Influence of Surface Coating on Plate Heat Exchanger Durability

JUL 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Coating Tech Evolution

The evolution of coating technologies for plate heat exchangers has been marked by significant advancements over the past few decades. Initially, basic metallic coatings were employed to enhance corrosion resistance and extend the lifespan of heat exchanger plates. These early coatings, often consisting of simple chromium or nickel layers, provided a rudimentary barrier against aggressive media but had limited effectiveness in harsh operating conditions.

As industrial processes became more demanding, the 1980s and 1990s saw the emergence of more sophisticated coating solutions. Polymer-based coatings, such as epoxy and fluoropolymers, gained popularity due to their superior chemical resistance and non-stick properties. These coatings not only improved durability but also enhanced heat transfer efficiency by reducing fouling on plate surfaces.

The turn of the millennium brought about a paradigm shift with the introduction of advanced ceramic coatings. Materials like titanium nitride (TiN) and chromium nitride (CrN) were applied using physical vapor deposition (PVD) techniques, offering unprecedented hardness and wear resistance. These coatings significantly extended the operational life of plate heat exchangers in abrasive environments.

In the 2010s, nanotechnology began to play a crucial role in coating development. Nanocomposite coatings, combining the benefits of different materials at the nanoscale, emerged as a promising solution. These coatings offered enhanced corrosion resistance, improved thermal conductivity, and better fouling mitigation, addressing multiple challenges simultaneously.

Recent years have witnessed the rise of smart and functional coatings. Self-healing coatings, capable of repairing minor damage autonomously, have shown potential in prolonging the service life of heat exchanger plates. Additionally, hydrophobic and oleophobic coatings have been developed to minimize fouling and simplify cleaning processes, thereby maintaining optimal heat transfer efficiency over extended periods.

The latest frontier in coating technology for plate heat exchangers involves the integration of nanomaterials and advanced polymers. Graphene-based coatings, for instance, are being explored for their exceptional thermal conductivity and mechanical strength. These cutting-edge coatings promise to revolutionize heat exchanger performance by significantly enhancing heat transfer rates while providing superior protection against corrosion and fouling.

As environmental concerns gain prominence, the focus has shifted towards developing eco-friendly coating solutions. Water-based and solvent-free coating systems are being increasingly adopted to reduce volatile organic compound (VOC) emissions during the coating process. Furthermore, research is underway to create biodegradable coatings that maintain high performance standards while minimizing environmental impact at the end of the heat exchanger's lifecycle.

As industrial processes became more demanding, the 1980s and 1990s saw the emergence of more sophisticated coating solutions. Polymer-based coatings, such as epoxy and fluoropolymers, gained popularity due to their superior chemical resistance and non-stick properties. These coatings not only improved durability but also enhanced heat transfer efficiency by reducing fouling on plate surfaces.

The turn of the millennium brought about a paradigm shift with the introduction of advanced ceramic coatings. Materials like titanium nitride (TiN) and chromium nitride (CrN) were applied using physical vapor deposition (PVD) techniques, offering unprecedented hardness and wear resistance. These coatings significantly extended the operational life of plate heat exchangers in abrasive environments.

In the 2010s, nanotechnology began to play a crucial role in coating development. Nanocomposite coatings, combining the benefits of different materials at the nanoscale, emerged as a promising solution. These coatings offered enhanced corrosion resistance, improved thermal conductivity, and better fouling mitigation, addressing multiple challenges simultaneously.

Recent years have witnessed the rise of smart and functional coatings. Self-healing coatings, capable of repairing minor damage autonomously, have shown potential in prolonging the service life of heat exchanger plates. Additionally, hydrophobic and oleophobic coatings have been developed to minimize fouling and simplify cleaning processes, thereby maintaining optimal heat transfer efficiency over extended periods.

The latest frontier in coating technology for plate heat exchangers involves the integration of nanomaterials and advanced polymers. Graphene-based coatings, for instance, are being explored for their exceptional thermal conductivity and mechanical strength. These cutting-edge coatings promise to revolutionize heat exchanger performance by significantly enhancing heat transfer rates while providing superior protection against corrosion and fouling.

