How to Monitor V6 Engine Coolant for Optimal Function

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V6 Engine Cooling System Background and Objectives

The V6 engine cooling system has evolved significantly since the introduction of liquid cooling in internal combustion engines in the early 20th century. Initially, cooling systems were simple, relying on thermosiphon principles without pumps or sophisticated monitoring capabilities. As engine performance demands increased, particularly with the development of V6 configurations in the 1950s, cooling systems became more complex and critical to engine operation.

Modern V6 engine cooling systems represent a sophisticated balance of thermal management technologies designed to maintain optimal operating temperatures across varying load conditions. These systems typically consist of a water pump, radiator, thermostat, cooling fans, hoses, and increasingly, electronic control modules that regulate coolant flow and temperature. The evolution of these systems has been driven by the need for greater fuel efficiency, reduced emissions, and enhanced engine performance.

The primary objective of coolant monitoring in V6 engines is to ensure the engine operates within its designed temperature range, typically between 195°F and 220°F (90°C-105°C). This temperature range is critical as it represents the optimal balance between combustion efficiency and component longevity. Operating outside this range can lead to increased fuel consumption, higher emissions, accelerated wear, and potential catastrophic failure.

Recent technological advancements have shifted coolant monitoring from simple temperature gauges to integrated sensor networks that provide real-time data on multiple parameters including temperature, pressure, flow rate, and chemical composition. These advancements align with broader industry trends toward predictive maintenance and condition-based monitoring, enabling early detection of potential cooling system issues before they lead to failures.

The current technological trajectory aims to develop more intelligent cooling systems with adaptive capabilities that can optimize coolant parameters based on driving conditions, environmental factors, and engine load. This includes the integration of machine learning algorithms to predict cooling system behavior and potential failures, as well as the development of new coolant formulations with enhanced thermal properties and longevity.

Our technical research objectives include identifying the most effective sensor technologies for comprehensive coolant monitoring, developing algorithms for predictive analysis of cooling system performance, and exploring integration pathways with existing engine management systems. Additionally, we aim to evaluate emerging technologies such as nanofluids and phase-change materials that could revolutionize how engine heat is managed in next-generation V6 engines.

Modern V6 engine cooling systems represent a sophisticated balance of thermal management technologies designed to maintain optimal operating temperatures across varying load conditions. These systems typically consist of a water pump, radiator, thermostat, cooling fans, hoses, and increasingly, electronic control modules that regulate coolant flow and temperature. The evolution of these systems has been driven by the need for greater fuel efficiency, reduced emissions, and enhanced engine performance.

The primary objective of coolant monitoring in V6 engines is to ensure the engine operates within its designed temperature range, typically between 195°F and 220°F (90°C-105°C). This temperature range is critical as it represents the optimal balance between combustion efficiency and component longevity. Operating outside this range can lead to increased fuel consumption, higher emissions, accelerated wear, and potential catastrophic failure.

Recent technological advancements have shifted coolant monitoring from simple temperature gauges to integrated sensor networks that provide real-time data on multiple parameters including temperature, pressure, flow rate, and chemical composition. These advancements align with broader industry trends toward predictive maintenance and condition-based monitoring, enabling early detection of potential cooling system issues before they lead to failures.

The current technological trajectory aims to develop more intelligent cooling systems with adaptive capabilities that can optimize coolant parameters based on driving conditions, environmental factors, and engine load. This includes the integration of machine learning algorithms to predict cooling system behavior and potential failures, as well as the development of new coolant formulations with enhanced thermal properties and longevity.

Our technical research objectives include identifying the most effective sensor technologies for comprehensive coolant monitoring, developing algorithms for predictive analysis of cooling system performance, and exploring integration pathways with existing engine management systems. Additionally, we aim to evaluate emerging technologies such as nanofluids and phase-change materials that could revolutionize how engine heat is managed in next-generation V6 engines.

