Investigating Temperature Monitoring Technology in Gas Welding

AUG 7, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Gas Welding Temp Monitoring Background

Gas welding, a fundamental technique in metalworking, has been widely used in various industries for over a century. The process involves the combustion of fuel gases, typically acetylene or propane, with oxygen to produce a high-temperature flame capable of melting and joining metals. As the welding industry evolved, the need for precise temperature control became increasingly apparent, leading to the development of temperature monitoring technologies.

The history of temperature monitoring in gas welding can be traced back to the early 20th century when visual inspection and operator experience were the primary means of temperature assessment. However, these methods were subjective and often led to inconsistencies in weld quality. The introduction of pyrometers in the 1920s marked a significant advancement, allowing for more accurate temperature measurements, albeit still requiring manual operation.

The advent of infrared thermography in the 1960s revolutionized temperature monitoring in welding processes. This non-contact method enabled real-time temperature mapping of the entire weld area, providing valuable insights into heat distribution and potential defects. As electronic technologies progressed, digital thermocouples and advanced infrared cameras became more accessible, offering higher precision and easier integration with automated welding systems.

In recent years, the focus has shifted towards developing smart temperature monitoring solutions that incorporate artificial intelligence and machine learning algorithms. These systems can analyze temperature data in real-time, predict potential issues, and automatically adjust welding parameters to maintain optimal conditions. The integration of Internet of Things (IoT) technologies has further enhanced monitoring capabilities, allowing for remote supervision and data collection across multiple welding stations.

The evolution of temperature monitoring in gas welding has been driven by the increasing demands for weld quality, productivity, and safety. Accurate temperature control is crucial for achieving proper fusion, minimizing distortion, and ensuring the structural integrity of welded components. Moreover, precise monitoring helps in reducing energy consumption and optimizing gas usage, contributing to cost-effectiveness and environmental sustainability.

As industries continue to adopt more advanced materials and complex welding applications, the importance of sophisticated temperature monitoring technologies grows. The current trend is towards developing comprehensive welding monitoring systems that not only track temperature but also integrate other critical parameters such as gas flow rates, arc stability, and weld pool dynamics. These holistic approaches aim to provide a complete picture of the welding process, enabling unprecedented levels of control and quality assurance.

The history of temperature monitoring in gas welding can be traced back to the early 20th century when visual inspection and operator experience were the primary means of temperature assessment. However, these methods were subjective and often led to inconsistencies in weld quality. The introduction of pyrometers in the 1920s marked a significant advancement, allowing for more accurate temperature measurements, albeit still requiring manual operation.

The advent of infrared thermography in the 1960s revolutionized temperature monitoring in welding processes. This non-contact method enabled real-time temperature mapping of the entire weld area, providing valuable insights into heat distribution and potential defects. As electronic technologies progressed, digital thermocouples and advanced infrared cameras became more accessible, offering higher precision and easier integration with automated welding systems.

In recent years, the focus has shifted towards developing smart temperature monitoring solutions that incorporate artificial intelligence and machine learning algorithms. These systems can analyze temperature data in real-time, predict potential issues, and automatically adjust welding parameters to maintain optimal conditions. The integration of Internet of Things (IoT) technologies has further enhanced monitoring capabilities, allowing for remote supervision and data collection across multiple welding stations.

The evolution of temperature monitoring in gas welding has been driven by the increasing demands for weld quality, productivity, and safety. Accurate temperature control is crucial for achieving proper fusion, minimizing distortion, and ensuring the structural integrity of welded components. Moreover, precise monitoring helps in reducing energy consumption and optimizing gas usage, contributing to cost-effectiveness and environmental sustainability.

As industries continue to adopt more advanced materials and complex welding applications, the importance of sophisticated temperature monitoring technologies grows. The current trend is towards developing comprehensive welding monitoring systems that not only track temperature but also integrate other critical parameters such as gas flow rates, arc stability, and weld pool dynamics. These holistic approaches aim to provide a complete picture of the welding process, enabling unprecedented levels of control and quality assurance.

