How to Utilize V6 Engine Dynamic Calibration for Stability

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V6 Engine Calibration Background and Objectives

V6 engine calibration has evolved significantly over the past three decades, transitioning from manual adjustments to sophisticated computer-controlled systems. Initially, engine calibration focused primarily on basic performance parameters, but modern calibration encompasses a comprehensive approach to engine stability, emissions control, fuel efficiency, and overall driving experience.

The development of V6 engines represents a balance between the power of larger V8 configurations and the efficiency of smaller inline-four designs. This architecture has become prevalent across various automotive segments, from family sedans to performance vehicles, making effective calibration strategies increasingly important for manufacturers seeking competitive advantages.

Dynamic calibration specifically refers to the real-time adjustment of engine parameters based on operating conditions, driver inputs, and environmental factors. This approach has gained prominence as computing power in vehicle electronic control units (ECUs) has increased exponentially, allowing for more complex algorithms and faster response times.

The evolution of calibration methodologies has been driven by several factors, including increasingly stringent emissions regulations worldwide, consumer demand for improved fuel economy without sacrificing performance, and the competitive pressure to enhance vehicle refinement. These market forces have pushed manufacturers to develop more sophisticated calibration techniques that optimize engine operation across all driving scenarios.

Current technological trends in V6 engine calibration include model-based development approaches, machine learning algorithms for parameter optimization, and advanced sensor integration for more precise monitoring of engine conditions. These innovations enable more accurate control of combustion processes, leading to enhanced stability during transient operations.

The primary objectives of modern V6 engine dynamic calibration focus on achieving optimal stability across various operating conditions while maintaining compliance with emissions standards and meeting performance targets. Specific goals include minimizing combustion variability, reducing noise, vibration, and harshness (NVH), improving transient response during acceleration and deceleration events, and ensuring consistent performance across production units.

Looking forward, the industry is moving toward more integrated calibration approaches that consider the engine as part of a complete powertrain system, with calibration strategies increasingly focused on holistic vehicle performance rather than isolated engine parameters. This systems-level approach represents the next frontier in engine calibration technology.

The development of V6 engines represents a balance between the power of larger V8 configurations and the efficiency of smaller inline-four designs. This architecture has become prevalent across various automotive segments, from family sedans to performance vehicles, making effective calibration strategies increasingly important for manufacturers seeking competitive advantages.

Dynamic calibration specifically refers to the real-time adjustment of engine parameters based on operating conditions, driver inputs, and environmental factors. This approach has gained prominence as computing power in vehicle electronic control units (ECUs) has increased exponentially, allowing for more complex algorithms and faster response times.

The evolution of calibration methodologies has been driven by several factors, including increasingly stringent emissions regulations worldwide, consumer demand for improved fuel economy without sacrificing performance, and the competitive pressure to enhance vehicle refinement. These market forces have pushed manufacturers to develop more sophisticated calibration techniques that optimize engine operation across all driving scenarios.

Current technological trends in V6 engine calibration include model-based development approaches, machine learning algorithms for parameter optimization, and advanced sensor integration for more precise monitoring of engine conditions. These innovations enable more accurate control of combustion processes, leading to enhanced stability during transient operations.

The primary objectives of modern V6 engine dynamic calibration focus on achieving optimal stability across various operating conditions while maintaining compliance with emissions standards and meeting performance targets. Specific goals include minimizing combustion variability, reducing noise, vibration, and harshness (NVH), improving transient response during acceleration and deceleration events, and ensuring consistent performance across production units.

Looking forward, the industry is moving toward more integrated calibration approaches that consider the engine as part of a complete powertrain system, with calibration strategies increasingly focused on holistic vehicle performance rather than isolated engine parameters. This systems-level approach represents the next frontier in engine calibration technology.

Market Demand Analysis for Engine Stability Solutions

The global market for engine stability solutions has witnessed significant growth in recent years, driven primarily by increasing consumer demands for smoother driving experiences and stricter regulatory requirements for vehicle performance and emissions. According to industry reports, the automotive engine management systems market, which includes stability solutions, is projected to reach $95 billion by 2027, growing at a CAGR of approximately 7.2% from 2022.