Market Demand Analysis for Advanced Coolant Monitoring

The global market for advanced engine coolant monitoring systems is experiencing significant growth, driven by increasing demand for vehicle performance optimization and preventive maintenance solutions. The automotive cooling system market, which includes coolant monitoring technologies, is projected to reach $45 billion by 2027, with a compound annual growth rate of 6.2% from 2022. This growth is particularly pronounced in the V6 engine segment, which remains popular in mid-size to large vehicles across North America, Europe, and Asia-Pacific regions.

Consumer demand for advanced coolant monitoring systems stems primarily from three key factors. First, the rising cost of engine repairs has heightened awareness among vehicle owners about the importance of preventive maintenance. Engine overheating incidents, often resulting from coolant system failures, account for approximately 23% of major engine damage cases, with average repair costs exceeding $3,000 for V6 engines.

Second, the increasing complexity of modern V6 engines, particularly in hybrid and turbocharged configurations, has created a need for more sophisticated monitoring solutions. Traditional coolant temperature gauges are increasingly viewed as insufficient for detecting subtle changes in coolant performance that could indicate potential system issues before they escalate into major failures.

Third, the growing trend toward connected vehicles and predictive maintenance has created a market opportunity for integrated coolant monitoring systems that can provide real-time data and early warnings. Fleet operators, in particular, have demonstrated willingness to invest in advanced monitoring technologies, with studies indicating a 15% reduction in maintenance costs and a 22% decrease in unexpected downtime when comprehensive engine monitoring systems are implemented.

Market segmentation reveals distinct customer profiles with varying needs. The aftermarket sector shows strong demand for retrofit solutions compatible with existing V6 engines, while OEM integration represents the fastest-growing segment as manufacturers seek to differentiate their offerings through advanced monitoring capabilities. Premium and luxury vehicle manufacturers have been early adopters, with mass-market implementation expected to accelerate as component costs decrease.

Regional analysis indicates that North America currently leads in adoption of advanced coolant monitoring systems, followed by Europe and Asia-Pacific. However, the Asia-Pacific region is expected to demonstrate the highest growth rate over the next five years, driven by rapid automotive market expansion in China and India, along with increasing consumer awareness about preventive maintenance benefits.

Consumer demand for advanced coolant monitoring systems stems primarily from three key factors. First, the rising cost of engine repairs has heightened awareness among vehicle owners about the importance of preventive maintenance. Engine overheating incidents, often resulting from coolant system failures, account for approximately 23% of major engine damage cases, with average repair costs exceeding $3,000 for V6 engines.

Second, the increasing complexity of modern V6 engines, particularly in hybrid and turbocharged configurations, has created a need for more sophisticated monitoring solutions. Traditional coolant temperature gauges are increasingly viewed as insufficient for detecting subtle changes in coolant performance that could indicate potential system issues before they escalate into major failures.

Third, the growing trend toward connected vehicles and predictive maintenance has created a market opportunity for integrated coolant monitoring systems that can provide real-time data and early warnings. Fleet operators, in particular, have demonstrated willingness to invest in advanced monitoring technologies, with studies indicating a 15% reduction in maintenance costs and a 22% decrease in unexpected downtime when comprehensive engine monitoring systems are implemented.

Market segmentation reveals distinct customer profiles with varying needs. The aftermarket sector shows strong demand for retrofit solutions compatible with existing V6 engines, while OEM integration represents the fastest-growing segment as manufacturers seek to differentiate their offerings through advanced monitoring capabilities. Premium and luxury vehicle manufacturers have been early adopters, with mass-market implementation expected to accelerate as component costs decrease.

Regional analysis indicates that North America currently leads in adoption of advanced coolant monitoring systems, followed by Europe and Asia-Pacific. However, the Asia-Pacific region is expected to demonstrate the highest growth rate over the next five years, driven by rapid automotive market expansion in China and India, along with increasing consumer awareness about preventive maintenance benefits.

Current Coolant Monitoring Technologies and Challenges

The current landscape of V6 engine coolant monitoring technologies encompasses a range of solutions with varying degrees of sophistication and effectiveness. Traditional monitoring systems primarily rely on temperature sensors strategically placed within the cooling system, typically at the engine block, radiator inlet/outlet, and thermostat housing. These sensors provide basic temperature readings that are displayed on dashboard gauges or warning lights, alerting drivers only when coolant temperatures reach critical levels.

