Innovations in Quantum Dot Stability through Surface Passivation

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Quantum Dot Passivation Background and Objectives

Quantum dots (QDs) have emerged as a revolutionary class of semiconductor nanocrystals with exceptional optical and electronic properties. Since their discovery in the early 1980s, these nanomaterials have evolved from laboratory curiosities to key components in commercial applications spanning display technologies, biomedical imaging, and photovoltaics. The unique size-dependent properties of quantum dots, governed by quantum confinement effects, allow precise tuning of emission wavelengths by simply adjusting particle dimensions.

Despite their remarkable potential, quantum dot technology has been consistently hindered by stability issues. The high surface-to-volume ratio of these nanocrystals renders them particularly vulnerable to surface defects, oxidation, and environmental degradation. These challenges manifest as decreased quantum yield, spectral shifts, and ultimately, complete photoluminescence quenching—significantly limiting their practical applications and commercial viability.

Surface passivation has emerged as the primary strategy to address these stability concerns. The fundamental objective of passivation is to neutralize surface trap states, protect the core material from environmental factors, and maintain the superior optical properties of quantum dots over extended periods. Early passivation approaches relied on simple organic ligands, but these proved insufficient for long-term stability in demanding applications.

The technical evolution of passivation strategies has progressed through several distinct phases: from basic organic ligand exchange to the development of core-shell architectures, and more recently, to hybrid passivation systems combining inorganic shells with specialized ligand chemistries. Each advancement has incrementally improved stability profiles, but significant challenges remain, particularly for applications requiring exposure to harsh conditions or prolonged operation.

Current research objectives in quantum dot passivation focus on developing multifunctional surface engineering approaches that simultaneously address multiple degradation pathways. These include photo-oxidation resistance, thermal stability enhancement, and protection against ion-induced degradation. Additionally, there is growing emphasis on environmentally benign passivation methods that eliminate toxic components while maintaining performance metrics.

The trajectory of quantum dot technology is increasingly dependent on breakthrough innovations in surface passivation. As applications expand into more demanding environments—from flexible electronics to in vivo biomedical imaging—the requirements for stability become more stringent. This technical investigation aims to comprehensively assess the current state of quantum dot passivation technologies, identify critical challenges, and explore promising research directions that could enable the next generation of ultra-stable quantum dot materials.

Despite their remarkable potential, quantum dot technology has been consistently hindered by stability issues. The high surface-to-volume ratio of these nanocrystals renders them particularly vulnerable to surface defects, oxidation, and environmental degradation. These challenges manifest as decreased quantum yield, spectral shifts, and ultimately, complete photoluminescence quenching—significantly limiting their practical applications and commercial viability.

Surface passivation has emerged as the primary strategy to address these stability concerns. The fundamental objective of passivation is to neutralize surface trap states, protect the core material from environmental factors, and maintain the superior optical properties of quantum dots over extended periods. Early passivation approaches relied on simple organic ligands, but these proved insufficient for long-term stability in demanding applications.

The technical evolution of passivation strategies has progressed through several distinct phases: from basic organic ligand exchange to the development of core-shell architectures, and more recently, to hybrid passivation systems combining inorganic shells with specialized ligand chemistries. Each advancement has incrementally improved stability profiles, but significant challenges remain, particularly for applications requiring exposure to harsh conditions or prolonged operation.

Current research objectives in quantum dot passivation focus on developing multifunctional surface engineering approaches that simultaneously address multiple degradation pathways. These include photo-oxidation resistance, thermal stability enhancement, and protection against ion-induced degradation. Additionally, there is growing emphasis on environmentally benign passivation methods that eliminate toxic components while maintaining performance metrics.

The trajectory of quantum dot technology is increasingly dependent on breakthrough innovations in surface passivation. As applications expand into more demanding environments—from flexible electronics to in vivo biomedical imaging—the requirements for stability become more stringent. This technical investigation aims to comprehensively assess the current state of quantum dot passivation technologies, identify critical challenges, and explore promising research directions that could enable the next generation of ultra-stable quantum dot materials.

Market Analysis for Stable Quantum Dot Applications

The quantum dot market is experiencing significant growth, with a projected CAGR of 23.5% between 2023 and 2030, reaching a market value of $16.5 billion by 2030. This growth is primarily driven by the increasing adoption of quantum dots in display technologies, which currently accounts for approximately 60% of the total market share. The demand for stable quantum dots has been particularly strong in consumer electronics, with major manufacturers incorporating quantum dot technology into premium television and monitor product lines.

