How to Reduce CFRP Shrinkage in Molding Processes

SEP 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CFRP Shrinkage Background and Reduction Objectives

Carbon Fiber Reinforced Polymers (CFRP) have emerged as revolutionary materials in various high-performance industries since their commercial introduction in the 1960s. Initially developed for aerospace applications, these lightweight composites have progressively expanded into automotive, sporting goods, and renewable energy sectors due to their exceptional strength-to-weight ratio and corrosion resistance properties.

The evolution of CFRP technology has been marked by significant advancements in manufacturing processes, from manual layup techniques to automated fiber placement and resin transfer molding. Despite these improvements, dimensional stability issues—particularly shrinkage during molding processes—remain a persistent challenge that limits broader industrial adoption and precision applications.

Shrinkage in CFRP components occurs primarily due to the volumetric contraction of the polymer matrix during curing, thermal expansion coefficient mismatches between fibers and matrix, and residual stress development. These phenomena lead to warpage, dimensional inaccuracies, and potential structural weaknesses that compromise the integrity and performance of final products.

Historical approaches to mitigating CFRP shrinkage have included empirical compensation methods, where mold dimensions are deliberately oversized to account for expected shrinkage. However, these methods lack precision and require extensive trial-and-error, resulting in material waste and increased production costs.

Recent technological trends indicate a shift toward more sophisticated shrinkage control strategies, including advanced simulation tools for predicting shrinkage behavior, innovative resin formulations with reduced shrinkage characteristics, and optimized cure cycles designed to minimize internal stresses.

The primary technical objectives for CFRP shrinkage reduction include achieving dimensional tolerances below ±0.1mm for high-precision applications, developing predictive models with at least 95% accuracy for various part geometries and processing conditions, and establishing standardized methodologies for shrinkage compensation across different CFRP systems.

Additionally, there are important secondary objectives related to maintaining or enhancing mechanical properties while reducing shrinkage, minimizing the environmental impact of any new additives or processes introduced, and ensuring that shrinkage reduction methods remain economically viable for mass production scenarios.

The pursuit of these objectives is driven by increasing demands from industries such as medical devices, precision robotics, and next-generation aerospace systems, where dimensional accuracy directly impacts functional performance. As CFRP applications continue to expand into these critical sectors, the ability to control shrinkage with greater precision will become a defining factor in unlocking new market opportunities and technological capabilities.

The evolution of CFRP technology has been marked by significant advancements in manufacturing processes, from manual layup techniques to automated fiber placement and resin transfer molding. Despite these improvements, dimensional stability issues—particularly shrinkage during molding processes—remain a persistent challenge that limits broader industrial adoption and precision applications.

Shrinkage in CFRP components occurs primarily due to the volumetric contraction of the polymer matrix during curing, thermal expansion coefficient mismatches between fibers and matrix, and residual stress development. These phenomena lead to warpage, dimensional inaccuracies, and potential structural weaknesses that compromise the integrity and performance of final products.

Historical approaches to mitigating CFRP shrinkage have included empirical compensation methods, where mold dimensions are deliberately oversized to account for expected shrinkage. However, these methods lack precision and require extensive trial-and-error, resulting in material waste and increased production costs.

Recent technological trends indicate a shift toward more sophisticated shrinkage control strategies, including advanced simulation tools for predicting shrinkage behavior, innovative resin formulations with reduced shrinkage characteristics, and optimized cure cycles designed to minimize internal stresses.

The primary technical objectives for CFRP shrinkage reduction include achieving dimensional tolerances below ±0.1mm for high-precision applications, developing predictive models with at least 95% accuracy for various part geometries and processing conditions, and establishing standardized methodologies for shrinkage compensation across different CFRP systems.

Additionally, there are important secondary objectives related to maintaining or enhancing mechanical properties while reducing shrinkage, minimizing the environmental impact of any new additives or processes introduced, and ensuring that shrinkage reduction methods remain economically viable for mass production scenarios.

The pursuit of these objectives is driven by increasing demands from industries such as medical devices, precision robotics, and next-generation aerospace systems, where dimensional accuracy directly impacts functional performance. As CFRP applications continue to expand into these critical sectors, the ability to control shrinkage with greater precision will become a defining factor in unlocking new market opportunities and technological capabilities.