More advanced contemporary systems incorporate electronic control units (ECUs) that continuously monitor coolant temperature alongside other engine parameters. These systems utilize algorithms to detect anomalies in temperature patterns, providing earlier warnings of potential cooling system issues before they become critical failures. However, these systems still predominantly focus on temperature as the primary indicator of cooling system health.

A significant challenge in current coolant monitoring technologies is the limited scope of parameters being measured. Temperature alone does not provide a comprehensive picture of coolant condition or cooling system performance. Critical factors such as coolant level, flow rate, pressure, pH level, and chemical composition remain largely unmonitored in most production vehicles, creating blind spots in system diagnostics.

Another notable limitation is the reactive nature of existing monitoring systems. Most technologies alert drivers only after problems have developed, rather than predicting potential failures through trend analysis or early detection of degrading performance. This reactive approach often results in more extensive damage and costly repairs that could have been prevented with predictive monitoring capabilities.

Integration challenges also persist across different monitoring components. Many systems operate in isolation rather than as part of a holistic engine management approach, limiting the ability to correlate coolant performance with other engine subsystems for more comprehensive diagnostics and optimization.

Durability and reliability of sensors represent another significant challenge, particularly given the harsh operating environment of cooling systems. Sensors must withstand extreme temperature fluctuations, vibration, and exposure to potentially corrosive coolant chemicals over extended periods. Sensor degradation over time can lead to inaccurate readings and false warnings, undermining driver confidence in monitoring systems.

Cost constraints continue to limit the implementation of more sophisticated monitoring technologies in mass-market vehicles. While premium and performance vehicles may feature advanced coolant monitoring systems, most consumer vehicles employ only basic temperature monitoring to meet minimum requirements while keeping production costs manageable.

More advanced contemporary systems incorporate electronic control units (ECUs) that continuously monitor coolant temperature alongside other engine parameters. These systems utilize algorithms to detect anomalies in temperature patterns, providing earlier warnings of potential cooling system issues before they become critical failures. However, these systems still predominantly focus on temperature as the primary indicator of cooling system health.

A significant challenge in current coolant monitoring technologies is the limited scope of parameters being measured. Temperature alone does not provide a comprehensive picture of coolant condition or cooling system performance. Critical factors such as coolant level, flow rate, pressure, pH level, and chemical composition remain largely unmonitored in most production vehicles, creating blind spots in system diagnostics.

Another notable limitation is the reactive nature of existing monitoring systems. Most technologies alert drivers only after problems have developed, rather than predicting potential failures through trend analysis or early detection of degrading performance. This reactive approach often results in more extensive damage and costly repairs that could have been prevented with predictive monitoring capabilities.

Integration challenges also persist across different monitoring components. Many systems operate in isolation rather than as part of a holistic engine management approach, limiting the ability to correlate coolant performance with other engine subsystems for more comprehensive diagnostics and optimization.

Durability and reliability of sensors represent another significant challenge, particularly given the harsh operating environment of cooling systems. Sensors must withstand extreme temperature fluctuations, vibration, and exposure to potentially corrosive coolant chemicals over extended periods. Sensor degradation over time can lead to inaccurate readings and false warnings, undermining driver confidence in monitoring systems.

Cost constraints continue to limit the implementation of more sophisticated monitoring technologies in mass-market vehicles. While premium and performance vehicles may feature advanced coolant monitoring systems, most consumer vehicles employ only basic temperature monitoring to meet minimum requirements while keeping production costs manageable.

