Integration of Virtual Reality in Gas Welding Training Programs

AUG 7, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

VR Gas Welding Background and Objectives

Virtual Reality (VR) technology has rapidly evolved over the past decade, revolutionizing various industries, including manufacturing and education. The integration of VR in gas welding training programs represents a significant advancement in the field of vocational education and industrial skills development. This technological convergence aims to enhance the safety, efficiency, and effectiveness of welding training while reducing costs and environmental impact.

The history of welding training has traditionally relied on hands-on experience with real equipment, which often involves high costs, safety risks, and material waste. As industries seek more sustainable and cost-effective training methods, VR has emerged as a promising solution. The evolution of VR technology, from early prototypes to today's sophisticated systems, has made it increasingly viable for practical applications in technical training.

The primary objective of integrating VR into gas welding training programs is to create a safe, immersive, and realistic learning environment that closely simulates real-world welding scenarios. This integration aims to accelerate skill acquisition, reduce training costs, and minimize the risks associated with traditional welding training methods. Additionally, it seeks to standardize training procedures and provide consistent, high-quality instruction regardless of geographical location or resource constraints.

Another key goal is to enhance the assessment and monitoring of trainee performance. VR systems can collect detailed data on welding techniques, allowing for precise evaluation and personalized feedback. This data-driven approach aims to identify areas for improvement more efficiently than traditional observation methods.

The technology also addresses the growing need for flexible and remote learning options in the welding industry. As the global workforce becomes more distributed, VR-based training programs offer the potential for standardized instruction across different locations, ensuring consistency in skill development and certification processes.

Furthermore, the integration of VR in welding training aligns with broader industry trends towards digitalization and Industry 4.0 principles. It represents a step towards creating more adaptive and technology-driven workforce development strategies that can quickly respond to changing industry needs and technological advancements.

As the welding industry faces challenges such as skill shortages and an aging workforce, VR training programs aim to attract younger generations to the field by offering a more engaging and technologically advanced learning experience. This approach not only seeks to address immediate training needs but also to future-proof the industry by fostering a new generation of tech-savvy welding professionals.

The history of welding training has traditionally relied on hands-on experience with real equipment, which often involves high costs, safety risks, and material waste. As industries seek more sustainable and cost-effective training methods, VR has emerged as a promising solution. The evolution of VR technology, from early prototypes to today's sophisticated systems, has made it increasingly viable for practical applications in technical training.

The primary objective of integrating VR into gas welding training programs is to create a safe, immersive, and realistic learning environment that closely simulates real-world welding scenarios. This integration aims to accelerate skill acquisition, reduce training costs, and minimize the risks associated with traditional welding training methods. Additionally, it seeks to standardize training procedures and provide consistent, high-quality instruction regardless of geographical location or resource constraints.

Another key goal is to enhance the assessment and monitoring of trainee performance. VR systems can collect detailed data on welding techniques, allowing for precise evaluation and personalized feedback. This data-driven approach aims to identify areas for improvement more efficiently than traditional observation methods.

The technology also addresses the growing need for flexible and remote learning options in the welding industry. As the global workforce becomes more distributed, VR-based training programs offer the potential for standardized instruction across different locations, ensuring consistency in skill development and certification processes.

Furthermore, the integration of VR in welding training aligns with broader industry trends towards digitalization and Industry 4.0 principles. It represents a step towards creating more adaptive and technology-driven workforce development strategies that can quickly respond to changing industry needs and technological advancements.

As the welding industry faces challenges such as skill shortages and an aging workforce, VR training programs aim to attract younger generations to the field by offering a more engaging and technologically advanced learning experience. This approach not only seeks to address immediate training needs but also to future-proof the industry by fostering a new generation of tech-savvy welding professionals.

Market Analysis for VR Welding Training

The market for virtual reality (VR) welding training programs has been experiencing significant growth in recent years, driven by the increasing demand for skilled welders and the need for cost-effective, safe, and efficient training methods. The global welding industry is projected to reach a substantial market value in the coming years, with a growing emphasis on advanced training techniques to address the skills gap in the sector.

VR welding training offers numerous advantages over traditional methods, including reduced material costs, enhanced safety, and the ability to simulate various welding scenarios without the need for physical equipment. This has led to a surge in adoption across various industries, including manufacturing, construction, and automotive sectors.