Market Demand Analysis for Precision CFRP Components

The global market for precision Carbon Fiber Reinforced Polymer (CFRP) components is experiencing robust growth, driven by increasing demand across multiple high-value industries. Aerospace and defense sectors remain the primary consumers, with commercial aviation manufacturers seeking lightweight components to improve fuel efficiency and reduce emissions. Boeing and Airbus have both increased their CFRP content in next-generation aircraft by approximately 50% compared to previous models, creating sustained demand for precision components with minimal dimensional variations.

The automotive industry represents the fastest-growing market segment for precision CFRP components, particularly in the premium and electric vehicle sectors. Major manufacturers are incorporating CFRP elements in structural components, battery enclosures, and chassis systems to extend range and performance. This transition has created a compound annual growth rate of 8.7% for automotive CFRP applications, with particular emphasis on components requiring tight dimensional tolerances.

Consumer electronics manufacturers are increasingly adopting precision CFRP components for device housings and internal structural elements, valuing both the material's strength-to-weight ratio and its premium aesthetic qualities. This market segment demands exceptionally tight tolerances and surface finish quality, making shrinkage control during molding processes critically important.

Medical device manufacturing represents an emerging application area with stringent requirements for dimensional accuracy. Surgical instruments, imaging equipment components, and prosthetics benefit from CFRP's properties but require near-zero shrinkage variation to maintain precision in critical applications.

Market analysis reveals that components with shrinkage-related defects face rejection rates between 15-20% in aerospace applications and 10-15% in automotive applications. This represents significant economic waste in high-value materials and processing time. Industry surveys indicate manufacturers would pay a premium of 20-30% for molding processes that could reduce shrinkage variability by half.

The renewable energy sector, particularly wind turbine manufacturing, has emerged as a volume driver for CFRP components. Blade manufacturers require increasingly precise components to optimize aerodynamic efficiency while maintaining structural integrity in larger blade designs.

Market forecasts indicate the global demand for precision CFRP components will reach $36 billion by 2027, with the highest growth rates in regions with strong aerospace, automotive, and renewable energy manufacturing bases. This growth trajectory creates significant economic incentive for developing improved molding processes that minimize shrinkage and dimensional variations.

The automotive industry represents the fastest-growing market segment for precision CFRP components, particularly in the premium and electric vehicle sectors. Major manufacturers are incorporating CFRP elements in structural components, battery enclosures, and chassis systems to extend range and performance. This transition has created a compound annual growth rate of 8.7% for automotive CFRP applications, with particular emphasis on components requiring tight dimensional tolerances.

Consumer electronics manufacturers are increasingly adopting precision CFRP components for device housings and internal structural elements, valuing both the material's strength-to-weight ratio and its premium aesthetic qualities. This market segment demands exceptionally tight tolerances and surface finish quality, making shrinkage control during molding processes critically important.

Medical device manufacturing represents an emerging application area with stringent requirements for dimensional accuracy. Surgical instruments, imaging equipment components, and prosthetics benefit from CFRP's properties but require near-zero shrinkage variation to maintain precision in critical applications.

Market analysis reveals that components with shrinkage-related defects face rejection rates between 15-20% in aerospace applications and 10-15% in automotive applications. This represents significant economic waste in high-value materials and processing time. Industry surveys indicate manufacturers would pay a premium of 20-30% for molding processes that could reduce shrinkage variability by half.

The renewable energy sector, particularly wind turbine manufacturing, has emerged as a volume driver for CFRP components. Blade manufacturers require increasingly precise components to optimize aerodynamic efficiency while maintaining structural integrity in larger blade designs.

Market forecasts indicate the global demand for precision CFRP components will reach $36 billion by 2027, with the highest growth rates in regions with strong aerospace, automotive, and renewable energy manufacturing bases. This growth trajectory creates significant economic incentive for developing improved molding processes that minimize shrinkage and dimensional variations.

Current Challenges in CFRP Shrinkage Control

Carbon Fiber Reinforced Polymers (CFRP) shrinkage control remains one of the most significant challenges in advanced composite manufacturing. The dimensional instability caused by shrinkage during molding processes directly impacts the geometric accuracy, mechanical properties, and overall quality of CFRP components. Current manufacturing processes struggle to consistently predict and control shrinkage rates, which typically range from 0.1% to 0.8% depending on fiber orientation, resin systems, and processing parameters.

