Investigating the Impact of Fluid Conductivity on Sensor Integration

JUL 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Fluid Conductivity Sensor Integration Background

Fluid conductivity sensor integration has become a critical area of research and development in various industries, including environmental monitoring, water treatment, and industrial process control. The integration of fluid conductivity sensors into existing systems and processes has gained significant attention due to its potential to enhance efficiency, accuracy, and real-time monitoring capabilities.

The concept of fluid conductivity refers to the ability of a liquid to conduct electricity, which is directly related to the concentration of dissolved ions in the solution. This property is crucial in many applications, as it provides valuable information about the composition and quality of fluids. The integration of sensors capable of measuring fluid conductivity has evolved over time, driven by advancements in sensor technology, data processing capabilities, and the increasing demand for precise and continuous monitoring in various sectors.

Historically, fluid conductivity measurements were primarily conducted through manual sampling and laboratory analysis. However, the need for real-time data and continuous monitoring has led to the development of in-situ sensors that can be directly integrated into fluid systems. This evolution has been marked by significant improvements in sensor design, materials, and signal processing techniques, enabling more accurate and reliable measurements in diverse environments.

The integration of fluid conductivity sensors faces several challenges, including the need for robust and durable sensor designs that can withstand harsh operating conditions, such as high temperatures, pressures, and corrosive environments. Additionally, the development of sensors with wide measurement ranges and high sensitivity is crucial to meet the diverse requirements of different applications.

Another key aspect of fluid conductivity sensor integration is the need for seamless data acquisition and communication systems. The ability to transmit and process sensor data in real-time has become increasingly important, particularly in industrial settings where rapid decision-making based on fluid properties is essential. This has led to the development of advanced sensor networks and data management systems that can handle large volumes of sensor data efficiently.

The integration of fluid conductivity sensors also intersects with other emerging technologies, such as Internet of Things (IoT) and artificial intelligence. These technologies offer new possibilities for data analysis, predictive maintenance, and automated control systems based on fluid conductivity measurements. As a result, the field of fluid conductivity sensor integration continues to evolve, driven by both technological advancements and the growing demand for more sophisticated monitoring and control solutions across various industries.

The concept of fluid conductivity refers to the ability of a liquid to conduct electricity, which is directly related to the concentration of dissolved ions in the solution. This property is crucial in many applications, as it provides valuable information about the composition and quality of fluids. The integration of sensors capable of measuring fluid conductivity has evolved over time, driven by advancements in sensor technology, data processing capabilities, and the increasing demand for precise and continuous monitoring in various sectors.

Historically, fluid conductivity measurements were primarily conducted through manual sampling and laboratory analysis. However, the need for real-time data and continuous monitoring has led to the development of in-situ sensors that can be directly integrated into fluid systems. This evolution has been marked by significant improvements in sensor design, materials, and signal processing techniques, enabling more accurate and reliable measurements in diverse environments.

The integration of fluid conductivity sensors faces several challenges, including the need for robust and durable sensor designs that can withstand harsh operating conditions, such as high temperatures, pressures, and corrosive environments. Additionally, the development of sensors with wide measurement ranges and high sensitivity is crucial to meet the diverse requirements of different applications.

Another key aspect of fluid conductivity sensor integration is the need for seamless data acquisition and communication systems. The ability to transmit and process sensor data in real-time has become increasingly important, particularly in industrial settings where rapid decision-making based on fluid properties is essential. This has led to the development of advanced sensor networks and data management systems that can handle large volumes of sensor data efficiently.

The integration of fluid conductivity sensors also intersects with other emerging technologies, such as Internet of Things (IoT) and artificial intelligence. These technologies offer new possibilities for data analysis, predictive maintenance, and automated control systems based on fluid conductivity measurements. As a result, the field of fluid conductivity sensor integration continues to evolve, driven by both technological advancements and the growing demand for more sophisticated monitoring and control solutions across various industries.

