Investigation of gasket materials for enhanced gate valve seal reliability

AUG 20, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Gasket Material Evolution

The evolution of gasket materials for gate valve seal reliability has been a journey of continuous innovation and improvement. In the early days of valve technology, simple materials like leather, rubber, and cork were commonly used as gaskets. These materials, while functional, had limitations in terms of durability and resistance to harsh environments.

As industrial processes became more demanding, the need for advanced gasket materials grew. The mid-20th century saw the introduction of synthetic rubber compounds, such as Nitrile (NBR) and Ethylene Propylene Diene Monomer (EPDM). These materials offered improved chemical resistance and temperature tolerance compared to their natural counterparts, marking a significant step forward in gasket technology.

The 1960s and 1970s witnessed the emergence of fluoroelastomers, with materials like Viton gaining popularity. These gaskets provided exceptional resistance to chemicals and high temperatures, making them suitable for a wide range of industrial applications. This period also saw the development of expanded graphite as a gasket material, offering excellent sealing properties and high-temperature resistance.

In the 1980s and 1990s, the focus shifted towards developing composite materials that could combine the benefits of different gasket types. PTFE-based gaskets, such as Gore-Tex, were introduced, offering excellent chemical resistance and low friction properties. These materials significantly improved the longevity and performance of gate valve seals in corrosive environments.

The turn of the millennium brought about a new era in gasket material development, with nanotechnology playing an increasingly important role. Nano-enhanced polymers and composites began to emerge, offering unprecedented levels of strength, flexibility, and chemical resistance. These materials allowed for the creation of gaskets that could maintain their sealing properties under extreme conditions for extended periods.

Recent years have seen a growing emphasis on environmentally friendly and sustainable gasket materials. Researchers are exploring bio-based polymers and recycled materials that can meet the performance requirements of industrial applications while reducing environmental impact. Additionally, smart materials that can self-heal or provide real-time monitoring of seal integrity are being developed, promising to revolutionize gate valve reliability.

The evolution of gasket materials has been driven by the need for improved performance, longevity, and reliability in increasingly demanding industrial environments. From simple natural materials to advanced composites and smart materials, each stage of development has brought new capabilities and solutions to the challenges of gate valve seal reliability. As technology continues to advance, we can expect further innovations in gasket materials that will enhance performance, reduce maintenance requirements, and contribute to more efficient and sustainable industrial processes.

As industrial processes became more demanding, the need for advanced gasket materials grew. The mid-20th century saw the introduction of synthetic rubber compounds, such as Nitrile (NBR) and Ethylene Propylene Diene Monomer (EPDM). These materials offered improved chemical resistance and temperature tolerance compared to their natural counterparts, marking a significant step forward in gasket technology.

The 1960s and 1970s witnessed the emergence of fluoroelastomers, with materials like Viton gaining popularity. These gaskets provided exceptional resistance to chemicals and high temperatures, making them suitable for a wide range of industrial applications. This period also saw the development of expanded graphite as a gasket material, offering excellent sealing properties and high-temperature resistance.

In the 1980s and 1990s, the focus shifted towards developing composite materials that could combine the benefits of different gasket types. PTFE-based gaskets, such as Gore-Tex, were introduced, offering excellent chemical resistance and low friction properties. These materials significantly improved the longevity and performance of gate valve seals in corrosive environments.

The turn of the millennium brought about a new era in gasket material development, with nanotechnology playing an increasingly important role. Nano-enhanced polymers and composites began to emerge, offering unprecedented levels of strength, flexibility, and chemical resistance. These materials allowed for the creation of gaskets that could maintain their sealing properties under extreme conditions for extended periods.

Recent years have seen a growing emphasis on environmentally friendly and sustainable gasket materials. Researchers are exploring bio-based polymers and recycled materials that can meet the performance requirements of industrial applications while reducing environmental impact. Additionally, smart materials that can self-heal or provide real-time monitoring of seal integrity are being developed, promising to revolutionize gate valve reliability.