As environmental concerns gain prominence, the focus has shifted towards developing eco-friendly coating solutions. Water-based and solvent-free coating systems are being increasingly adopted to reduce volatile organic compound (VOC) emissions during the coating process. Furthermore, research is underway to create biodegradable coatings that maintain high performance standards while minimizing environmental impact at the end of the heat exchanger's lifecycle.

Market Demand Analysis

The market demand for surface coatings on plate heat exchangers has been steadily increasing due to the growing emphasis on energy efficiency and equipment longevity across various industries. As industries strive to optimize their processes and reduce operational costs, the durability of heat exchangers has become a critical factor. Surface coatings play a pivotal role in enhancing the lifespan and performance of plate heat exchangers, leading to a surge in demand for advanced coating technologies.

The global plate heat exchanger market is experiencing significant growth, with a projected CAGR of 7.5% from 2021 to 2026. This growth is largely attributed to the rising demand for energy-efficient heat transfer solutions in industries such as chemical processing, food and beverage, HVAC, and power generation. Within this market, the demand for surface coatings is particularly strong, as they offer substantial benefits in terms of corrosion resistance, fouling mitigation, and overall heat transfer efficiency.

Industries dealing with corrosive fluids or harsh operating conditions are driving the demand for specialized surface coatings. The chemical processing sector, for instance, requires heat exchangers that can withstand aggressive chemicals and maintain their integrity over extended periods. Similarly, the food and beverage industry demands coatings that not only enhance durability but also comply with strict hygiene standards. These industry-specific requirements are fueling innovation in coating technologies and expanding the market for specialized solutions.

The increasing focus on sustainability and environmental regulations is another factor boosting the demand for surface coatings. As companies strive to reduce their carbon footprint and comply with stringent emissions standards, they are turning to more efficient heat exchange systems. Surface coatings that improve heat transfer efficiency and reduce fouling contribute to lower energy consumption and decreased maintenance frequency, aligning with sustainability goals and regulatory requirements.

Geographically, the Asia-Pacific region is witnessing the highest growth in demand for surface coatings for plate heat exchangers. This is primarily due to rapid industrialization, particularly in countries like China and India, where there is a significant expansion of manufacturing facilities and power plants. North America and Europe, while mature markets, are also seeing steady demand growth driven by the need to upgrade existing infrastructure and improve energy efficiency in industrial processes.

The market is also witnessing a trend towards customized coating solutions. As different industries face unique challenges in their heat exchange processes, there is a growing demand for tailored surface coatings that address specific operational conditions. This trend is encouraging coating manufacturers to invest in research and development to create innovative, application-specific solutions, further driving market growth and technological advancements in the field.

The global plate heat exchanger market is experiencing significant growth, with a projected CAGR of 7.5% from 2021 to 2026. This growth is largely attributed to the rising demand for energy-efficient heat transfer solutions in industries such as chemical processing, food and beverage, HVAC, and power generation. Within this market, the demand for surface coatings is particularly strong, as they offer substantial benefits in terms of corrosion resistance, fouling mitigation, and overall heat transfer efficiency.

Industries dealing with corrosive fluids or harsh operating conditions are driving the demand for specialized surface coatings. The chemical processing sector, for instance, requires heat exchangers that can withstand aggressive chemicals and maintain their integrity over extended periods. Similarly, the food and beverage industry demands coatings that not only enhance durability but also comply with strict hygiene standards. These industry-specific requirements are fueling innovation in coating technologies and expanding the market for specialized solutions.

The increasing focus on sustainability and environmental regulations is another factor boosting the demand for surface coatings. As companies strive to reduce their carbon footprint and comply with stringent emissions standards, they are turning to more efficient heat exchange systems. Surface coatings that improve heat transfer efficiency and reduce fouling contribute to lower energy consumption and decreased maintenance frequency, aligning with sustainability goals and regulatory requirements.