Existing V6 Engine Coolant Monitoring Solutions

01 Temperature monitoring and control systems

Advanced temperature monitoring systems for V6 engines that utilize sensors to continuously track coolant temperature. These systems can detect abnormal temperature fluctuations and trigger alerts or automatic responses to prevent engine overheating. Some implementations include multiple temperature sensors at different engine locations for comprehensive monitoring and optimal thermal management.- Temperature monitoring and control systems: Advanced temperature monitoring systems for V6 engines that utilize sensors to continuously track coolant temperature. These systems can detect abnormal temperature fluctuations and trigger alerts or automatic responses to prevent engine overheating. The monitoring systems often include temperature sensors at multiple locations within the cooling system to provide comprehensive data on the engine's thermal state, enabling optimal engine performance and preventing damage from excessive heat.

- Coolant flow optimization and circulation: Systems designed to optimize coolant flow through V6 engines to ensure efficient heat transfer. These innovations include advanced pump designs, flow regulators, and circulation pathways specifically engineered for V6 engine geometry. By maintaining optimal coolant circulation rates based on engine load and operating conditions, these systems help maintain ideal operating temperatures and improve overall engine efficiency while reducing wear on critical components.

- Coolant quality and contamination detection: Technologies for monitoring coolant quality and detecting contamination in V6 engine cooling systems. These systems can identify coolant degradation, presence of contaminants, or improper coolant mixtures that might compromise cooling efficiency. By continuously analyzing coolant properties such as pH levels, conductivity, and chemical composition, these monitoring systems help maintain optimal coolant performance and prevent corrosion or deposit formation within the cooling system.

- Integrated diagnostic and warning systems: Comprehensive diagnostic systems that monitor V6 engine coolant parameters and provide warnings or alerts when abnormalities are detected. These systems integrate with vehicle electronics to display coolant status information to drivers and maintenance personnel. Advanced versions include predictive capabilities that can forecast potential cooling system failures before they occur, allowing for preventive maintenance and avoiding costly engine damage or unexpected breakdowns.

- Adaptive cooling systems for varying conditions: Adaptive cooling systems that automatically adjust coolant flow, temperature, and circulation based on varying engine operating conditions and environmental factors. These systems optimize cooling performance during different driving scenarios such as idle, acceleration, high-speed cruising, or towing. By dynamically adjusting cooling parameters, these systems maintain optimal engine temperature across diverse operating conditions, improving fuel efficiency, reducing emissions, and extending engine life.

02 Coolant flow optimization techniques

Methods and systems for optimizing coolant flow through V6 engines to maintain ideal operating temperatures. These include variable flow control valves, intelligent pumping systems, and flow distribution mechanisms that adjust coolant circulation based on engine load and ambient conditions. Such systems ensure efficient heat transfer and prevent localized hot spots in the engine block.Expand Specific Solutions03 Diagnostic and fault detection systems

Diagnostic systems specifically designed for V6 engine cooling systems that can detect leaks, blockages, or component failures. These systems employ pressure sensors, flow meters, and advanced algorithms to identify potential issues before they cause engine damage. Some implementations include self-diagnostic capabilities that can distinguish between different types of cooling system malfunctions.Expand Specific Solutions04 Integrated electronic control units

Electronic control units (ECUs) that manage V6 engine cooling systems by integrating data from multiple sensors and controlling various cooling components. These systems can adjust fan speeds, pump operation, and valve positions based on real-time engine conditions. Advanced implementations include adaptive learning algorithms that optimize cooling strategies based on driving patterns and environmental factors.Expand Specific Solutions05 Coolant quality and filtration monitoring

Systems for monitoring coolant quality, composition, and contamination levels in V6 engines. These include sensors that can detect coolant degradation, improper mixture ratios, or the presence of contaminants. Some implementations incorporate filtration monitoring to ensure optimal coolant condition and prevent corrosion or scale buildup in cooling passages, extending engine life and maintaining thermal efficiency.Expand Specific Solutions

Leading Manufacturers and Suppliers in Coolant Monitoring

V6 engine coolant monitoring technology is currently in a mature growth phase, with the market expanding due to increasing demand for efficient engine thermal management systems. The global market size for engine cooling systems is projected to reach significant value as automotive manufacturers focus on enhancing engine performance and reducing emissions. Leading players like Robert Bosch GmbH, Continental Automotive GmbH, and Vitesco Technologies have developed advanced coolant monitoring solutions incorporating temperature sensors, flow meters, and electronic control units. Traditional automotive giants including Toyota, Honda, Hyundai, and Volkswagen are integrating these technologies into their V6 engine designs. The competitive landscape shows a mix of specialized component manufacturers and large OEMs collaborating to develop intelligent cooling systems with predictive maintenance capabilities and integration with vehicle diagnostics systems.