Market Analysis for Welding Temp Sensors

The global market for welding temperature sensors is experiencing significant growth, driven by the increasing demand for precision and quality control in various industries. The gas welding sector, in particular, has shown a strong need for advanced temperature monitoring technologies to enhance welding processes and ensure product integrity.

Market research indicates that the welding temperature sensor market is expected to grow steadily over the next five years. This growth is primarily attributed to the rising adoption of automation in manufacturing processes, stringent quality standards in industries such as automotive and aerospace, and the need for improved energy efficiency in welding operations.

The automotive industry remains a key driver for the welding temperature sensor market. With the increasing complexity of vehicle designs and the growing use of lightweight materials, precise temperature control during welding has become crucial. This has led to a surge in demand for high-performance temperature sensors that can withstand harsh welding environments while providing accurate real-time data.

Another significant market segment is the aerospace industry, where welding quality directly impacts safety and performance. The need for temperature sensors capable of monitoring complex welding processes in aerospace applications has created opportunities for sensor manufacturers to develop specialized solutions.

The construction and shipbuilding industries are also contributing to market growth, as these sectors increasingly adopt advanced welding technologies to improve productivity and meet stringent safety regulations. Temperature sensors play a vital role in ensuring the structural integrity of welded components in these applications.

Geographically, Asia-Pacific is emerging as the fastest-growing market for welding temperature sensors, driven by rapid industrialization in countries like China and India. North America and Europe continue to be significant markets, with a focus on high-end sensors for specialized applications.

The market is characterized by intense competition among established players and new entrants. Key market players are investing heavily in research and development to introduce innovative sensor technologies that offer higher accuracy, faster response times, and improved durability in harsh welding environments.

There is a growing trend towards the integration of temperature sensors with digital technologies and Industry 4.0 concepts. This includes the development of smart sensors capable of data logging, wireless communication, and integration with welding control systems. Such advancements are expected to drive market growth and open up new opportunities for sensor manufacturers.

Market research indicates that the welding temperature sensor market is expected to grow steadily over the next five years. This growth is primarily attributed to the rising adoption of automation in manufacturing processes, stringent quality standards in industries such as automotive and aerospace, and the need for improved energy efficiency in welding operations.

The automotive industry remains a key driver for the welding temperature sensor market. With the increasing complexity of vehicle designs and the growing use of lightweight materials, precise temperature control during welding has become crucial. This has led to a surge in demand for high-performance temperature sensors that can withstand harsh welding environments while providing accurate real-time data.

Another significant market segment is the aerospace industry, where welding quality directly impacts safety and performance. The need for temperature sensors capable of monitoring complex welding processes in aerospace applications has created opportunities for sensor manufacturers to develop specialized solutions.

The construction and shipbuilding industries are also contributing to market growth, as these sectors increasingly adopt advanced welding technologies to improve productivity and meet stringent safety regulations. Temperature sensors play a vital role in ensuring the structural integrity of welded components in these applications.

Geographically, Asia-Pacific is emerging as the fastest-growing market for welding temperature sensors, driven by rapid industrialization in countries like China and India. North America and Europe continue to be significant markets, with a focus on high-end sensors for specialized applications.

The market is characterized by intense competition among established players and new entrants. Key market players are investing heavily in research and development to introduce innovative sensor technologies that offer higher accuracy, faster response times, and improved durability in harsh welding environments.

There is a growing trend towards the integration of temperature sensors with digital technologies and Industry 4.0 concepts. This includes the development of smart sensors capable of data logging, wireless communication, and integration with welding control systems. Such advancements are expected to drive market growth and open up new opportunities for sensor manufacturers.

Current Challenges in Welding Temp Measurement

Temperature monitoring in gas welding faces several significant challenges that hinder accurate and reliable measurement. One of the primary issues is the extreme and rapidly changing thermal conditions inherent in the welding process. The intense heat generated during welding can exceed 3000°C at the weld pool, creating a harsh environment for sensing equipment.