Geographically, the Asia-Pacific region is witnessing the highest growth in demand for surface coatings for plate heat exchangers. This is primarily due to rapid industrialization, particularly in countries like China and India, where there is a significant expansion of manufacturing facilities and power plants. North America and Europe, while mature markets, are also seeing steady demand growth driven by the need to upgrade existing infrastructure and improve energy efficiency in industrial processes.

The market is also witnessing a trend towards customized coating solutions. As different industries face unique challenges in their heat exchange processes, there is a growing demand for tailored surface coatings that address specific operational conditions. This trend is encouraging coating manufacturers to invest in research and development to create innovative, application-specific solutions, further driving market growth and technological advancements in the field.

Current Challenges

The surface coating of plate heat exchangers (PHEs) plays a crucial role in their durability and performance. However, several challenges currently hinder the widespread adoption and optimization of these coatings. One of the primary issues is the lack of standardization in coating materials and application processes across the industry. This inconsistency makes it difficult to compare and evaluate the effectiveness of different coating solutions, leading to uncertainty in decision-making for manufacturers and end-users.

Another significant challenge is the trade-off between coating thickness and heat transfer efficiency. While thicker coatings generally provide better protection against corrosion and fouling, they can also reduce heat transfer rates due to increased thermal resistance. Striking the right balance between durability and thermal performance remains a complex task that requires careful consideration of specific operating conditions and fluid properties.

The long-term stability of surface coatings under various operating conditions poses another challenge. Many PHEs are subjected to harsh environments, including high temperatures, corrosive fluids, and frequent thermal cycling. These factors can lead to coating degradation over time, resulting in reduced protection and potential failure of the heat exchanger. Developing coatings that can withstand these extreme conditions without compromising their protective properties is an ongoing challenge for researchers and manufacturers.

Furthermore, the cost-effectiveness of advanced coating technologies remains a significant hurdle. While some high-performance coatings demonstrate excellent durability and fouling resistance, their high production and application costs often make them economically unfeasible for widespread use. This economic constraint limits the adoption of potentially beneficial coating solutions, particularly in cost-sensitive industries.

The environmental impact of coating materials and processes is also becoming an increasingly important consideration. Many traditional coating methods involve the use of volatile organic compounds (VOCs) and other environmentally harmful substances. Developing eco-friendly coating alternatives that maintain or improve upon the performance of conventional coatings is a pressing challenge facing the industry.

Lastly, the lack of comprehensive, long-term field data on coating performance in real-world applications hinders the development and optimization of coating solutions. While laboratory tests provide valuable insights, they often fail to capture the full complexity of operational environments. This gap in knowledge makes it difficult to accurately predict coating lifespan and performance, leading to uncertainty in maintenance scheduling and overall lifecycle cost estimations for PHEs.

Another significant challenge is the trade-off between coating thickness and heat transfer efficiency. While thicker coatings generally provide better protection against corrosion and fouling, they can also reduce heat transfer rates due to increased thermal resistance. Striking the right balance between durability and thermal performance remains a complex task that requires careful consideration of specific operating conditions and fluid properties.

The long-term stability of surface coatings under various operating conditions poses another challenge. Many PHEs are subjected to harsh environments, including high temperatures, corrosive fluids, and frequent thermal cycling. These factors can lead to coating degradation over time, resulting in reduced protection and potential failure of the heat exchanger. Developing coatings that can withstand these extreme conditions without compromising their protective properties is an ongoing challenge for researchers and manufacturers.

Furthermore, the cost-effectiveness of advanced coating technologies remains a significant hurdle. While some high-performance coatings demonstrate excellent durability and fouling resistance, their high production and application costs often make them economically unfeasible for widespread use. This economic constraint limits the adoption of potentially beneficial coating solutions, particularly in cost-sensitive industries.

The environmental impact of coating materials and processes is also becoming an increasingly important consideration. Many traditional coating methods involve the use of volatile organic compounds (VOCs) and other environmentally harmful substances. Developing eco-friendly coating alternatives that maintain or improve upon the performance of conventional coatings is a pressing challenge facing the industry.