The evolution of gasket materials has been driven by the need for improved performance, longevity, and reliability in increasingly demanding industrial environments. From simple natural materials to advanced composites and smart materials, each stage of development has brought new capabilities and solutions to the challenges of gate valve seal reliability. As technology continues to advance, we can expect further innovations in gasket materials that will enhance performance, reduce maintenance requirements, and contribute to more efficient and sustainable industrial processes.

Market Demand Analysis

The market demand for enhanced gate valve seal reliability through improved gasket materials is driven by several key factors in various industries. The oil and gas sector, in particular, has been a significant driver of this demand due to the critical nature of valve performance in their operations. As exploration and production activities expand into more challenging environments, such as deep-water and high-pressure/high-temperature (HPHT) fields, the need for robust sealing solutions has intensified.

In the petrochemical industry, there is a growing emphasis on reducing fugitive emissions and improving overall plant efficiency. This has led to increased scrutiny of valve performance, with a focus on minimizing leakage and extending maintenance intervals. The demand for advanced gasket materials that can withstand aggressive chemicals, extreme temperatures, and high pressures has consequently risen.

The power generation sector, including nuclear and conventional thermal plants, also contributes significantly to the market demand. These facilities require valve seals that can maintain integrity under demanding operating conditions, ensuring safety and reliability in critical systems. The push towards more efficient and cleaner energy production has further accentuated the need for high-performance gasket materials.

Water and wastewater treatment facilities represent another substantial market segment. As municipalities and industries face stricter environmental regulations, the demand for reliable valve seals that prevent contamination and ensure proper flow control has increased. This sector values gasket materials that offer long-term durability and resistance to various water treatment chemicals.

The pharmaceutical and food processing industries have unique requirements for gasket materials, focusing on materials that meet stringent hygiene standards and can withstand frequent cleaning and sterilization processes. These sectors demand gaskets that are compliant with FDA regulations and can prevent product contamination.

Market analysis indicates a trend towards the adoption of advanced composite materials and engineered polymers for gasket applications. These materials offer superior performance characteristics compared to traditional options, including better chemical resistance, improved temperature tolerance, and enhanced sealing properties.

The global valve market, which directly influences the demand for gasket materials, is projected to grow steadily over the coming years. This growth is driven by infrastructure development in emerging economies, ongoing industrialization, and the need to replace aging equipment in developed markets. The specific segment of high-performance gaskets for gate valves is expected to outpace the overall market growth rate, reflecting the increasing focus on reliability and efficiency across industries.

In the petrochemical industry, there is a growing emphasis on reducing fugitive emissions and improving overall plant efficiency. This has led to increased scrutiny of valve performance, with a focus on minimizing leakage and extending maintenance intervals. The demand for advanced gasket materials that can withstand aggressive chemicals, extreme temperatures, and high pressures has consequently risen.

The power generation sector, including nuclear and conventional thermal plants, also contributes significantly to the market demand. These facilities require valve seals that can maintain integrity under demanding operating conditions, ensuring safety and reliability in critical systems. The push towards more efficient and cleaner energy production has further accentuated the need for high-performance gasket materials.

Water and wastewater treatment facilities represent another substantial market segment. As municipalities and industries face stricter environmental regulations, the demand for reliable valve seals that prevent contamination and ensure proper flow control has increased. This sector values gasket materials that offer long-term durability and resistance to various water treatment chemicals.

The pharmaceutical and food processing industries have unique requirements for gasket materials, focusing on materials that meet stringent hygiene standards and can withstand frequent cleaning and sterilization processes. These sectors demand gaskets that are compliant with FDA regulations and can prevent product contamination.

Market analysis indicates a trend towards the adoption of advanced composite materials and engineered polymers for gasket applications. These materials offer superior performance characteristics compared to traditional options, including better chemical resistance, improved temperature tolerance, and enhanced sealing properties.

The global valve market, which directly influences the demand for gasket materials, is projected to grow steadily over the coming years. This growth is driven by infrastructure development in emerging economies, ongoing industrialization, and the need to replace aging equipment in developed markets. The specific segment of high-performance gaskets for gate valves is expected to outpace the overall market growth rate, reflecting the increasing focus on reliability and efficiency across industries.

