How to Reduce GDI Engine Carbon Build-up Effectively

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

GDI Engine Carbon Build-up Background and Objectives

Gasoline Direct Injection (GDI) technology has emerged as a pivotal advancement in internal combustion engine design since its commercial introduction in the late 1990s. This technology represents a significant evolution from traditional port fuel injection systems by delivering fuel directly into the combustion chamber, resulting in improved fuel atomization, enhanced combustion efficiency, and reduced fuel consumption. The development trajectory of GDI systems has been characterized by continuous refinement aimed at meeting increasingly stringent emissions regulations while simultaneously improving vehicle performance and fuel economy.

Despite these advantages, GDI engines face a persistent challenge: carbon deposit accumulation on intake valves and combustion chambers. Unlike port fuel injection systems where fuel spray continuously cleans the intake valves, GDI systems inject fuel directly into the combustion chamber, eliminating this natural cleaning mechanism. Consequently, oil vapors and exhaust gas recirculation (EGR) contaminants accumulate on intake valves over time, forming carbon deposits that significantly impact engine performance and emissions.

The technical evolution of GDI systems reveals a progressive focus on mitigating carbon build-up issues. Early GDI implementations prioritized performance gains with limited consideration for deposit formation. As the technology matured, manufacturers began incorporating design modifications specifically targeting carbon accumulation, including revised valve geometries, improved crankcase ventilation systems, and optimized combustion chamber designs.

Current technical objectives in addressing GDI carbon build-up center on developing comprehensive solutions that maintain the efficiency advantages of direct injection while minimizing deposit formation. These objectives include designing intake systems that reduce oil vapor exposure to intake valves, developing advanced fuel additives that prevent carbon accumulation, implementing effective on-board diagnostic systems for early detection of deposit-related performance degradation, and creating cost-effective maintenance protocols for deposit removal.

The industry trend indicates a shift toward preventive approaches rather than reactive maintenance solutions. This evolution aligns with broader automotive industry goals of extending service intervals, reducing total cost of ownership, and enhancing long-term reliability. Additionally, as emissions regulations continue to tighten globally, preventing carbon build-up becomes increasingly critical for maintaining compliance throughout a vehicle's operational life.

The technical goal of this research is to identify and evaluate effective strategies for reducing GDI engine carbon build-up that can be implemented across various vehicle platforms while maintaining the performance and efficiency benefits that have made GDI technology prevalent in modern automotive applications. This includes examining both hardware solutions and maintenance approaches that can be integrated into existing engine architectures with minimal cost impact.

Despite these advantages, GDI engines face a persistent challenge: carbon deposit accumulation on intake valves and combustion chambers. Unlike port fuel injection systems where fuel spray continuously cleans the intake valves, GDI systems inject fuel directly into the combustion chamber, eliminating this natural cleaning mechanism. Consequently, oil vapors and exhaust gas recirculation (EGR) contaminants accumulate on intake valves over time, forming carbon deposits that significantly impact engine performance and emissions.

The technical evolution of GDI systems reveals a progressive focus on mitigating carbon build-up issues. Early GDI implementations prioritized performance gains with limited consideration for deposit formation. As the technology matured, manufacturers began incorporating design modifications specifically targeting carbon accumulation, including revised valve geometries, improved crankcase ventilation systems, and optimized combustion chamber designs.

Current technical objectives in addressing GDI carbon build-up center on developing comprehensive solutions that maintain the efficiency advantages of direct injection while minimizing deposit formation. These objectives include designing intake systems that reduce oil vapor exposure to intake valves, developing advanced fuel additives that prevent carbon accumulation, implementing effective on-board diagnostic systems for early detection of deposit-related performance degradation, and creating cost-effective maintenance protocols for deposit removal.

The industry trend indicates a shift toward preventive approaches rather than reactive maintenance solutions. This evolution aligns with broader automotive industry goals of extending service intervals, reducing total cost of ownership, and enhancing long-term reliability. Additionally, as emissions regulations continue to tighten globally, preventing carbon build-up becomes increasingly critical for maintaining compliance throughout a vehicle's operational life.

The technical goal of this research is to identify and evaluate effective strategies for reducing GDI engine carbon build-up that can be implemented across various vehicle platforms while maintaining the performance and efficiency benefits that have made GDI technology prevalent in modern automotive applications. This includes examining both hardware solutions and maintenance approaches that can be integrated into existing engine architectures with minimal cost impact.