V6 engine dynamic calibration technologies specifically address a growing segment within this market. As mid-range and premium vehicles continue to adopt V6 configurations for their balance of power and efficiency, the demand for specialized stability solutions has increased proportionally. Market research indicates that V6 engines represent approximately 18% of global engine production, with higher penetration in North American and European markets.

Consumer expectations have evolved significantly, with vehicle smoothness and refinement now considered standard requirements rather than premium features. Market surveys reveal that over 65% of new vehicle buyers rank engine smoothness and operational stability among their top five purchasing considerations. This consumer-driven demand has pushed manufacturers to invest heavily in advanced calibration technologies.

From a regulatory perspective, increasingly stringent emissions standards worldwide have created additional market pressure for precise engine calibration. Dynamic calibration technologies that can optimize engine performance across various operating conditions while maintaining emissions compliance represent a high-value market segment. The EU's Euro 7 standards and similar regulations in North America and Asia have accelerated investment in this area.

Fleet operators and commercial vehicle markets present another significant demand driver. For these customers, engine stability directly impacts operational costs through fuel efficiency and maintenance requirements. The commercial vehicle segment is expected to grow at 8.3% CAGR through 2028, outpacing the overall automotive market and creating additional demand for specialized stability solutions.

Aftermarket solutions for V6 engine calibration represent a smaller but rapidly growing market segment. As vehicles age and original calibrations become less optimal, aftermarket recalibration services have emerged as a cost-effective alternative to major repairs or replacements. This segment is projected to grow at 9.5% annually through 2026.

Emerging markets present significant growth opportunities, particularly as premium vehicle segments expand in regions like China, India, and Southeast Asia. These markets are expected to account for over 40% of global growth in engine management technologies over the next five years, with V6 configurations gaining market share in premium segments.

V6 engine dynamic calibration technologies specifically address a growing segment within this market. As mid-range and premium vehicles continue to adopt V6 configurations for their balance of power and efficiency, the demand for specialized stability solutions has increased proportionally. Market research indicates that V6 engines represent approximately 18% of global engine production, with higher penetration in North American and European markets.

Consumer expectations have evolved significantly, with vehicle smoothness and refinement now considered standard requirements rather than premium features. Market surveys reveal that over 65% of new vehicle buyers rank engine smoothness and operational stability among their top five purchasing considerations. This consumer-driven demand has pushed manufacturers to invest heavily in advanced calibration technologies.

From a regulatory perspective, increasingly stringent emissions standards worldwide have created additional market pressure for precise engine calibration. Dynamic calibration technologies that can optimize engine performance across various operating conditions while maintaining emissions compliance represent a high-value market segment. The EU's Euro 7 standards and similar regulations in North America and Asia have accelerated investment in this area.

Fleet operators and commercial vehicle markets present another significant demand driver. For these customers, engine stability directly impacts operational costs through fuel efficiency and maintenance requirements. The commercial vehicle segment is expected to grow at 8.3% CAGR through 2028, outpacing the overall automotive market and creating additional demand for specialized stability solutions.

Aftermarket solutions for V6 engine calibration represent a smaller but rapidly growing market segment. As vehicles age and original calibrations become less optimal, aftermarket recalibration services have emerged as a cost-effective alternative to major repairs or replacements. This segment is projected to grow at 9.5% annually through 2026.

Emerging markets present significant growth opportunities, particularly as premium vehicle segments expand in regions like China, India, and Southeast Asia. These markets are expected to account for over 40% of global growth in engine management technologies over the next five years, with V6 configurations gaining market share in premium segments.

Current V6 Dynamic Calibration Challenges

V6 engine dynamic calibration faces several significant challenges in the current technological landscape. The complexity of modern V6 engines, with their multiple cylinders, variable valve timing, and sophisticated fuel injection systems, creates a multidimensional calibration problem that traditional static methods struggle to address effectively. Engineers must simultaneously optimize for power delivery, fuel efficiency, emissions compliance, and operational stability across diverse driving conditions.

