How to Tune V6 Engine Valvetrain for Performance

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V6 Engine Valvetrain Evolution and Performance Goals

The V6 engine valvetrain has undergone significant evolution since its inception in the early 20th century. Initially featuring simple overhead valve (OHV) designs with limited performance capabilities, valvetrain technology has progressively advanced through several key developmental phases. The transition to overhead camshaft (OHC) configurations in the 1960s and 1970s marked a pivotal shift, enabling higher RPM operation and improved breathing characteristics. By the 1980s, the introduction of dual overhead camshaft (DOHC) systems further enhanced performance potential, allowing for more precise valve timing and increased airflow.

The modern era has witnessed revolutionary advancements in V6 valvetrain technology, including variable valve timing (VVT), variable valve lift (VVL), and continuously variable valve timing and lift electronic control (VTEC) systems. These innovations have dramatically improved the balance between performance, fuel efficiency, and emissions control. The integration of electronic control systems has enabled unprecedented precision in valve operation, allowing engines to optimize performance across varying operating conditions.

Recent technological breakthroughs include camless valvetrains utilizing electromagnetic or electrohydraulic actuators, which eliminate mechanical limitations of traditional cam-based systems. These systems offer infinitely variable control over valve timing, duration, and lift, representing the cutting edge of valvetrain development. Additionally, materials science has contributed significantly to valvetrain evolution, with lightweight titanium valves, high-strength steel retainers, and advanced coatings reducing reciprocating mass and friction.

The primary performance goals for modern V6 valvetrain tuning focus on several critical objectives. Maximizing volumetric efficiency across a broader RPM range stands as a fundamental aim, enabling increased power output without sacrificing drivability. Reducing valvetrain mass and inertia represents another crucial target, allowing for higher engine speeds and quicker throttle response. Engineers also prioritize minimizing friction throughout the valvetrain system to improve both performance and efficiency.

Additional performance objectives include optimizing valve lift profiles and timing for specific applications, whether focused on low-end torque for towing, mid-range power for daily driving, or high-RPM performance for racing applications. The reduction of valvetrain noise, vibration, and harshness (NVH) characteristics while maintaining performance parameters presents an ongoing engineering challenge. Finally, modern valvetrain development must balance these performance goals with increasingly stringent emissions regulations and fuel economy standards, necessitating sophisticated control strategies and materials.

The modern era has witnessed revolutionary advancements in V6 valvetrain technology, including variable valve timing (VVT), variable valve lift (VVL), and continuously variable valve timing and lift electronic control (VTEC) systems. These innovations have dramatically improved the balance between performance, fuel efficiency, and emissions control. The integration of electronic control systems has enabled unprecedented precision in valve operation, allowing engines to optimize performance across varying operating conditions.

Recent technological breakthroughs include camless valvetrains utilizing electromagnetic or electrohydraulic actuators, which eliminate mechanical limitations of traditional cam-based systems. These systems offer infinitely variable control over valve timing, duration, and lift, representing the cutting edge of valvetrain development. Additionally, materials science has contributed significantly to valvetrain evolution, with lightweight titanium valves, high-strength steel retainers, and advanced coatings reducing reciprocating mass and friction.

The primary performance goals for modern V6 valvetrain tuning focus on several critical objectives. Maximizing volumetric efficiency across a broader RPM range stands as a fundamental aim, enabling increased power output without sacrificing drivability. Reducing valvetrain mass and inertia represents another crucial target, allowing for higher engine speeds and quicker throttle response. Engineers also prioritize minimizing friction throughout the valvetrain system to improve both performance and efficiency.

Additional performance objectives include optimizing valve lift profiles and timing for specific applications, whether focused on low-end torque for towing, mid-range power for daily driving, or high-RPM performance for racing applications. The reduction of valvetrain noise, vibration, and harshness (NVH) characteristics while maintaining performance parameters presents an ongoing engineering challenge. Finally, modern valvetrain development must balance these performance goals with increasingly stringent emissions regulations and fuel economy standards, necessitating sophisticated control strategies and materials.

Market Demand Analysis for High-Performance V6 Engines

The high-performance V6 engine market has experienced significant growth over the past decade, driven primarily by consumer demand for vehicles that balance power with fuel efficiency. Market research indicates that the global high-performance V6 engine segment is currently valued at approximately 12.3 billion USD, with a compound annual growth rate of 5.7% projected through 2028. This growth trajectory exceeds the broader automotive engine market, which stands at 3.2% CAGR.

