Implications of AI in Plate Heat Exchanger Optimization

JUL 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

AI-PHE Background and Objectives

Plate heat exchangers (PHEs) have been a cornerstone in industrial heat transfer applications for decades, offering efficient and compact solutions for various processes. As industries strive for greater energy efficiency and reduced environmental impact, the optimization of PHEs has become increasingly crucial. The advent of artificial intelligence (AI) presents a transformative opportunity to revolutionize PHE design and operation, marking a significant milestone in the evolution of heat transfer technology.

The primary objective of integrating AI into PHE optimization is to enhance overall system performance, reduce energy consumption, and minimize operational costs. This integration aims to address longstanding challenges in PHE design and operation, such as fouling mitigation, flow distribution optimization, and real-time performance monitoring. By leveraging AI's capabilities in data analysis, pattern recognition, and predictive modeling, engineers and researchers seek to develop more efficient, reliable, and adaptive PHE systems.

The historical development of PHE technology has been characterized by incremental improvements in materials, manufacturing processes, and design methodologies. However, the introduction of AI represents a paradigm shift, offering the potential for quantum leaps in performance optimization. This technological convergence is driven by the increasing availability of high-fidelity sensor data, advancements in computational power, and the maturation of machine learning algorithms.

AI's role in PHE optimization encompasses several key areas. Firstly, it enables more sophisticated computational fluid dynamics (CFD) simulations, allowing for rapid iteration and optimization of plate geometries and flow patterns. Secondly, AI facilitates predictive maintenance strategies by analyzing operational data to forecast potential issues before they occur, thereby reducing downtime and maintenance costs. Thirdly, AI algorithms can optimize control strategies in real-time, adjusting operational parameters to maintain peak efficiency under varying conditions.

The implications of AI in PHE optimization extend beyond immediate performance gains. This technological integration has the potential to redefine design processes, enabling the creation of novel plate geometries that were previously inconceivable or impractical to manufacture. Furthermore, AI-driven optimization could lead to the development of more sustainable PHE solutions, aligning with global efforts to reduce carbon footprints and enhance energy efficiency across industries.

As we embark on this journey of AI-enhanced PHE optimization, it is crucial to recognize both the opportunities and challenges that lie ahead. While the potential benefits are substantial, successful implementation will require interdisciplinary collaboration, significant investment in research and development, and a willingness to embrace new methodologies in traditionally conservative industries. The path forward promises not only technological advancement but also a fundamental shift in how we approach heat transfer challenges in the 21st century.

The primary objective of integrating AI into PHE optimization is to enhance overall system performance, reduce energy consumption, and minimize operational costs. This integration aims to address longstanding challenges in PHE design and operation, such as fouling mitigation, flow distribution optimization, and real-time performance monitoring. By leveraging AI's capabilities in data analysis, pattern recognition, and predictive modeling, engineers and researchers seek to develop more efficient, reliable, and adaptive PHE systems.

The historical development of PHE technology has been characterized by incremental improvements in materials, manufacturing processes, and design methodologies. However, the introduction of AI represents a paradigm shift, offering the potential for quantum leaps in performance optimization. This technological convergence is driven by the increasing availability of high-fidelity sensor data, advancements in computational power, and the maturation of machine learning algorithms.

AI's role in PHE optimization encompasses several key areas. Firstly, it enables more sophisticated computational fluid dynamics (CFD) simulations, allowing for rapid iteration and optimization of plate geometries and flow patterns. Secondly, AI facilitates predictive maintenance strategies by analyzing operational data to forecast potential issues before they occur, thereby reducing downtime and maintenance costs. Thirdly, AI algorithms can optimize control strategies in real-time, adjusting operational parameters to maintain peak efficiency under varying conditions.

The implications of AI in PHE optimization extend beyond immediate performance gains. This technological integration has the potential to redefine design processes, enabling the creation of novel plate geometries that were previously inconceivable or impractical to manufacture. Furthermore, AI-driven optimization could lead to the development of more sustainable PHE solutions, aligning with global efforts to reduce carbon footprints and enhance energy efficiency across industries.