Lastly, the lack of comprehensive, long-term field data on coating performance in real-world applications hinders the development and optimization of coating solutions. While laboratory tests provide valuable insights, they often fail to capture the full complexity of operational environments. This gap in knowledge makes it difficult to accurately predict coating lifespan and performance, leading to uncertainty in maintenance scheduling and overall lifecycle cost estimations for PHEs.

Existing Coating Solutions

01 Corrosion-resistant materials

Utilizing corrosion-resistant materials such as stainless steel, titanium, or specialized alloys in the construction of plate heat exchangers significantly enhances their durability. These materials provide superior resistance to chemical attack and erosion, extending the operational life of the exchanger in harsh environments.- Material selection for improved durability: Selecting appropriate materials for plate heat exchangers can significantly enhance their durability. High-quality, corrosion-resistant materials such as stainless steel, titanium, or specialized alloys can be used to manufacture plates and gaskets. These materials help prevent degradation due to chemical reactions, temperature fluctuations, and mechanical stress, thereby extending the lifespan of the heat exchanger.

- Plate design optimization: Optimizing the design of heat exchanger plates can improve durability. This includes enhancing plate geometry, thickness, and surface patterns to distribute fluid flow evenly, reduce pressure drop, and minimize areas of high stress or wear. Advanced plate designs can also incorporate features that improve sealing and reduce the risk of leakage.

- Gasket and sealing improvements: Developing advanced gasket materials and sealing techniques can significantly enhance the durability of plate heat exchangers. This includes using high-performance elastomers, implementing innovative gasket designs, and improving the sealing mechanism between plates. These improvements help prevent leaks, resist chemical degradation, and withstand high temperatures and pressures.

- Corrosion prevention techniques: Implementing various corrosion prevention techniques can extend the lifespan of plate heat exchangers. This may include applying protective coatings, using cathodic protection systems, or incorporating sacrificial anodes. Additionally, proper selection of materials based on the specific operating environment and fluid properties can significantly reduce corrosion-related issues.

- Maintenance and cleaning innovations: Developing innovative maintenance and cleaning methods can improve the long-term durability of plate heat exchangers. This includes designing easy-to-disassemble units, implementing automated cleaning systems, and using advanced cleaning agents that effectively remove fouling without damaging the plates or gaskets. Regular maintenance and proper cleaning procedures help maintain optimal performance and extend the equipment's lifespan.

02 Advanced plate design

Implementing advanced plate designs with optimized flow patterns and improved heat transfer characteristics can enhance the durability of plate heat exchangers. These designs reduce fluid velocity variations and minimize areas of stagnation, thereby reducing wear and extending the operational lifespan of the exchanger.Expand Specific Solutions03 Gasket and sealing improvements

Developing high-performance gaskets and sealing systems that can withstand extreme temperatures, pressures, and chemical environments improves the overall durability of plate heat exchangers. These advancements prevent leakage and maintain the integrity of the exchanger over extended periods of operation.Expand Specific Solutions04 Surface treatment and coatings

Applying specialized surface treatments and coatings to the plates can significantly enhance their resistance to fouling, scaling, and corrosion. These treatments improve heat transfer efficiency and extend the time between maintenance intervals, thereby increasing the overall durability of the exchanger.Expand Specific Solutions05 Modular and serviceable design

Incorporating modular and easily serviceable designs in plate heat exchangers allows for efficient maintenance, cleaning, and replacement of individual components. This approach extends the overall lifespan of the exchanger by facilitating regular upkeep and reducing the impact of localized wear or damage.Expand Specific Solutions

Key Industry Players

The market for surface coating technologies in plate heat exchangers is in a growth phase, driven by increasing demand for energy-efficient and durable heat transfer solutions across industries. The global plate heat exchanger market is projected to reach $5.5 billion by 2025, with a CAGR of 7.8%. Technologically, surface coatings are advancing rapidly, with companies like Hangzhou Sanhua Research Institute, Mitsubishi Electric, and Alfa Laval leading innovation in nano-coatings and anti-fouling materials. These advancements aim to enhance heat transfer efficiency, corrosion resistance, and overall exchanger lifespan. Emerging players such as HurRain NanoTech and Qitaihe Xinke Nano are also contributing to the field with novel nanomaterial solutions, indicating a competitive and dynamic market landscape.