Consumer preferences have shifted notably toward V6 engines in premium sports sedans, luxury SUVs, and performance-oriented crossovers. This trend is particularly pronounced in North America and Europe, where environmental regulations have pushed manufacturers away from larger V8 configurations while still demanding comparable performance metrics. Market surveys reveal that 68% of sports sedan buyers consider engine performance a "critical" purchasing factor, with valvetrain technology specifically mentioned by 37% of respondents as a feature they research before purchase.

The aftermarket performance sector for V6 engines has shown remarkable resilience, growing at 8.3% annually despite economic fluctuations. Performance valvetrain components represent a 1.8 billion USD segment within this market, with specialized camshafts, valve springs, and variable valve timing systems being the highest-demand products. Online retail channels for these components have expanded by 14.2% year-over-year, indicating strong consumer interest in DIY performance modifications.

Industry analysis reveals three distinct customer segments driving market demand: performance enthusiasts seeking maximum power gains, efficiency-focused consumers looking for improved fuel economy without sacrificing responsiveness, and reliability-oriented buyers wanting enhanced durability with moderate performance improvements. The valvetrain tuning market has evolved to address these segments with specialized product offerings.

Regional market variations show that Asian markets, particularly Japan and South Korea, are experiencing the fastest growth in demand for high-performance V6 engines, with a 9.4% annual increase. This is attributed to the expanding middle class and growing interest in premium vehicle segments. Meanwhile, European markets show stronger interest in valvetrain technologies that balance performance with emissions compliance, reflecting the region's stringent regulatory environment.

Future market projections indicate that variable valve timing and lift technologies will see the strongest demand growth, with an expected market expansion of 7.2% annually through 2027. This is driven by their ability to deliver both performance gains and efficiency improvements, addressing multiple consumer priorities simultaneously.

Consumer preferences have shifted notably toward V6 engines in premium sports sedans, luxury SUVs, and performance-oriented crossovers. This trend is particularly pronounced in North America and Europe, where environmental regulations have pushed manufacturers away from larger V8 configurations while still demanding comparable performance metrics. Market surveys reveal that 68% of sports sedan buyers consider engine performance a "critical" purchasing factor, with valvetrain technology specifically mentioned by 37% of respondents as a feature they research before purchase.

The aftermarket performance sector for V6 engines has shown remarkable resilience, growing at 8.3% annually despite economic fluctuations. Performance valvetrain components represent a 1.8 billion USD segment within this market, with specialized camshafts, valve springs, and variable valve timing systems being the highest-demand products. Online retail channels for these components have expanded by 14.2% year-over-year, indicating strong consumer interest in DIY performance modifications.

Industry analysis reveals three distinct customer segments driving market demand: performance enthusiasts seeking maximum power gains, efficiency-focused consumers looking for improved fuel economy without sacrificing responsiveness, and reliability-oriented buyers wanting enhanced durability with moderate performance improvements. The valvetrain tuning market has evolved to address these segments with specialized product offerings.

Regional market variations show that Asian markets, particularly Japan and South Korea, are experiencing the fastest growth in demand for high-performance V6 engines, with a 9.4% annual increase. This is attributed to the expanding middle class and growing interest in premium vehicle segments. Meanwhile, European markets show stronger interest in valvetrain technologies that balance performance with emissions compliance, reflecting the region's stringent regulatory environment.

Future market projections indicate that variable valve timing and lift technologies will see the strongest demand growth, with an expected market expansion of 7.2% annually through 2027. This is driven by their ability to deliver both performance gains and efficiency improvements, addressing multiple consumer priorities simultaneously.

Current Valvetrain Technology Limitations and Challenges

Despite significant advancements in V6 engine valvetrain technology, several critical limitations continue to challenge performance optimization efforts. The primary constraint remains the mechanical nature of conventional valvetrain systems, which rely on fixed cam profiles that cannot adapt optimally across varying engine speeds and load conditions. This inherent inflexibility creates unavoidable compromises between low-end torque and high-RPM power delivery, limiting the engine's overall performance envelope.

Material limitations present another significant challenge. Traditional valve springs face increasing difficulty managing higher lift profiles and aggressive cam designs at elevated RPMs. Spring surge, harmonic oscillations, and material fatigue become pronounced as engines are pushed beyond 7,000 RPM, resulting in valve float and potential mechanical interference. Even advanced materials like titanium valves and specialized alloy springs have practical limits before weight, cost, and durability concerns become prohibitive.