Surface-passivated quantum dots with enhanced stability are creating new market opportunities beyond displays. The healthcare and biomedical imaging sector represents the fastest-growing application segment, with an estimated growth rate of 27% annually. Stable quantum dots are increasingly utilized in fluorescence imaging, cell tracking, and diagnostic applications where long-term stability is crucial for reliable results.

The photovoltaic industry has begun incorporating stable quantum dots into next-generation solar cells, with the market for quantum dot solar applications expected to reach $1.2 billion by 2028. This growth is fueled by the improved efficiency and durability that properly passivated quantum dots offer compared to traditional materials.

Lighting applications represent another significant market segment, with quantum dot-enhanced LED lighting solutions gaining traction in commercial and residential settings. The market for quantum dot lighting is projected to grow at 19% annually, driven by energy efficiency requirements and improved color rendering capabilities.

Regional analysis indicates that North America currently leads the market with approximately 40% share, followed by Asia-Pacific at 35%, which is expected to become the dominant region by 2025 due to extensive manufacturing capabilities and increasing adoption rates. Europe accounts for 20% of the market, with particular strength in research and development of new quantum dot applications.

Customer demand patterns show increasing preference for environmentally friendly quantum dot formulations, with cadmium-free variants gaining market share despite higher costs. This trend is reinforced by regulatory pressures, particularly in Europe and parts of Asia, restricting the use of heavy metals in consumer electronics.

Price sensitivity varies significantly by application sector, with display manufacturers willing to pay premium prices for quantum dots offering superior stability and performance, while emerging application areas remain more price-sensitive as they work to establish commercial viability.

Surface-passivated quantum dots with enhanced stability are creating new market opportunities beyond displays. The healthcare and biomedical imaging sector represents the fastest-growing application segment, with an estimated growth rate of 27% annually. Stable quantum dots are increasingly utilized in fluorescence imaging, cell tracking, and diagnostic applications where long-term stability is crucial for reliable results.

The photovoltaic industry has begun incorporating stable quantum dots into next-generation solar cells, with the market for quantum dot solar applications expected to reach $1.2 billion by 2028. This growth is fueled by the improved efficiency and durability that properly passivated quantum dots offer compared to traditional materials.

Lighting applications represent another significant market segment, with quantum dot-enhanced LED lighting solutions gaining traction in commercial and residential settings. The market for quantum dot lighting is projected to grow at 19% annually, driven by energy efficiency requirements and improved color rendering capabilities.

Regional analysis indicates that North America currently leads the market with approximately 40% share, followed by Asia-Pacific at 35%, which is expected to become the dominant region by 2025 due to extensive manufacturing capabilities and increasing adoption rates. Europe accounts for 20% of the market, with particular strength in research and development of new quantum dot applications.

Customer demand patterns show increasing preference for environmentally friendly quantum dot formulations, with cadmium-free variants gaining market share despite higher costs. This trend is reinforced by regulatory pressures, particularly in Europe and parts of Asia, restricting the use of heavy metals in consumer electronics.

Price sensitivity varies significantly by application sector, with display manufacturers willing to pay premium prices for quantum dots offering superior stability and performance, while emerging application areas remain more price-sensitive as they work to establish commercial viability.

Current Challenges in Quantum Dot Surface Stability

Quantum dots (QDs) face significant stability challenges that hinder their widespread commercial application despite their exceptional optoelectronic properties. The primary issue stems from their high surface-to-volume ratio, which creates numerous dangling bonds and surface defects that act as non-radiative recombination centers. These surface imperfections dramatically reduce quantum yield and compromise long-term performance stability, particularly when QDs are exposed to environmental factors.

Oxidation represents one of the most detrimental processes affecting QD stability. When exposed to oxygen, the surface atoms of QDs undergo oxidation, leading to the formation of oxide layers that alter the electronic structure and optical properties. This is especially problematic for chalcogenide-based QDs (CdSe, PbS, etc.), where oxidation can cause blue-shifts in emission wavelengths, decreased photoluminescence intensity, and eventually complete photoluminescence quenching.