The primary technical challenge lies in the complex interaction between the anisotropic thermal expansion behavior of carbon fibers and the volumetric contraction of polymer matrices during curing. This mismatch creates internal stresses that manifest as warpage, spring-back effects, and dimensional variations in the final parts. The heterogeneous nature of CFRP materials further complicates shrinkage prediction models, as local variations in fiber volume fraction can lead to differential shrinkage across a single component.

Process-induced residual stresses represent another significant hurdle in shrinkage control. During the curing cycle, chemical shrinkage occurs as the resin crosslinks, while thermal contraction takes place during cooling. These phenomena occur simultaneously but at different rates throughout the part thickness, creating a complex stress state that is difficult to model accurately. Current simulation tools often fail to capture these multi-physics interactions with sufficient precision for high-performance applications.

Tool-part interaction during molding introduces additional variables affecting shrinkage behavior. The coefficient of thermal expansion mismatch between tooling materials and CFRP parts creates friction forces that can either constrain or exacerbate shrinkage effects. Traditional metal tooling approaches lack the adaptability needed to compensate for these dynamic material behaviors during processing.

The industry also faces challenges in real-time monitoring and control of shrinkage during manufacturing. Current sensor technologies and in-situ measurement methods provide limited visibility into the actual state of cure and dimensional changes occurring within closed mold systems. This knowledge gap prevents the implementation of adaptive control strategies that could potentially mitigate shrinkage issues during processing.

For high-precision applications in aerospace, automotive, and medical industries, these shrinkage control limitations represent a significant barrier to wider CFRP adoption. The need for extensive trial-and-error approaches and over-designed compensation strategies increases production costs and lead times. Furthermore, the lack of standardized shrinkage prediction methodologies across the industry hampers knowledge transfer and consistent quality control practices.

The primary technical challenge lies in the complex interaction between the anisotropic thermal expansion behavior of carbon fibers and the volumetric contraction of polymer matrices during curing. This mismatch creates internal stresses that manifest as warpage, spring-back effects, and dimensional variations in the final parts. The heterogeneous nature of CFRP materials further complicates shrinkage prediction models, as local variations in fiber volume fraction can lead to differential shrinkage across a single component.

Process-induced residual stresses represent another significant hurdle in shrinkage control. During the curing cycle, chemical shrinkage occurs as the resin crosslinks, while thermal contraction takes place during cooling. These phenomena occur simultaneously but at different rates throughout the part thickness, creating a complex stress state that is difficult to model accurately. Current simulation tools often fail to capture these multi-physics interactions with sufficient precision for high-performance applications.

Tool-part interaction during molding introduces additional variables affecting shrinkage behavior. The coefficient of thermal expansion mismatch between tooling materials and CFRP parts creates friction forces that can either constrain or exacerbate shrinkage effects. Traditional metal tooling approaches lack the adaptability needed to compensate for these dynamic material behaviors during processing.

The industry also faces challenges in real-time monitoring and control of shrinkage during manufacturing. Current sensor technologies and in-situ measurement methods provide limited visibility into the actual state of cure and dimensional changes occurring within closed mold systems. This knowledge gap prevents the implementation of adaptive control strategies that could potentially mitigate shrinkage issues during processing.

For high-precision applications in aerospace, automotive, and medical industries, these shrinkage control limitations represent a significant barrier to wider CFRP adoption. The need for extensive trial-and-error approaches and over-designed compensation strategies increases production costs and lead times. Furthermore, the lack of standardized shrinkage prediction methodologies across the industry hampers knowledge transfer and consistent quality control practices.

Existing Shrinkage Mitigation Techniques

01 Manufacturing techniques to control CFRP shrinkage

Various manufacturing techniques can be employed to control shrinkage in carbon fiber reinforced polymers. These include optimized curing processes, controlled cooling rates, and specialized molding techniques. By carefully managing the manufacturing parameters, the dimensional stability of CFRP components can be significantly improved, reducing warpage and ensuring more precise final dimensions.- Manufacturing methods to control CFRP shrinkage: Various manufacturing techniques can be employed to control shrinkage in carbon fiber reinforced polymers. These include optimized curing processes, controlled cooling rates, and specialized molding techniques that account for the dimensional changes during production. By carefully managing the manufacturing parameters, the shrinkage of CFRP components can be minimized, resulting in more dimensionally stable final products.