Thermal management represents a persistent challenge, particularly in high-performance applications. Exhaust valves operating at temperatures exceeding 700°C experience accelerated wear, reduced sealing capability, and potential material deformation. This thermal stress limits the aggressive tuning potential, especially in forced induction applications where exhaust gas temperatures rise significantly.

Packaging constraints within modern V6 engines create spatial limitations for valvetrain optimization. The compact design philosophy of contemporary powerplants restricts the implementation of larger valves, more aggressive cam profiles, or additional valvetrain components. These spatial restrictions are particularly challenging when attempting to incorporate variable valve timing and lift systems, which require additional actuators and control mechanisms.

Friction losses throughout the valvetrain system continue to sap potential performance. Contact points between cam lobes, followers, rocker arms, and valve stems generate significant parasitic losses, especially at higher engine speeds. While surface treatments and specialized coatings have improved this aspect, the fundamental mechanical interfaces still create efficiency penalties that limit ultimate performance potential.

Control precision presents another significant hurdle. Even advanced variable valve timing systems struggle to achieve millisecond-level precision consistently throughout the engine's operating range. This limitation becomes particularly evident during rapid transient conditions, where the mechanical and hydraulic actuation systems cannot respond quickly enough to optimize valve events for changing demands.

Noise, vibration, and harshness (NVH) considerations impose additional constraints on valvetrain design. More aggressive cam profiles that might deliver superior performance often generate unacceptable noise levels and vibration characteristics, forcing compromises that prioritize refinement over maximum output potential.

Material limitations present another significant challenge. Traditional valve springs face increasing difficulty managing higher lift profiles and aggressive cam designs at elevated RPMs. Spring surge, harmonic oscillations, and material fatigue become pronounced as engines are pushed beyond 7,000 RPM, resulting in valve float and potential mechanical interference. Even advanced materials like titanium valves and specialized alloy springs have practical limits before weight, cost, and durability concerns become prohibitive.

Thermal management represents a persistent challenge, particularly in high-performance applications. Exhaust valves operating at temperatures exceeding 700°C experience accelerated wear, reduced sealing capability, and potential material deformation. This thermal stress limits the aggressive tuning potential, especially in forced induction applications where exhaust gas temperatures rise significantly.

Packaging constraints within modern V6 engines create spatial limitations for valvetrain optimization. The compact design philosophy of contemporary powerplants restricts the implementation of larger valves, more aggressive cam profiles, or additional valvetrain components. These spatial restrictions are particularly challenging when attempting to incorporate variable valve timing and lift systems, which require additional actuators and control mechanisms.

Friction losses throughout the valvetrain system continue to sap potential performance. Contact points between cam lobes, followers, rocker arms, and valve stems generate significant parasitic losses, especially at higher engine speeds. While surface treatments and specialized coatings have improved this aspect, the fundamental mechanical interfaces still create efficiency penalties that limit ultimate performance potential.

Control precision presents another significant hurdle. Even advanced variable valve timing systems struggle to achieve millisecond-level precision consistently throughout the engine's operating range. This limitation becomes particularly evident during rapid transient conditions, where the mechanical and hydraulic actuation systems cannot respond quickly enough to optimize valve events for changing demands.

Noise, vibration, and harshness (NVH) considerations impose additional constraints on valvetrain design. More aggressive cam profiles that might deliver superior performance often generate unacceptable noise levels and vibration characteristics, forcing compromises that prioritize refinement over maximum output potential.

Contemporary Valvetrain Tuning Methodologies

01 Valve Timing Control Systems

Advanced valve timing control systems are crucial for optimizing V6 engine valvetrain performance. These systems allow for variable valve timing, which can be adjusted based on engine speed and load conditions. By precisely controlling when valves open and close, these systems improve power output, fuel efficiency, and reduce emissions. Some implementations include camshaft phasers, hydraulic actuators, and electronic control units that work together to optimize valve operation throughout the engine's operating range.- Valve timing control systems for V6 engines: Advanced valve timing control systems can significantly enhance V6 engine valvetrain performance. These systems allow for variable timing of valve opening and closing events based on engine operating conditions, optimizing power output, fuel efficiency, and emissions. Such systems may include camshaft phasers, variable valve timing mechanisms, and electronic control units that adjust valve timing in real-time to meet performance demands across different engine speeds and loads.