Mitsubishi Electric Corp.

Technical Solution: Mitsubishi Electric has developed advanced surface coating technologies for their plate heat exchangers, focusing on improving durability and performance in various applications. Their proprietary Diamond-Like Carbon (DLC) coating technology provides exceptional wear resistance and low friction properties, extending the lifespan of heat exchanger components[7]. This coating is particularly effective in high-temperature and high-pressure environments. Mitsubishi Electric has also introduced their Hybrid Coating System, which combines organic and inorganic materials to create a multi-layer protective coating[8]. This system offers superior corrosion resistance and thermal stability. Additionally, the company has developed a self-cleaning coating technology that utilizes photocatalytic properties to break down organic contaminants on the heat exchanger surface, reducing maintenance requirements and improving long-term performance[9].

Strengths: Exceptional wear resistance, improved performance in extreme conditions, and reduced maintenance requirements. Weaknesses: Potentially higher initial costs and limited applicability to certain specialized applications.

DAIKIN INDUSTRIES Ltd.

Technical Solution: DAIKIN has developed innovative surface coating technologies for their plate heat exchangers, focusing on improving durability and efficiency. Their proprietary Super Hydrophilic Coating (SHC) technology creates a thin film on the heat exchanger surface that attracts water molecules, forming a protective layer that prevents fouling and corrosion[4]. This coating has been shown to reduce scaling by up to 80% compared to untreated surfaces. DAIKIN has also introduced their e-coating technology, which uses electrodeposition to apply a uniform, corrosion-resistant layer to heat exchanger components[5]. This coating is particularly effective in protecting against galvanic corrosion in mixed-metal systems. Furthermore, DAIKIN has developed a nano-composite coating that incorporates ceramic nanoparticles to enhance wear resistance and thermal conductivity[6].

Strengths: Significant reduction in fouling and corrosion, improved heat transfer efficiency, and enhanced protection against galvanic corrosion. Weaknesses: Potential for increased manufacturing complexity and costs associated with advanced coating processes.

Innovative Coating Tech

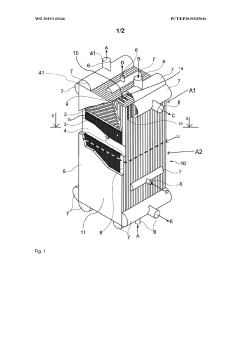

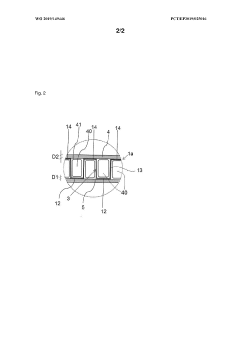

Insulating surface coating on heat exchangers for reducing thermal stresses

PatentWO2019149446A1

Innovation

- A plate heat exchanger with heat-insulating coatings applied to partition walls, heat-conducting elements, and side strips within the heat exchange passages, reducing thermal gradients by minimizing heat transfer and distributing temperature changes more evenly.

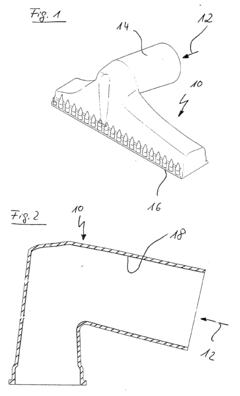

Heat exchanger, more particularly supercharge air cooler

PatentInactiveEP1245417A2

Innovation

- The use of thermoplastic materials for heat exchanger components with a surface coating, such as polysiloxane, epoxyphenol, or polyamide-imide lacquer, enhances thermal resistance and durability by inhibiting oxidation and hydrolysis, while maintaining economic production costs.

Environmental Impact

The environmental impact of surface coatings on plate heat exchangers is a critical consideration in the context of sustainability and ecological responsibility. These coatings, while enhancing durability and performance, can have both positive and negative effects on the environment throughout their lifecycle.