- Resin formulations to reduce shrinkage: Specific resin formulations can be developed to minimize shrinkage in CFRP materials. These formulations may include the addition of fillers, modifiers, or specialized additives that counteract the natural tendency of polymers to shrink during curing. By optimizing the resin chemistry, manufacturers can produce CFRP components with improved dimensional stability and reduced internal stresses caused by shrinkage.

- Fiber orientation and layup strategies: The orientation and layup of carbon fibers within the polymer matrix significantly affects shrinkage behavior. By strategically designing the fiber architecture, including fiber direction, stacking sequence, and fiber volume fraction, manufacturers can control and predict shrinkage patterns. This approach allows for compensation during design and manufacturing stages to achieve the desired final dimensions despite shrinkage effects.

- Thermal management during CFRP processing: Effective thermal management during the processing of CFRP materials is crucial for controlling shrinkage. This includes precise temperature control during curing, gradual cooling strategies, and thermal cycling techniques. By managing the thermal history of the composite material, manufacturers can minimize differential shrinkage between the fiber and matrix components, resulting in more dimensionally stable parts.

- Shrinkage compensation techniques: Various compensation techniques can be employed to address the inevitable shrinkage in CFRP components. These include designing oversized molds that account for expected shrinkage, using expandable tooling that adjusts during the curing process, and implementing post-processing methods to correct dimensional changes. Advanced simulation and modeling approaches can also predict shrinkage patterns, allowing for preemptive design adjustments.

02 Resin formulations for minimizing shrinkage

Specific resin formulations can be developed to minimize shrinkage in CFRP materials. These formulations may include modified epoxy systems, specialized additives, or fillers that compensate for volumetric changes during curing. By engineering the polymer matrix to have reduced shrinkage characteristics, the overall dimensional stability of the composite can be enhanced while maintaining mechanical properties.Expand Specific Solutions03 Fiber orientation and layup strategies

The orientation and layup of carbon fibers significantly impact the shrinkage behavior of CFRP components. By strategically designing the fiber architecture, including fiber direction, stacking sequence, and ply orientation, manufacturers can counteract shrinkage forces and achieve more dimensionally stable parts. This approach leverages the anisotropic nature of carbon fiber composites to control dimensional changes.Expand Specific Solutions04 Post-processing techniques for shrinkage compensation

Various post-processing techniques can be applied to CFRP components to compensate for shrinkage effects. These include thermal treatments, machining operations, and specialized finishing processes that can correct dimensional deviations caused by shrinkage. By implementing these techniques after the initial manufacturing process, the final dimensions of CFRP parts can be brought within required tolerances.Expand Specific Solutions05 Tooling and mold design for shrinkage control

Advanced tooling and mold designs play a crucial role in controlling CFRP shrinkage. These designs may incorporate features such as adjustable dimensions, compensation factors for expected shrinkage, and specialized heating/cooling systems. By anticipating shrinkage behavior and designing tools accordingly, manufacturers can produce CFRP components with improved dimensional accuracy and consistency.Expand Specific Solutions

Leading Manufacturers and Research Institutions in CFRP Industry

The CFRP shrinkage reduction market is currently in a growth phase, with increasing demand driven by aerospace, automotive, and renewable energy sectors. The global market for advanced composite manufacturing solutions is estimated at $12-15 billion annually, with 8-10% growth projected through 2030. Leading players demonstrate varying levels of technical maturity: Toray Industries, Mitsubishi Heavy Industries, and Airbus Operations represent mature technology implementers with established solutions, while Toyota, Nissan, and Honda are advancing automotive-specific applications. Companies like ThyssenKrupp Carbon Components and Siemens Gamesa are developing specialized solutions for renewable energy applications. Research institutions such as Korea Institute of Materials Science are bridging fundamental research with industrial applications, creating a competitive landscape where cross-industry collaboration is increasingly critical for innovation.