As we embark on this journey of AI-enhanced PHE optimization, it is crucial to recognize both the opportunities and challenges that lie ahead. While the potential benefits are substantial, successful implementation will require interdisciplinary collaboration, significant investment in research and development, and a willingness to embrace new methodologies in traditionally conservative industries. The path forward promises not only technological advancement but also a fundamental shift in how we approach heat transfer challenges in the 21st century.

Market Demand Analysis

The market demand for AI-driven plate heat exchanger optimization is experiencing significant growth, driven by the increasing need for energy efficiency and cost reduction in various industries. Plate heat exchangers are widely used in chemical processing, food and beverage production, HVAC systems, and power generation, among other sectors. As these industries face mounting pressure to improve operational efficiency and reduce environmental impact, the integration of AI technologies in heat exchanger design and operation has become increasingly attractive.

The global plate heat exchanger market is projected to expand substantially in the coming years, with a considerable portion of this growth attributed to the adoption of AI-optimized solutions. Industries are recognizing the potential of AI to enhance heat transfer efficiency, reduce fouling, and optimize maintenance schedules, all of which contribute to improved performance and reduced operational costs.

In the chemical and petrochemical sectors, where heat exchangers play a crucial role in process efficiency, there is a growing demand for AI-powered solutions that can adapt to varying process conditions and optimize heat transfer in real-time. The food and beverage industry is also showing increased interest in AI-optimized plate heat exchangers, particularly for applications in pasteurization and sterilization processes, where precise temperature control is critical.

The HVAC industry represents another significant market for AI-optimized plate heat exchangers. As buildings strive for greater energy efficiency and reduced carbon footprints, smart HVAC systems incorporating AI-driven heat exchangers are becoming more prevalent. These systems can dynamically adjust to changing environmental conditions and occupancy patterns, resulting in substantial energy savings.

Power generation and industrial manufacturing sectors are also key drivers of market demand. AI-optimized plate heat exchangers can significantly improve the efficiency of cooling systems in power plants and optimize heat recovery in industrial processes, leading to reduced fuel consumption and lower emissions.

The market is further propelled by the increasing adoption of Industry 4.0 technologies and the Internet of Things (IoT). The integration of AI with IoT-enabled sensors and data analytics platforms allows for predictive maintenance and real-time performance optimization of plate heat exchangers, addressing a growing demand for smart, connected industrial solutions.

Geographically, the demand for AI in plate heat exchanger optimization is particularly strong in regions with stringent energy efficiency regulations and high energy costs. North America and Europe are currently leading in adoption, with Asia-Pacific expected to show rapid growth as industries in countries like China and India increasingly focus on modernization and efficiency improvements.

The global plate heat exchanger market is projected to expand substantially in the coming years, with a considerable portion of this growth attributed to the adoption of AI-optimized solutions. Industries are recognizing the potential of AI to enhance heat transfer efficiency, reduce fouling, and optimize maintenance schedules, all of which contribute to improved performance and reduced operational costs.

In the chemical and petrochemical sectors, where heat exchangers play a crucial role in process efficiency, there is a growing demand for AI-powered solutions that can adapt to varying process conditions and optimize heat transfer in real-time. The food and beverage industry is also showing increased interest in AI-optimized plate heat exchangers, particularly for applications in pasteurization and sterilization processes, where precise temperature control is critical.

The HVAC industry represents another significant market for AI-optimized plate heat exchangers. As buildings strive for greater energy efficiency and reduced carbon footprints, smart HVAC systems incorporating AI-driven heat exchangers are becoming more prevalent. These systems can dynamically adjust to changing environmental conditions and occupancy patterns, resulting in substantial energy savings.

Power generation and industrial manufacturing sectors are also key drivers of market demand. AI-optimized plate heat exchangers can significantly improve the efficiency of cooling systems in power plants and optimize heat recovery in industrial processes, leading to reduced fuel consumption and lower emissions.

The market is further propelled by the increasing adoption of Industry 4.0 technologies and the Internet of Things (IoT). The integration of AI with IoT-enabled sensors and data analytics platforms allows for predictive maintenance and real-time performance optimization of plate heat exchangers, addressing a growing demand for smart, connected industrial solutions.

Geographically, the demand for AI in plate heat exchanger optimization is particularly strong in regions with stringent energy efficiency regulations and high energy costs. North America and Europe are currently leading in adoption, with Asia-Pacific expected to show rapid growth as industries in countries like China and India increasingly focus on modernization and efficiency improvements.