Photodegradation presents another critical challenge, occurring when QDs are exposed to light—ironically the very condition required for many of their applications. Under illumination, photoexcited carriers can initiate chemical reactions at the QD surface, leading to the formation of surface traps and accelerating degradation processes. This photodegradation is particularly problematic in display technologies and solar cells where continuous light exposure is inevitable.

Thermal instability further complicates QD implementation in commercial devices. At elevated temperatures, surface ligands can detach from the QD surface, leaving unpassivated sites vulnerable to oxidation and aggregation. Additionally, high temperatures can promote interdiffusion between the QD core and shell materials in core-shell structures, degrading the carefully engineered electronic confinement properties.

The ligand dynamics at the QD surface represent another significant challenge. Traditional organic ligands used for colloidal stability often exhibit dynamic binding-unbinding processes, creating temporal fluctuations in surface passivation quality. This phenomenon contributes to "blinking" behavior in single QD emission and inconsistent performance in QD ensembles. Furthermore, long-chain organic ligands, while providing good surface passivation, create insulating barriers that impede charge transport in electronic devices.

In biological and aqueous environments, QDs face additional stability challenges. The hydrophobic nature of conventional surface ligands makes QDs incompatible with aqueous media without additional surface modification. When transferred to aqueous environments, QDs often experience dramatic decreases in quantum yield and increased susceptibility to aggregation and precipitation.

Manufacturing scalability presents yet another obstacle, as current methods for producing highly stable QDs typically involve complex, multi-step processes that are difficult to scale industrially while maintaining consistent quality. The trade-off between stability enhancement and cost-effective mass production remains a significant hurdle for commercial adoption.

Oxidation represents one of the most detrimental processes affecting QD stability. When exposed to oxygen, the surface atoms of QDs undergo oxidation, leading to the formation of oxide layers that alter the electronic structure and optical properties. This is especially problematic for chalcogenide-based QDs (CdSe, PbS, etc.), where oxidation can cause blue-shifts in emission wavelengths, decreased photoluminescence intensity, and eventually complete photoluminescence quenching.

Photodegradation presents another critical challenge, occurring when QDs are exposed to light—ironically the very condition required for many of their applications. Under illumination, photoexcited carriers can initiate chemical reactions at the QD surface, leading to the formation of surface traps and accelerating degradation processes. This photodegradation is particularly problematic in display technologies and solar cells where continuous light exposure is inevitable.

Thermal instability further complicates QD implementation in commercial devices. At elevated temperatures, surface ligands can detach from the QD surface, leaving unpassivated sites vulnerable to oxidation and aggregation. Additionally, high temperatures can promote interdiffusion between the QD core and shell materials in core-shell structures, degrading the carefully engineered electronic confinement properties.

The ligand dynamics at the QD surface represent another significant challenge. Traditional organic ligands used for colloidal stability often exhibit dynamic binding-unbinding processes, creating temporal fluctuations in surface passivation quality. This phenomenon contributes to "blinking" behavior in single QD emission and inconsistent performance in QD ensembles. Furthermore, long-chain organic ligands, while providing good surface passivation, create insulating barriers that impede charge transport in electronic devices.

In biological and aqueous environments, QDs face additional stability challenges. The hydrophobic nature of conventional surface ligands makes QDs incompatible with aqueous media without additional surface modification. When transferred to aqueous environments, QDs often experience dramatic decreases in quantum yield and increased susceptibility to aggregation and precipitation.

Manufacturing scalability presents yet another obstacle, as current methods for producing highly stable QDs typically involve complex, multi-step processes that are difficult to scale industrially while maintaining consistent quality. The trade-off between stability enhancement and cost-effective mass production remains a significant hurdle for commercial adoption.

State-of-the-Art Surface Passivation Methodologies

01 Surface modification techniques for quantum dot stability

Various surface modification techniques can be employed to enhance the stability of quantum dots. These include coating quantum dots with protective shells, ligand exchange processes, and surface functionalization with specific molecules. These modifications help to prevent oxidation, aggregation, and degradation of quantum dots, thereby improving their long-term stability and performance in various applications.- Surface modification for quantum dot stability: Surface modification techniques are employed to enhance the stability of quantum dots by preventing aggregation and oxidation. These methods include coating quantum dots with protective shells, ligand exchange processes, and surface functionalization with stabilizing agents. Such modifications create a barrier against environmental factors that could degrade quantum dot performance, thereby extending their operational lifetime and maintaining their optical properties.