The dynamic nature of the welding process further complicates temperature measurement. As the welding torch moves along the workpiece, the temperature distribution changes rapidly, making it difficult to capture accurate real-time data. This challenge is exacerbated by the presence of electromagnetic interference from the welding equipment, which can affect the performance of electronic temperature sensors.

Another significant obstacle is the limited access to the weld zone. The small and often confined spaces where welding occurs make it challenging to position temperature sensors without interfering with the welding process itself. This constraint often leads to compromises in sensor placement, potentially reducing measurement accuracy.

The presence of molten metal, sparks, and fumes in the welding environment poses a risk to temperature monitoring equipment. These harsh conditions can damage or degrade sensors over time, leading to reduced accuracy and increased maintenance requirements. Additionally, the high-temperature gradients present in the weld area can cause thermal shock to sensing devices, further impacting their longevity and reliability.

Calibration and standardization of temperature measurement techniques across different welding applications present another challenge. The variety of materials, welding techniques, and environmental conditions encountered in industrial settings makes it difficult to establish universally applicable measurement protocols.

Furthermore, the need for non-contact measurement methods to avoid interfering with the weld process limits the available technology options. While infrared thermography offers a potential solution, it faces challenges related to emissivity variations in different materials and surface conditions, as well as potential interference from the bright light emitted during welding.

The integration of temperature monitoring systems with existing welding equipment and processes also presents logistical and technical hurdles. Ensuring seamless operation without compromising welding efficiency or quality requires careful design and implementation considerations.

Lastly, the cost-effectiveness of advanced temperature monitoring solutions remains a challenge, particularly for smaller welding operations. Balancing the need for accurate temperature measurement with budget constraints often leads to compromises in monitoring capabilities.

The dynamic nature of the welding process further complicates temperature measurement. As the welding torch moves along the workpiece, the temperature distribution changes rapidly, making it difficult to capture accurate real-time data. This challenge is exacerbated by the presence of electromagnetic interference from the welding equipment, which can affect the performance of electronic temperature sensors.

Another significant obstacle is the limited access to the weld zone. The small and often confined spaces where welding occurs make it challenging to position temperature sensors without interfering with the welding process itself. This constraint often leads to compromises in sensor placement, potentially reducing measurement accuracy.

The presence of molten metal, sparks, and fumes in the welding environment poses a risk to temperature monitoring equipment. These harsh conditions can damage or degrade sensors over time, leading to reduced accuracy and increased maintenance requirements. Additionally, the high-temperature gradients present in the weld area can cause thermal shock to sensing devices, further impacting their longevity and reliability.

Calibration and standardization of temperature measurement techniques across different welding applications present another challenge. The variety of materials, welding techniques, and environmental conditions encountered in industrial settings makes it difficult to establish universally applicable measurement protocols.

Furthermore, the need for non-contact measurement methods to avoid interfering with the weld process limits the available technology options. While infrared thermography offers a potential solution, it faces challenges related to emissivity variations in different materials and surface conditions, as well as potential interference from the bright light emitted during welding.

The integration of temperature monitoring systems with existing welding equipment and processes also presents logistical and technical hurdles. Ensuring seamless operation without compromising welding efficiency or quality requires careful design and implementation considerations.

Lastly, the cost-effectiveness of advanced temperature monitoring solutions remains a challenge, particularly for smaller welding operations. Balancing the need for accurate temperature measurement with budget constraints often leads to compromises in monitoring capabilities.

Existing Welding Temp Monitoring Solutions

01 Wireless temperature monitoring systems

These systems utilize wireless sensors to continuously monitor temperature in various environments. They offer real-time data transmission, remote access, and improved efficiency in temperature management across different applications.- Wireless temperature monitoring systems: These systems utilize wireless technology to transmit temperature data from sensors to a central monitoring unit. They offer real-time monitoring and can cover large areas or multiple locations simultaneously, improving efficiency and reducing the need for manual checks.