Current Challenges

The current challenges in enhancing gate valve seal reliability through improved gasket materials are multifaceted and complex. One of the primary issues is the harsh operating environments that these seals must endure. Gate valves are often used in industries such as oil and gas, chemical processing, and power generation, where they are exposed to extreme temperatures, high pressures, and corrosive substances. These conditions can rapidly degrade traditional gasket materials, leading to premature failure and potential leaks.

Material selection presents another significant challenge. While there are numerous gasket materials available, each with its own set of properties, finding the optimal balance between performance characteristics such as chemical resistance, temperature tolerance, compression set resistance, and longevity is often difficult. Moreover, the material must maintain its sealing properties under varying operational conditions, including frequent cycling and long periods of inactivity.

The issue of standardization across different industries and applications further complicates the development of enhanced gasket materials. Different sectors may have varying requirements and regulations, making it challenging to create a universally applicable solution. This diversity in standards can lead to increased costs and complexity in manufacturing and inventory management.

Another critical challenge is the trade-off between seal effectiveness and operational efficiency. Tighter seals may provide better leak prevention but can also increase the torque required to operate the valve, potentially leading to increased wear on valve components and higher energy consumption during operation. Striking the right balance between these factors is crucial for overall system performance and longevity.

The long-term behavior of gasket materials under real-world conditions is also a significant concern. Laboratory testing may not always accurately predict how a material will perform over extended periods in actual industrial settings. This uncertainty can make it difficult to guarantee the long-term reliability of new gasket materials, potentially leading to hesitancy in adoption by conservative industries where reliability is paramount.

Environmental considerations add another layer of complexity to the challenge. As industries face increasing pressure to reduce their environmental impact, there is a growing need for gasket materials that are not only high-performing but also environmentally friendly. This includes considerations such as recyclability, biodegradability, and the reduction of harmful emissions during production and use.

Lastly, the cost-effectiveness of new gasket materials remains a significant hurdle. While advanced materials may offer superior performance, their higher cost can be a barrier to widespread adoption, especially in industries with tight profit margins. Balancing the need for improved reliability with economic feasibility is an ongoing challenge that requires innovative solutions and careful cost-benefit analysis.

Material selection presents another significant challenge. While there are numerous gasket materials available, each with its own set of properties, finding the optimal balance between performance characteristics such as chemical resistance, temperature tolerance, compression set resistance, and longevity is often difficult. Moreover, the material must maintain its sealing properties under varying operational conditions, including frequent cycling and long periods of inactivity.

The issue of standardization across different industries and applications further complicates the development of enhanced gasket materials. Different sectors may have varying requirements and regulations, making it challenging to create a universally applicable solution. This diversity in standards can lead to increased costs and complexity in manufacturing and inventory management.

Another critical challenge is the trade-off between seal effectiveness and operational efficiency. Tighter seals may provide better leak prevention but can also increase the torque required to operate the valve, potentially leading to increased wear on valve components and higher energy consumption during operation. Striking the right balance between these factors is crucial for overall system performance and longevity.

The long-term behavior of gasket materials under real-world conditions is also a significant concern. Laboratory testing may not always accurately predict how a material will perform over extended periods in actual industrial settings. This uncertainty can make it difficult to guarantee the long-term reliability of new gasket materials, potentially leading to hesitancy in adoption by conservative industries where reliability is paramount.

Environmental considerations add another layer of complexity to the challenge. As industries face increasing pressure to reduce their environmental impact, there is a growing need for gasket materials that are not only high-performing but also environmentally friendly. This includes considerations such as recyclability, biodegradability, and the reduction of harmful emissions during production and use.

Lastly, the cost-effectiveness of new gasket materials remains a significant hurdle. While advanced materials may offer superior performance, their higher cost can be a barrier to widespread adoption, especially in industries with tight profit margins. Balancing the need for improved reliability with economic feasibility is an ongoing challenge that requires innovative solutions and careful cost-benefit analysis.