Toray Industries, Inc.

Technical Solution: Toray has developed an advanced resin transfer molding (RTM) process specifically designed to minimize CFRP shrinkage. Their approach incorporates a proprietary resin formulation with optimized viscosity characteristics that allows for better fiber wetting and reduced void formation. The process utilizes precise temperature and pressure control systems that adapt in real-time based on cure monitoring sensors embedded within the mold. Toray's solution includes a two-stage curing protocol where initial gelation occurs at lower temperatures to establish dimensional stability before final cross-linking at elevated temperatures. Additionally, they've implemented specialized mold designs with variable heating zones to create more uniform temperature distribution, significantly reducing residual stresses that contribute to shrinkage. Their technology also incorporates nano-additives that act as shrinkage compensators by creating microscopic expansions during cure to offset the natural contraction of the resin system.

Strengths: Superior dimensional accuracy with reported shrinkage reduction of up to 65% compared to conventional processes. Excellent surface finish quality and consistent mechanical properties across complex geometries. Weaknesses: Higher initial equipment investment and longer cycle times compared to traditional methods. Process requires more sophisticated control systems and operator expertise.

Mitsubishi Heavy Industries, Ltd.

Technical Solution: Mitsubishi Heavy Industries has pioneered a comprehensive approach to CFRP shrinkage reduction through their Vacuum-assisted High-Pressure RTM (VaHPRTM) technology. This system combines vacuum assistance with precisely controlled high-pressure injection to minimize void content to below 0.5% by volume. Their process incorporates a proprietary mold design featuring micro-channeled surfaces that enhance resin flow while maintaining fiber orientation. MHI's solution includes an adaptive cure cycle management system that continuously adjusts temperature ramps based on real-time dielectric analysis of the curing state, preventing localized exotherms that contribute to differential shrinkage. The company has also developed specialized fiber preform technologies with stabilized architectures that resist deformation during molding. Additionally, their system utilizes tailored pressure profiles during the cure cycle, applying counterforce at critical transition points to physically oppose shrinkage forces as they develop during polymerization.

Strengths: Achieves exceptional dimensional stability with reported deviation tolerances below ±0.1mm for aerospace components. Process is highly repeatable with minimal part-to-part variation. Weaknesses: System requires significant capital investment and specialized training. Limited flexibility for rapid design changes due to complex mold requirements.

Key Patents and Research on Shrinkage Reduction

Carbon fiber-reinforced plastic molding

PatentInactiveJP2012162062A

Innovation

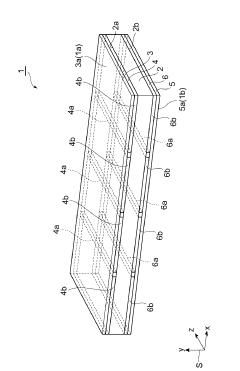

- A carbon fiber reinforced plastic molded article with a first and second carbon fiber reinforced plastic layer, and a first and second damping layer with voids intersecting the orientation direction of the carbon fibers, arranged to relieve stress and improve vibration damping.

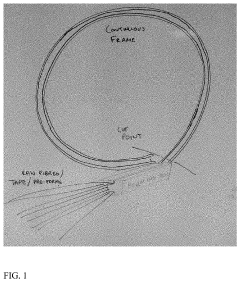

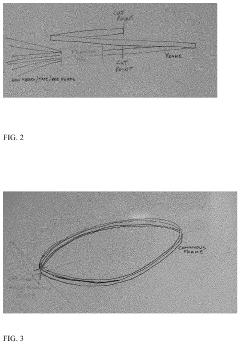

Continuous molded carbon fiber reinforced polymer slender curved component

PatentActiveUS20200353700A1

Innovation

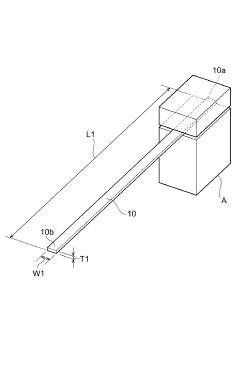

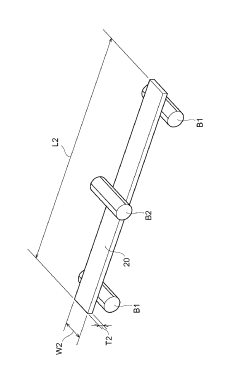

- A method and apparatus for continuously molding CFRP slender components by introducing out-of-plane curvature using a forming tool with a 'corkscrew' or 'pigtail' design, either through mold geometry or mechanical deflection, allowing for curved shapes without clashing with tooling, and optionally including a heating and re-curing process to eliminate curvature.