- Temperature monitoring in industrial processes: Advanced temperature monitoring technologies are employed in various industrial processes to ensure product quality, safety, and efficiency. These systems often integrate with process control systems and can trigger alarms or automated responses when temperature thresholds are exceeded.

- Wearable temperature monitoring devices: Wearable devices equipped with temperature sensors allow for continuous monitoring of body temperature. These devices can be particularly useful in healthcare settings, sports performance monitoring, and occupational safety applications.

- IoT-based temperature monitoring solutions: Internet of Things (IoT) technology is being applied to temperature monitoring, enabling the collection and analysis of temperature data from multiple sources. These systems can provide insights through data analytics and facilitate remote monitoring and control.

- High-precision temperature measurement techniques: Advanced techniques for high-precision temperature measurement are being developed, including the use of novel sensor materials and calibration methods. These technologies aim to improve accuracy and reliability in critical applications such as scientific research and semiconductor manufacturing.

02 Temperature monitoring in industrial processes

Advanced temperature monitoring technologies are employed in industrial settings to ensure optimal process control, product quality, and safety. These systems often integrate with existing industrial control systems and provide alerts for temperature anomalies.Expand Specific Solutions03 Wearable temperature monitoring devices

Wearable devices equipped with temperature sensors allow for continuous body temperature monitoring. These devices can be used for personal health tracking, early disease detection, and remote patient monitoring in healthcare settings.Expand Specific Solutions04 IoT-based temperature monitoring solutions

Internet of Things (IoT) technology is utilized to create interconnected temperature monitoring systems. These solutions enable data collection from multiple sensors, cloud-based data storage, and advanced analytics for temperature trend analysis and predictive maintenance.Expand Specific Solutions05 Temperature monitoring in smart buildings

Smart building systems incorporate temperature monitoring technologies to optimize energy efficiency, occupant comfort, and HVAC system performance. These systems often use a network of sensors and integrate with building management systems for automated temperature control.Expand Specific Solutions

Key Players in Welding Temp Sensor Industry

The temperature monitoring technology in gas welding is currently in a growth phase, with increasing market demand driven by safety and quality concerns in industrial applications. The global market size for welding equipment and consumables is projected to reach $32 billion by 2026, with temperature monitoring systems playing a crucial role. Technologically, the field is advancing rapidly, with companies like Fronius International GmbH and Siemens AG leading innovation in smart welding solutions. Other key players such as Illinois Tool Works Inc. and Lincoln Global, Inc. are also contributing to the development of advanced temperature monitoring systems, integrating IoT and AI technologies to enhance precision and efficiency in gas welding processes.

Fronius International GmbH

Technical Solution: Fronius has developed advanced temperature monitoring systems for gas welding, incorporating real-time thermal imaging and data analytics. Their technology utilizes high-resolution infrared sensors to continuously monitor the weld pool and surrounding areas, providing precise temperature measurements with an accuracy of ±2°C [1]. The system integrates with their welding power sources, allowing for automatic adjustments to welding parameters based on temperature feedback. This helps maintain optimal weld quality and prevents overheating or undercooling. Fronius has also implemented machine learning algorithms to predict potential defects based on temperature patterns, enabling proactive quality control [3].

Strengths: High accuracy, real-time monitoring, and integration with welding equipment. Weaknesses: May require significant initial investment and operator training.

Illinois Tool Works Inc.

Technical Solution: Illinois Tool Works (ITW) has developed a comprehensive temperature monitoring solution for gas welding through their Miller Electric division. Their system, called WeldSense, combines multiple temperature monitoring technologies to provide a holistic view of the welding process. WeldSense uses a combination of infrared cameras, thermocouples, and pyrometers to monitor the weld pool, base metal, and surrounding areas. The data is processed in real-time using ITW's proprietary algorithms, which can detect temperature anomalies and predict potential weld defects with high accuracy [6]. The system also integrates with Miller's welding power sources, allowing for automatic adjustments to welding parameters based on temperature feedback. Additionally, WeldSense includes a user-friendly interface that provides visual temperature maps and alerts to operators, enhancing real-time decision-making during the welding process.