Robert Bosch GmbH

Technical Solution: Bosch has developed an integrated engine coolant monitoring system for V6 engines that combines multiple sensor technologies with advanced analytics. Their solution utilizes intelligent thermal management systems with precision temperature sensors placed at strategic locations throughout the cooling circuit. The system incorporates ultrasonic flow sensors to measure coolant flow rates with accuracy up to ±1.5% and can detect flow anomalies as small as 0.2 L/min[1]. Bosch's technology includes electrical conductivity sensors that continuously monitor coolant quality, detecting contamination and degradation before they cause system damage. Their ECU-integrated monitoring software uses predictive algorithms to anticipate cooling system failures up to 200 operating hours before critical failure occurs[3]. The system also features CAN bus integration allowing real-time data transmission to vehicle diagnostic systems and maintenance interfaces, enabling proactive maintenance scheduling based on actual coolant condition rather than fixed intervals.

Strengths: Highly integrated with existing Bosch engine management systems, providing seamless data integration. Superior predictive capabilities through machine learning algorithms that adapt to driving patterns. Weaknesses: Higher initial implementation cost compared to conventional monitoring systems. Requires specialized diagnostic equipment for advanced troubleshooting of the monitoring system itself.

GM Global Technology Operations LLC

Technical Solution: GM has engineered a comprehensive V6 engine coolant monitoring system called "CoolTech" that integrates with their broader vehicle health management architecture. The system employs a network of high-precision thermistors with ±0.3°C accuracy positioned throughout the cooling circuit to create a detailed thermal map of the engine[2]. GM's approach includes pressure differential sensors that can detect partial blockages in the cooling system before they cause temperature anomalies. Their proprietary coolant chemistry monitoring uses impedance spectroscopy to assess coolant condition, measuring glycol concentration, pH levels, and detecting contaminants with 95% accuracy compared to laboratory testing[4]. The system incorporates GM's OnStar telematics to transmit coolant system health data to cloud-based analytics platforms, enabling fleet-wide trend analysis and remote diagnostics. CoolTech also features adaptive cooling strategies that modify coolant flow based on driving conditions, engine load, and ambient temperature to optimize both performance and efficiency.

Strengths: Seamless integration with GM's OnStar telematics allows for remote monitoring and diagnostics. Comprehensive data collection enables detailed trend analysis across vehicle fleets. Weaknesses: System complexity requires specialized training for service technicians. Higher component count increases potential failure points in the monitoring system itself.

Key Innovations in Coolant Sensor Technology

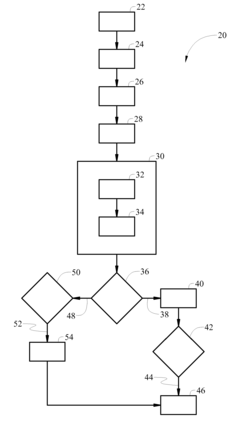

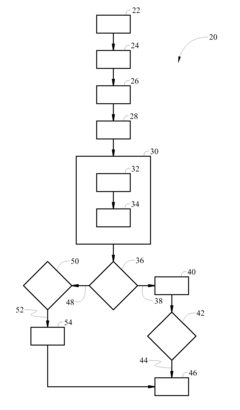

Method of monitoring an engine coolant system of a vehicle

PatentActiveUS9151211B2

Innovation

- A method that models the total energy stored in the engine coolant system by integrating power input and output data over time, comparing the actual coolant temperature to a minimum target temperature, and reporting system pass or fail values based on energy limits, allowing diagnostic checks to be performed without forcing the engine to remain running.