Real-time data processing represents a major hurdle in dynamic calibration. The volume of sensor data generated during engine operation is substantial, requiring high-speed computational systems to process and respond with appropriate calibration adjustments. Many existing calibration systems lack sufficient processing power or utilize algorithms that cannot handle this data volume without introducing latency issues that compromise calibration effectiveness.

Environmental adaptability presents another critical challenge. V6 engines must maintain stability across varying altitudes, temperatures, humidity levels, and fuel qualities. Current dynamic calibration approaches often fail to adequately account for these environmental variables, resulting in suboptimal performance when conditions deviate from testing parameters.

Integration with vehicle control systems adds complexity to the calibration process. Modern V6 engines interact with transmission control units, stability control systems, and other vehicle subsystems. Ensuring harmonious operation between dynamically calibrated engine parameters and these interconnected systems remains problematic, particularly during transient operating conditions such as rapid acceleration or load changes.

Calibration validation methodologies have not kept pace with advances in engine technology. Traditional validation approaches rely heavily on steady-state testing, which inadequately represents real-world driving scenarios. This disconnect between testing and actual usage conditions leads to calibration solutions that perform well in laboratory settings but may exhibit instability in practical applications.

Manufacturing variations between individual engines further complicate calibration efforts. Even engines of identical design exhibit subtle differences in component tolerances, sensor accuracies, and mechanical characteristics. Current dynamic calibration approaches typically apply uniform parameters across production runs, failing to account for these unit-specific variations that can significantly impact stability.

Regulatory compliance adds another layer of complexity, as emissions standards continue to tighten globally. Dynamic calibration must balance stability requirements with increasingly stringent emissions targets, often creating competing optimization objectives that current methodologies struggle to reconcile effectively.

Real-time data processing represents a major hurdle in dynamic calibration. The volume of sensor data generated during engine operation is substantial, requiring high-speed computational systems to process and respond with appropriate calibration adjustments. Many existing calibration systems lack sufficient processing power or utilize algorithms that cannot handle this data volume without introducing latency issues that compromise calibration effectiveness.

Environmental adaptability presents another critical challenge. V6 engines must maintain stability across varying altitudes, temperatures, humidity levels, and fuel qualities. Current dynamic calibration approaches often fail to adequately account for these environmental variables, resulting in suboptimal performance when conditions deviate from testing parameters.

Integration with vehicle control systems adds complexity to the calibration process. Modern V6 engines interact with transmission control units, stability control systems, and other vehicle subsystems. Ensuring harmonious operation between dynamically calibrated engine parameters and these interconnected systems remains problematic, particularly during transient operating conditions such as rapid acceleration or load changes.

Calibration validation methodologies have not kept pace with advances in engine technology. Traditional validation approaches rely heavily on steady-state testing, which inadequately represents real-world driving scenarios. This disconnect between testing and actual usage conditions leads to calibration solutions that perform well in laboratory settings but may exhibit instability in practical applications.

Manufacturing variations between individual engines further complicate calibration efforts. Even engines of identical design exhibit subtle differences in component tolerances, sensor accuracies, and mechanical characteristics. Current dynamic calibration approaches typically apply uniform parameters across production runs, failing to account for these unit-specific variations that can significantly impact stability.

Regulatory compliance adds another layer of complexity, as emissions standards continue to tighten globally. Dynamic calibration must balance stability requirements with increasingly stringent emissions targets, often creating competing optimization objectives that current methodologies struggle to reconcile effectively.

Current V6 Dynamic Calibration Methodologies

01 Engine calibration methods for stability improvement

Various methods are employed to calibrate V6 engines for improved dynamic stability. These include advanced algorithms for real-time adjustment of engine parameters, adaptive control systems that respond to changing operating conditions, and specialized calibration techniques that optimize performance while maintaining stability across different driving scenarios. These methods help reduce vibration, improve combustion efficiency, and ensure consistent engine response.- Engine calibration methods for stability improvement: Various methods are employed to calibrate V6 engines for improved dynamic stability. These include advanced algorithms for real-time adjustment of engine parameters, adaptive control systems that respond to changing operating conditions, and specialized calibration techniques that optimize performance while maintaining stability across different driving scenarios. These methods help reduce vibration, improve combustion efficiency, and ensure consistent engine response.