Existing Seal Solutions

01 Material selection for gasket reliability

Choosing appropriate materials is crucial for gasket reliability. Materials such as elastomers, metals, and composites are commonly used. The selection depends on factors like temperature, pressure, and chemical compatibility. Advanced materials with improved properties can enhance seal performance and longevity.- Material selection for gasket seals: Choosing appropriate materials for gaskets is crucial for seal reliability. Various materials such as elastomers, metals, and composites are used depending on the application requirements. Factors like temperature resistance, chemical compatibility, and compression set are considered when selecting gasket materials to ensure long-term sealing performance.

- Gasket design and configuration: The design and configuration of gaskets play a significant role in seal reliability. This includes considerations such as gasket thickness, shape, and profile. Innovative designs like multi-layer gaskets or those with specific sealing elements can enhance sealing performance and durability under various operating conditions.

- Surface treatment and coatings: Surface treatments and coatings applied to gaskets can improve their sealing properties and reliability. These treatments may enhance chemical resistance, reduce friction, or improve adhesion to mating surfaces. Techniques such as plasma treatment or the application of specialized coatings can significantly impact the gasket's performance and longevity.

- Environmental and operating condition considerations: Seal reliability is heavily influenced by the environmental and operating conditions the gasket is exposed to. Factors such as temperature fluctuations, pressure changes, and exposure to chemicals or fluids must be considered when designing and selecting gaskets. Specialized gaskets may be required for extreme conditions to maintain reliable sealing performance.

- Installation and maintenance practices: Proper installation and maintenance practices are essential for ensuring gasket seal reliability. This includes correct torque application, proper alignment, and regular inspection and replacement schedules. Advanced installation techniques or tools may be employed to optimize gasket performance and extend service life.

02 Gasket design for improved sealing

Innovative gasket designs can significantly improve seal reliability. This includes features like multi-layer constructions, reinforced edges, and specialized profiles. Proper design considerations account for factors such as compression set, recovery, and stress distribution to ensure optimal sealing performance.Expand Specific Solutions03 Surface treatment and coatings

Surface treatments and coatings can enhance gasket reliability by improving adhesion, reducing friction, and increasing chemical resistance. Techniques such as plasma treatment, fluoropolymer coatings, or nanoparticle additives can be applied to gasket surfaces to optimize their sealing properties and extend their service life.Expand Specific Solutions04 Environmental and operational considerations

Accounting for environmental and operational factors is essential for gasket reliability. This includes considering temperature fluctuations, pressure cycles, chemical exposure, and vibration. Designing gaskets to withstand these conditions and implementing proper installation and maintenance procedures can significantly improve seal reliability.Expand Specific Solutions05 Testing and quality control methods

Implementing rigorous testing and quality control methods is crucial for ensuring gasket reliability. This includes leak testing, compression set testing, and accelerated aging tests. Advanced techniques such as finite element analysis and real-time monitoring can be used to predict and evaluate gasket performance under various conditions.Expand Specific Solutions

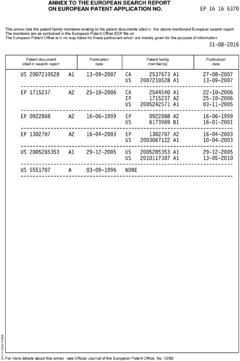

Key Industry Players

The investigation of gasket materials for enhanced gate valve seal reliability is in a mature stage of development, with a significant market size driven by industrial applications. The technology's maturity is evident from the involvement of established players like W. L. Gore & Associates, NICHIAS Corp., and Nitto Denko Corp., who have extensive experience in advanced materials and sealing solutions. These companies, along with others like Flexitallic Investments and Parker-Hannifin Corp., are continuously innovating to improve seal performance and reliability. The competitive landscape is characterized by a mix of specialized sealing solution providers and diversified industrial conglomerates, indicating a robust and evolving market with ongoing research and development efforts.