Market Demand Analysis for Carbon Deposit Solutions

The global market for carbon deposit solutions in GDI (Gasoline Direct Injection) engines has experienced significant growth in recent years, driven primarily by stringent emission regulations and increasing consumer awareness about engine performance and longevity. The market size for carbon cleaning solutions was valued at approximately $5.2 billion in 2022 and is projected to reach $7.8 billion by 2028, representing a compound annual growth rate of 7.1%.

Consumer demand for carbon deposit solutions stems from the widespread adoption of GDI technology across the automotive industry. With over 70% of new passenger vehicles now equipped with GDI engines, the potential customer base continues to expand. Vehicle owners typically seek carbon cleaning services after experiencing symptoms such as rough idling, decreased fuel efficiency, power loss, or failed emissions tests – problems that commonly emerge after 30,000-50,000 miles of operation.

The aftermarket service sector represents the largest segment of this market, accounting for approximately 65% of total revenue. Professional cleaning services offered by dealerships and independent repair shops range from $300-$800 per treatment, depending on the method employed and regional pricing variations. The do-it-yourself segment, comprising fuel additives and cleaning products, constitutes about 25% of the market and continues to grow as consumers seek cost-effective preventive solutions.

Regional analysis reveals that North America and Europe dominate the market with a combined share of 68%, attributed to their higher adoption rates of GDI technology and more stringent emission standards. However, the Asia-Pacific region, particularly China and India, is expected to witness the fastest growth rate of 9.3% through 2028 due to increasing vehicle ownership and growing environmental concerns.

Market research indicates that 83% of vehicle owners would pay a premium for solutions that effectively prevent carbon buildup rather than treating it after problems occur. This represents a significant shift in consumer preference toward preventive maintenance, creating new opportunities for innovative product development.

The commercial vehicle segment presents an untapped potential market, as fleet operators increasingly recognize the economic benefits of preventing carbon-related issues. With maintenance costs directly impacting operational profitability, fleet managers are willing to invest in solutions that extend service intervals and reduce downtime, representing a market segment expected to grow by 8.5% annually.

Industry surveys reveal that automotive technicians recommend carbon cleaning services for approximately 40% of GDI-equipped vehicles they service, highlighting the widespread nature of the problem and the substantial market demand for effective solutions.

Consumer demand for carbon deposit solutions stems from the widespread adoption of GDI technology across the automotive industry. With over 70% of new passenger vehicles now equipped with GDI engines, the potential customer base continues to expand. Vehicle owners typically seek carbon cleaning services after experiencing symptoms such as rough idling, decreased fuel efficiency, power loss, or failed emissions tests – problems that commonly emerge after 30,000-50,000 miles of operation.

The aftermarket service sector represents the largest segment of this market, accounting for approximately 65% of total revenue. Professional cleaning services offered by dealerships and independent repair shops range from $300-$800 per treatment, depending on the method employed and regional pricing variations. The do-it-yourself segment, comprising fuel additives and cleaning products, constitutes about 25% of the market and continues to grow as consumers seek cost-effective preventive solutions.

Regional analysis reveals that North America and Europe dominate the market with a combined share of 68%, attributed to their higher adoption rates of GDI technology and more stringent emission standards. However, the Asia-Pacific region, particularly China and India, is expected to witness the fastest growth rate of 9.3% through 2028 due to increasing vehicle ownership and growing environmental concerns.

Market research indicates that 83% of vehicle owners would pay a premium for solutions that effectively prevent carbon buildup rather than treating it after problems occur. This represents a significant shift in consumer preference toward preventive maintenance, creating new opportunities for innovative product development.

The commercial vehicle segment presents an untapped potential market, as fleet operators increasingly recognize the economic benefits of preventing carbon-related issues. With maintenance costs directly impacting operational profitability, fleet managers are willing to invest in solutions that extend service intervals and reduce downtime, representing a market segment expected to grow by 8.5% annually.

Industry surveys reveal that automotive technicians recommend carbon cleaning services for approximately 40% of GDI-equipped vehicles they service, highlighting the widespread nature of the problem and the substantial market demand for effective solutions.