Strengths: Multi-sensor approach, integration with welding equipment, and user-friendly interface. Weaknesses: May require significant investment in compatible Miller equipment for full functionality.

Innovations in High-Temp Sensing for Welding

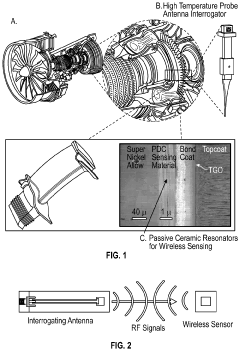

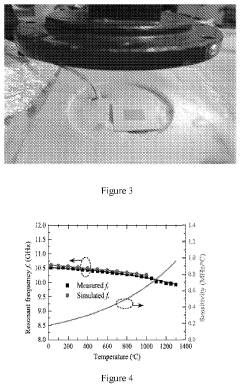

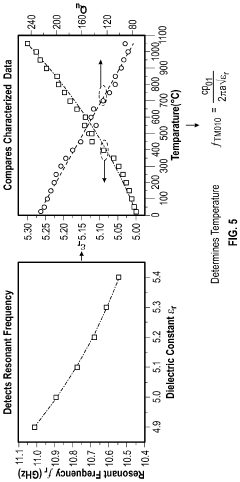

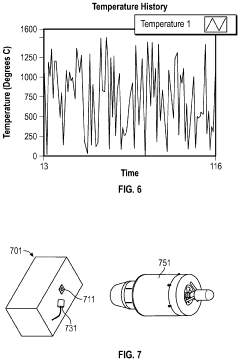

Apparatus, systems, and methods for wireless monitoring of gas turbine engine temperature

PatentActiveUS20200308978A1

Innovation

- A wireless monitoring system comprising sensing antennas made of polymer-derived ceramics (PDC) installed on engine components, such as blades and vanes, that transmit temperature data via RF signals to an interrogating antenna, allowing for real-time, continuous temperature measurement across multiple areas of the engine, even at extreme temperatures (up to 1800°C) and pressures (200-600 psi).

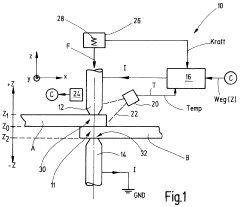

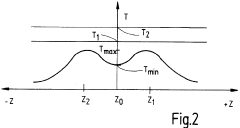

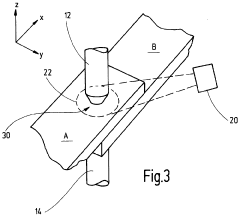

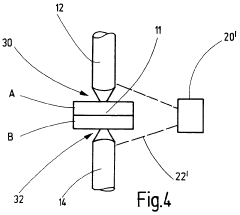

Method for monitoring a resistance welding process for joining components at a welding site comprises measuring the temperature of the welding site during the welding process using a heat sensor

PatentActiveDE102007017962A1

Innovation

- Implementing a method to monitor the resistance welding process by detecting the temperature distribution and history using thermal sensors, such as infrared cameras or arrays, to assess the spatial and temporal characteristics of the weld, allowing for precise evaluation against preset thresholds and tolerance ranges.

Safety Standards in Gas Welding

Safety standards play a crucial role in ensuring the well-being of workers and maintaining a secure work environment in gas welding operations. These standards encompass a wide range of aspects, including equipment specifications, operational procedures, and protective measures. One of the key areas of focus within these safety standards is temperature monitoring, which is essential for preventing accidents and maintaining optimal welding conditions.

International organizations such as the American Welding Society (AWS) and the International Organization for Standardization (ISO) have developed comprehensive guidelines for gas welding safety. These standards typically address temperature-related issues, such as the proper handling of hot materials, monitoring of flame temperatures, and the use of appropriate personal protective equipment (PPE) to guard against heat-related injuries.