One of the primary environmental benefits of surface coatings is their ability to extend the lifespan of plate heat exchangers. By protecting against corrosion, fouling, and wear, coatings reduce the frequency of replacement and maintenance. This longevity translates to reduced resource consumption and waste generation associated with manufacturing and disposing of heat exchanger components.

However, the production of surface coatings often involves the use of chemicals and processes that can be environmentally harmful. Many coatings contain volatile organic compounds (VOCs) and other potentially toxic substances. The application process may release these compounds into the atmosphere, contributing to air pollution and potential health hazards for workers and surrounding communities.

Water-based coatings have emerged as a more environmentally friendly alternative to solvent-based options. These coatings significantly reduce VOC emissions and minimize the risk of environmental contamination. However, they may not always provide the same level of performance as their solvent-based counterparts, particularly in high-temperature or chemically aggressive environments.

The disposal of coated heat exchanger plates at the end of their lifecycle presents another environmental challenge. Some coatings may contain materials that are difficult to recycle or require special handling to prevent environmental contamination. This can complicate the recycling process and potentially increase the volume of waste sent to landfills.

On the other hand, certain advanced coatings can improve the energy efficiency of plate heat exchangers by enhancing heat transfer and reducing fouling. This increased efficiency can lead to significant energy savings over the lifetime of the equipment, indirectly reducing greenhouse gas emissions and other environmental impacts associated with energy production.

Nanotechnology-based coatings show promise in further improving environmental performance. These coatings can provide superior protection and efficiency improvements while using less material, potentially reducing the overall environmental footprint of the coating process.

As environmental regulations become more stringent, manufacturers are increasingly focusing on developing eco-friendly coating solutions. This includes research into biodegradable coatings, coatings derived from renewable resources, and those that facilitate easier recycling of heat exchanger components at the end of their useful life.

In conclusion, while surface coatings play a crucial role in enhancing the durability of plate heat exchangers, their environmental impact is complex and multifaceted. The industry continues to strive for a balance between performance, durability, and environmental responsibility, driving innovation towards more sustainable coating technologies.

One of the primary environmental benefits of surface coatings is their ability to extend the lifespan of plate heat exchangers. By protecting against corrosion, fouling, and wear, coatings reduce the frequency of replacement and maintenance. This longevity translates to reduced resource consumption and waste generation associated with manufacturing and disposing of heat exchanger components.

However, the production of surface coatings often involves the use of chemicals and processes that can be environmentally harmful. Many coatings contain volatile organic compounds (VOCs) and other potentially toxic substances. The application process may release these compounds into the atmosphere, contributing to air pollution and potential health hazards for workers and surrounding communities.

Water-based coatings have emerged as a more environmentally friendly alternative to solvent-based options. These coatings significantly reduce VOC emissions and minimize the risk of environmental contamination. However, they may not always provide the same level of performance as their solvent-based counterparts, particularly in high-temperature or chemically aggressive environments.

The disposal of coated heat exchanger plates at the end of their lifecycle presents another environmental challenge. Some coatings may contain materials that are difficult to recycle or require special handling to prevent environmental contamination. This can complicate the recycling process and potentially increase the volume of waste sent to landfills.

On the other hand, certain advanced coatings can improve the energy efficiency of plate heat exchangers by enhancing heat transfer and reducing fouling. This increased efficiency can lead to significant energy savings over the lifetime of the equipment, indirectly reducing greenhouse gas emissions and other environmental impacts associated with energy production.

Nanotechnology-based coatings show promise in further improving environmental performance. These coatings can provide superior protection and efficiency improvements while using less material, potentially reducing the overall environmental footprint of the coating process.

As environmental regulations become more stringent, manufacturers are increasingly focusing on developing eco-friendly coating solutions. This includes research into biodegradable coatings, coatings derived from renewable resources, and those that facilitate easier recycling of heat exchanger components at the end of their useful life.

In conclusion, while surface coatings play a crucial role in enhancing the durability of plate heat exchangers, their environmental impact is complex and multifaceted. The industry continues to strive for a balance between performance, durability, and environmental responsibility, driving innovation towards more sustainable coating technologies.