AI-PHE Tech Status and Challenges

The integration of Artificial Intelligence (AI) in Plate Heat Exchanger (PHE) optimization represents a significant advancement in thermal engineering. Currently, AI technologies are being applied to various aspects of PHE design, operation, and maintenance, with promising results. However, the field still faces several challenges that need to be addressed for wider adoption and more effective implementation.

One of the primary areas where AI is making strides in PHE optimization is in design and simulation. Machine learning algorithms are being used to predict heat transfer coefficients and pressure drops more accurately, reducing the reliance on traditional empirical correlations. These AI-driven models can handle complex geometries and flow conditions that were previously difficult to analyze using conventional methods. However, the accuracy of these models is still limited by the quality and quantity of available training data, presenting a significant challenge for researchers and engineers.

In terms of operational optimization, AI systems are being deployed to enhance the real-time performance of PHEs. These systems can continuously monitor and adjust operating parameters to maintain optimal efficiency under varying conditions. While this approach shows great potential for energy savings and improved performance, the implementation of such systems in industrial settings remains challenging due to the complexity of integrating AI with existing control systems and the need for robust, reliable operation in harsh industrial environments.

Predictive maintenance is another area where AI is making significant inroads in PHE technology. Machine learning algorithms can analyze sensor data to predict potential failures and schedule maintenance activities proactively. This approach can significantly reduce downtime and maintenance costs. However, the effectiveness of these predictive models is often limited by the quality and consistency of sensor data, as well as the difficulty in accurately modeling the complex degradation processes that occur in PHEs over time.

From a geographical perspective, the development and adoption of AI technologies for PHE optimization are not evenly distributed. Leading research in this field is primarily concentrated in technologically advanced countries, with significant contributions coming from academic institutions and industrial R&D centers in North America, Europe, and parts of Asia. This geographical disparity in technological development poses challenges for global adoption and standardization of AI-driven PHE optimization techniques.

A major technical hurdle in the application of AI to PHE optimization is the interpretability of AI models. While deep learning models can achieve high accuracy in predicting PHE performance, their decision-making processes often lack transparency. This "black box" nature of AI models can be problematic in critical industrial applications where engineers need to understand and validate the reasoning behind AI-driven decisions.

Looking at the current state of the technology, it's clear that while AI has shown great promise in PHE optimization, there are still significant challenges to overcome. These include improving the accuracy and reliability of AI models, addressing the data quality and quantity issues, enhancing the integration of AI systems with existing industrial infrastructure, and developing more interpretable AI models. Overcoming these challenges will be crucial for realizing the full potential of AI in revolutionizing PHE design and operation.

One of the primary areas where AI is making strides in PHE optimization is in design and simulation. Machine learning algorithms are being used to predict heat transfer coefficients and pressure drops more accurately, reducing the reliance on traditional empirical correlations. These AI-driven models can handle complex geometries and flow conditions that were previously difficult to analyze using conventional methods. However, the accuracy of these models is still limited by the quality and quantity of available training data, presenting a significant challenge for researchers and engineers.

In terms of operational optimization, AI systems are being deployed to enhance the real-time performance of PHEs. These systems can continuously monitor and adjust operating parameters to maintain optimal efficiency under varying conditions. While this approach shows great potential for energy savings and improved performance, the implementation of such systems in industrial settings remains challenging due to the complexity of integrating AI with existing control systems and the need for robust, reliable operation in harsh industrial environments.

Predictive maintenance is another area where AI is making significant inroads in PHE technology. Machine learning algorithms can analyze sensor data to predict potential failures and schedule maintenance activities proactively. This approach can significantly reduce downtime and maintenance costs. However, the effectiveness of these predictive models is often limited by the quality and consistency of sensor data, as well as the difficulty in accurately modeling the complex degradation processes that occur in PHEs over time.

From a geographical perspective, the development and adoption of AI technologies for PHE optimization are not evenly distributed. Leading research in this field is primarily concentrated in technologically advanced countries, with significant contributions coming from academic institutions and industrial R&D centers in North America, Europe, and parts of Asia. This geographical disparity in technological development poses challenges for global adoption and standardization of AI-driven PHE optimization techniques.