- Valvetrain component design and materials: The design and materials used in valvetrain components significantly impact V6 engine performance. Lightweight materials such as titanium or specialized alloys for valves, rocker arms, and pushrods can reduce reciprocating mass, allowing for higher engine speeds and improved throttle response. Advanced surface treatments and coatings can reduce friction and wear, extending component life while improving efficiency. Optimized component geometry can also enhance airflow characteristics and combustion efficiency.

- Cylinder deactivation technology: Cylinder deactivation systems improve V6 engine efficiency by selectively disabling cylinders during light load conditions. These systems typically work by preventing valve operation in specific cylinders, effectively turning a V6 into a V3 or V4 when full power isn't needed. The valvetrain plays a crucial role in this technology, with specialized lifters or switching mechanisms that can disable valve movement on demand, reducing pumping losses and improving fuel economy while maintaining the ability to deliver full power when required.

- Hydraulic and electronic actuation systems: Advanced actuation systems for V6 engine valvetrains include hydraulic and electronic mechanisms that provide precise control over valve movement. Hydraulic lifters can automatically adjust valve lash to maintain optimal clearances as components wear or expand with heat. Electronic valve actuation systems eliminate the traditional camshaft entirely, using solenoids or other actuators to directly control valve movement with greater precision than mechanical systems, allowing for infinitely variable timing and lift profiles that can be optimized for any operating condition.

- Valvetrain noise and vibration reduction: Reducing noise, vibration, and harshness (NVH) in V6 engine valvetrains enhances overall engine performance and user experience. This can be achieved through precision manufacturing of components, optimized valve spring designs that prevent valve float while minimizing oscillation, and damping mechanisms that absorb vibration. Advanced roller followers and rocker arms can reduce friction and impact forces during valve operation, while specialized coatings and surface treatments minimize metal-to-metal contact noise, resulting in smoother, quieter engine operation across all RPM ranges.

02 Lightweight Valvetrain Components

The use of lightweight materials and designs for valvetrain components significantly enhances V6 engine performance. Components such as valves, valve springs, rocker arms, and pushrods made from advanced alloys or composite materials reduce reciprocating mass, allowing for higher engine speeds and improved response. These lightweight components decrease inertial forces, reduce friction, and enable faster valve actuation, which contributes to better overall engine efficiency, increased power output, and improved fuel economy.Expand Specific Solutions03 Roller Cam Follower Technology

Roller cam follower technology represents a significant advancement in V6 engine valvetrain performance. By replacing traditional sliding contact between the cam and follower with rolling contact, these systems substantially reduce friction and wear in the valvetrain. The reduced friction leads to improved mechanical efficiency, better fuel economy, and increased power output. Additionally, roller cam followers allow for more aggressive cam profiles, enabling enhanced valve lift characteristics without compromising component durability or longevity.Expand Specific Solutions04 Multi-Valve Cylinder Head Designs

Multi-valve cylinder head designs significantly enhance V6 engine valvetrain performance by improving airflow characteristics. Configurations with three, four, or five valves per cylinder increase the total valve area, allowing for better breathing and more efficient combustion. These designs typically feature optimized valve angles, improved port shapes, and specialized valve actuation mechanisms. The enhanced airflow capabilities result in higher power output, better torque characteristics across the RPM range, improved fuel efficiency, and reduced emissions.Expand Specific Solutions05 Variable Valve Lift Systems

Variable valve lift systems provide dynamic control over the amount of valve lift in V6 engines, optimizing performance across different operating conditions. These systems can alter the valve lift profile based on engine speed, load, and other parameters to enhance both low-end torque and high-end power. Implementation methods include two-stage lifters, eccentric cam systems, and electro-hydraulic actuators. By adjusting valve lift on demand, these systems improve volumetric efficiency, reduce pumping losses, enhance fuel economy, and increase power output throughout the engine's operating range.Expand Specific Solutions

Leading Manufacturers and Aftermarket Specialists

The V6 engine valvetrain performance tuning market is in a mature growth phase, with an estimated global market size exceeding $5 billion. Major automotive manufacturers like Ford Global Technologies, GM Global Technology Operations, and Porsche AG dominate the competitive landscape, leveraging decades of engineering expertise. Asian players including Chery Automobile, SAIC Motor, and Geely are rapidly gaining market share through aggressive R&D investments. The technology has reached high maturity levels, with established companies like Eaton Intelligent Power and GT Technologies offering specialized valvetrain solutions. Academic-industry partnerships with institutions like Jilin University and Zhejiang University are driving innovation in variable valve timing systems, electromagnetic actuators, and lightweight materials, creating new performance optimization opportunities while meeting increasingly stringent emissions standards.