Market Analysis for Fluid Conductivity Sensors

The fluid conductivity sensor market has experienced significant growth in recent years, driven by increasing demand across various industries. The global market for these sensors is expected to continue its upward trajectory, with a compound annual growth rate (CAGR) projected to be in the high single digits over the next five years. This growth is primarily attributed to the expanding applications in water treatment, chemical processing, and environmental monitoring sectors.

In the water treatment industry, fluid conductivity sensors play a crucial role in ensuring water quality and process efficiency. The increasing focus on water conservation and stringent regulations regarding water quality have led to a surge in demand for these sensors. Municipal water treatment plants, industrial wastewater management facilities, and desalination plants are key end-users driving market growth in this sector.

The chemical processing industry represents another significant market for fluid conductivity sensors. These sensors are essential for monitoring and controlling chemical reactions, ensuring product quality, and maintaining safety standards. As the chemical industry continues to grow and innovate, the demand for advanced fluid conductivity sensors is expected to rise correspondingly.

Environmental monitoring applications have also contributed to the market expansion. With growing concerns about pollution and climate change, there is an increased need for accurate and reliable water quality monitoring systems. Fluid conductivity sensors are integral components of these systems, used in rivers, lakes, and coastal waters to detect pollutants and assess overall water health.

Geographically, North America and Europe currently dominate the fluid conductivity sensor market, owing to their well-established industrial sectors and stringent environmental regulations. However, the Asia-Pacific region is anticipated to witness the highest growth rate in the coming years. This growth is fueled by rapid industrialization, increasing investments in water infrastructure, and rising awareness about water quality issues in countries like China and India.

The market is characterized by the presence of both large multinational corporations and smaller specialized manufacturers. Key players are focusing on developing innovative sensor technologies to improve accuracy, reliability, and integration capabilities. There is a growing trend towards the development of smart sensors with advanced features such as self-calibration, wireless connectivity, and compatibility with Internet of Things (IoT) platforms.

Despite the positive outlook, the market faces challenges such as price sensitivity in developing regions and the need for continuous technological advancements to meet evolving industry requirements. However, these challenges also present opportunities for innovation and market differentiation for sensor manufacturers.

In the water treatment industry, fluid conductivity sensors play a crucial role in ensuring water quality and process efficiency. The increasing focus on water conservation and stringent regulations regarding water quality have led to a surge in demand for these sensors. Municipal water treatment plants, industrial wastewater management facilities, and desalination plants are key end-users driving market growth in this sector.

The chemical processing industry represents another significant market for fluid conductivity sensors. These sensors are essential for monitoring and controlling chemical reactions, ensuring product quality, and maintaining safety standards. As the chemical industry continues to grow and innovate, the demand for advanced fluid conductivity sensors is expected to rise correspondingly.

Environmental monitoring applications have also contributed to the market expansion. With growing concerns about pollution and climate change, there is an increased need for accurate and reliable water quality monitoring systems. Fluid conductivity sensors are integral components of these systems, used in rivers, lakes, and coastal waters to detect pollutants and assess overall water health.

Geographically, North America and Europe currently dominate the fluid conductivity sensor market, owing to their well-established industrial sectors and stringent environmental regulations. However, the Asia-Pacific region is anticipated to witness the highest growth rate in the coming years. This growth is fueled by rapid industrialization, increasing investments in water infrastructure, and rising awareness about water quality issues in countries like China and India.

The market is characterized by the presence of both large multinational corporations and smaller specialized manufacturers. Key players are focusing on developing innovative sensor technologies to improve accuracy, reliability, and integration capabilities. There is a growing trend towards the development of smart sensors with advanced features such as self-calibration, wireless connectivity, and compatibility with Internet of Things (IoT) platforms.

Despite the positive outlook, the market faces challenges such as price sensitivity in developing regions and the need for continuous technological advancements to meet evolving industry requirements. However, these challenges also present opportunities for innovation and market differentiation for sensor manufacturers.