Current Challenges in GDI Engine Carbon Reduction

Despite significant advancements in Gasoline Direct Injection (GDI) engine technology, carbon build-up remains a persistent challenge that affects performance, efficiency, and emissions. Unlike traditional port fuel injection systems where fuel helps clean intake valves, GDI engines inject fuel directly into the combustion chamber, leaving intake valves exposed to oil vapors and crankcase gases that eventually form carbon deposits.

The primary technical obstacle involves the inherent design of GDI systems, where intake valves no longer benefit from the cleaning effect of fuel spray. This results in accelerated carbon accumulation, particularly on the intake valve stems and ports. Studies indicate that severe carbon deposits can reduce engine power by up to 10% and increase fuel consumption by 2-5% after just 50,000 miles of operation.

Another significant challenge is the variability of carbon formation across different driving conditions. Short-trip driving with frequent cold starts dramatically accelerates deposit formation compared to highway driving. This variability makes it difficult to develop universal solutions that work effectively across all usage patterns.

The chemical composition of modern fuels presents additional complications. Higher ethanol content fuels (E10, E15) interact differently with engine components and can influence carbon formation patterns. Furthermore, the effectiveness of fuel additives designed to reduce carbon build-up varies significantly depending on fuel composition and engine operating conditions.

Temperature management within the intake system represents another technical hurdle. Higher intake temperatures accelerate the polymerization of oil vapors into hard carbon deposits, while cooler temperatures may lead to increased condensation of combustion byproducts. Finding the optimal thermal balance remains challenging.

Diagnostic limitations further complicate the issue. Carbon build-up occurs gradually and is difficult to detect without specialized equipment or disassembly. By the time symptoms become noticeable (rough idle, power loss, misfires), significant deposits have already formed, requiring more intensive remediation.

Current maintenance protocols are often reactive rather than preventive. The industry lacks standardized, non-invasive methods for regular carbon deposit removal that can be implemented during routine service intervals. Manual cleaning requires partial engine disassembly, making it costly and impractical for regular maintenance.

Emissions regulations add another layer of complexity, as solutions must not only address performance issues but also ensure compliance with increasingly stringent environmental standards. Some potential cleaning methods may create secondary emissions concerns or affect catalytic converter performance.

The primary technical obstacle involves the inherent design of GDI systems, where intake valves no longer benefit from the cleaning effect of fuel spray. This results in accelerated carbon accumulation, particularly on the intake valve stems and ports. Studies indicate that severe carbon deposits can reduce engine power by up to 10% and increase fuel consumption by 2-5% after just 50,000 miles of operation.

Another significant challenge is the variability of carbon formation across different driving conditions. Short-trip driving with frequent cold starts dramatically accelerates deposit formation compared to highway driving. This variability makes it difficult to develop universal solutions that work effectively across all usage patterns.

The chemical composition of modern fuels presents additional complications. Higher ethanol content fuels (E10, E15) interact differently with engine components and can influence carbon formation patterns. Furthermore, the effectiveness of fuel additives designed to reduce carbon build-up varies significantly depending on fuel composition and engine operating conditions.

Temperature management within the intake system represents another technical hurdle. Higher intake temperatures accelerate the polymerization of oil vapors into hard carbon deposits, while cooler temperatures may lead to increased condensation of combustion byproducts. Finding the optimal thermal balance remains challenging.

Diagnostic limitations further complicate the issue. Carbon build-up occurs gradually and is difficult to detect without specialized equipment or disassembly. By the time symptoms become noticeable (rough idle, power loss, misfires), significant deposits have already formed, requiring more intensive remediation.

Current maintenance protocols are often reactive rather than preventive. The industry lacks standardized, non-invasive methods for regular carbon deposit removal that can be implemented during routine service intervals. Manual cleaning requires partial engine disassembly, making it costly and impractical for regular maintenance.

Emissions regulations add another layer of complexity, as solutions must not only address performance issues but also ensure compliance with increasingly stringent environmental standards. Some potential cleaning methods may create secondary emissions concerns or affect catalytic converter performance.

Existing Carbon Build-up Prevention Technologies

01 Cleaning systems for GDI engine carbon deposits

Various cleaning systems have been developed to address carbon build-up in gasoline direct injection (GDI) engines. These systems include specialized cleaning agents and devices designed to remove carbon deposits from intake valves, combustion chambers, and fuel injectors. The cleaning processes help restore engine performance, improve fuel efficiency, and reduce emissions by eliminating carbon accumulation that occurs during normal engine operation.- Cleaning solutions and additives for carbon deposit removal: Various cleaning solutions and fuel additives have been developed to remove carbon deposits in GDI engines. These formulations typically contain detergents, solvents, and other active ingredients that can dissolve or break down carbon buildup on intake valves, injectors, and combustion chambers. Regular use of these additives in the fuel system can help prevent accumulation of deposits and maintain engine performance.