Temperature monitoring in gas welding is particularly important due to the high heat involved in the process. Safety standards often require the use of specialized temperature monitoring devices, such as infrared thermometers or thermocouples, to accurately measure and track temperatures during welding operations. These devices help operators maintain safe working temperatures and prevent overheating, which can lead to material failures or workplace accidents.

In addition to equipment-specific standards, safety regulations also cover workplace design and ventilation requirements. Proper ventilation is crucial for dissipating heat and removing potentially harmful fumes generated during the welding process. Standards may specify minimum airflow rates and the placement of ventilation systems to ensure adequate heat management and air quality.

Personal protective equipment standards for gas welding typically include specifications for heat-resistant clothing, gloves, and face shields. These items are designed to protect workers from high temperatures, sparks, and radiation associated with welding processes. Safety standards often detail the minimum heat resistance ratings for such equipment and provide guidelines for their proper use and maintenance.

Emergency procedures related to temperature-induced incidents are another critical component of gas welding safety standards. These may include protocols for dealing with burns, fires, or equipment malfunctions caused by excessive heat. Standards often require the presence of fire extinguishers, first aid kits, and emergency shut-off mechanisms in welding areas.

Regular training and certification programs are typically mandated by safety standards to ensure that welders are knowledgeable about temperature-related hazards and proper monitoring techniques. These programs often cover topics such as recognizing signs of overheating, interpreting temperature readings, and responding to temperature-related emergencies.

Compliance with these safety standards is not only a legal requirement in many jurisdictions but also a fundamental aspect of responsible business practices in the welding industry. Regular audits and inspections are often recommended or required to ensure ongoing adherence to these standards, helping to create a culture of safety and continuous improvement in temperature monitoring and overall welding practices.

International organizations such as the American Welding Society (AWS) and the International Organization for Standardization (ISO) have developed comprehensive guidelines for gas welding safety. These standards typically address temperature-related issues, such as the proper handling of hot materials, monitoring of flame temperatures, and the use of appropriate personal protective equipment (PPE) to guard against heat-related injuries.

Temperature monitoring in gas welding is particularly important due to the high heat involved in the process. Safety standards often require the use of specialized temperature monitoring devices, such as infrared thermometers or thermocouples, to accurately measure and track temperatures during welding operations. These devices help operators maintain safe working temperatures and prevent overheating, which can lead to material failures or workplace accidents.

In addition to equipment-specific standards, safety regulations also cover workplace design and ventilation requirements. Proper ventilation is crucial for dissipating heat and removing potentially harmful fumes generated during the welding process. Standards may specify minimum airflow rates and the placement of ventilation systems to ensure adequate heat management and air quality.

Personal protective equipment standards for gas welding typically include specifications for heat-resistant clothing, gloves, and face shields. These items are designed to protect workers from high temperatures, sparks, and radiation associated with welding processes. Safety standards often detail the minimum heat resistance ratings for such equipment and provide guidelines for their proper use and maintenance.

Emergency procedures related to temperature-induced incidents are another critical component of gas welding safety standards. These may include protocols for dealing with burns, fires, or equipment malfunctions caused by excessive heat. Standards often require the presence of fire extinguishers, first aid kits, and emergency shut-off mechanisms in welding areas.

Regular training and certification programs are typically mandated by safety standards to ensure that welders are knowledgeable about temperature-related hazards and proper monitoring techniques. These programs often cover topics such as recognizing signs of overheating, interpreting temperature readings, and responding to temperature-related emergencies.

Compliance with these safety standards is not only a legal requirement in many jurisdictions but also a fundamental aspect of responsible business practices in the welding industry. Regular audits and inspections are often recommended or required to ensure ongoing adherence to these standards, helping to create a culture of safety and continuous improvement in temperature monitoring and overall welding practices.