The market for VR welding training can be segmented based on end-users, including educational institutions, vocational training centers, and industrial organizations. Educational institutions are increasingly incorporating VR technology into their welding curricula to provide students with hands-on experience in a controlled environment. Vocational training centers are leveraging VR to offer more comprehensive and accessible training programs, while industrial organizations are using it for both new employee training and skill enhancement of existing workers.

Geographically, North America and Europe currently dominate the VR welding training market, owing to their advanced technological infrastructure and early adoption of innovative training methods. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid industrialization and increasing investments in workforce development.

Key market drivers include the rising demand for skilled welders, the need for cost-effective training solutions, and the increasing focus on workplace safety. The shortage of skilled welders in many countries has created a pressing need for efficient training methods that can quickly produce competent professionals. VR training addresses this need by offering accelerated learning curves and the ability to practice without material waste.

However, the market also faces certain challenges, such as the high initial investment required for VR equipment and software, and the need for continuous updates to keep pace with evolving welding technologies. Additionally, there is a learning curve associated with implementing VR training programs, which may slow adoption in some sectors.

Despite these challenges, the future outlook for the VR welding training market remains positive. As technology continues to advance and become more affordable, the adoption of VR training is expected to increase across various industries. The integration of artificial intelligence and machine learning into VR welding simulations is likely to further enhance the effectiveness of these training programs, providing more personalized and adaptive learning experiences.

VR welding training offers numerous advantages over traditional methods, including reduced material costs, enhanced safety, and the ability to simulate various welding scenarios without the need for physical equipment. This has led to a surge in adoption across various industries, including manufacturing, construction, and automotive sectors.

The market for VR welding training can be segmented based on end-users, including educational institutions, vocational training centers, and industrial organizations. Educational institutions are increasingly incorporating VR technology into their welding curricula to provide students with hands-on experience in a controlled environment. Vocational training centers are leveraging VR to offer more comprehensive and accessible training programs, while industrial organizations are using it for both new employee training and skill enhancement of existing workers.

Geographically, North America and Europe currently dominate the VR welding training market, owing to their advanced technological infrastructure and early adoption of innovative training methods. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid industrialization and increasing investments in workforce development.

Key market drivers include the rising demand for skilled welders, the need for cost-effective training solutions, and the increasing focus on workplace safety. The shortage of skilled welders in many countries has created a pressing need for efficient training methods that can quickly produce competent professionals. VR training addresses this need by offering accelerated learning curves and the ability to practice without material waste.

However, the market also faces certain challenges, such as the high initial investment required for VR equipment and software, and the need for continuous updates to keep pace with evolving welding technologies. Additionally, there is a learning curve associated with implementing VR training programs, which may slow adoption in some sectors.

Despite these challenges, the future outlook for the VR welding training market remains positive. As technology continues to advance and become more affordable, the adoption of VR training is expected to increase across various industries. The integration of artificial intelligence and machine learning into VR welding simulations is likely to further enhance the effectiveness of these training programs, providing more personalized and adaptive learning experiences.

Current VR Integration Challenges in Welding Education

The integration of Virtual Reality (VR) in gas welding training programs faces several significant challenges that hinder its widespread adoption and effectiveness. One of the primary obstacles is the high initial cost associated with implementing VR technology. The expense of VR hardware, software development, and maintenance can be prohibitive for many educational institutions and training centers, particularly those with limited budgets.

Another major challenge is the technical complexity of creating realistic and accurate VR simulations for gas welding. Replicating the intricate physical properties of welding processes, such as heat transfer, material deformation, and gas flow dynamics, requires sophisticated modeling and rendering techniques. This level of complexity often demands specialized expertise and resources that may not be readily available to many institutions.

The lack of standardization in VR welding training systems poses additional difficulties. Different VR platforms and software may offer varying levels of fidelity and features, making it challenging to ensure consistent training quality across different institutions or even within the same organization. This inconsistency can lead to discrepancies in skill development and assessment, potentially undermining the credibility of VR-based training programs.

Ergonomic issues also present significant challenges in VR welding education. Extended use of VR headsets can cause discomfort, eye strain, and motion sickness in some users. These physical discomforts can negatively impact the learning experience and limit the duration of training sessions, potentially reducing the overall effectiveness of the training program.