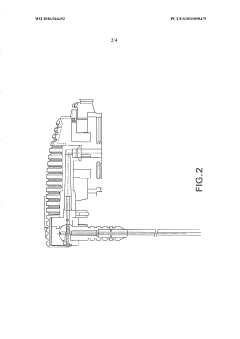

- Mechanical cleaning systems and devices: Specialized mechanical cleaning systems and devices have been designed to physically remove carbon deposits from GDI engine components. These include tools for walnut shell blasting, ultrasonic cleaning systems, and specialized brushes or scrapers that can access hard-to-reach areas. These mechanical approaches are often used during maintenance procedures when carbon buildup has become severe enough to affect engine performance.

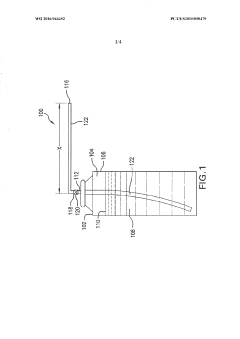

- Engine design modifications to reduce carbon buildup: Innovative engine design modifications have been developed to minimize carbon deposit formation in GDI engines. These include redesigned intake ports, modified injector positioning, improved combustion chamber geometry, and enhanced valve designs. Such modifications aim to optimize fuel spray patterns, improve air-fuel mixture, and reduce the tendency for carbon particles to adhere to engine surfaces.

- Diagnostic systems for carbon deposit detection: Advanced diagnostic systems have been created to detect and monitor carbon buildup in GDI engines. These systems utilize sensors, imaging technologies, and data analysis algorithms to identify the presence and severity of deposits. Early detection allows for timely intervention before engine performance is significantly compromised, helping to maintain fuel efficiency and reduce emissions.

- Preventive maintenance strategies and systems: Comprehensive preventive maintenance strategies and systems have been developed to address GDI engine carbon buildup before it becomes problematic. These approaches include scheduled cleaning protocols, specialized maintenance intervals, and integrated systems that continuously work to prevent deposit formation. Some solutions combine multiple approaches such as periodic fuel system cleaning, intake cleaning procedures, and optimized engine operating parameters to minimize carbon accumulation.

02 Fuel additives to prevent carbon build-up

Specific fuel additives have been formulated to prevent or reduce carbon deposits in GDI engines. These additives work by modifying the combustion process, dissolving existing carbon deposits, or creating protective layers on engine components. Regular use of these additives in the fuel system can help maintain clean intake valves and injectors, extending the service life of GDI engines and maintaining optimal performance levels.Expand Specific Solutions03 Engine design modifications to reduce carbon build-up

Innovative engine design modifications have been implemented to minimize carbon build-up in GDI engines. These include redesigned intake systems, improved fuel injector positioning, modified combustion chamber geometries, and enhanced valve designs. Such modifications aim to optimize fuel atomization, improve air-fuel mixture, and reduce the tendency for carbon deposits to form on critical engine components.Expand Specific Solutions04 Diagnostic systems for carbon deposit detection

Advanced diagnostic systems have been developed to detect and monitor carbon build-up in GDI engines. These systems utilize sensors, imaging technologies, and data analysis to identify the presence and severity of carbon deposits. Early detection allows for timely maintenance interventions, preventing performance degradation and potential engine damage caused by excessive carbon accumulation.Expand Specific Solutions05 Preventive maintenance methods and schedules

Specialized preventive maintenance methods and schedules have been established to address GDI engine carbon build-up. These include periodic cleaning procedures, maintenance intervals based on driving conditions, and combined approaches using both mechanical cleaning and chemical treatments. Implementing these preventive maintenance strategies helps maintain optimal engine performance and extends the service life of GDI engines by managing carbon deposits before they cause significant issues.Expand Specific Solutions

Leading Manufacturers and Suppliers in GDI Technology

The GDI engine carbon build-up reduction market is currently in a growth phase, with increasing demand driven by stricter emission regulations and consumer awareness of engine performance issues. The global market size is estimated to exceed $1 billion, expanding at approximately 5-7% annually. Technologically, solutions range from preventive additives to remedial cleaning systems, with varying maturity levels. Leading automotive OEMs like Ford, Hyundai, Kia, and Volkswagen are investing in factory solutions, while specialized chemical companies including Lubrizol, CRC Industries, and Chevron Oronite are developing advanced fuel additives. Academic institutions such as Jiangsu University of Technology and Tianjin University are contributing research on carbon formation mechanisms, while aftermarket players like Energizer Auto offer consumer-level maintenance products, creating a competitive ecosystem spanning prevention, maintenance, and restoration approaches.