Material Science Advancements for CFRP Composites

Recent advancements in material science have significantly contributed to improving the performance and processability of Carbon Fiber Reinforced Polymers (CFRP). These developments focus on addressing key challenges in CFRP manufacturing, particularly shrinkage during molding processes, which can lead to dimensional inaccuracies, residual stresses, and potential structural weaknesses.

Novel matrix systems have emerged as a primary area of innovation, with modified epoxy resins incorporating nano-silica particles demonstrating reduced shrinkage rates of up to 30% compared to conventional systems. These particles create a more stable network structure during curing, effectively constraining the polymer chains and limiting volumetric contraction.

Thermoplastic-modified thermoset systems represent another breakthrough, combining the processing advantages of thermosets with the dimensional stability of thermoplastics. Research indicates that incorporating 15-20% thermoplastic content can reduce overall shrinkage by 25-40% while maintaining mechanical properties within acceptable ranges.

Fiber surface treatments have evolved beyond traditional sizing agents to include specialized coupling agents that create stronger interfacial bonds between fibers and matrix. These enhanced interfaces distribute shrinkage stresses more uniformly throughout the composite, minimizing localized deformation and warpage during cooling phases.

Hybrid reinforcement architectures combining carbon fibers with other reinforcement types (such as glass or aramid) in strategic orientations have shown promise in controlling directional shrinkage. These multi-material systems leverage the different thermal expansion characteristics of various fiber types to counterbalance shrinkage forces.

Cure kinetics modifiers represent a cutting-edge approach, with chemical additives designed to alter the crosslinking behavior of thermoset resins. By extending gel time and promoting more uniform network formation, these additives enable more controlled dimensional changes during processing, reducing overall shrinkage by 15-25% in laboratory studies.

Computational material design has accelerated development through molecular dynamics simulations that predict shrinkage behavior based on polymer chemistry and processing conditions. This approach has enabled the rapid screening of potential matrix formulations, identifying promising candidates with optimized shrinkage characteristics before physical testing.

These material science advancements collectively provide manufacturers with an expanded toolkit for addressing CFRP shrinkage challenges, enabling the production of higher precision components for demanding applications in aerospace, automotive, and other high-performance sectors.

Novel matrix systems have emerged as a primary area of innovation, with modified epoxy resins incorporating nano-silica particles demonstrating reduced shrinkage rates of up to 30% compared to conventional systems. These particles create a more stable network structure during curing, effectively constraining the polymer chains and limiting volumetric contraction.

Thermoplastic-modified thermoset systems represent another breakthrough, combining the processing advantages of thermosets with the dimensional stability of thermoplastics. Research indicates that incorporating 15-20% thermoplastic content can reduce overall shrinkage by 25-40% while maintaining mechanical properties within acceptable ranges.

Fiber surface treatments have evolved beyond traditional sizing agents to include specialized coupling agents that create stronger interfacial bonds between fibers and matrix. These enhanced interfaces distribute shrinkage stresses more uniformly throughout the composite, minimizing localized deformation and warpage during cooling phases.

Hybrid reinforcement architectures combining carbon fibers with other reinforcement types (such as glass or aramid) in strategic orientations have shown promise in controlling directional shrinkage. These multi-material systems leverage the different thermal expansion characteristics of various fiber types to counterbalance shrinkage forces.

Cure kinetics modifiers represent a cutting-edge approach, with chemical additives designed to alter the crosslinking behavior of thermoset resins. By extending gel time and promoting more uniform network formation, these additives enable more controlled dimensional changes during processing, reducing overall shrinkage by 15-25% in laboratory studies.

Computational material design has accelerated development through molecular dynamics simulations that predict shrinkage behavior based on polymer chemistry and processing conditions. This approach has enabled the rapid screening of potential matrix formulations, identifying promising candidates with optimized shrinkage characteristics before physical testing.