Current Challenges in Sensor Integration

The integration of sensors in fluid environments presents several significant challenges that researchers and engineers must address to ensure reliable and accurate measurements. One of the primary obstacles is the impact of fluid conductivity on sensor performance and longevity. As the conductivity of the fluid changes, it can affect the electrical properties of the sensors, leading to inaccurate readings or even sensor failure.

Corrosion and degradation of sensor components pose another major challenge in fluid environments. The constant exposure to potentially corrosive or reactive fluids can compromise the integrity of sensor materials, affecting their functionality and lifespan. This issue is particularly pronounced in harsh industrial settings or marine applications where sensors are subjected to extreme conditions.

Signal interference and noise are persistent problems in fluid-based sensor integration. The conductive nature of many fluids can create electromagnetic interference, distorting sensor signals and reducing measurement accuracy. Additionally, turbulence and fluid dynamics can introduce mechanical noise, further complicating data interpretation and analysis.

Maintaining sensor calibration in dynamic fluid environments is a complex task. Fluctuations in temperature, pressure, and fluid composition can alter sensor responses, necessitating frequent recalibration or the development of advanced self-calibrating systems. This challenge is particularly acute in applications where continuous, long-term monitoring is required.

Power management and energy harvesting present unique difficulties in fluid-based sensor systems. Traditional power sources may not be suitable or safe in certain fluid environments, driving the need for innovative energy solutions. Researchers are exploring energy harvesting techniques from fluid flow or thermal gradients, but these approaches are still in their infancy and face efficiency and reliability hurdles.

Miniaturization and integration of sensors into compact fluid systems introduce design and manufacturing challenges. As devices become smaller, issues such as fluid flow disruption, heat dissipation, and component isolation become more pronounced. Balancing the need for miniaturization with sensor performance and reliability is an ongoing area of research and development.

Data transmission from sensors in fluid environments to external systems is another critical challenge. Wireless communication can be severely attenuated or disrupted by conductive fluids, while wired connections may compromise system integrity or introduce potential leak points. Developing robust, reliable communication protocols for fluid-based sensor networks remains an active area of investigation.

Corrosion and degradation of sensor components pose another major challenge in fluid environments. The constant exposure to potentially corrosive or reactive fluids can compromise the integrity of sensor materials, affecting their functionality and lifespan. This issue is particularly pronounced in harsh industrial settings or marine applications where sensors are subjected to extreme conditions.

Signal interference and noise are persistent problems in fluid-based sensor integration. The conductive nature of many fluids can create electromagnetic interference, distorting sensor signals and reducing measurement accuracy. Additionally, turbulence and fluid dynamics can introduce mechanical noise, further complicating data interpretation and analysis.

Maintaining sensor calibration in dynamic fluid environments is a complex task. Fluctuations in temperature, pressure, and fluid composition can alter sensor responses, necessitating frequent recalibration or the development of advanced self-calibrating systems. This challenge is particularly acute in applications where continuous, long-term monitoring is required.

Power management and energy harvesting present unique difficulties in fluid-based sensor systems. Traditional power sources may not be suitable or safe in certain fluid environments, driving the need for innovative energy solutions. Researchers are exploring energy harvesting techniques from fluid flow or thermal gradients, but these approaches are still in their infancy and face efficiency and reliability hurdles.

Miniaturization and integration of sensors into compact fluid systems introduce design and manufacturing challenges. As devices become smaller, issues such as fluid flow disruption, heat dissipation, and component isolation become more pronounced. Balancing the need for miniaturization with sensor performance and reliability is an ongoing area of research and development.

Data transmission from sensors in fluid environments to external systems is another critical challenge. Wireless communication can be severely attenuated or disrupted by conductive fluids, while wired connections may compromise system integrity or introduce potential leak points. Developing robust, reliable communication protocols for fluid-based sensor networks remains an active area of investigation.

Existing Sensor Integration Solutions

01 Conductivity measurement techniques

Various techniques are employed to measure conductivity in sensors, including electromagnetic methods, electrode-based systems, and non-contact approaches. These methods allow for accurate and reliable conductivity measurements in different environments and applications.- Conductivity measurement techniques: Various techniques are employed to measure conductivity in sensors, including electromagnetic methods, electrode-based systems, and non-contact approaches. These methods allow for accurate and reliable conductivity measurements in different environments and applications.