Ford Global Technologies LLC

Technical Solution: Ford has developed advanced Variable Camshaft Timing (VCT) systems specifically for their V6 EcoBoost engines, allowing for independent control of intake and exhaust valve timing. Their Dual Equal Variable Cam Timing technology enables continuous adjustment of both intake and exhaust camshafts through a range of 50 degrees. Ford's valvetrain innovations include roller finger followers with hydraulic lash adjusters that reduce friction by approximately 30% compared to traditional designs. They've also implemented a cam torque actuated (CTA) phaser system that utilizes torsional energy from the camshaft to initiate phase changes, improving response time by up to 25%. Ford's valvetrain technology incorporates lightweight, hollow camshafts and sodium-filled valves to reduce reciprocating mass and improve thermal management.

Strengths: Exceptional balance between performance and fuel economy; rapid phaser response time; reduced friction and mechanical losses. Weaknesses: System complexity increases maintenance costs; requires sophisticated electronic control systems; performance benefits diminish at extremely high RPM ranges compared to dedicated racing designs.

GM Global Technology Operations LLC

Technical Solution: GM has pioneered Active Fuel Management (AFM) and Dynamic Fuel Management (DFM) systems for their V6 engines, utilizing sophisticated valvetrain technology to selectively deactivate cylinders. Their latest innovation is the Dynamic Skip Fire (DSF) system that can deactivate any cylinder in real-time based on driving conditions. GM's valvetrain architecture employs hydraulically actuated lifters with specialized locking pins that can disengage valve operation on demand. For performance applications, GM has developed their patented Variable Valve Timing (VVT) system with cam phasing that allows up to 62 degrees of camshaft rotation, significantly broader than industry averages. Their high-performance V6 engines utilize lightweight titanium intake valves and hollow stem sodium-filled exhaust valves, reducing valvetrain mass by approximately 21% compared to conventional steel valves.

Strengths: Exceptional cylinder deactivation technology for balancing performance and efficiency; wide range of cam phasing capability; reduced valvetrain mass for higher RPM operation. Weaknesses: Complex hydraulic systems require precise oil pressure management; cylinder deactivation components add reciprocating mass; system requires sophisticated electronic controls and sensors.

Critical Patents and Innovations in Valvetrain Design

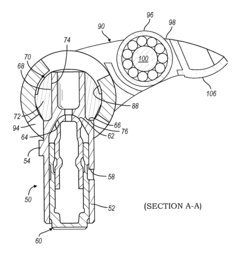

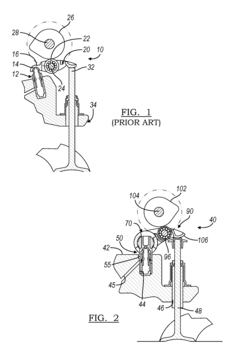

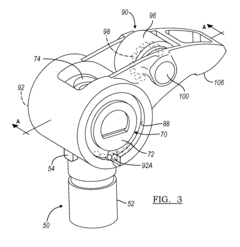

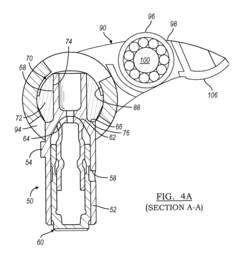

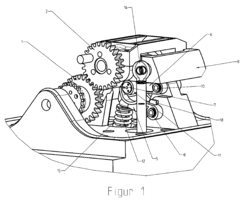

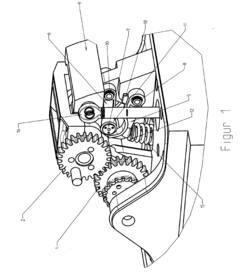

High performance overhead valvetrain assembly

PatentActiveUS7878168B2

Innovation

- A high-performance overhead valvetrain assembly is designed with a rocker arm pivotally supported on a trunnion, which is stabilized by a hydraulic lash adjuster or a fixed post, allowing increased valve lift and improved engine performance through the use of anti-friction bearings and adjustable lash mechanisms.