W. L. Gore & Associates, Inc.

Technical Solution: W. L. Gore & Associates has developed advanced PTFE-based gasket materials specifically designed for gate valve seal applications. Their proprietary ePTFE (expanded PTFE) technology offers superior chemical resistance and durability[1]. The company's GORE GR sheet gasketing, for instance, provides excellent sealability and creep resistance, crucial for maintaining seal integrity in gate valves[2]. Gore's gaskets incorporate a unique microstructure that allows for better conformability to flange surfaces, enhancing sealing performance even under fluctuating temperatures and pressures[3].

Strengths: Exceptional chemical resistance, high temperature tolerance, and superior sealability. Weaknesses: Potentially higher cost compared to traditional gasket materials, may require specialized installation techniques.

NICHIAS Corp.

Technical Solution: NICHIAS Corporation has innovated in the field of gasket materials with their TOMBO No.1120 series, specifically engineered for high-temperature and high-pressure applications in gate valves. This material combines expanded graphite with a stainless steel core, offering excellent sealing properties and resistance to thermal cycling[4]. NICHIAS has also developed nano-scale ceramic particles that, when incorporated into their gasket materials, significantly enhance creep resistance and reduce relaxation, crucial for maintaining seal integrity in gate valves over extended periods[5].

Strengths: High temperature and pressure resistance, excellent creep resistance. Weaknesses: May be less suitable for applications involving certain chemicals due to the graphite content.

Innovative Gasket Patents

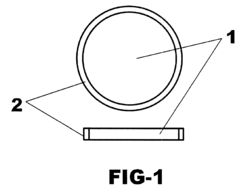

Improve sealing gasket

PatentInactiveEP3086002A1

Innovation

- A gasket combining a thermoplastic material with an elastomeric material, where the thermoplastic material provides mechanical strength and low permeability, and the elastomeric material ensures sealing tightness and chemical resistance, achieved through a two-step molding process with potential adhesive bonding.

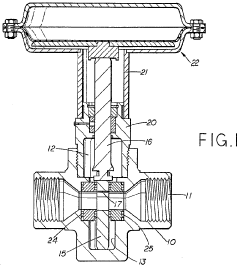

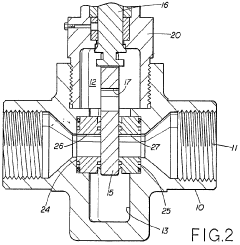

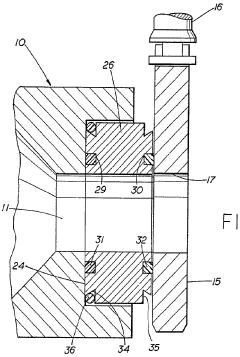

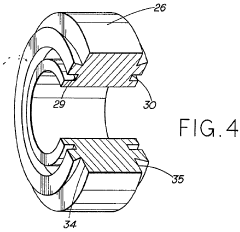

Gate valve seal system

PatentInactiveGB2182119A

Innovation

- A self-relieving gate valve design featuring reversible, self-aligning annular sealing elements with non-elastomeric and elastomeric materials, allowing limited axial movement to maintain continuous sealing engagement with both the gate and seat pockets, ensuring reliable operation under varying pressure conditions.

Material Testing Standards

Material testing standards play a crucial role in ensuring the reliability and performance of gasket materials used in gate valve seals. These standards provide a systematic approach to evaluating the physical, chemical, and mechanical properties of gasket materials, enabling engineers and manufacturers to make informed decisions about material selection and quality control.

ASTM International, formerly known as the American Society for Testing and Materials, has developed several key standards specifically for gasket materials. ASTM F36 is a widely used standard that outlines the test method for compressibility and recovery of gasket materials. This test is particularly relevant for gate valve seals, as it simulates the compression and relaxation cycles that gaskets experience during valve operation.