- Temperature compensation in conductivity sensors: Temperature compensation is crucial for accurate conductivity measurements. Sensors incorporate temperature sensing elements and algorithms to adjust readings based on temperature variations, ensuring consistent and reliable results across different thermal conditions.

- Multi-parameter sensing systems: Advanced sensors combine conductivity measurements with other parameters such as pH, dissolved oxygen, or turbidity. These integrated systems provide comprehensive water quality analysis and are used in various industries including environmental monitoring and process control.

- Miniaturization and portability of conductivity sensors: Recent developments focus on miniaturizing conductivity sensors for portable and in-situ applications. These compact designs incorporate advanced materials and fabrication techniques to maintain accuracy while reducing size and power consumption.

- Smart and IoT-enabled conductivity sensors: Integration of conductivity sensors with IoT technologies enables real-time monitoring, data logging, and remote access. These smart sensors offer improved data management, predictive maintenance capabilities, and seamless integration with existing industrial control systems.

02 Temperature compensation in conductivity sensors

Temperature compensation is crucial for accurate conductivity measurements. Sensors incorporate temperature sensing elements and algorithms to adjust readings based on temperature variations, ensuring consistent and reliable results across different thermal conditions.Expand Specific Solutions03 Multi-parameter sensing systems

Advanced sensors combine conductivity measurements with other parameters such as pH, dissolved oxygen, or turbidity. These integrated systems provide comprehensive water quality analysis and are used in various industries including environmental monitoring and process control.Expand Specific Solutions04 Miniaturization and portability of conductivity sensors

Recent developments focus on miniaturizing conductivity sensors for portable and in-situ applications. These compact designs incorporate advanced materials and microfabrication techniques to achieve high sensitivity and reliability in a small form factor.Expand Specific Solutions05 Wireless and IoT-enabled conductivity sensors

Integration of wireless communication technologies and Internet of Things (IoT) capabilities in conductivity sensors enables real-time data transmission, remote monitoring, and cloud-based analytics. This enhances data accessibility and facilitates predictive maintenance in industrial applications.Expand Specific Solutions

Key Players in Fluid Sensor Industry

The investigation into fluid conductivity's impact on sensor integration is at a critical juncture, with the market showing significant growth potential. The technology is in a transitional phase, moving from early adoption to mainstream implementation. Major players like Honeywell International Technologies, Analog Devices, and Texas Instruments are driving innovation, while academic institutions such as Tianjin University and the University of Twente contribute valuable research. The market is characterized by a mix of established industrial giants and specialized sensor manufacturers, indicating a maturing but still evolving technological landscape. As the demand for precise fluid conductivity measurements increases across industries, competition is intensifying, spurring further advancements in sensor integration techniques.

Honeywell International Technologies Ltd.

Technical Solution: Honeywell has developed a comprehensive approach to investigating fluid conductivity and its impact on sensor integration, particularly in industrial process control applications. Their technology includes advanced toroidal conductivity sensors that offer non-contact measurement, reducing the risk of sensor fouling and contamination in harsh environments[10]. Honeywell's sensors incorporate smart diagnostics and predictive maintenance features, allowing for real-time monitoring of sensor performance and early detection of potential issues. The company has also developed specialized transmitters and analyzers that can handle multiple sensor inputs, enabling integrated measurement of conductivity, pH, and other fluid parameters. Honeywell's solutions often include advanced data analytics capabilities, allowing for trend analysis and process optimization based on conductivity measurements[11].

Strengths: Robust design for industrial environments, advanced diagnostics, and integrated process control solutions. Weaknesses: May have higher complexity and cost for simple applications that do not require advanced features.

Analog Devices, Inc.