These material science advancements collectively provide manufacturers with an expanded toolkit for addressing CFRP shrinkage challenges, enabling the production of higher precision components for demanding applications in aerospace, automotive, and other high-performance sectors.

Environmental Impact of CFRP Manufacturing Methods

The manufacturing of Carbon Fiber Reinforced Polymers (CFRP) involves several processes that have significant environmental implications. Traditional CFRP production methods, particularly those involving thermoset resins, generate substantial waste and consume considerable energy. The autoclave curing process, widely used in aerospace applications, requires heating large structures to high temperatures for extended periods, resulting in substantial energy consumption and associated carbon emissions.

Chemical emissions present another environmental concern in CFRP manufacturing. The release of volatile organic compounds (VOCs) during resin curing processes contributes to air pollution and potential health hazards for workers. Additionally, the use of solvents for cleaning and preparation stages further compounds these environmental impacts, with many conventional solvents being hazardous substances requiring careful handling and disposal.

Water usage in CFRP production processes, particularly in cooling systems and cleaning operations, represents a significant environmental burden. The contamination of water with resin residues, release agents, and other chemicals necessitates extensive treatment before discharge, adding to the environmental footprint of manufacturing operations.

Waste management poses a particular challenge for the CFRP industry. Thermoset composites, once cured, cannot be easily recycled through conventional methods, leading to significant end-of-life disposal issues. Trim waste from manufacturing processes, rejected parts, and expired prepreg materials often end up in landfills, contributing to long-term environmental degradation.

Recent innovations in manufacturing methods have begun addressing these environmental concerns. Out-of-autoclave processing techniques reduce energy consumption by eliminating the need for high-pressure, high-temperature curing cycles. Resin transfer molding (RTM) and vacuum-assisted processes offer more efficient material utilization, reducing waste generation during manufacturing.

The development of thermoplastic CFRP materials presents promising environmental advantages over traditional thermoset systems. These materials can be remelted and reformed, enabling more effective recycling pathways. Additionally, thermoplastic processing typically involves lower VOC emissions and eliminates the need for refrigerated storage of raw materials, further reducing the environmental impact.

Advanced manufacturing technologies, such as automated fiber placement and additive manufacturing for composite structures, optimize material usage and minimize waste generation. These precision techniques allow for near-net-shape manufacturing, significantly reducing the amount of trim waste compared to conventional layup methods.

Chemical emissions present another environmental concern in CFRP manufacturing. The release of volatile organic compounds (VOCs) during resin curing processes contributes to air pollution and potential health hazards for workers. Additionally, the use of solvents for cleaning and preparation stages further compounds these environmental impacts, with many conventional solvents being hazardous substances requiring careful handling and disposal.

Water usage in CFRP production processes, particularly in cooling systems and cleaning operations, represents a significant environmental burden. The contamination of water with resin residues, release agents, and other chemicals necessitates extensive treatment before discharge, adding to the environmental footprint of manufacturing operations.

Waste management poses a particular challenge for the CFRP industry. Thermoset composites, once cured, cannot be easily recycled through conventional methods, leading to significant end-of-life disposal issues. Trim waste from manufacturing processes, rejected parts, and expired prepreg materials often end up in landfills, contributing to long-term environmental degradation.

Recent innovations in manufacturing methods have begun addressing these environmental concerns. Out-of-autoclave processing techniques reduce energy consumption by eliminating the need for high-pressure, high-temperature curing cycles. Resin transfer molding (RTM) and vacuum-assisted processes offer more efficient material utilization, reducing waste generation during manufacturing.

The development of thermoplastic CFRP materials presents promising environmental advantages over traditional thermoset systems. These materials can be remelted and reformed, enabling more effective recycling pathways. Additionally, thermoplastic processing typically involves lower VOC emissions and eliminates the need for refrigerated storage of raw materials, further reducing the environmental impact.

Advanced manufacturing technologies, such as automated fiber placement and additive manufacturing for composite structures, optimize material usage and minimize waste generation. These precision techniques allow for near-net-shape manufacturing, significantly reducing the amount of trim waste compared to conventional layup methods.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!