techniques have limitations in terms of achieving uniform dispersion of reinforcements and controlling porosity. Innovative approaches such as additive manufacturing and spark plasma sintering are being investigated to overcome these limitations and enable the production of complex-shaped components with improved properties.

Tungsten composites face challenges related to their high density, which can limit their use in weight-sensitive applications. Efforts are underway to develop lightweight tungsten composites by incorporating low-density reinforcements or creating porous structures without compromising mechanical properties. This research aims to expand the potential applications of tungsten composites in aerospace and automotive industries.

The high cost of tungsten and its processing remains a significant barrier to widespread adoption. Researchers are exploring cost-effective production methods and alternative raw materials to make tungsten composites more economically viable for commercial applications. Additionally, recycling and reuse of tungsten composites are being investigated to address sustainability concerns and reduce overall costs.

Tungsten composite technology also faces challenges in terms of joining and integration with other materials. Developing effective joining techniques that maintain the integrity of the composite structure while ensuring strong bonding with other components is crucial for expanding its use in complex systems and assemblies.

The current research landscape is focused on addressing these challenges through interdisciplinary approaches. Collaborations between materials scientists, engineers, and industry partners are driving innovation in tungsten composite technology. Advanced characterization techniques, computational modeling, and simulation tools are being employed to gain deeper insights into material behavior and guide the development of next-generation tungsten composites.

As the technology continues to evolve, there is a growing emphasis on tailoring tungsten composites for specific applications. This includes developing composites with enhanced radiation shielding properties for nuclear applications, improved thermal management capabilities for electronics, and superior wear resistance for cutting tools and mining equipment.

Existing Tungsten Composite Solutions

01 Tungsten composite manufacturing methods

Various techniques for producing tungsten composites, including powder metallurgy, sintering, and infiltration processes. These methods aim to create materials with improved properties such as density, strength, and wear resistance.- Tungsten composite manufacturing methods: Various methods for manufacturing tungsten composites are described, including powder metallurgy techniques, sintering processes, and advanced fabrication methods. These processes aim to create composites with improved properties such as strength, hardness, and wear resistance.

- Tungsten composite materials for radiation shielding: Tungsten composites are utilized in radiation shielding applications due to their high density and ability to attenuate various types of radiation. These composites are designed to provide effective protection in medical, nuclear, and aerospace industries.

- Tungsten composites for high-temperature applications: Specialized tungsten composites are developed for use in high-temperature environments, such as aerospace and industrial applications. These materials exhibit excellent thermal stability, creep resistance, and maintain their mechanical properties at elevated temperatures.

- Tungsten composite coatings and surface treatments: Advanced coating techniques and surface treatments are applied to tungsten composites to enhance their properties, such as wear resistance, corrosion protection, and thermal management. These processes improve the performance and longevity of tungsten composite components in various applications.

- Nanostructured tungsten composites: Research and development of nanostructured tungsten composites focus on improving material properties through the incorporation of nanoscale reinforcements or by controlling the grain structure at the nanoscale. These advanced materials offer enhanced mechanical, thermal, and electrical properties compared to conventional tungsten composites.

02 Tungsten composite applications in armor and ballistics

Tungsten composites are utilized in armor systems and ballistic protection due to their high density and strength. These materials are designed to provide enhanced protection against projectiles and explosive threats.Expand Specific Solutions03 Tungsten composite coatings and surface treatments

Development of tungsten composite coatings and surface treatments to enhance wear resistance, corrosion protection, and thermal properties of various substrates. These coatings find applications in industries such as aerospace and automotive.Expand Specific Solutions04 Tungsten composites for high-temperature applications

Formulation of tungsten composites designed to withstand extreme temperatures and harsh environments. These materials are used in applications such as rocket nozzles, furnace components, and nuclear reactors.Expand Specific Solutions05 Nanostructured tungsten composites

Development of nanostructured tungsten composites with enhanced properties such as improved ductility, strength, and radiation resistance. These materials are being explored for advanced applications in energy and nuclear sectors.Expand Specific Solutions

Key Players in Tungsten Composite Industry

The innovation landscape for tungsten composites is in a growth phase, with increasing market size and technological advancements. The industry is characterized by a mix of established players and emerging companies, reflecting a competitive yet collaborative environment. Companies like Applied Materials, Inc. and Lam Research Corp. are driving innovation in semiconductor applications, while Xiamen Tungsten Co., Ltd. and Plansee SE focus on advanced materials development. Universities such as Beijing University of Technology and Central South University contribute significantly to research and development. The technology's maturity varies across applications, with some areas like aerospace and defense seeing more mature solutions, while others like additive manufacturing are still evolving. This diverse ecosystem suggests ample opportunities for further innovation and market expansion in tungsten composites.

Applied Materials, Inc.

Ganzhou Hongfei Tungsten & Molybdenum Materials Co., Ltd.