Technical Solution: Analog Devices has developed a comprehensive approach to investigating the impact of fluid conductivity on sensor integration, focusing on precision measurement and signal integrity. Their solution incorporates high-performance analog-to-digital converters (ADCs) and precision amplifiers specifically designed for conductivity measurement applications[6]. ADI's technology includes advanced signal conditioning techniques to mitigate the effects of parasitic capacitance and interference, which are critical in fluid conductivity sensing. The company has also developed specialized impedance analyzers that can characterize fluid properties across a wide frequency range, providing detailed insights into conductivity variations[7]. ADI's sensors often integrate temperature measurement capabilities for accurate compensation, ensuring reliable results in dynamic fluid environments.

Strengths: High precision, excellent signal integrity, and advanced signal processing capabilities. Weaknesses: May require more complex integration and higher component costs compared to simpler solutions.

Core Innovations in Conductivity Sensing

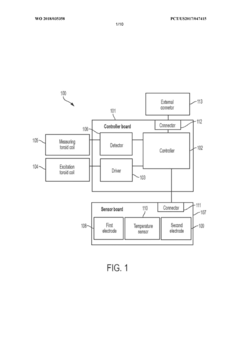

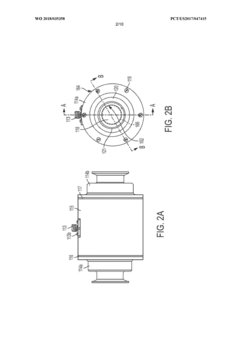

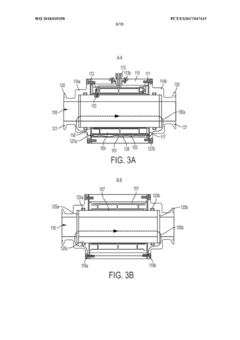

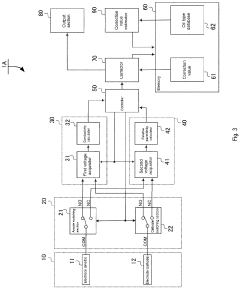

Conductivity sensor with void correction

PatentWO2018035358A1

Innovation

- A conductivity sensor system that includes capacitance electrodes and a controller to measure and correct for voids by correlating capacitance and conductivity measurements, using temperature data and fluid type-specific relationships to adjust conductivity readings, ensuring accurate fluid conductivity measurements despite the presence of air bubbles or foam.

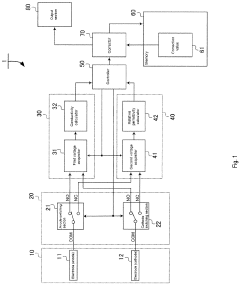

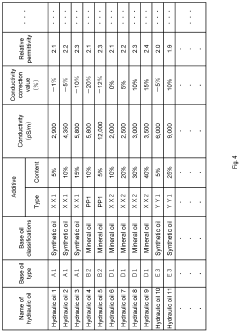

Fluid state detection sensor

PatentPendingEP4317955A1

Innovation

- A fluid state detection sensor with a conductivity acquisition unit, memory for storing correction values, and a corrector to adjust conductivity calculations based on predetermined values, along with a relative permittivity acquisition unit and a correction value estimator using a database of hydraulic oil information to enhance measurement accuracy.

Environmental Impact Assessment

The integration of sensors in fluid environments necessitates a thorough assessment of potential environmental impacts. Fluid conductivity, a key parameter in sensor performance, can significantly influence the surrounding ecosystem when altered. This environmental impact assessment focuses on the potential consequences of sensor integration in relation to fluid conductivity changes.

Aquatic ecosystems are particularly vulnerable to shifts in fluid conductivity. The introduction of sensors may lead to localized changes in conductivity, potentially disrupting the delicate balance of ionic concentrations in water bodies. This can affect the osmotic processes of aquatic organisms, impacting their ability to regulate internal salt concentrations. Fish, amphibians, and various invertebrates may experience physiological stress or behavioral changes as a result.