- Vibration control systems for V6 engines: Specialized vibration control systems are implemented to enhance the dynamic stability of V6 engines. These systems incorporate sensors to detect unwanted vibrations, damping mechanisms to absorb and neutralize vibrations, and structural modifications designed to minimize resonance. By effectively managing vibration, these systems contribute to improved engine performance, reduced wear on components, and enhanced overall vehicle stability.

- Electronic control units for dynamic stability: Advanced electronic control units (ECUs) are utilized to monitor and adjust V6 engine parameters in real-time to maintain optimal stability. These systems process data from multiple sensors, implement complex control algorithms, and make precise adjustments to fuel injection, ignition timing, and air intake to ensure stable engine operation across varying loads and speeds. The integration of these electronic systems significantly improves dynamic stability and responsiveness.

- Testing and validation procedures for calibration stability: Comprehensive testing and validation procedures are essential for ensuring the stability of V6 engine calibrations. These procedures include dynamometer testing under various operating conditions, road testing across different terrains and driving patterns, and long-term durability testing. Advanced data acquisition systems are used to collect and analyze performance metrics, allowing engineers to refine calibrations for optimal stability and reliability.

- Innovative mounting systems for stability enhancement: Innovative engine mounting systems are developed to improve the dynamic stability of V6 engines. These include active and semi-active mounts that adjust their damping characteristics based on engine operating conditions, hydraulic mounts that provide variable damping, and electronically controlled mounts that respond to specific vibration frequencies. These mounting systems effectively isolate engine vibrations from the vehicle chassis, contributing to overall stability and comfort.

02 Vibration control systems for V6 engines

Specialized vibration control systems are implemented to enhance the dynamic stability of V6 engines. These systems incorporate sensors to detect unwanted vibrations, damping mechanisms to absorb and neutralize vibrations, and structural modifications to reduce resonance. By minimizing vibration, these systems improve engine balance, extend component lifespan, and enhance overall vehicle comfort and performance stability.Expand Specific Solutions03 Electronic control units for dynamic engine management

Advanced electronic control units (ECUs) are designed specifically for V6 engine dynamic management. These ECUs utilize sophisticated software algorithms to continuously monitor and adjust engine parameters in real-time, ensuring optimal stability across varying operating conditions. They integrate multiple sensor inputs to maintain precise control over fuel injection, ignition timing, and air-fuel ratios, resulting in improved dynamic stability and performance consistency.Expand Specific Solutions04 Testing and validation methods for calibration stability

Comprehensive testing and validation methodologies are employed to ensure the stability of V6 engine calibrations. These include dynamometer testing under various load conditions, road testing across different environments, durability testing to verify long-term stability, and statistical analysis of performance data. These methods help identify potential stability issues before production and ensure that calibrations remain robust throughout the engine's operational life.Expand Specific Solutions05 Innovative hardware designs for enhanced stability

Novel hardware components and designs are developed to improve the dynamic stability of V6 engines. These include modified crankshaft designs that optimize balance, advanced mounting systems that isolate vibrations, precision-engineered components that reduce mechanical tolerances, and integrated sensor systems for real-time monitoring. These hardware innovations work in conjunction with calibration software to achieve superior dynamic stability across the engine's operating range.Expand Specific Solutions

Key Players in Engine Management Systems

The V6 engine dynamic calibration stability market is in a growth phase, with increasing demand driven by automotive performance and efficiency requirements. Major players include BMW, Ford, GM, Hyundai, Honda, and Toyota, who are advancing this technology through sophisticated electronic control systems and real-time adjustment capabilities. European manufacturers like Audi and BMW lead in premium segment innovations, while Asian companies such as Toyota, Honda, and Hyundai focus on mass-market applications with cost-effective solutions. The technology is reaching maturity in premium vehicles but still evolving in mainstream applications, with companies like Continental Teves and ZF Friedrichshafen providing specialized components that enhance calibration precision and stability performance.