The integration of haptic feedback in VR welding simulations remains a significant technical hurdle. Accurately replicating the tactile sensations experienced during welding, such as the weight of the welding torch and the resistance of the molten metal, is crucial for developing proper technique and muscle memory. Current haptic technologies often fall short in providing realistic feedback, potentially leading to a disconnect between virtual training and real-world application.

Furthermore, there is a notable shortage of qualified instructors who are proficient in both traditional welding techniques and VR technology. This skills gap can hinder the effective implementation and utilization of VR training systems, as instructors may struggle to bridge the gap between virtual and physical welding environments.

Lastly, the rapid pace of technological advancement in VR presents a challenge for long-term planning and investment. Educational institutions may hesitate to commit resources to current VR systems, fearing obsolescence in the face of continual improvements in hardware and software capabilities. This uncertainty can slow down the adoption and integration of VR technology in welding education programs.

Another major challenge is the technical complexity of creating realistic and accurate VR simulations for gas welding. Replicating the intricate physical properties of welding processes, such as heat transfer, material deformation, and gas flow dynamics, requires sophisticated modeling and rendering techniques. This level of complexity often demands specialized expertise and resources that may not be readily available to many institutions.

The lack of standardization in VR welding training systems poses additional difficulties. Different VR platforms and software may offer varying levels of fidelity and features, making it challenging to ensure consistent training quality across different institutions or even within the same organization. This inconsistency can lead to discrepancies in skill development and assessment, potentially undermining the credibility of VR-based training programs.

Ergonomic issues also present significant challenges in VR welding education. Extended use of VR headsets can cause discomfort, eye strain, and motion sickness in some users. These physical discomforts can negatively impact the learning experience and limit the duration of training sessions, potentially reducing the overall effectiveness of the training program.

The integration of haptic feedback in VR welding simulations remains a significant technical hurdle. Accurately replicating the tactile sensations experienced during welding, such as the weight of the welding torch and the resistance of the molten metal, is crucial for developing proper technique and muscle memory. Current haptic technologies often fall short in providing realistic feedback, potentially leading to a disconnect between virtual training and real-world application.

Furthermore, there is a notable shortage of qualified instructors who are proficient in both traditional welding techniques and VR technology. This skills gap can hinder the effective implementation and utilization of VR training systems, as instructors may struggle to bridge the gap between virtual and physical welding environments.

Lastly, the rapid pace of technological advancement in VR presents a challenge for long-term planning and investment. Educational institutions may hesitate to commit resources to current VR systems, fearing obsolescence in the face of continual improvements in hardware and software capabilities. This uncertainty can slow down the adoption and integration of VR technology in welding education programs.

Existing VR Gas Welding Training Solutions

01 Immersive VR Environments

Creating realistic and immersive virtual reality environments through advanced rendering techniques, 3D modeling, and interactive elements. This includes the development of virtual worlds, objects, and characters that respond to user input and provide a sense of presence.- Immersive Virtual Reality Systems: Advanced systems that create fully immersive virtual reality experiences, incorporating visual, auditory, and haptic feedback. These systems often include head-mounted displays, motion tracking, and interactive controllers to provide users with a sense of presence in virtual environments.

- Virtual Reality User Interfaces: Innovative user interface designs specifically tailored for virtual reality applications. These interfaces may include gesture recognition, eye tracking, and voice commands to enhance user interaction within virtual environments, improving navigation and control in 3D spaces.

- Virtual Reality Content Creation and Rendering: Tools and techniques for creating, rendering, and optimizing virtual reality content. This includes 3D modeling, real-time rendering engines, and methods for reducing latency and improving frame rates to enhance the overall VR experience and prevent motion sickness.

- Virtual Reality in Training and Simulation: Applications of virtual reality technology in training and simulation scenarios, such as medical procedures, military exercises, and industrial operations. These systems provide safe, repeatable environments for skill development and assessment without real-world risks.

- Social and Collaborative Virtual Reality: Platforms and technologies that enable multiple users to interact within shared virtual environments. These systems focus on creating social experiences, collaborative workspaces, and multiplayer gaming environments in virtual reality, often incorporating avatars and real-time communication features.