Furthermore, alterations in fluid conductivity can influence the distribution and abundance of microbial communities. These microorganisms play crucial roles in nutrient cycling and form the foundation of aquatic food webs. Changes in conductivity may favor certain species over others, potentially leading to shifts in community composition and ecosystem functioning.

Sensor integration may also impact water quality parameters beyond conductivity. The presence of sensors and associated equipment could introduce trace amounts of materials that affect pH levels, dissolved oxygen content, or nutrient availability. While these effects may be minimal at the individual sensor level, the cumulative impact of multiple sensors or large-scale deployments should be carefully considered.

Terrestrial environments near water bodies may also experience indirect effects. Changes in aquatic ecosystems can ripple through the food chain, affecting terrestrial species that rely on aquatic resources. Additionally, any physical disturbances during sensor installation or maintenance activities should be evaluated for their potential impact on shoreline habitats and associated flora and fauna.

Long-term environmental monitoring is essential to fully understand the impacts of sensor integration on fluid conductivity. This should include regular assessments of water quality parameters, biodiversity indices, and ecosystem health indicators. Such monitoring programs can help identify any unforeseen consequences and inform adaptive management strategies to mitigate negative impacts.

Mitigation measures should be developed and implemented to minimize environmental disturbances. These may include using environmentally friendly materials in sensor construction, optimizing sensor placement to reduce localized conductivity changes, and implementing strict protocols for installation and maintenance to minimize physical disturbances to habitats.

In conclusion, while sensor integration offers valuable data for environmental monitoring and management, it is crucial to carefully assess and mitigate potential impacts on fluid conductivity and associated environmental parameters. A balanced approach that weighs the benefits of improved environmental monitoring against potential ecological disruptions is essential for sustainable sensor deployment in fluid environments.

Aquatic ecosystems are particularly vulnerable to shifts in fluid conductivity. The introduction of sensors may lead to localized changes in conductivity, potentially disrupting the delicate balance of ionic concentrations in water bodies. This can affect the osmotic processes of aquatic organisms, impacting their ability to regulate internal salt concentrations. Fish, amphibians, and various invertebrates may experience physiological stress or behavioral changes as a result.

Furthermore, alterations in fluid conductivity can influence the distribution and abundance of microbial communities. These microorganisms play crucial roles in nutrient cycling and form the foundation of aquatic food webs. Changes in conductivity may favor certain species over others, potentially leading to shifts in community composition and ecosystem functioning.

Sensor integration may also impact water quality parameters beyond conductivity. The presence of sensors and associated equipment could introduce trace amounts of materials that affect pH levels, dissolved oxygen content, or nutrient availability. While these effects may be minimal at the individual sensor level, the cumulative impact of multiple sensors or large-scale deployments should be carefully considered.

Terrestrial environments near water bodies may also experience indirect effects. Changes in aquatic ecosystems can ripple through the food chain, affecting terrestrial species that rely on aquatic resources. Additionally, any physical disturbances during sensor installation or maintenance activities should be evaluated for their potential impact on shoreline habitats and associated flora and fauna.

Long-term environmental monitoring is essential to fully understand the impacts of sensor integration on fluid conductivity. This should include regular assessments of water quality parameters, biodiversity indices, and ecosystem health indicators. Such monitoring programs can help identify any unforeseen consequences and inform adaptive management strategies to mitigate negative impacts.

Mitigation measures should be developed and implemented to minimize environmental disturbances. These may include using environmentally friendly materials in sensor construction, optimizing sensor placement to reduce localized conductivity changes, and implementing strict protocols for installation and maintenance to minimize physical disturbances to habitats.

In conclusion, while sensor integration offers valuable data for environmental monitoring and management, it is crucial to carefully assess and mitigate potential impacts on fluid conductivity and associated environmental parameters. A balanced approach that weighs the benefits of improved environmental monitoring against potential ecological disruptions is essential for sustainable sensor deployment in fluid environments.

Sensor Calibration Techniques

Sensor calibration techniques play a crucial role in investigating the impact of fluid conductivity on sensor integration. These techniques ensure accurate and reliable measurements across varying conductivity levels, which is essential for maintaining sensor performance in diverse fluid environments.