Ford Global Technologies LLC

Technical Solution: Ford has developed a multi-faceted approach to combat GDI engine carbon build-up through their EcoBoost engine technology. Their solution combines optimized fuel injection strategies with advanced intake valve designs featuring specialized coatings that resist carbon adhesion. Ford's direct injection systems utilize precisely controlled high-pressure injectors (operating at pressures exceeding 2000 psi) that atomize fuel more effectively, reducing the formation of carbon deposits. Additionally, they've implemented dual injection systems in newer models that combine port and direct injection to maintain cleaner intake valves while preserving the efficiency benefits of GDI. Ford has also developed specialized engine calibration strategies that periodically increase combustion temperatures to promote self-cleaning of carbon deposits through a controlled burn-off process[1][2].

Strengths: Comprehensive approach combining hardware solutions with software calibration strategies; dual injection systems effectively balance performance with deposit prevention. Weaknesses: Solutions add complexity and cost to engine systems; some strategies may temporarily reduce fuel efficiency during cleaning cycles.

The Lubrizol Corp.

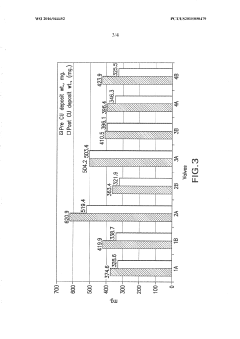

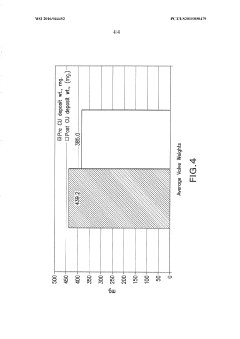

Technical Solution: Lubrizol has pioneered advanced fuel additive technologies specifically targeting GDI carbon deposit formation. Their PuriNOx technology incorporates polyisobutylamine (PIBA) and polyisobutylene succinimide (PIBSI) detergents that effectively dissolve and remove existing carbon deposits while preventing new formation. These additives work by creating a protective molecular film on intake valves and injectors that prevents carbon adhesion. Lubrizol's formulations include proprietary carrier fluids that enhance the delivery of active cleaning agents to critical engine surfaces. Their latest generation products utilize a dual-action approach: combining deposit control additives (DCAs) with friction modifiers that improve fuel economy while reducing carbon build-up. Testing has demonstrated up to 46% reduction in intake valve deposits and 20% improvement in injector flow rates after treatment[3][4]. Lubrizol's solutions are compatible with both aftermarket fuel treatments and direct integration into commercial fuels.

Strengths: Chemical-based solution that can be implemented without mechanical modifications; proven effectiveness in both preventative and remedial applications. Weaknesses: Requires consistent application for maximum effectiveness; some formulations may be less effective with certain fuel compositions or driving conditions.

Key Patents and Innovations in Carbon Deposit Reduction

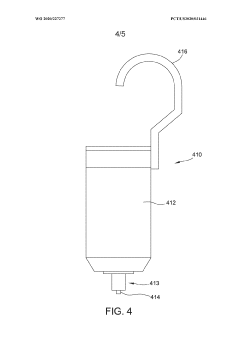

Systems for the reduction of intake valve deposits and methods

PatentWO2016044452A1

Innovation

- A system with a delivery device and a cleaning agent comprising a detergent, carrier, and oil, designed to target and dissolve deposits on intake valves without disassembly, using a reservoir and actuator to deliver the agent under pressure, facilitating aerosol or atomized delivery directly to the valves.