- Core-shell structures for improved stability: Core-shell architectures significantly enhance quantum dot stability by providing physical isolation of the core material from environmental factors. The shell material, typically a semiconductor with a wider bandgap than the core, protects against oxidation and surface defects while preserving the quantum confinement effects. These structures can be engineered with gradient compositions or multiple shell layers to minimize lattice mismatch and further improve stability under various operating conditions.

- Encapsulation methods for environmental protection: Encapsulation strategies protect quantum dots from environmental degradation by embedding them in matrices such as polymers, silica, or other inorganic materials. These encapsulation methods create physical barriers against oxygen, moisture, and other reactive species while maintaining the optical and electronic properties of the quantum dots. Advanced encapsulation techniques can also provide mechanical stability and enable integration into various device architectures.

- Chemical composition optimization for stability: Optimizing the chemical composition of quantum dots enhances their stability through careful selection of constituent materials and dopants. This approach involves engineering the stoichiometry, incorporating stabilizing elements, and controlling defect concentrations to minimize degradation pathways. Alloyed quantum dots with gradient compositions can reduce internal strain and surface defects, leading to improved thermal and chemical stability without compromising optical performance.

- Synthesis methods affecting quantum dot stability: The synthesis methodology significantly impacts quantum dot stability through control of nucleation, growth kinetics, and surface chemistry. Advanced synthesis techniques such as hot-injection, microfluidic approaches, and continuous flow methods enable precise control over size distribution, crystallinity, and surface defects. Post-synthesis treatments including annealing, purification, and surface passivation further enhance stability by removing impurities and healing structural defects that could serve as degradation initiation sites.

02 Core-shell structures for improved quantum dot stability

Core-shell structured quantum dots, where the core quantum dot is encapsulated within a shell of another semiconductor material, demonstrate enhanced stability. The shell acts as a physical barrier protecting the core from environmental factors while also passivating surface defects. This structure effectively reduces non-radiative recombination pathways and improves quantum yield and stability under various operating conditions.Expand Specific Solutions03 Polymer encapsulation for quantum dot stabilization

Encapsulating quantum dots within polymer matrices provides significant stability improvements. Polymers create a protective environment that shields quantum dots from oxygen, moisture, and other degradation factors. Various polymers including silicones, acrylates, and specialized copolymers can be used to create stable quantum dot composites that maintain their optical and electronic properties over extended periods.Expand Specific Solutions04 Chemical stabilization methods for quantum dots

Chemical approaches to quantum dot stabilization involve the use of specific ligands, additives, and chemical treatments that enhance stability. These methods include the incorporation of antioxidants, cross-linking agents, and specialized binding molecules that prevent degradation. Chemical stabilization can be tailored to specific quantum dot compositions and intended applications, providing targeted protection against particular degradation mechanisms.Expand Specific Solutions05 Environmental control for quantum dot stability

Controlling the environmental conditions surrounding quantum dots is crucial for maintaining their stability. This includes managing temperature, humidity, light exposure, and atmospheric composition during both manufacturing and application. Specialized packaging, inert atmospheres, and environmental barrier coatings can significantly extend quantum dot lifetime by minimizing exposure to degradation factors such as oxygen and moisture.Expand Specific Solutions

Leading Organizations in Quantum Dot Passivation Research

The quantum dot stability through surface passivation market is currently in a growth phase, with increasing adoption across display and optoelectronic applications. The global market is projected to expand significantly as quantum dot technology matures, driven by demand for higher performance displays and lighting solutions. Leading players like Samsung Electronics, Mojo Vision, and Huawei are advancing commercial applications, while specialized companies such as QustomDot and Wuxi UtmoLight are developing innovative passivation techniques. Research institutions including Ghent University and KAUST are contributing fundamental breakthroughs in surface chemistry. The technology is approaching maturity in display applications but remains in development for more advanced quantum computing and biomedical uses, with companies like Shin-Etsu Chemical and SABIC providing essential materials support for the ecosystem.