One of the primary calibration methods involves the use of standard solutions with known conductivity values. By exposing sensors to these reference solutions, researchers can establish a baseline for sensor response and create calibration curves. This process typically involves multiple points across a range of conductivities to account for potential non-linear relationships between sensor output and fluid conductivity.

In-situ calibration techniques have gained prominence in recent years, allowing for real-time adjustments to sensor readings based on changing environmental conditions. These methods often incorporate secondary sensors or reference electrodes to provide continuous feedback on fluid conductivity, enabling dynamic calibration of the primary sensor array.

Advanced calibration approaches utilize machine learning algorithms to improve sensor accuracy and adaptability. By training models on extensive datasets that encompass various conductivity scenarios, these systems can predict and compensate for sensor drift and interference effects. This is particularly valuable in applications where fluid conductivity may fluctuate rapidly or unpredictably.

Temperature compensation is another critical aspect of sensor calibration when investigating fluid conductivity impacts. As temperature significantly influences conductivity measurements, calibration techniques must account for these thermal effects. This often involves integrating temperature sensors and applying correction factors to maintain accuracy across a wide range of operating conditions.

Multi-parameter calibration strategies have emerged as a comprehensive solution for addressing the complex interplay between fluid conductivity and other environmental factors. These techniques simultaneously calibrate sensors for conductivity, temperature, pressure, and other relevant parameters, providing a more holistic approach to sensor integration in variable fluid environments.

Frequency-domain analysis has proven effective in calibrating sensors for fluid conductivity measurements. By examining sensor response across different excitation frequencies, researchers can isolate conductivity-specific signals from other interfering factors. This technique enhances the selectivity and sensitivity of sensors in complex fluid matrices.

As sensor miniaturization continues to advance, novel calibration methods are being developed to address the unique challenges of micro- and nano-scale devices. These include on-chip calibration circuits and self-calibrating sensor arrays that can autonomously adjust their performance based on local conductivity conditions.

One of the primary calibration methods involves the use of standard solutions with known conductivity values. By exposing sensors to these reference solutions, researchers can establish a baseline for sensor response and create calibration curves. This process typically involves multiple points across a range of conductivities to account for potential non-linear relationships between sensor output and fluid conductivity.

In-situ calibration techniques have gained prominence in recent years, allowing for real-time adjustments to sensor readings based on changing environmental conditions. These methods often incorporate secondary sensors or reference electrodes to provide continuous feedback on fluid conductivity, enabling dynamic calibration of the primary sensor array.

Advanced calibration approaches utilize machine learning algorithms to improve sensor accuracy and adaptability. By training models on extensive datasets that encompass various conductivity scenarios, these systems can predict and compensate for sensor drift and interference effects. This is particularly valuable in applications where fluid conductivity may fluctuate rapidly or unpredictably.

Temperature compensation is another critical aspect of sensor calibration when investigating fluid conductivity impacts. As temperature significantly influences conductivity measurements, calibration techniques must account for these thermal effects. This often involves integrating temperature sensors and applying correction factors to maintain accuracy across a wide range of operating conditions.

Multi-parameter calibration strategies have emerged as a comprehensive solution for addressing the complex interplay between fluid conductivity and other environmental factors. These techniques simultaneously calibrate sensors for conductivity, temperature, pressure, and other relevant parameters, providing a more holistic approach to sensor integration in variable fluid environments.

Frequency-domain analysis has proven effective in calibrating sensors for fluid conductivity measurements. By examining sensor response across different excitation frequencies, researchers can isolate conductivity-specific signals from other interfering factors. This technique enhances the selectivity and sensitivity of sensors in complex fluid matrices.

As sensor miniaturization continues to advance, novel calibration methods are being developed to address the unique challenges of micro- and nano-scale devices. These include on-chip calibration circuits and self-calibrating sensor arrays that can autonomously adjust their performance based on local conductivity conditions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!