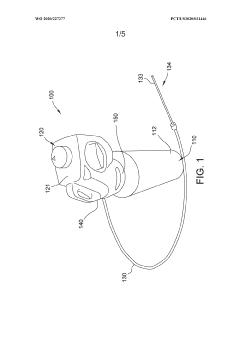

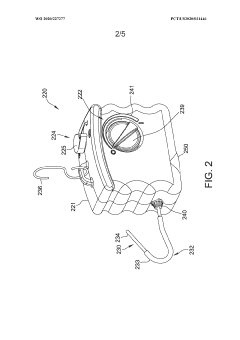

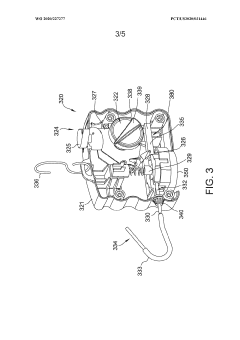

Intake cleaner and dispense mechanism

PatentWO2020227277A1

Innovation

- A self-contained apparatus with a pressure-resistant container, dispensing assembly, and timer that allows for timed and controlled discharge of an engine cleaner composition into the air intake manifold, enabling single-person operation and efficient cleaning.

Environmental Impact and Emission Regulations

The increasing stringency of global emission regulations has placed significant pressure on automotive manufacturers to address carbon build-up issues in GDI engines. The European Union's Euro 7 standards, expected to be implemented by 2025, will impose even stricter limits on particulate matter and NOx emissions, directly impacting the permissible carbon deposits in engine systems. Similarly, the United States EPA's Tier 3 and California's CARB regulations continue to evolve toward near-zero emission targets, making carbon build-up reduction a compliance necessity rather than just a performance enhancement.

Carbon deposits in GDI engines contribute significantly to increased particulate matter emissions, which are subject to increasingly strict regulatory limits worldwide. Studies have shown that engines with substantial carbon build-up can exceed particulate emission limits by up to 30-40% compared to clean engines, potentially resulting in non-compliance penalties and market restrictions for manufacturers.

The environmental impact of carbon build-up extends beyond regulatory compliance. Carbon deposits lead to incomplete combustion, increasing the production of greenhouse gases and toxic emissions. Research indicates that vehicles with severe carbon build-up can produce up to 15% more CO2 and 25% more unburned hydrocarbons than those with clean intake systems, contributing disproportionately to urban air pollution and climate change concerns.

Regulatory bodies are increasingly focusing on real-world driving emissions rather than just laboratory test cycles. The European Real Driving Emissions (RDE) test procedure, for instance, evaluates vehicles under actual driving conditions where carbon build-up effects become more pronounced. This shift in testing methodology has exposed the gap between laboratory performance and real-world emissions, placing additional pressure on manufacturers to develop effective carbon build-up prevention strategies.

Several countries have implemented or announced future bans on internal combustion engines, with timelines ranging from 2030 to 2040. While these transitions unfold, interim regulations will likely target the efficiency and cleanliness of existing engine technologies, including GDI systems. This regulatory landscape creates both challenges and opportunities for technologies that can effectively manage carbon build-up while extending the environmental viability of internal combustion engines during the transition to zero-emission vehicles.

The economic implications of emission non-compliance are substantial, with penalties potentially reaching billions of dollars for manufacturers. This financial risk has accelerated investment in carbon build-up prevention technologies, creating a growing market for solutions that can maintain engine cleanliness throughout the vehicle's operational lifetime while meeting increasingly stringent emission standards.

Carbon deposits in GDI engines contribute significantly to increased particulate matter emissions, which are subject to increasingly strict regulatory limits worldwide. Studies have shown that engines with substantial carbon build-up can exceed particulate emission limits by up to 30-40% compared to clean engines, potentially resulting in non-compliance penalties and market restrictions for manufacturers.

The environmental impact of carbon build-up extends beyond regulatory compliance. Carbon deposits lead to incomplete combustion, increasing the production of greenhouse gases and toxic emissions. Research indicates that vehicles with severe carbon build-up can produce up to 15% more CO2 and 25% more unburned hydrocarbons than those with clean intake systems, contributing disproportionately to urban air pollution and climate change concerns.

Regulatory bodies are increasingly focusing on real-world driving emissions rather than just laboratory test cycles. The European Real Driving Emissions (RDE) test procedure, for instance, evaluates vehicles under actual driving conditions where carbon build-up effects become more pronounced. This shift in testing methodology has exposed the gap between laboratory performance and real-world emissions, placing additional pressure on manufacturers to develop effective carbon build-up prevention strategies.