Another important standard is ASTM F38, which focuses on creep relaxation of gasket materials. This test is essential for predicting the long-term performance of gaskets under constant stress, a critical factor in maintaining seal integrity over extended periods. ASTM F152 provides a standardized method for measuring the tensile strength and elongation of gasket materials, which are important indicators of a material's ability to withstand the stresses encountered in valve applications.

For chemical resistance testing, ASTM F146 outlines procedures for evaluating the fluid resistance of gasket materials. This standard is particularly relevant for gate valves used in chemical processing or other environments where exposure to aggressive fluids is common. The test results help engineers select materials that can maintain their sealing properties in specific chemical environments.

In addition to ASTM standards, the International Organization for Standardization (ISO) has developed relevant standards for gasket materials. ISO 37 provides guidelines for determining the tensile stress-strain properties of rubber, including many elastomeric gasket materials. ISO 815 focuses on compression set tests, which are crucial for assessing a gasket's ability to maintain sealing force over time.

The European Committee for Standardization (CEN) has also contributed to the field with standards such as EN 13555, which specifically addresses gasket parameters and test procedures for the design of bolted flange connections. While not directly focused on gate valves, this standard provides valuable insights into gasket behavior that can be applied to valve seal design.

When investigating gasket materials for enhanced gate valve seal reliability, it is essential to consider industry-specific standards as well. For example, the American Petroleum Institute (API) has developed standards like API 6A and API 6D, which include specifications for valve seals used in oil and gas applications. These standards often reference or incorporate elements of the more general material testing standards mentioned earlier.

By adhering to these established material testing standards, researchers and engineers can ensure that their investigations into gasket materials for gate valve seals are conducted in a rigorous and comparable manner. This standardization not only facilitates the development of more reliable sealing solutions but also enables effective communication of material properties across the industry, ultimately contributing to improved gate valve performance and longevity.

ASTM International, formerly known as the American Society for Testing and Materials, has developed several key standards specifically for gasket materials. ASTM F36 is a widely used standard that outlines the test method for compressibility and recovery of gasket materials. This test is particularly relevant for gate valve seals, as it simulates the compression and relaxation cycles that gaskets experience during valve operation.

Another important standard is ASTM F38, which focuses on creep relaxation of gasket materials. This test is essential for predicting the long-term performance of gaskets under constant stress, a critical factor in maintaining seal integrity over extended periods. ASTM F152 provides a standardized method for measuring the tensile strength and elongation of gasket materials, which are important indicators of a material's ability to withstand the stresses encountered in valve applications.

For chemical resistance testing, ASTM F146 outlines procedures for evaluating the fluid resistance of gasket materials. This standard is particularly relevant for gate valves used in chemical processing or other environments where exposure to aggressive fluids is common. The test results help engineers select materials that can maintain their sealing properties in specific chemical environments.

In addition to ASTM standards, the International Organization for Standardization (ISO) has developed relevant standards for gasket materials. ISO 37 provides guidelines for determining the tensile stress-strain properties of rubber, including many elastomeric gasket materials. ISO 815 focuses on compression set tests, which are crucial for assessing a gasket's ability to maintain sealing force over time.

The European Committee for Standardization (CEN) has also contributed to the field with standards such as EN 13555, which specifically addresses gasket parameters and test procedures for the design of bolted flange connections. While not directly focused on gate valves, this standard provides valuable insights into gasket behavior that can be applied to valve seal design.

When investigating gasket materials for enhanced gate valve seal reliability, it is essential to consider industry-specific standards as well. For example, the American Petroleum Institute (API) has developed standards like API 6A and API 6D, which include specifications for valve seals used in oil and gas applications. These standards often reference or incorporate elements of the more general material testing standards mentioned earlier.

By adhering to these established material testing standards, researchers and engineers can ensure that their investigations into gasket materials for gate valve seals are conducted in a rigorous and comparable manner. This standardization not only facilitates the development of more reliable sealing solutions but also enables effective communication of material properties across the industry, ultimately contributing to improved gate valve performance and longevity.