Core Innovations in Tungsten Composite Materials

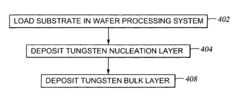

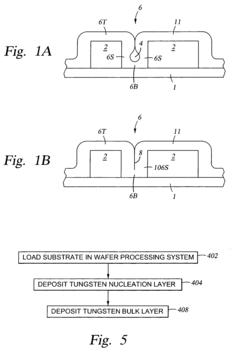

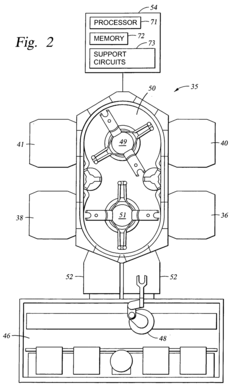

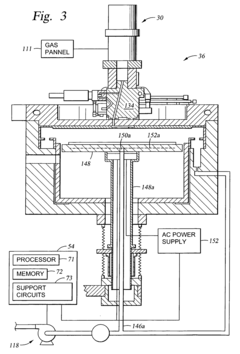

- A composite tungsten film is formed using a cyclical deposition process for the nucleation layer, followed by a chemical vapor deposition process for the bulk layer, involving alternating pulses of tungsten-containing precursors and reducing gases to ensure uniform coverage without overhangs or seams.

- The method involves mixing metal composite powders with a protective liquid in an inert atmosphere, optionally adding ceramic components, and then combining with a binder for injection molding, ensuring low oxygen content and sintering at relatively low temperatures to produce high-quality composite components.

Environmental Impact of Tungsten Composite Production

The production of tungsten composites has significant environmental implications that must be carefully considered and addressed. The extraction and processing of tungsten ore, primarily wolframite and scheelite, involve energy-intensive mining operations and chemical treatments that can lead to soil degradation, water pollution, and air emissions. The refining process to obtain pure tungsten powder often requires the use of strong acids and high temperatures, resulting in the generation of hazardous waste and greenhouse gas emissions.

In the manufacturing of tungsten composites, additional environmental concerns arise from the use of binder materials and the sintering process. Common binders like cobalt or nickel can be toxic if released into the environment, necessitating stringent waste management practices. The high-temperature sintering process consumes substantial energy, contributing to the carbon footprint of tungsten composite production.

Water usage is another critical environmental factor in tungsten composite manufacturing. Large volumes of water are required for cooling, cleaning, and processing, potentially straining local water resources. Proper water treatment and recycling systems are essential to minimize the impact on aquatic ecosystems and ensure sustainable water management.

The disposal of tungsten composite waste and end-of-life products presents further environmental challenges. While tungsten itself is not considered toxic, the composite nature of these materials can complicate recycling efforts. Improper disposal may lead to the leaching of harmful substances into soil and groundwater, emphasizing the need for effective recycling and waste management strategies.

To mitigate these environmental impacts, innovative approaches in tungsten composite production are being developed. These include the implementation of cleaner production technologies, such as more efficient ore processing methods and the use of environmentally friendly binders. Advanced recycling techniques are being explored to recover tungsten and other valuable materials from composite waste, reducing the demand for primary raw materials and minimizing landfill disposal.

Furthermore, the industry is increasingly adopting life cycle assessment (LCA) methodologies to comprehensively evaluate the environmental footprint of tungsten composite products from cradle to grave. This holistic approach enables manufacturers to identify and address key environmental hotspots throughout the production chain, driving continuous improvement in environmental performance.

Tungsten Composite Applications in Emerging Industries

Tungsten composites are finding increasingly diverse applications across emerging industries, driven by their unique combination of properties. In the aerospace sector, these materials are being explored for use in advanced propulsion systems, where their high temperature resistance and strength-to-weight ratio offer significant advantages over traditional alloys. Tungsten composites are being incorporated into nozzle components and combustion chambers, enabling more efficient and durable rocket engines for next-generation space exploration missions.

The renewable energy industry is another area where tungsten composites are making inroads. Wind turbine manufacturers are investigating the use of tungsten-reinforced polymer composites for blade construction, aiming to increase the size and efficiency of turbines while reducing overall weight. In solar energy applications, tungsten composites are being developed for high-temperature receivers in concentrated solar power systems, leveraging their excellent thermal conductivity and stability.

In the field of advanced electronics, tungsten composites are playing a crucial role in the development of next-generation semiconductor devices. As chip manufacturers push the boundaries of miniaturization and performance, tungsten-based interconnects and heat spreaders are becoming essential for managing thermal loads and ensuring reliable operation at the nanoscale. Additionally, tungsten composites are being explored for use in advanced packaging solutions for high-power electronic components in electric vehicles and 5G infrastructure.

The medical industry is also benefiting from innovations in tungsten composites. These materials are being used to develop more effective radiation shielding for diagnostic and therapeutic equipment, offering superior protection while reducing the overall weight of medical devices. In orthopedic implants, tungsten composites are being investigated for their potential to create stronger, more biocompatible prosthetics with improved wear resistance and longevity.

Emerging applications in the defense sector include the use of tungsten composites in advanced armor systems and kinetic energy penetrators. The high density and strength of these materials make them ideal for protective applications, while their ability to maintain structural integrity under extreme conditions is valuable for developing more effective munitions.

As these emerging industries continue to evolve, the demand for innovative tungsten composite solutions is likely to grow. Research efforts are focusing on optimizing manufacturing processes, exploring novel composite formulations, and developing tailored properties for specific applications. The versatility of tungsten composites positions them as a key enabling technology for addressing challenges across multiple sectors, from energy and transportation to healthcare and defense.