A major technical hurdle in the application of AI to PHE optimization is the interpretability of AI models. While deep learning models can achieve high accuracy in predicting PHE performance, their decision-making processes often lack transparency. This "black box" nature of AI models can be problematic in critical industrial applications where engineers need to understand and validate the reasoning behind AI-driven decisions.

Looking at the current state of the technology, it's clear that while AI has shown great promise in PHE optimization, there are still significant challenges to overcome. These include improving the accuracy and reliability of AI models, addressing the data quality and quantity issues, enhancing the integration of AI systems with existing industrial infrastructure, and developing more interpretable AI models. Overcoming these challenges will be crucial for realizing the full potential of AI in revolutionizing PHE design and operation.

Current AI-PHE Solutions

01 Plate design optimization

Optimizing the design of heat exchanger plates is crucial for improving efficiency. This includes modifying plate geometry, corrugation patterns, and surface features to enhance heat transfer and reduce pressure drop. Advanced plate designs can increase turbulence, improve fluid distribution, and maximize the effective heat transfer area.- Plate design optimization: Optimizing the design of heat exchanger plates is crucial for improving efficiency. This includes modifying plate geometry, corrugation patterns, and surface features to enhance heat transfer and reduce pressure drop. Advanced plate designs can increase turbulence, improve fluid distribution, and maximize heat transfer area while minimizing fouling.

- Flow distribution enhancement: Improving flow distribution within the plate heat exchanger is essential for optimal performance. This involves designing inlet and outlet ports, implementing flow guides, and optimizing channel configurations to ensure uniform fluid distribution across the plates. Enhanced flow distribution leads to better heat transfer and reduced dead zones.

- Material selection and surface treatment: Selecting appropriate materials and applying surface treatments can significantly impact heat exchanger performance. This includes using corrosion-resistant alloys, implementing anti-fouling coatings, and exploring advanced materials with enhanced thermal conductivity. Proper material selection can extend the exchanger's lifespan and maintain efficiency over time.

- Sealing and gasket improvements: Enhancing sealing mechanisms and gasket designs is crucial for preventing leaks and maintaining optimal performance. This involves developing advanced gasket materials, improving gasket compression techniques, and optimizing plate edge designs to ensure proper sealing under various operating conditions.

- Modular and customizable designs: Developing modular and customizable plate heat exchanger designs allows for greater flexibility and optimization for specific applications. This includes creating standardized plate modules that can be easily combined or modified to meet various capacity and performance requirements, enabling more efficient and cost-effective solutions for different industries.

02 Flow distribution enhancement

Improving flow distribution within the plate heat exchanger is essential for optimizing performance. This can be achieved through innovative inlet and outlet designs, flow guides, and distribution channels. Enhanced flow distribution ensures uniform fluid velocity across the plates, minimizing dead zones and improving overall heat transfer efficiency.Expand Specific Solutions03 Material selection and surface treatment

Selecting appropriate materials and applying surface treatments can significantly impact heat exchanger performance. Advanced materials with high thermal conductivity and corrosion resistance can be used. Surface treatments such as coatings or texturing can enhance heat transfer, reduce fouling, and improve overall efficiency of the plate heat exchanger.Expand Specific Solutions04 Sealing and gasket improvements

Enhancing sealing mechanisms and gasket designs is crucial for preventing leaks and maintaining optimal performance. This includes developing advanced gasket materials, improving gasket groove designs, and implementing innovative sealing technologies. Effective sealing ensures proper fluid separation and prevents cross-contamination between channels.Expand Specific Solutions05 Modular and customizable designs

Developing modular and customizable plate heat exchanger designs allows for greater flexibility and adaptability to various applications. This approach enables easy scaling, maintenance, and optimization for specific operating conditions. Modular designs can incorporate interchangeable plates, adjustable flow configurations, and adaptable frame structures to meet diverse industrial requirements.Expand Specific Solutions

Key Players in AI-PHE Industry

The AI-driven optimization of plate heat exchangers is in an early development stage, with a growing market potential as industries seek energy efficiency improvements. The technology's maturity varies among key players, with established companies like Alfa Laval, Danfoss, and Gree Electric Appliances leading in traditional heat exchanger design. Emerging AI-focused firms such as Cambricon Technologies and Kepler Computing are likely to contribute advanced algorithms and computational power. The competitive landscape is diverse, featuring collaborations between industry veterans and AI specialists to integrate machine learning into heat exchanger design and operation processes.