Environmental Considerations

Environmental considerations play a crucial role in the selection and performance of gasket materials for gate valve seal reliability. The operating environment of gate valves can significantly impact the longevity and effectiveness of the sealing system. Temperature fluctuations, chemical exposure, and pressure variations are key factors that must be carefully evaluated when choosing appropriate gasket materials.

In harsh industrial settings, gate valves may be exposed to extreme temperatures, ranging from cryogenic conditions to high-heat environments. The selected gasket material must maintain its integrity and sealing properties across this temperature spectrum. Thermal expansion and contraction of both the valve body and the gasket material can lead to potential leakage points if not properly addressed. Materials such as graphite-based composites or high-performance fluoropolymers have shown promising results in maintaining seal reliability under varying temperature conditions.

Chemical compatibility is another critical environmental factor. Gate valves are often used in pipelines carrying corrosive fluids, aggressive chemicals, or abrasive slurries. The gasket material must resist degradation and maintain its mechanical properties when in contact with these media. Elastomers like fluoroelastomers (FKM) or perfluoroelastomers (FFKM) offer excellent chemical resistance for a wide range of applications. However, for particularly challenging chemical environments, specialized materials such as polytetrafluoroethylene (PTFE) or metal-reinforced composites may be necessary.

Pressure cycling and fluctuations can also impact gasket performance. In high-pressure applications, the gasket material must withstand compression forces while preventing extrusion. Conversely, in low-pressure scenarios, the material should maintain sufficient elasticity to ensure proper sealing. Fiber-reinforced gaskets or metal-jacketed designs have shown improved performance in managing these pressure-related challenges.

Environmental regulations and sustainability concerns are increasingly influencing gasket material selection. Materials that comply with stringent environmental standards, such as those free from asbestos or heavy metals, are becoming more prevalent. Additionally, the potential for fugitive emissions and their environmental impact must be considered when evaluating gasket materials for gate valve applications.

Lastly, the presence of particulates or debris in the fluid stream can affect gasket performance. Abrasion-resistant materials or designs that incorporate protective features may be necessary to enhance seal reliability in such environments. The use of advanced surface treatments or coatings on gasket materials can provide additional protection against wear and erosion, further improving long-term seal performance in challenging environmental conditions.

In harsh industrial settings, gate valves may be exposed to extreme temperatures, ranging from cryogenic conditions to high-heat environments. The selected gasket material must maintain its integrity and sealing properties across this temperature spectrum. Thermal expansion and contraction of both the valve body and the gasket material can lead to potential leakage points if not properly addressed. Materials such as graphite-based composites or high-performance fluoropolymers have shown promising results in maintaining seal reliability under varying temperature conditions.

Chemical compatibility is another critical environmental factor. Gate valves are often used in pipelines carrying corrosive fluids, aggressive chemicals, or abrasive slurries. The gasket material must resist degradation and maintain its mechanical properties when in contact with these media. Elastomers like fluoroelastomers (FKM) or perfluoroelastomers (FFKM) offer excellent chemical resistance for a wide range of applications. However, for particularly challenging chemical environments, specialized materials such as polytetrafluoroethylene (PTFE) or metal-reinforced composites may be necessary.

Pressure cycling and fluctuations can also impact gasket performance. In high-pressure applications, the gasket material must withstand compression forces while preventing extrusion. Conversely, in low-pressure scenarios, the material should maintain sufficient elasticity to ensure proper sealing. Fiber-reinforced gaskets or metal-jacketed designs have shown improved performance in managing these pressure-related challenges.

Environmental regulations and sustainability concerns are increasingly influencing gasket material selection. Materials that comply with stringent environmental standards, such as those free from asbestos or heavy metals, are becoming more prevalent. Additionally, the potential for fugitive emissions and their environmental impact must be considered when evaluating gasket materials for gate valve applications.

Lastly, the presence of particulates or debris in the fluid stream can affect gasket performance. Abrasion-resistant materials or designs that incorporate protective features may be necessary to enhance seal reliability in such environments. The use of advanced surface treatments or coatings on gasket materials can provide additional protection against wear and erosion, further improving long-term seal performance in challenging environmental conditions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!