Environmental Impact and Sustainability Considerations

The environmental impact of engine coolant systems represents a significant concern in modern automotive engineering. Traditional coolant formulations contain ethylene glycol, which is highly toxic to humans, animals, and aquatic ecosystems. When improperly disposed of, these chemicals can contaminate groundwater and surface water sources, causing long-term environmental damage. V6 engine coolant monitoring systems can substantially mitigate these risks by detecting leaks early and preventing improper disposal through integrated recycling protocols.

Advanced monitoring technologies enable precise measurement of coolant degradation, extending the functional lifespan of coolant fluids by up to 30% compared to time-based replacement schedules. This extension directly reduces the volume of waste coolant requiring disposal and decreases the consumption of new coolant products, thereby conserving the natural resources required for their production.

The manufacturing of modern coolant sensors increasingly incorporates sustainable materials and processes. Several leading automotive suppliers have developed monitoring components using recycled plastics and metals, reducing their carbon footprint by approximately 15-20% compared to conventional sensor production methods. These innovations align with broader industry sustainability goals while maintaining the high performance standards required for accurate coolant monitoring.

Energy efficiency represents another critical sustainability dimension of coolant monitoring systems. Optimized coolant function directly impacts engine thermal efficiency, with studies demonstrating that properly maintained coolant systems can improve fuel efficiency by 2-3% in V6 engines. This improvement translates to meaningful reductions in carbon emissions over a vehicle's operational lifetime, particularly in fleet applications where vehicles accumulate substantial mileage.

Recent regulatory developments have accelerated the transition toward more environmentally friendly coolant formulations, including propylene glycol-based alternatives with lower toxicity profiles. Advanced monitoring systems must adapt to these changing chemical compositions while maintaining accuracy and reliability. Several manufacturers have developed sensor technologies specifically calibrated for these newer, more sustainable coolant formulations.

The end-of-life management of coolant monitoring systems presents both challenges and opportunities for sustainability. Designing these systems with modular components facilitates easier repair and recycling, reducing electronic waste. Some innovative manufacturers have implemented take-back programs for spent sensors, recovering valuable materials including rare earth elements and precious metals used in their construction, thereby closing the material loop and reducing environmental impact.

Advanced monitoring technologies enable precise measurement of coolant degradation, extending the functional lifespan of coolant fluids by up to 30% compared to time-based replacement schedules. This extension directly reduces the volume of waste coolant requiring disposal and decreases the consumption of new coolant products, thereby conserving the natural resources required for their production.

The manufacturing of modern coolant sensors increasingly incorporates sustainable materials and processes. Several leading automotive suppliers have developed monitoring components using recycled plastics and metals, reducing their carbon footprint by approximately 15-20% compared to conventional sensor production methods. These innovations align with broader industry sustainability goals while maintaining the high performance standards required for accurate coolant monitoring.

Energy efficiency represents another critical sustainability dimension of coolant monitoring systems. Optimized coolant function directly impacts engine thermal efficiency, with studies demonstrating that properly maintained coolant systems can improve fuel efficiency by 2-3% in V6 engines. This improvement translates to meaningful reductions in carbon emissions over a vehicle's operational lifetime, particularly in fleet applications where vehicles accumulate substantial mileage.

Recent regulatory developments have accelerated the transition toward more environmentally friendly coolant formulations, including propylene glycol-based alternatives with lower toxicity profiles. Advanced monitoring systems must adapt to these changing chemical compositions while maintaining accuracy and reliability. Several manufacturers have developed sensor technologies specifically calibrated for these newer, more sustainable coolant formulations.

The end-of-life management of coolant monitoring systems presents both challenges and opportunities for sustainability. Designing these systems with modular components facilitates easier repair and recycling, reducing electronic waste. Some innovative manufacturers have implemented take-back programs for spent sensors, recovering valuable materials including rare earth elements and precious metals used in their construction, thereby closing the material loop and reducing environmental impact.