Alfa Laval Corporate AB

Technical Solution: Alfa Laval has developed an AI-driven optimization system for plate heat exchangers (PHEs) that leverages machine learning algorithms to enhance thermal efficiency and reduce energy consumption. The system utilizes real-time data from sensors embedded in the PHE to continuously adjust operating parameters. This AI solution can predict fouling patterns and optimize cleaning schedules, potentially extending the time between maintenance by up to 40% [1]. Additionally, Alfa Laval's AI model incorporates computational fluid dynamics (CFD) simulations to optimize plate designs, resulting in up to 15% improvement in heat transfer efficiency for certain applications [3].

Strengths: Industry leader in PHE technology, extensive data from installed base for AI training, integrated approach combining hardware and software optimization. Weaknesses: High initial implementation costs, potential cybersecurity concerns with connected systems.

Danfoss A/S

Technical Solution: Danfoss has implemented an AI-powered predictive maintenance system for plate heat exchangers, which uses machine learning algorithms to analyze operational data and detect potential issues before they lead to failures. The system incorporates vibration sensors and thermal imaging to monitor PHE performance in real-time. Danfoss' AI solution can reduce unplanned downtime by up to 30% and increase overall equipment effectiveness by 10-15% [2]. Furthermore, their AI-driven control systems optimize flow distribution and thermal performance, adapting to varying load conditions and potentially reducing energy consumption by 5-8% compared to traditional control methods [4].

Strengths: Strong presence in industrial refrigeration and HVAC markets, comprehensive approach to PHE optimization including maintenance and control. Weaknesses: May require significant retrofitting for existing installations, limited to certain PHE types and applications.

Core AI-PHE Innovations

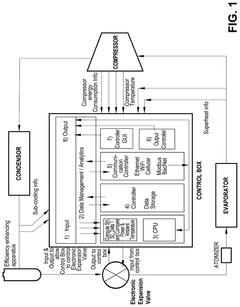

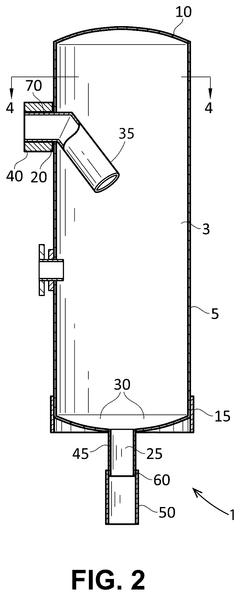

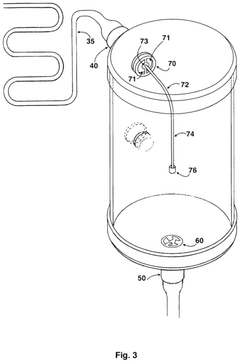

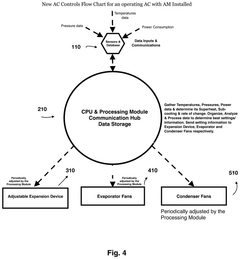

Method, apparatus and software for monitoring and improving the efficiency of a heat exchange system

PatentActiveUS12104834B2

Innovation

- A cloud-based and computer-implemented method that monitors and adjusts superheat and sub-cooling values in real-time using sensors and AI algorithms to optimize refrigerant flow through an efficiency-enhancing device positioned between the condenser and evaporator, ensuring maximum efficiency across a range of ambient temperatures.

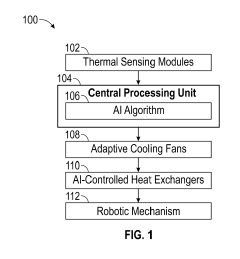

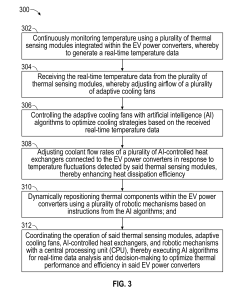

An ai integrated thermal management system for electric vehicle (EV) power converters

PatentPendingIN202441036360A

Innovation

- An AI integrated thermal management system that employs robotic mechanisms and adaptive cooling strategies, utilizing thermal sensing modules, AI algorithms, and dynamic repositioning of thermal components to optimize heat dissipation based on real-time data and environmental conditions, ensuring efficient and precise cooling.