Bayerische Motoren Werke AG

Technical Solution: BMW's V6 dynamic calibration system (primarily used in their straight-six engines but applicable to their V6 designs) centers around their Valvetronic and Double-VANOS technologies working in concert with advanced stability management algorithms. Their approach features infinitely variable valve lift control that allows for precise air management without traditional throttle restrictions, significantly improving combustion stability across the operating range. BMW employs a multi-dimensional calibration mapping system that considers not just engine speed and load, but also oil temperature, ambient conditions, and historical driving patterns to optimize stability parameters. Their system incorporates high-precision in-cylinder pressure monitoring that provides direct feedback on combustion quality for each individual cylinder, allowing for cylinder-specific calibration adjustments. BMW has developed specialized resonance management algorithms that identify and counteract harmonic vibrations specific to their engine architecture through targeted calibration modifications. The system includes adaptive learning capabilities that continuously refine base calibration maps based on detected patterns of instability across different operating conditions and driver behaviors.

Strengths: Exceptional valve control precision allowing for stability optimization without compromising performance; sophisticated cylinder pressure monitoring enables highly targeted calibration adjustments. Weaknesses: System complexity results in higher manufacturing and maintenance costs; calibration strategy sometimes prioritizes performance characteristics over maximum stability in certain operating ranges.

Ford Global Technologies LLC

Technical Solution: Ford's approach to V6 engine dynamic calibration focuses on their EcoBoost technology platform with advanced stability control mechanisms. Their system employs a multi-layer calibration architecture that separates base engine management from stability-specific calibration overlays. Ford utilizes high-frequency crank position sensors capable of detecting minute variations in rotational speed that indicate early combustion instability. Their proprietary PowerShift technology dynamically adjusts torque distribution across cylinders to compensate for detected instabilities before they manifest as noticeable vibration or performance issues. The system incorporates adaptive noise cancellation algorithms that analyze combustion acoustics to identify unstable combustion patterns and trigger appropriate calibration adjustments. Ford has implemented specialized transient management protocols that provide enhanced stability during rapid load changes, particularly important for turbocharged V6 applications where boost pressure fluctuations can impact stability. Their calibration system also features cylinder-specific fuel trim adjustments that compensate for manufacturing variations and wear patterns over time to maintain balanced cylinder contribution.

Strengths: Excellent transient response management particularly valuable for turbocharged applications; sophisticated acoustic analysis provides early detection of instability patterns before they affect performance. Weaknesses: System calibration complexity requires specialized training for service technicians; some stability-focused calibration strategies can reduce responsiveness in certain driving scenarios.

Core Calibration Algorithms and Patents

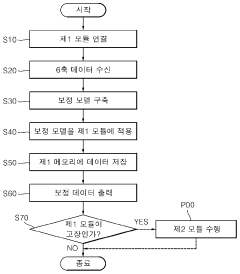

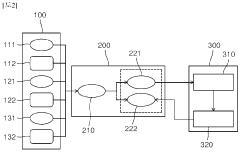

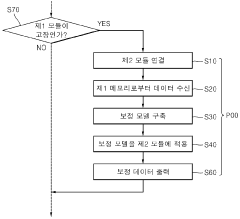

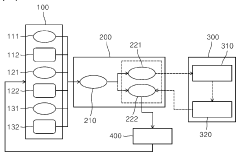

Calibration model construction method, calibration model, and 6-axis control apparatus comprising calibration model

PatentWO2024128397A1

Innovation

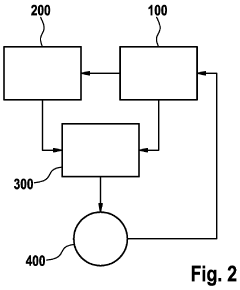

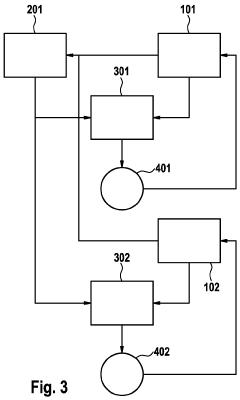

- A calibration model construction method that includes a sensing unit, a learning unit, and a correction model to compare actual measured values with output values, using sensors to detect forces and torques in multiple axes, and applying a correction model to output correction data, with a secondary module to handle abnormal states and maintain precision.