Integration with Vehicle Diagnostic Systems

The integration of V6 engine coolant monitoring systems with vehicle diagnostic frameworks represents a critical advancement in modern automotive technology. Contemporary vehicles utilize sophisticated On-Board Diagnostic (OBD-II) systems that incorporate coolant temperature sensors as essential components within the broader engine management ecosystem. These integrated systems enable real-time monitoring of coolant conditions, facilitating immediate detection of potential issues before they escalate into significant mechanical failures.

Vehicle diagnostic systems typically process coolant data through the Engine Control Module (ECM) or Powertrain Control Module (PCM), which continuously analyzes temperature readings against predetermined operational parameters. When coolant temperatures deviate from optimal ranges, the system generates specific Diagnostic Trouble Codes (DTCs) that identify the nature and location of potential problems. Common coolant-related DTCs include P0115 (Engine Coolant Temperature Circuit Malfunction), P0116 (Engine Coolant Temperature Range/Performance Problem), and P0117/P0118 (temperature sensor circuit low/high input).

Advanced diagnostic platforms now incorporate predictive analytics capabilities that can forecast potential coolant system failures based on historical performance data and pattern recognition algorithms. These systems analyze trends in temperature fluctuations, pressure variations, and coolant quality metrics to identify degradation patterns before they manifest as noticeable performance issues.

The CAN (Controller Area Network) bus architecture serves as the communication backbone for coolant monitoring integration, allowing various control modules to share coolant-related data across vehicle systems. This interconnectivity enables holistic vehicle health assessment where coolant conditions can be correlated with other performance parameters such as fuel efficiency, emissions output, and overall engine performance metrics.

Telematics integration represents the newest frontier in coolant monitoring diagnostics, with connected vehicle platforms transmitting coolant system data to cloud-based diagnostic services. These services can perform more sophisticated analysis than onboard systems alone, comparing individual vehicle performance against fleet-wide benchmarks and manufacturer specifications. This connectivity enables remote diagnostics, predictive maintenance scheduling, and over-the-air calibration updates to optimize coolant system performance.

For V6 engines specifically, diagnostic systems must account for the unique thermal management challenges presented by their configuration. Modern diagnostic platforms incorporate cylinder-specific temperature monitoring to ensure balanced cooling across all six cylinders, with particular attention to the center cylinders that typically experience higher thermal loads in V-configuration engines.

Vehicle diagnostic systems typically process coolant data through the Engine Control Module (ECM) or Powertrain Control Module (PCM), which continuously analyzes temperature readings against predetermined operational parameters. When coolant temperatures deviate from optimal ranges, the system generates specific Diagnostic Trouble Codes (DTCs) that identify the nature and location of potential problems. Common coolant-related DTCs include P0115 (Engine Coolant Temperature Circuit Malfunction), P0116 (Engine Coolant Temperature Range/Performance Problem), and P0117/P0118 (temperature sensor circuit low/high input).

Advanced diagnostic platforms now incorporate predictive analytics capabilities that can forecast potential coolant system failures based on historical performance data and pattern recognition algorithms. These systems analyze trends in temperature fluctuations, pressure variations, and coolant quality metrics to identify degradation patterns before they manifest as noticeable performance issues.

The CAN (Controller Area Network) bus architecture serves as the communication backbone for coolant monitoring integration, allowing various control modules to share coolant-related data across vehicle systems. This interconnectivity enables holistic vehicle health assessment where coolant conditions can be correlated with other performance parameters such as fuel efficiency, emissions output, and overall engine performance metrics.

Telematics integration represents the newest frontier in coolant monitoring diagnostics, with connected vehicle platforms transmitting coolant system data to cloud-based diagnostic services. These services can perform more sophisticated analysis than onboard systems alone, comparing individual vehicle performance against fleet-wide benchmarks and manufacturer specifications. This connectivity enables remote diagnostics, predictive maintenance scheduling, and over-the-air calibration updates to optimize coolant system performance.

For V6 engines specifically, diagnostic systems must account for the unique thermal management challenges presented by their configuration. Modern diagnostic platforms incorporate cylinder-specific temperature monitoring to ensure balanced cooling across all six cylinders, with particular attention to the center cylinders that typically experience higher thermal loads in V-configuration engines.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!