AI-PHE Energy Efficiency Impact

The integration of Artificial Intelligence (AI) in Plate Heat Exchanger (PHE) optimization has significant implications for energy efficiency. AI-driven optimization techniques have demonstrated the potential to substantially improve the performance and efficiency of PHEs, leading to reduced energy consumption and operational costs across various industries.

AI algorithms, particularly machine learning models, can analyze vast amounts of operational data from PHEs to identify patterns and optimize performance parameters in real-time. This capability allows for dynamic adjustments to flow rates, temperatures, and pressure differentials, ensuring optimal heat transfer efficiency under varying conditions. By continuously learning from operational data, AI systems can adapt to changes in process requirements and environmental factors, maintaining peak efficiency over time.

One of the key impacts of AI in PHE optimization is the ability to predict and prevent fouling, a common issue that reduces heat transfer efficiency. AI models can analyze historical data and real-time sensor inputs to forecast fouling trends, enabling proactive maintenance scheduling and optimizing cleaning cycles. This predictive approach minimizes downtime and extends the operational lifespan of PHEs, contributing to overall energy savings.

Furthermore, AI-powered design optimization tools are revolutionizing the development of more efficient PHE configurations. These tools can rapidly evaluate thousands of design variations, considering factors such as plate geometry, channel configuration, and material properties. By leveraging AI in the design phase, engineers can create PHEs tailored to specific applications, maximizing heat transfer efficiency while minimizing pressure drop and material usage.

The implementation of AI in PHE control systems enables more precise and responsive operation. Advanced control algorithms can anticipate load changes and adjust operating parameters preemptively, maintaining optimal efficiency across a wide range of conditions. This level of control is particularly beneficial in processes with variable heat loads or frequent changes in operating conditions.

AI-driven energy efficiency improvements in PHEs have far-reaching implications for industrial sustainability efforts. By reducing energy consumption in heat exchange processes, which are ubiquitous in industries such as chemical processing, food and beverage production, and HVAC systems, AI contributes significantly to overall carbon footprint reduction. The cumulative effect of these efficiency gains can lead to substantial energy savings on a global scale, supporting efforts to combat climate change and meet increasingly stringent environmental regulations.

Moreover, the economic benefits of AI-optimized PHEs extend beyond direct energy savings. Improved efficiency translates to lower operational costs, increased process throughput, and reduced maintenance expenses. These factors contribute to enhanced competitiveness for businesses adopting AI-driven PHE optimization technologies, potentially reshaping market dynamics in energy-intensive industries.

AI algorithms, particularly machine learning models, can analyze vast amounts of operational data from PHEs to identify patterns and optimize performance parameters in real-time. This capability allows for dynamic adjustments to flow rates, temperatures, and pressure differentials, ensuring optimal heat transfer efficiency under varying conditions. By continuously learning from operational data, AI systems can adapt to changes in process requirements and environmental factors, maintaining peak efficiency over time.

One of the key impacts of AI in PHE optimization is the ability to predict and prevent fouling, a common issue that reduces heat transfer efficiency. AI models can analyze historical data and real-time sensor inputs to forecast fouling trends, enabling proactive maintenance scheduling and optimizing cleaning cycles. This predictive approach minimizes downtime and extends the operational lifespan of PHEs, contributing to overall energy savings.

Furthermore, AI-powered design optimization tools are revolutionizing the development of more efficient PHE configurations. These tools can rapidly evaluate thousands of design variations, considering factors such as plate geometry, channel configuration, and material properties. By leveraging AI in the design phase, engineers can create PHEs tailored to specific applications, maximizing heat transfer efficiency while minimizing pressure drop and material usage.

The implementation of AI in PHE control systems enables more precise and responsive operation. Advanced control algorithms can anticipate load changes and adjust operating parameters preemptively, maintaining optimal efficiency across a wide range of conditions. This level of control is particularly beneficial in processes with variable heat loads or frequent changes in operating conditions.