Environmental Impact of Welding Processes

Welding processes, while essential in many industries, can have significant environmental impacts that need to be carefully considered and mitigated. Gas welding, in particular, contributes to various environmental concerns due to its reliance on combustible gases and the generation of fumes and emissions during the welding process.

One of the primary environmental impacts of gas welding is air pollution. The combustion of gases such as acetylene or propane produces carbon dioxide and other greenhouse gases, contributing to global warming and climate change. Additionally, the welding process generates metal fumes and particulate matter, which can be harmful to both human health and the environment. These airborne pollutants can lead to respiratory issues and contribute to the formation of smog and acid rain.

Water pollution is another concern associated with welding processes. Cooling water used in welding operations may become contaminated with metal particles and other pollutants. If not properly treated, this contaminated water can find its way into local water systems, potentially harming aquatic ecosystems and affecting water quality for both human and wildlife populations.

The production and disposal of welding consumables also have environmental implications. Gas cylinders, welding rods, and other materials used in the welding process require energy and resources to manufacture. Improper disposal of these items can lead to soil contamination and contribute to landfill waste.

Energy consumption is a significant factor in the environmental impact of welding processes. Gas welding requires the production and transportation of combustible gases, which involves energy-intensive processes. The welding operation itself also consumes energy, contributing to overall energy demand and associated environmental impacts.

Noise pollution is another environmental concern, particularly in industrial settings where multiple welding operations may be occurring simultaneously. Prolonged exposure to high noise levels can have detrimental effects on both human health and local wildlife populations.

To mitigate these environmental impacts, various strategies can be employed. Implementing more efficient welding techniques and equipment can reduce energy consumption and emissions. Proper ventilation systems and personal protective equipment can minimize the release of harmful fumes and particles into the environment. Recycling programs for welding consumables and proper waste management practices can help reduce the environmental footprint of welding operations.

Advancements in welding technology, such as the development of more environmentally friendly welding gases and improved temperature monitoring systems, can also contribute to reducing the environmental impact of welding processes. By accurately monitoring and controlling temperatures during gas welding, it is possible to optimize the process, reducing both energy consumption and emissions.

One of the primary environmental impacts of gas welding is air pollution. The combustion of gases such as acetylene or propane produces carbon dioxide and other greenhouse gases, contributing to global warming and climate change. Additionally, the welding process generates metal fumes and particulate matter, which can be harmful to both human health and the environment. These airborne pollutants can lead to respiratory issues and contribute to the formation of smog and acid rain.

Water pollution is another concern associated with welding processes. Cooling water used in welding operations may become contaminated with metal particles and other pollutants. If not properly treated, this contaminated water can find its way into local water systems, potentially harming aquatic ecosystems and affecting water quality for both human and wildlife populations.

The production and disposal of welding consumables also have environmental implications. Gas cylinders, welding rods, and other materials used in the welding process require energy and resources to manufacture. Improper disposal of these items can lead to soil contamination and contribute to landfill waste.

Energy consumption is a significant factor in the environmental impact of welding processes. Gas welding requires the production and transportation of combustible gases, which involves energy-intensive processes. The welding operation itself also consumes energy, contributing to overall energy demand and associated environmental impacts.

Noise pollution is another environmental concern, particularly in industrial settings where multiple welding operations may be occurring simultaneously. Prolonged exposure to high noise levels can have detrimental effects on both human health and local wildlife populations.

To mitigate these environmental impacts, various strategies can be employed. Implementing more efficient welding techniques and equipment can reduce energy consumption and emissions. Proper ventilation systems and personal protective equipment can minimize the release of harmful fumes and particles into the environment. Recycling programs for welding consumables and proper waste management practices can help reduce the environmental footprint of welding operations.

Advancements in welding technology, such as the development of more environmentally friendly welding gases and improved temperature monitoring systems, can also contribute to reducing the environmental impact of welding processes. By accurately monitoring and controlling temperatures during gas welding, it is possible to optimize the process, reducing both energy consumption and emissions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!