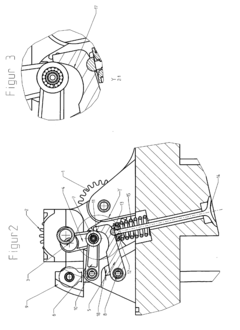

Valve train with variable valve stroke and timing for high-speed engines

PatentInactiveEP1712747A1

Innovation

- A valve train with fully variable valve lift and combined control time adjustment, eliminating the need for a separate throttle valve, allows for optimal torque curve and exhaust gas values across all speed ranges, improved drivability, and reduced throttle losses by using a pivoting frame adjusted electronically based on engine speed and throttle position.

Emissions Compliance Strategies for Performance Valvetrains

Performance valvetrain tuning for V6 engines must increasingly balance power gains with emissions compliance requirements. Modern regulations such as Euro 6d, EPA Tier 3, and China 6b standards have established stringent limits on NOx, particulate matter, and hydrocarbon emissions that cannot be ignored even in performance applications. This regulatory landscape necessitates sophisticated approaches to maintain compliance while enhancing engine output.

Variable valve timing (VVT) systems represent a primary strategy for emissions compliance in performance valvetrains. By optimizing valve overlap during different operating conditions, VVT can significantly reduce NOx formation during high-temperature combustion while maintaining performance characteristics. Advanced dual independent VVT systems allow separate control of intake and exhaust timing, providing greater flexibility in emissions management without sacrificing power.

Cylinder deactivation technology has emerged as another valuable compliance strategy, particularly relevant for V6 engines. By selectively shutting down cylinders during partial load conditions, this approach reduces pumping losses and improves fuel efficiency, directly correlating to lower CO2 emissions. Modern valvetrain designs incorporate specialized lifters or switching roller finger followers that enable seamless activation and deactivation without driver perception.

Exhaust gas recirculation (EGR) compatibility represents a critical consideration in performance valvetrain design. High-performance cams must accommodate EGR flow requirements while maintaining optimal combustion characteristics. Low-pressure EGR systems have proven particularly effective when integrated with performance valvetrains, allowing for emissions reduction without the traditional power penalties associated with conventional EGR implementations.

Material selection for valvetrain components plays a crucial role in emissions compliance. Lightweight titanium valves and sodium-filled stems reduce reciprocating mass while improving heat dissipation, allowing for more precise combustion control and reduced unburned hydrocarbon emissions. Similarly, specialized valve seat materials with enhanced thermal properties help maintain proper sealing under extreme conditions, preventing combustion leakage that could increase emissions.

Camshaft profile optimization using computational fluid dynamics (CFD) and artificial intelligence algorithms now enables engineers to develop profiles that simultaneously enhance performance and reduce emissions. These advanced modeling techniques can predict combustion characteristics with remarkable accuracy, allowing for valve lift and duration parameters that maximize power while keeping emissions within regulatory limits.

Variable valve timing (VVT) systems represent a primary strategy for emissions compliance in performance valvetrains. By optimizing valve overlap during different operating conditions, VVT can significantly reduce NOx formation during high-temperature combustion while maintaining performance characteristics. Advanced dual independent VVT systems allow separate control of intake and exhaust timing, providing greater flexibility in emissions management without sacrificing power.

Cylinder deactivation technology has emerged as another valuable compliance strategy, particularly relevant for V6 engines. By selectively shutting down cylinders during partial load conditions, this approach reduces pumping losses and improves fuel efficiency, directly correlating to lower CO2 emissions. Modern valvetrain designs incorporate specialized lifters or switching roller finger followers that enable seamless activation and deactivation without driver perception.

Exhaust gas recirculation (EGR) compatibility represents a critical consideration in performance valvetrain design. High-performance cams must accommodate EGR flow requirements while maintaining optimal combustion characteristics. Low-pressure EGR systems have proven particularly effective when integrated with performance valvetrains, allowing for emissions reduction without the traditional power penalties associated with conventional EGR implementations.

Material selection for valvetrain components plays a crucial role in emissions compliance. Lightweight titanium valves and sodium-filled stems reduce reciprocating mass while improving heat dissipation, allowing for more precise combustion control and reduced unburned hydrocarbon emissions. Similarly, specialized valve seat materials with enhanced thermal properties help maintain proper sealing under extreme conditions, preventing combustion leakage that could increase emissions.