02 VR Input and Interaction Methods

Innovative input methods and interaction techniques for virtual reality systems, including gesture recognition, eye tracking, and haptic feedback. These technologies enhance user engagement and provide more natural ways to interact with virtual environments.Expand Specific Solutions03 VR Display Technologies

Advancements in display technologies for virtual reality headsets, including high-resolution screens, wide field of view optics, and reduced latency. These improvements aim to enhance visual quality and reduce motion sickness in VR experiences.Expand Specific Solutions04 VR Content Creation and Authoring Tools

Development of software tools and platforms for creating, editing, and publishing virtual reality content. These tools enable developers and content creators to build immersive experiences more efficiently and with greater flexibility.Expand Specific Solutions05 VR Applications in Various Industries

Implementation of virtual reality technologies in diverse fields such as education, healthcare, entertainment, and industrial training. These applications leverage VR's immersive capabilities to enhance learning, improve medical procedures, and simulate complex scenarios for training purposes.Expand Specific Solutions

Key Players in VR Welding Simulation Industry

The integration of Virtual Reality in Gas Welding Training Programs is in its early stages of development, with the market showing significant growth potential. The technology's maturity varies among key players, with companies like Lincoln Global, Inc. and Fronius International GmbH leading in welding equipment, while Seabery Soluciones SL and Wuhan ONEW Technology Co., Ltd. specialize in VR training solutions. Educational institutions such as Xi'an Jiaotong University and Ulsan National Institute of Science & Technology are contributing to research and development. The market is characterized by a mix of established industrial players and innovative tech startups, indicating a dynamic and competitive landscape with ample room for technological advancements and market expansion.

Lincoln Global, Inc.

Technical Solution: Lincoln Electric, a subsidiary of Lincoln Global, Inc., has developed the VRTEX virtual reality welding training system. While primarily focused on arc welding, the system's principles and technology are applicable to gas welding training as well. The VRTEX system uses a VR helmet and motion-tracking technology to create a highly immersive welding simulation environment. It offers a range of welding processes and scenarios, allowing trainees to practice in various positions and with different materials. The system provides real-time feedback on welding parameters such as travel speed, work angle, and contact tip to work distance, helping trainees develop proper technique without material waste or safety risks[8]. VRTEX also includes a comprehensive scoring system and progress tracking tools, enabling instructors to assess trainee performance and identify areas for improvement. The system can be integrated with Lincoln Electric's educational curriculum, providing a holistic approach to welding education that combines theory with virtual practice[9].

Strengths: Highly immersive VR experience, comprehensive feedback and assessment tools, integration with educational curriculum. Weaknesses: May require adaptation for specific gas welding applications, potential high initial costs for smaller training programs.

Illinois Tool Works Inc.

Technical Solution: Illinois Tool Works (ITW) has integrated virtual reality into its welding training programs through its Miller Electric division. The company has developed the AugmentedArc Augmented Reality Welding System, which, while primarily focused on arc welding, also incorporates elements applicable to gas welding training. The system uses a blend of augmented reality and real welding equipment to create a hybrid training environment. Trainees use actual welding guns fitted with sensors, interacting with virtual workpieces displayed through an AR helmet. This approach allows for the development of proper muscle memory and body positioning while eliminating material waste and safety risks associated with traditional training methods[6]. The AugmentedArc system provides real-time feedback on technique, travel speed, and work angle, allowing trainees to quickly identify and correct errors. It also includes a comprehensive curriculum covering welding theory and practice, with modules that can be customized to specific training needs[7].

Strengths: Hybrid AR-physical approach, development of real muscle memory, customizable training modules. Weaknesses: Primary focus on arc welding may limit some gas welding-specific features, potential high initial investment costs.

Core VR Technologies for Welding Simulation

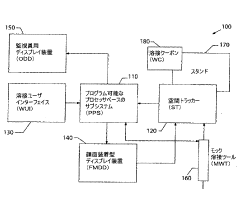

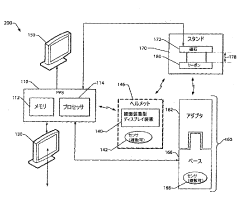

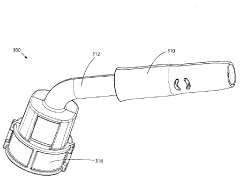

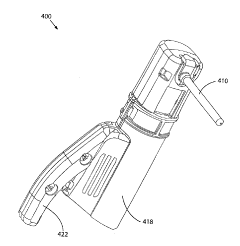

Virtual welding system

PatentActiveJP2017223966A

Innovation

- A virtual welding system utilizing a programmable processor-based subsystem, spatial tracker, and mock welding tools with interchangeable adapters that simulate various weld types, providing real-time visual feedback on melt fluidity and heat dissipation characteristics to enhance welding technique.