SAMSUNG SDI CO LTD

Technical Solution: Samsung SDI has pioneered a comprehensive quantum dot surface passivation system called "QD-Matrix" that addresses multiple stability challenges simultaneously. Their approach combines core-shell engineering with advanced ligand chemistry to create quantum dots with exceptional environmental and thermal stability. The technology employs a gradient-alloyed shell structure that distributes lattice strain across multiple atomic layers rather than concentrating it at interfaces. This is complemented by a proprietary mixture of short and long-chain ligands that provide both electronic passivation and steric protection. Samsung SDI has developed a unique post-synthesis treatment involving controlled oxidation of the quantum dot surface, which counter-intuitively improves stability by creating a self-limiting oxide layer that prevents further degradation. Their quantum dots demonstrate remarkable resistance to photo-oxidation, maintaining over 95% quantum efficiency after 5,000 hours of continuous blue light exposure at elevated temperatures (85°C), significantly outperforming conventional passivation methods.

Strengths: Superior thermal and photo-stability compared to industry standards; scalable manufacturing processes already implemented in production; comprehensive protection against multiple degradation mechanisms. Weaknesses: Higher production costs than conventional phosphors; technology primarily optimized for display and lighting applications; requires precise control of manufacturing conditions.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung Electronics has developed an advanced quantum dot surface passivation technology called "QD-Shield" specifically designed for their QLED display products. This technology employs a multi-layered approach where quantum dots are encapsulated with an inorganic shell followed by specially engineered metal-organic compounds that form covalent bonds with the quantum dot surface. Samsung's innovation includes a proprietary metal halide treatment process that effectively passivates surface trap states, reducing non-radiative recombination pathways. Their quantum dots feature a gradient composition shell that gradually transitions from core to surface, minimizing interfacial strain and associated defects. The company has also developed a unique vapor-phase deposition technique for applying uniform passivation layers at scale, enabling industrial production of highly stable quantum dots that maintain over 90% efficiency after 30,000 hours of operation in display environments.

Strengths: Extensive manufacturing infrastructure for commercial-scale production; comprehensive intellectual property portfolio in QD passivation; proven implementation in consumer products. Weaknesses: Technology primarily optimized for display applications rather than broader quantum dot applications; relatively high production costs compared to conventional phosphor technologies; heavy reliance on specific rare materials.

Key Patents and Publications on Quantum Dot Stability

Quantum dots, composition comprising same, and method for manufacturing quantum dots

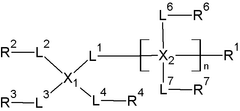

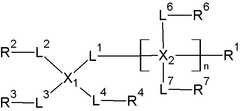

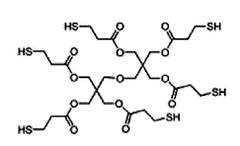

PatentWO2016195188A1

Innovation

- Passivating quantum dots with an oligomer or polymer formed from a monomer with multiple thiol groups and a spacer group, which forms a three-dimensional network on the surface, enhancing stability and dispersibility, and using specific monomers like dipentaerythritol hexakis(3-mercaptopropionate) and tricyclodecane dimethanol diacrylate to improve compatibility with solvents and matrix resins.

Surface-passivated quantum dots and method for passivating surface of quantum dots