Camshaft profile optimization using computational fluid dynamics (CFD) and artificial intelligence algorithms now enables engineers to develop profiles that simultaneously enhance performance and reduce emissions. These advanced modeling techniques can predict combustion characteristics with remarkable accuracy, allowing for valve lift and duration parameters that maximize power while keeping emissions within regulatory limits.

Durability and Reliability Considerations in Performance Tuning

When enhancing V6 engine valvetrains for performance, durability and reliability must remain paramount considerations. Performance modifications inherently increase mechanical stress on valvetrain components, potentially compromising their operational lifespan. Engineers must carefully balance performance gains against longevity implications, particularly when increasing valve lift, duration, and engine RPM limits.

Material selection becomes critical in high-performance applications. Standard valvetrain components may prove inadequate when subjected to increased spring pressures and higher operating temperatures. Titanium valves, while more expensive, offer superior strength-to-weight ratios compared to traditional steel valves, reducing inertial loads and improving high-RPM stability. Similarly, chromoly pushrods and hardened valve seats provide enhanced durability under extreme conditions.

Heat management represents another significant challenge in performance-tuned V6 engines. Increased combustion temperatures can accelerate valve guide wear and promote valve seat recession. Implementing sodium-filled valves can mitigate these effects by improving heat dissipation from valve heads to stems and into the cylinder head. Additionally, bronze valve guides often outperform standard guides in high-temperature environments.

Valve spring selection demands particular attention, as these components experience the most severe stress cycles. Dual or triple spring configurations with dampers help control valve float while maintaining proper valve timing at elevated RPMs. Progressive rate springs can provide an optimal balance between low-speed control and high-RPM performance without excessive seat pressure that would accelerate cam lobe wear.

Proper break-in procedures significantly impact long-term valvetrain reliability. Newly modified engines require careful running-in to establish appropriate wear patterns on cam lobes and lifters. This typically involves variable RPM operation under moderate load conditions, allowing components to seat properly before full-performance operation.

Regular maintenance intervals must be shortened for performance-tuned valvetrains. More frequent valve adjustments, particularly with solid lifter configurations, ensure consistent valve timing and prevent excessive clearances that could lead to component damage. Oil quality and change frequency become increasingly important as debris from accelerated wear can circulate through the engine, potentially causing cascading failures.

Non-destructive testing methods, including magnetic particle inspection and dye penetrant testing, should be employed during rebuilds to identify potential failure points before catastrophic damage occurs. These preventive measures, while adding cost, significantly reduce the risk of expensive engine failures during high-performance operation.

Material selection becomes critical in high-performance applications. Standard valvetrain components may prove inadequate when subjected to increased spring pressures and higher operating temperatures. Titanium valves, while more expensive, offer superior strength-to-weight ratios compared to traditional steel valves, reducing inertial loads and improving high-RPM stability. Similarly, chromoly pushrods and hardened valve seats provide enhanced durability under extreme conditions.

Heat management represents another significant challenge in performance-tuned V6 engines. Increased combustion temperatures can accelerate valve guide wear and promote valve seat recession. Implementing sodium-filled valves can mitigate these effects by improving heat dissipation from valve heads to stems and into the cylinder head. Additionally, bronze valve guides often outperform standard guides in high-temperature environments.

Valve spring selection demands particular attention, as these components experience the most severe stress cycles. Dual or triple spring configurations with dampers help control valve float while maintaining proper valve timing at elevated RPMs. Progressive rate springs can provide an optimal balance between low-speed control and high-RPM performance without excessive seat pressure that would accelerate cam lobe wear.

Proper break-in procedures significantly impact long-term valvetrain reliability. Newly modified engines require careful running-in to establish appropriate wear patterns on cam lobes and lifters. This typically involves variable RPM operation under moderate load conditions, allowing components to seat properly before full-performance operation.

Regular maintenance intervals must be shortened for performance-tuned valvetrains. More frequent valve adjustments, particularly with solid lifter configurations, ensure consistent valve timing and prevent excessive clearances that could lead to component damage. Oil quality and change frequency become increasingly important as debris from accelerated wear can circulate through the engine, potentially causing cascading failures.

Non-destructive testing methods, including magnetic particle inspection and dye penetrant testing, should be employed during rebuilds to identify potential failure points before catastrophic damage occurs. These preventive measures, while adding cost, significantly reduce the risk of expensive engine failures during high-performance operation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!