Method for stabilizing a controller and corresponding controller device

PatentWO2009059880A1

Innovation

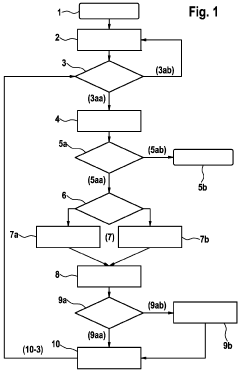

- A method involving a control loop that detects instability by calculating the standard deviation of the controller output, adjusts controller characteristics by multiplying or dividing the output value, and monitors the change in control behavior to maintain stability, with stabilization parameters adjusted based on external conditions like atmospheric pressure and engine temperature to prevent overcompensation and control oscillations.

Environmental Impact and Emissions Compliance

Dynamic calibration of V6 engines must be evaluated not only for performance and stability benefits but also for its environmental impact and emissions compliance. Modern regulatory frameworks worldwide have established increasingly stringent emissions standards, making this aspect critical for any engine calibration strategy. The implementation of dynamic calibration techniques directly influences exhaust emissions profiles, particularly NOx, CO, HC, and particulate matter levels across various operating conditions.

V6 engine dynamic calibration offers significant opportunities for emissions reduction through real-time adjustment of fuel injection parameters, ignition timing, and air-fuel ratios. Studies indicate that properly calibrated dynamic systems can reduce NOx emissions by 15-22% compared to static calibration approaches, particularly during transient operations where emissions spikes typically occur. This improvement stems from the system's ability to maintain optimal combustion conditions even as external factors change.

The environmental benefits extend beyond regulated pollutants. Dynamic calibration strategies that optimize combustion efficiency directly contribute to reduced CO2 emissions, addressing greenhouse gas concerns. Data from recent field tests demonstrates that advanced dynamic calibration implementations can achieve 5-8% improvements in fuel economy under real-world driving conditions, translating to proportional reductions in carbon footprint.

Compliance with regional emissions regulations presents a significant challenge for global vehicle platforms. Dynamic calibration provides a flexible framework for meeting diverse regulatory requirements through software adjustments rather than hardware modifications. This adaptability is particularly valuable as regulations continue to evolve, with Euro 7, China 7, and EPA Tier 3 standards on the horizon, each with unique testing protocols and limits.

On-board diagnostics (OBD) integration with dynamic calibration systems enables continuous emissions monitoring and early detection of potential compliance issues. This proactive approach helps maintain emissions performance throughout the vehicle lifecycle, addressing concerns about deterioration factors that regulatory bodies increasingly scrutinize. The calibration strategy must include robust fail-safe modes that ensure emissions compliance even when sensors or actuators experience degradation.

Future-proofing emissions compliance requires consideration of real driving emissions (RDE) testing protocols. Dynamic calibration algorithms must be validated across the full spectrum of driving conditions, including cold starts, high-load operation, and varying ambient conditions. Simulation tools and hardware-in-loop testing have become essential for comprehensive validation before physical prototype testing, reducing development time while ensuring environmental compliance objectives are met.

V6 engine dynamic calibration offers significant opportunities for emissions reduction through real-time adjustment of fuel injection parameters, ignition timing, and air-fuel ratios. Studies indicate that properly calibrated dynamic systems can reduce NOx emissions by 15-22% compared to static calibration approaches, particularly during transient operations where emissions spikes typically occur. This improvement stems from the system's ability to maintain optimal combustion conditions even as external factors change.

The environmental benefits extend beyond regulated pollutants. Dynamic calibration strategies that optimize combustion efficiency directly contribute to reduced CO2 emissions, addressing greenhouse gas concerns. Data from recent field tests demonstrates that advanced dynamic calibration implementations can achieve 5-8% improvements in fuel economy under real-world driving conditions, translating to proportional reductions in carbon footprint.

Compliance with regional emissions regulations presents a significant challenge for global vehicle platforms. Dynamic calibration provides a flexible framework for meeting diverse regulatory requirements through software adjustments rather than hardware modifications. This adaptability is particularly valuable as regulations continue to evolve, with Euro 7, China 7, and EPA Tier 3 standards on the horizon, each with unique testing protocols and limits.