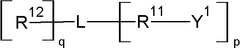

PatentActiveUS20200339875A1

Innovation

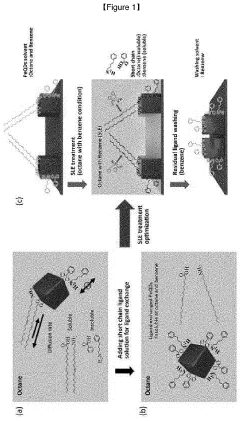

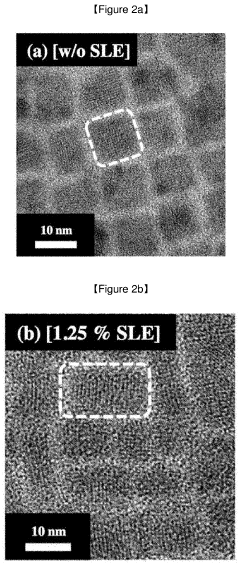

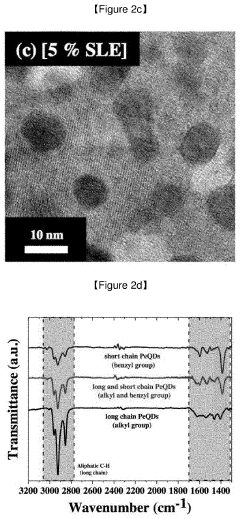

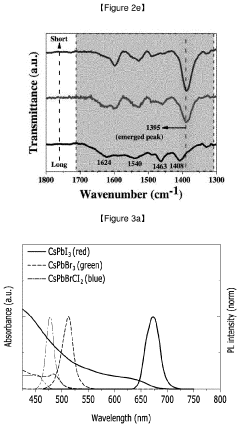

- Surface-passivated perovskite quantum dots are developed using a short chain ligand exchange method, where a pretreatment layer is formed with fatty acid and amine-based organic ligands, followed by a ligand exchange reaction with organic ligands represented by Chemical Formulas 2 and 3, to create a stable passivation layer, optimizing optical properties and reducing surface defects.

Environmental Impact of Quantum Dot Materials

The environmental impact of quantum dot materials represents a critical consideration in their development and application, particularly as innovations in surface passivation techniques advance. Quantum dots (QDs), while offering revolutionary potential in display technologies, solar cells, and biomedical applications, present significant environmental challenges throughout their lifecycle.

Heavy metal content in conventional quantum dots, particularly cadmium, lead, and selenium compounds, poses substantial ecological risks. These materials can leach into soil and water systems when improperly disposed of, potentially entering food chains and causing bioaccumulation in organisms. Surface passivation innovations using less toxic materials such as zinc sulfide shells or completely cadmium-free formulations (indium phosphide-based QDs) represent important steps toward reducing this environmental burden.

Manufacturing processes for quantum dots typically involve energy-intensive conditions and hazardous solvents. The high-temperature synthesis methods and organic solvents used in traditional QD production contribute significantly to their environmental footprint. Recent passivation techniques utilizing aqueous-based synthesis routes and greener solvents demonstrate promising reductions in process-related environmental impacts, though scale-up challenges remain.

End-of-life considerations for quantum dot materials present particular challenges. The nanoscale nature of these materials complicates conventional recycling approaches, and their increasing incorporation into consumer electronics creates potential for widespread environmental dispersion. Surface passivation innovations that enhance stability may inadvertently extend environmental persistence, requiring careful balance between product longevity and environmental degradation pathways.

Regulatory frameworks worldwide are increasingly addressing nanomaterial environmental impacts, with specific attention to quantum dots. The European Union's RoHS directive restricts hazardous substances in electronics, while the U.S. EPA continues developing nanomaterial-specific guidelines. Surface passivation research must navigate these evolving regulatory landscapes, particularly as QD applications expand into consumer markets.

Life cycle assessment (LCA) studies indicate that environmental benefits from quantum dot applications, such as energy efficiency improvements in displays and solar cells, may offset production impacts. However, these analyses remain incomplete without comprehensive data on long-term environmental fate and behavior of passivated quantum dots. Research gaps persist regarding degradation mechanisms, transformation products, and ecological interactions of these materials in real-world environmental conditions.

Heavy metal content in conventional quantum dots, particularly cadmium, lead, and selenium compounds, poses substantial ecological risks. These materials can leach into soil and water systems when improperly disposed of, potentially entering food chains and causing bioaccumulation in organisms. Surface passivation innovations using less toxic materials such as zinc sulfide shells or completely cadmium-free formulations (indium phosphide-based QDs) represent important steps toward reducing this environmental burden.

Manufacturing processes for quantum dots typically involve energy-intensive conditions and hazardous solvents. The high-temperature synthesis methods and organic solvents used in traditional QD production contribute significantly to their environmental footprint. Recent passivation techniques utilizing aqueous-based synthesis routes and greener solvents demonstrate promising reductions in process-related environmental impacts, though scale-up challenges remain.

End-of-life considerations for quantum dot materials present particular challenges. The nanoscale nature of these materials complicates conventional recycling approaches, and their increasing incorporation into consumer electronics creates potential for widespread environmental dispersion. Surface passivation innovations that enhance stability may inadvertently extend environmental persistence, requiring careful balance between product longevity and environmental degradation pathways.