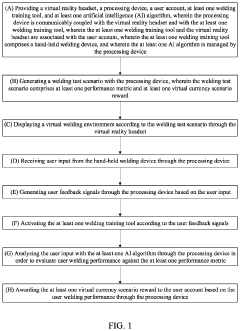

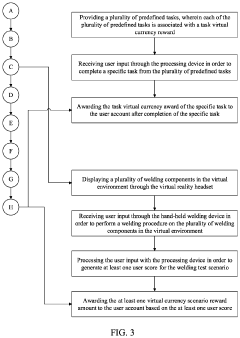

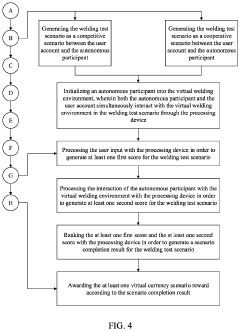

Method Of Training for Welding Through Virtual Reality

PatentActiveUS20210383721A1

Innovation

- A virtual reality-based training system, VRWeld, that uses a combination of VR headsets, AI, and gamification to simulate welding scenarios, allowing users to practice and improve their skills in a realistic and immersive environment without the need for physical equipment, covering multiple welding types and techniques.

Safety Considerations in VR Welding Programs

The integration of Virtual Reality (VR) in gas welding training programs brings significant advancements in safety and skill development. However, it also introduces new safety considerations that must be addressed to ensure a secure and effective learning environment. One primary concern is the potential for physical injuries due to disorientation or loss of spatial awareness while immersed in the VR environment. Trainees may inadvertently collide with real-world objects or lose balance, leading to accidents. To mitigate this risk, training facilities should implement clear safety zones, use padded flooring, and ensure constant supervision during VR sessions.

Another crucial aspect is the prevention of cybersickness, a condition similar to motion sickness that can occur during VR experiences. Symptoms may include nausea, dizziness, and eye strain, which can not only disrupt the learning process but also pose safety risks if trainees become disoriented. To address this, VR welding programs should incorporate regular breaks, adjust frame rates and resolution for optimal comfort, and gradually increase exposure times to allow users to acclimate to the virtual environment.

Electrical safety is also a key consideration, given the combination of VR equipment and welding simulation. Proper cable management, regular equipment inspections, and the use of surge protectors are essential to prevent electrical hazards. Additionally, the VR system should be designed with fail-safes that automatically shut down in case of overheating or electrical irregularities.

Psychological safety is another important factor to consider. While VR welding simulations can provide a safe environment for practicing potentially dangerous tasks, some trainees may experience anxiety or stress when faced with realistic hazard scenarios. Training programs should include proper psychological preparation and debriefing sessions to ensure that trainees can effectively manage their emotional responses to virtual dangers.

Data security and privacy concerns must also be addressed, as VR systems often collect and store user data, including performance metrics and potentially sensitive information. Implementing robust data encryption, secure storage protocols, and clear privacy policies is crucial to protect trainees' information and maintain compliance with data protection regulations.

Lastly, it is essential to establish clear emergency procedures specific to VR training environments. This includes protocols for quickly removing VR headsets in case of real-world emergencies, as well as systems for immediate communication between instructors and trainees during simulations. Regular safety drills and training for both instructors and participants should be conducted to ensure swift and effective responses to any potential incidents.

Another crucial aspect is the prevention of cybersickness, a condition similar to motion sickness that can occur during VR experiences. Symptoms may include nausea, dizziness, and eye strain, which can not only disrupt the learning process but also pose safety risks if trainees become disoriented. To address this, VR welding programs should incorporate regular breaks, adjust frame rates and resolution for optimal comfort, and gradually increase exposure times to allow users to acclimate to the virtual environment.

Electrical safety is also a key consideration, given the combination of VR equipment and welding simulation. Proper cable management, regular equipment inspections, and the use of surge protectors are essential to prevent electrical hazards. Additionally, the VR system should be designed with fail-safes that automatically shut down in case of overheating or electrical irregularities.

Psychological safety is another important factor to consider. While VR welding simulations can provide a safe environment for practicing potentially dangerous tasks, some trainees may experience anxiety or stress when faced with realistic hazard scenarios. Training programs should include proper psychological preparation and debriefing sessions to ensure that trainees can effectively manage their emotional responses to virtual dangers.