On-board diagnostics (OBD) integration with dynamic calibration systems enables continuous emissions monitoring and early detection of potential compliance issues. This proactive approach helps maintain emissions performance throughout the vehicle lifecycle, addressing concerns about deterioration factors that regulatory bodies increasingly scrutinize. The calibration strategy must include robust fail-safe modes that ensure emissions compliance even when sensors or actuators experience degradation.

Future-proofing emissions compliance requires consideration of real driving emissions (RDE) testing protocols. Dynamic calibration algorithms must be validated across the full spectrum of driving conditions, including cold starts, high-load operation, and varying ambient conditions. Simulation tools and hardware-in-loop testing have become essential for comprehensive validation before physical prototype testing, reducing development time while ensuring environmental compliance objectives are met.

Real-time Monitoring and Adaptive Systems

Real-time monitoring and adaptive systems represent a critical advancement in V6 engine dynamic calibration for stability. These systems continuously collect and analyze engine performance data through an array of strategically positioned sensors that measure parameters including combustion pressure, temperature variations, air-fuel ratios, and vibration patterns. The collected data undergoes immediate processing through sophisticated algorithms capable of detecting performance anomalies and stability issues before they escalate into significant problems.

Modern V6 engine management systems incorporate adaptive learning capabilities that evolve based on operational patterns. These systems can automatically adjust calibration parameters in response to changing conditions such as ambient temperature, fuel quality variations, and engine wear over time. This self-adjusting functionality ensures optimal performance across diverse operating environments without requiring manual recalibration.

The integration of machine learning algorithms has substantially enhanced the effectiveness of adaptive systems. These algorithms identify complex patterns in engine behavior that might escape traditional rule-based systems, enabling more nuanced calibration adjustments. For instance, neural networks can predict potential stability issues by recognizing subtle vibration signatures that precede more noticeable performance degradation.

Cloud connectivity has further revolutionized real-time monitoring capabilities. V6 engines equipped with telemetry systems can transmit performance data to centralized servers where more powerful computational resources analyze fleet-wide patterns. This collective intelligence approach allows for the identification of systemic issues and the development of calibration updates that can be deployed remotely to all connected vehicles.

Edge computing implementations have addressed latency concerns in adaptive systems by processing critical data directly within the engine control unit. This architectural approach enables millisecond-level response times for stability-critical adjustments while still benefiting from cloud-based analytics for longer-term calibration optimization.

Closed-loop control systems represent another significant advancement, creating feedback mechanisms that continuously verify the effectiveness of calibration adjustments. These systems compare actual performance metrics against target values and iteratively refine calibration parameters until optimal stability is achieved. This approach is particularly valuable for maintaining stability during transient operations such as rapid acceleration or load changes.

Modern V6 engine management systems incorporate adaptive learning capabilities that evolve based on operational patterns. These systems can automatically adjust calibration parameters in response to changing conditions such as ambient temperature, fuel quality variations, and engine wear over time. This self-adjusting functionality ensures optimal performance across diverse operating environments without requiring manual recalibration.

The integration of machine learning algorithms has substantially enhanced the effectiveness of adaptive systems. These algorithms identify complex patterns in engine behavior that might escape traditional rule-based systems, enabling more nuanced calibration adjustments. For instance, neural networks can predict potential stability issues by recognizing subtle vibration signatures that precede more noticeable performance degradation.

Cloud connectivity has further revolutionized real-time monitoring capabilities. V6 engines equipped with telemetry systems can transmit performance data to centralized servers where more powerful computational resources analyze fleet-wide patterns. This collective intelligence approach allows for the identification of systemic issues and the development of calibration updates that can be deployed remotely to all connected vehicles.

Edge computing implementations have addressed latency concerns in adaptive systems by processing critical data directly within the engine control unit. This architectural approach enables millisecond-level response times for stability-critical adjustments while still benefiting from cloud-based analytics for longer-term calibration optimization.

Closed-loop control systems represent another significant advancement, creating feedback mechanisms that continuously verify the effectiveness of calibration adjustments. These systems compare actual performance metrics against target values and iteratively refine calibration parameters until optimal stability is achieved. This approach is particularly valuable for maintaining stability during transient operations such as rapid acceleration or load changes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!