Cost-Benefit Analysis

The cost-benefit analysis of surface coating for plate heat exchangers (PHEs) is a critical consideration for manufacturers and end-users alike. The initial investment in surface coating technology can be substantial, encompassing research and development costs, specialized equipment, and skilled labor. However, these upfront expenses must be weighed against the long-term benefits of enhanced durability and performance.

One of the primary advantages of surface coating is the significant extension of PHE lifespan. Coated plates can resist corrosion, fouling, and wear more effectively than uncoated alternatives, potentially doubling or even tripling the operational life of the equipment. This longevity translates to reduced replacement frequency and associated costs, including material expenses, labor, and downtime for installation.

Improved heat transfer efficiency is another key benefit of surface coating. By maintaining a cleaner surface over time, coated plates can sustain higher heat transfer rates, leading to energy savings in the long run. These savings can be substantial, especially in large-scale industrial applications where even small improvements in efficiency can result in significant cost reductions over the equipment's lifetime.

Maintenance costs are also markedly reduced with coated PHEs. The enhanced resistance to fouling means less frequent cleaning is required, reducing labor costs and minimizing the use of potentially harsh cleaning chemicals. This not only saves on direct maintenance expenses but also reduces the environmental impact and associated regulatory compliance costs.

However, the cost-benefit equation is not uniformly positive across all applications. The value proposition of surface coating varies depending on factors such as the operating environment, fluid properties, and process requirements. In some cases, the additional cost of coating may not be justified if the operational conditions are relatively benign or if the expected service life is short.

It's also important to consider the potential drawbacks. Some coatings may have limitations in terms of temperature resistance or compatibility with certain fluids, potentially restricting the operational flexibility of the PHE. Additionally, if a coating fails or is damaged, it may be more challenging and expensive to repair compared to an uncoated plate.

In conclusion, while the upfront costs of surface coating for PHEs can be significant, the long-term benefits often outweigh these initial investments. The decision to implement surface coating should be based on a comprehensive analysis of the specific application, considering factors such as expected lifespan, operational conditions, and maintenance requirements. For many industrial applications, particularly those involving corrosive fluids or prone to fouling, the cost-benefit analysis strongly favors the adoption of surface coating technologies for plate heat exchangers.

One of the primary advantages of surface coating is the significant extension of PHE lifespan. Coated plates can resist corrosion, fouling, and wear more effectively than uncoated alternatives, potentially doubling or even tripling the operational life of the equipment. This longevity translates to reduced replacement frequency and associated costs, including material expenses, labor, and downtime for installation.

Improved heat transfer efficiency is another key benefit of surface coating. By maintaining a cleaner surface over time, coated plates can sustain higher heat transfer rates, leading to energy savings in the long run. These savings can be substantial, especially in large-scale industrial applications where even small improvements in efficiency can result in significant cost reductions over the equipment's lifetime.

Maintenance costs are also markedly reduced with coated PHEs. The enhanced resistance to fouling means less frequent cleaning is required, reducing labor costs and minimizing the use of potentially harsh cleaning chemicals. This not only saves on direct maintenance expenses but also reduces the environmental impact and associated regulatory compliance costs.

However, the cost-benefit equation is not uniformly positive across all applications. The value proposition of surface coating varies depending on factors such as the operating environment, fluid properties, and process requirements. In some cases, the additional cost of coating may not be justified if the operational conditions are relatively benign or if the expected service life is short.

It's also important to consider the potential drawbacks. Some coatings may have limitations in terms of temperature resistance or compatibility with certain fluids, potentially restricting the operational flexibility of the PHE. Additionally, if a coating fails or is damaged, it may be more challenging and expensive to repair compared to an uncoated plate.

In conclusion, while the upfront costs of surface coating for PHEs can be significant, the long-term benefits often outweigh these initial investments. The decision to implement surface coating should be based on a comprehensive analysis of the specific application, considering factors such as expected lifespan, operational conditions, and maintenance requirements. For many industrial applications, particularly those involving corrosive fluids or prone to fouling, the cost-benefit analysis strongly favors the adoption of surface coating technologies for plate heat exchangers.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!