Regulatory frameworks worldwide are increasingly addressing nanomaterial environmental impacts, with specific attention to quantum dots. The European Union's RoHS directive restricts hazardous substances in electronics, while the U.S. EPA continues developing nanomaterial-specific guidelines. Surface passivation research must navigate these evolving regulatory landscapes, particularly as QD applications expand into consumer markets.

Life cycle assessment (LCA) studies indicate that environmental benefits from quantum dot applications, such as energy efficiency improvements in displays and solar cells, may offset production impacts. However, these analyses remain incomplete without comprehensive data on long-term environmental fate and behavior of passivated quantum dots. Research gaps persist regarding degradation mechanisms, transformation products, and ecological interactions of these materials in real-world environmental conditions.

Scalability and Manufacturing Considerations

The scalability of quantum dot (QD) manufacturing processes incorporating advanced surface passivation techniques presents significant challenges for commercial implementation. Current laboratory-scale synthesis methods that achieve high stability through surface passivation often involve complex multi-step procedures that are difficult to scale. Batch-to-batch reproducibility remains a critical concern, with variations in passivation layer thickness and coverage directly impacting quantum yield consistency and long-term stability profiles.

Manufacturing considerations must address the economic viability of large-scale production. While traditional QD synthesis methods have been successfully scaled, the integration of sophisticated passivation techniques often requires specialized equipment and precise control of reaction parameters. The cost of high-purity precursors and ligands used in passivation processes can significantly impact the final product price point, potentially limiting market penetration in cost-sensitive applications.

Environmental and safety considerations also play a crucial role in scaling passivation technologies. Many effective passivation approaches utilize toxic materials such as lead or cadmium compounds, necessitating robust containment systems and waste management protocols. Regulatory compliance across different markets adds another layer of complexity to manufacturing scale-up strategies.

Recent innovations in continuous flow synthesis represent a promising direction for scalable production of surface-passivated quantum dots. These approaches allow for precise control of reaction conditions and can potentially reduce batch-to-batch variations. Several research groups have demonstrated automated systems capable of producing gram-scale quantities of passivated QDs with consistent optical properties, though further engineering is required to reach industrial production volumes.

The integration of in-line quality control methods presents another frontier in manufacturing scale-up. Real-time spectroscopic monitoring during synthesis can provide immediate feedback on passivation quality, enabling process adjustments that maintain product consistency. Machine learning algorithms are increasingly being employed to optimize reaction parameters and predict stability outcomes based on manufacturing data.

Industry-academic partnerships have emerged as a key strategy for addressing scalability challenges. Companies like Nanosys, QD Vision, and Samsung have established collaborations with research institutions to bridge the gap between laboratory innovations and commercial manufacturing requirements. These partnerships focus on developing simplified passivation protocols that maintain stability while reducing process complexity and cost.

Manufacturing considerations must address the economic viability of large-scale production. While traditional QD synthesis methods have been successfully scaled, the integration of sophisticated passivation techniques often requires specialized equipment and precise control of reaction parameters. The cost of high-purity precursors and ligands used in passivation processes can significantly impact the final product price point, potentially limiting market penetration in cost-sensitive applications.

Environmental and safety considerations also play a crucial role in scaling passivation technologies. Many effective passivation approaches utilize toxic materials such as lead or cadmium compounds, necessitating robust containment systems and waste management protocols. Regulatory compliance across different markets adds another layer of complexity to manufacturing scale-up strategies.

Recent innovations in continuous flow synthesis represent a promising direction for scalable production of surface-passivated quantum dots. These approaches allow for precise control of reaction conditions and can potentially reduce batch-to-batch variations. Several research groups have demonstrated automated systems capable of producing gram-scale quantities of passivated QDs with consistent optical properties, though further engineering is required to reach industrial production volumes.

The integration of in-line quality control methods presents another frontier in manufacturing scale-up. Real-time spectroscopic monitoring during synthesis can provide immediate feedback on passivation quality, enabling process adjustments that maintain product consistency. Machine learning algorithms are increasingly being employed to optimize reaction parameters and predict stability outcomes based on manufacturing data.

Industry-academic partnerships have emerged as a key strategy for addressing scalability challenges. Companies like Nanosys, QD Vision, and Samsung have established collaborations with research institutions to bridge the gap between laboratory innovations and commercial manufacturing requirements. These partnerships focus on developing simplified passivation protocols that maintain stability while reducing process complexity and cost.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!