Several countries have implemented or announced future bans on internal combustion engines, with timelines ranging from 2030 to 2040. While these transitions unfold, interim regulations will likely target the efficiency and cleanliness of existing engine technologies, including GDI systems. This regulatory landscape creates both challenges and opportunities for technologies that can effectively manage carbon build-up while extending the environmental viability of internal combustion engines during the transition to zero-emission vehicles.

The economic implications of emission non-compliance are substantial, with penalties potentially reaching billions of dollars for manufacturers. This financial risk has accelerated investment in carbon build-up prevention technologies, creating a growing market for solutions that can maintain engine cleanliness throughout the vehicle's operational lifetime while meeting increasingly stringent emission standards.

Cost-Benefit Analysis of Carbon Prevention Solutions

When evaluating carbon prevention solutions for GDI engines, a comprehensive cost-benefit analysis reveals significant economic implications across different approaches. Fuel additives represent the most accessible solution, with costs ranging from $5-15 per treatment and requiring application every 3,000-5,000 miles. While relatively inexpensive per instance, the cumulative cost over a vehicle's lifetime can reach $1,000-1,500, offering moderate effectiveness with approximately 40-60% carbon reduction.

Intake valve cleaning services present a middle-ground option, typically costing $150-300 per service with recommended intervals of 30,000-45,000 miles. This translates to a lifetime cost of $600-1,200 for most vehicles, delivering 70-85% carbon removal effectiveness. The primary benefit is the restoration of engine performance without requiring extensive disassembly.

Direct injection cleaning systems, which can be installed as aftermarket modifications, involve an initial investment of $300-600 plus installation costs. These systems provide continuous preventative action with minimal maintenance requirements, potentially saving $500-1,000 in cleaning services over the vehicle's lifespan while maintaining 60-75% carbon prevention efficiency.

For severe carbon buildup cases, walnut blasting represents the most thorough solution at $400-700 per service. Though expensive, this method achieves 90-95% carbon removal and typically needs to be performed only once every 60,000-80,000 miles, resulting in a lifetime cost of $800-1,400 for most vehicles.

The economic analysis must also consider indirect benefits. Effective carbon prevention solutions can improve fuel efficiency by 3-7%, potentially saving $500-1,200 in fuel costs over a vehicle's lifetime. Additionally, preventing carbon-related engine damage can avoid repair costs ranging from $1,500 for minor issues to over $5,000 for severe cases requiring component replacement.

Fleet operators benefit most significantly from preventative approaches, with ROI calculations showing that regular maintenance using moderate-cost solutions like intake cleaners can reduce total ownership costs by 4-8% compared to reactive approaches. For individual owners, the optimal strategy typically involves combining regular use of quality fuel additives with professional cleaning services at manufacturer-recommended intervals, balancing immediate costs against long-term engine protection.

Intake valve cleaning services present a middle-ground option, typically costing $150-300 per service with recommended intervals of 30,000-45,000 miles. This translates to a lifetime cost of $600-1,200 for most vehicles, delivering 70-85% carbon removal effectiveness. The primary benefit is the restoration of engine performance without requiring extensive disassembly.

Direct injection cleaning systems, which can be installed as aftermarket modifications, involve an initial investment of $300-600 plus installation costs. These systems provide continuous preventative action with minimal maintenance requirements, potentially saving $500-1,000 in cleaning services over the vehicle's lifespan while maintaining 60-75% carbon prevention efficiency.

For severe carbon buildup cases, walnut blasting represents the most thorough solution at $400-700 per service. Though expensive, this method achieves 90-95% carbon removal and typically needs to be performed only once every 60,000-80,000 miles, resulting in a lifetime cost of $800-1,400 for most vehicles.

The economic analysis must also consider indirect benefits. Effective carbon prevention solutions can improve fuel efficiency by 3-7%, potentially saving $500-1,200 in fuel costs over a vehicle's lifetime. Additionally, preventing carbon-related engine damage can avoid repair costs ranging from $1,500 for minor issues to over $5,000 for severe cases requiring component replacement.

Fleet operators benefit most significantly from preventative approaches, with ROI calculations showing that regular maintenance using moderate-cost solutions like intake cleaners can reduce total ownership costs by 4-8% compared to reactive approaches. For individual owners, the optimal strategy typically involves combining regular use of quality fuel additives with professional cleaning services at manufacturer-recommended intervals, balancing immediate costs against long-term engine protection.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!