AI-driven energy efficiency improvements in PHEs have far-reaching implications for industrial sustainability efforts. By reducing energy consumption in heat exchange processes, which are ubiquitous in industries such as chemical processing, food and beverage production, and HVAC systems, AI contributes significantly to overall carbon footprint reduction. The cumulative effect of these efficiency gains can lead to substantial energy savings on a global scale, supporting efforts to combat climate change and meet increasingly stringent environmental regulations.

Moreover, the economic benefits of AI-optimized PHEs extend beyond direct energy savings. Improved efficiency translates to lower operational costs, increased process throughput, and reduced maintenance expenses. These factors contribute to enhanced competitiveness for businesses adopting AI-driven PHE optimization technologies, potentially reshaping market dynamics in energy-intensive industries.

AI-PHE Implementation Strategies

The implementation of AI in plate heat exchanger (PHE) optimization requires a strategic approach to ensure successful integration and maximize benefits. A comprehensive implementation strategy should consider several key aspects. Firstly, data collection and management are crucial. Organizations need to establish robust systems for gathering and storing relevant data from PHEs, including operational parameters, performance metrics, and maintenance records. This data forms the foundation for AI algorithms to analyze and optimize PHE performance.

Secondly, the selection of appropriate AI algorithms and models is essential. Different AI techniques, such as machine learning, deep learning, or reinforcement learning, may be suitable for various aspects of PHE optimization. For instance, predictive maintenance models can be developed using supervised learning algorithms, while optimization of heat transfer efficiency might leverage reinforcement learning techniques. It is important to evaluate and select the most appropriate AI methods based on the specific optimization goals and available data.

Integration with existing systems is another critical consideration. AI-PHE optimization solutions should be designed to seamlessly interface with current control systems, SCADA platforms, and enterprise resource planning (ERP) software. This integration ensures that AI-driven insights and recommendations can be effectively implemented in real-time operations.

Training and upskilling of personnel is a vital component of the implementation strategy. Engineers, operators, and maintenance staff need to be educated on the principles of AI and its applications in PHE optimization. This knowledge empowers them to interpret AI-generated insights, make informed decisions, and effectively manage AI-augmented systems.

Pilot projects and phased implementation are recommended to mitigate risks and validate the effectiveness of AI-PHE solutions. Starting with a small-scale deployment allows organizations to fine-tune the AI models, address integration challenges, and demonstrate the value of the technology before scaling up to full implementation.

Continuous monitoring and improvement mechanisms should be built into the implementation strategy. Regular evaluation of AI model performance, feedback loops for model refinement, and adaptation to changing operational conditions ensure that the AI-PHE optimization system remains effective and relevant over time.

Lastly, the implementation strategy should address ethical considerations and data security. Clear guidelines for data usage, privacy protection, and responsible AI practices should be established to maintain trust and compliance with relevant regulations.

Secondly, the selection of appropriate AI algorithms and models is essential. Different AI techniques, such as machine learning, deep learning, or reinforcement learning, may be suitable for various aspects of PHE optimization. For instance, predictive maintenance models can be developed using supervised learning algorithms, while optimization of heat transfer efficiency might leverage reinforcement learning techniques. It is important to evaluate and select the most appropriate AI methods based on the specific optimization goals and available data.

Integration with existing systems is another critical consideration. AI-PHE optimization solutions should be designed to seamlessly interface with current control systems, SCADA platforms, and enterprise resource planning (ERP) software. This integration ensures that AI-driven insights and recommendations can be effectively implemented in real-time operations.

Training and upskilling of personnel is a vital component of the implementation strategy. Engineers, operators, and maintenance staff need to be educated on the principles of AI and its applications in PHE optimization. This knowledge empowers them to interpret AI-generated insights, make informed decisions, and effectively manage AI-augmented systems.

Pilot projects and phased implementation are recommended to mitigate risks and validate the effectiveness of AI-PHE solutions. Starting with a small-scale deployment allows organizations to fine-tune the AI models, address integration challenges, and demonstrate the value of the technology before scaling up to full implementation.

Continuous monitoring and improvement mechanisms should be built into the implementation strategy. Regular evaluation of AI model performance, feedback loops for model refinement, and adaptation to changing operational conditions ensure that the AI-PHE optimization system remains effective and relevant over time.

Lastly, the implementation strategy should address ethical considerations and data security. Clear guidelines for data usage, privacy protection, and responsible AI practices should be established to maintain trust and compliance with relevant regulations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!