Data security and privacy concerns must also be addressed, as VR systems often collect and store user data, including performance metrics and potentially sensitive information. Implementing robust data encryption, secure storage protocols, and clear privacy policies is crucial to protect trainees' information and maintain compliance with data protection regulations.

Lastly, it is essential to establish clear emergency procedures specific to VR training environments. This includes protocols for quickly removing VR headsets in case of real-world emergencies, as well as systems for immediate communication between instructors and trainees during simulations. Regular safety drills and training for both instructors and participants should be conducted to ensure swift and effective responses to any potential incidents.

Cost-Benefit Analysis of VR Welding Integration

The integration of Virtual Reality (VR) in gas welding training programs represents a significant investment for educational institutions and industrial training centers. A comprehensive cost-benefit analysis is crucial to determine the long-term value and return on investment of implementing VR technology in welding education.

Initial costs for VR welding systems are substantial, including hardware such as VR headsets, haptic feedback devices, and high-performance computers. Software licenses and custom content development also contribute to the upfront expenses. Additionally, there are costs associated with training instructors to use the new technology effectively and potentially modifying existing training spaces to accommodate VR equipment.

However, these initial investments can be offset by several long-term benefits. VR welding simulators significantly reduce material costs by eliminating the need for physical consumables such as metal, gas, and welding rods during training sessions. This not only saves money but also aligns with sustainability goals by reducing waste and energy consumption.

Safety is another critical factor in the cost-benefit equation. VR training environments eliminate the risks associated with traditional welding practice, potentially reducing insurance costs and the likelihood of workplace injuries. This can lead to substantial savings in terms of worker compensation claims and lost productivity due to accidents.

The efficiency of VR training is a major benefit. Students can practice welding techniques repeatedly without the need for setup time or material preparation. This increased practice time can lead to faster skill acquisition and potentially shorter overall training periods, allowing institutions to train more welders in less time.

Scalability is an additional advantage of VR welding systems. Once the initial investment is made, the marginal cost of training additional students is minimal. This can be particularly beneficial for large institutions or companies with multiple training locations.

Data analytics capabilities inherent in VR systems provide valuable insights into student performance and learning patterns. This data can be used to optimize training programs, identify areas for improvement, and provide personalized instruction, potentially increasing the overall effectiveness of the training and producing better-skilled welders.

While the initial investment in VR welding technology is significant, the long-term benefits in terms of cost savings, improved safety, increased efficiency, and enhanced learning outcomes suggest that for many institutions, the integration of VR into gas welding training programs can provide a positive return on investment over time.

Initial costs for VR welding systems are substantial, including hardware such as VR headsets, haptic feedback devices, and high-performance computers. Software licenses and custom content development also contribute to the upfront expenses. Additionally, there are costs associated with training instructors to use the new technology effectively and potentially modifying existing training spaces to accommodate VR equipment.

However, these initial investments can be offset by several long-term benefits. VR welding simulators significantly reduce material costs by eliminating the need for physical consumables such as metal, gas, and welding rods during training sessions. This not only saves money but also aligns with sustainability goals by reducing waste and energy consumption.

Safety is another critical factor in the cost-benefit equation. VR training environments eliminate the risks associated with traditional welding practice, potentially reducing insurance costs and the likelihood of workplace injuries. This can lead to substantial savings in terms of worker compensation claims and lost productivity due to accidents.

The efficiency of VR training is a major benefit. Students can practice welding techniques repeatedly without the need for setup time or material preparation. This increased practice time can lead to faster skill acquisition and potentially shorter overall training periods, allowing institutions to train more welders in less time.

Scalability is an additional advantage of VR welding systems. Once the initial investment is made, the marginal cost of training additional students is minimal. This can be particularly beneficial for large institutions or companies with multiple training locations.

Data analytics capabilities inherent in VR systems provide valuable insights into student performance and learning patterns. This data can be used to optimize training programs, identify areas for improvement, and provide personalized instruction, potentially increasing the overall effectiveness of the training and producing better-skilled welders.

While the initial investment in VR welding technology is significant, the long-term benefits in terms of cost savings, improved safety, increased efficiency, and enhanced learning outcomes suggest that for many institutions, the integration of VR into gas welding training programs can provide a positive return on investment over time.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!