Liquid Nitrogen vs Cryogenic Refrigerants: Cost Efficiency Compared

OCT 7, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cryogenic Cooling Technology Background and Objectives

Cryogenic cooling technology has evolved significantly over the past century, transforming from laboratory curiosities to essential industrial processes. The fundamental principle behind cryogenic cooling involves reducing temperatures to extremely low levels, typically below -150°C (-238°F), where gases liquefy and materials exhibit unique properties. This technology originated in the late 19th century with the liquefaction of oxygen and nitrogen, but has since expanded to encompass a diverse range of refrigerants and applications across multiple industries.

The historical progression of cryogenic cooling technology can be traced through several key milestones. The first commercial air separation plant was established in 1902, marking the beginning of industrial-scale cryogenic processes. By the mid-20th century, advances in insulation materials and refrigeration cycles enabled more efficient and widespread use of cryogenic systems. The development of superconducting materials in the 1980s further accelerated research in this field, demanding increasingly sophisticated cooling solutions.

Today's cryogenic landscape features two primary cooling approaches: expendable refrigerants (primarily liquid nitrogen) and closed-cycle cryogenic refrigeration systems. Liquid nitrogen, with its boiling point of -196°C, offers simplicity and accessibility but operates as a single-use coolant. In contrast, mechanical cryocoolers and other refrigeration systems provide continuous cooling through recirculation of refrigerants, though with greater complexity and initial investment.

The global cryogenic equipment market is projected to reach $26.5 billion by 2026, growing at a CAGR of approximately 7.1%. This growth is driven by expanding applications in healthcare, electronics manufacturing, food preservation, and emerging quantum computing technologies. Environmental considerations are also reshaping the industry, with increasing focus on energy efficiency and sustainable refrigerants.

The primary objective of this technical research is to conduct a comprehensive cost-efficiency comparison between liquid nitrogen and mechanical cryogenic refrigeration systems across various application scenarios. This analysis aims to establish quantitative metrics for determining optimal cooling solutions based on factors including cooling capacity requirements, duration of operation, energy costs, and capital investment constraints. Additionally, the research seeks to identify technological trends that may alter the cost-efficiency equation in the coming decade, particularly innovations in insulation materials, refrigeration cycles, and energy recovery systems.

By establishing clear cost-benefit frameworks for different cryogenic cooling approaches, this research will provide decision-makers with actionable insights for technology selection and implementation strategies across industrial, medical, and research applications.

The historical progression of cryogenic cooling technology can be traced through several key milestones. The first commercial air separation plant was established in 1902, marking the beginning of industrial-scale cryogenic processes. By the mid-20th century, advances in insulation materials and refrigeration cycles enabled more efficient and widespread use of cryogenic systems. The development of superconducting materials in the 1980s further accelerated research in this field, demanding increasingly sophisticated cooling solutions.

Today's cryogenic landscape features two primary cooling approaches: expendable refrigerants (primarily liquid nitrogen) and closed-cycle cryogenic refrigeration systems. Liquid nitrogen, with its boiling point of -196°C, offers simplicity and accessibility but operates as a single-use coolant. In contrast, mechanical cryocoolers and other refrigeration systems provide continuous cooling through recirculation of refrigerants, though with greater complexity and initial investment.

The global cryogenic equipment market is projected to reach $26.5 billion by 2026, growing at a CAGR of approximately 7.1%. This growth is driven by expanding applications in healthcare, electronics manufacturing, food preservation, and emerging quantum computing technologies. Environmental considerations are also reshaping the industry, with increasing focus on energy efficiency and sustainable refrigerants.

The primary objective of this technical research is to conduct a comprehensive cost-efficiency comparison between liquid nitrogen and mechanical cryogenic refrigeration systems across various application scenarios. This analysis aims to establish quantitative metrics for determining optimal cooling solutions based on factors including cooling capacity requirements, duration of operation, energy costs, and capital investment constraints. Additionally, the research seeks to identify technological trends that may alter the cost-efficiency equation in the coming decade, particularly innovations in insulation materials, refrigeration cycles, and energy recovery systems.

By establishing clear cost-benefit frameworks for different cryogenic cooling approaches, this research will provide decision-makers with actionable insights for technology selection and implementation strategies across industrial, medical, and research applications.

Market Demand Analysis for Industrial Refrigeration Solutions

The industrial refrigeration market is experiencing significant growth driven by expanding food processing, pharmaceutical, and chemical industries. Global demand for industrial refrigeration solutions reached $25 billion in 2022, with projections indicating a compound annual growth rate of 5.7% through 2030. This growth is particularly pronounced in emerging economies where rapid industrialization and cold chain development are creating new market opportunities.

Within this broader market, cryogenic refrigeration represents a specialized segment valued at approximately $4.3 billion, with liquid nitrogen and other cryogenic refrigerants playing crucial roles. The demand for these ultra-low temperature solutions is primarily driven by healthcare applications (particularly vaccine storage), semiconductor manufacturing, and specialized food processing techniques like flash freezing.

Cost efficiency has emerged as the primary consideration for industrial customers selecting refrigeration technologies. A recent industry survey revealed that 78% of procurement managers rank operational costs as their top decision factor, followed by initial investment (62%) and maintenance requirements (57%). This cost sensitivity is particularly acute in energy-intensive industries where refrigeration can represent up to 15% of total operational expenses.

Liquid nitrogen systems are experiencing increased adoption in specific applications due to their rapid cooling capabilities and relatively simple infrastructure requirements. Market data indicates a 9.2% growth in liquid nitrogen refrigeration system installations over the past three years, particularly in food processing and pharmaceutical manufacturing. However, this growth is geographically uneven, with stronger adoption in regions with reliable nitrogen production and distribution networks.

Alternative cryogenic refrigerants are gaining market share in specialized applications where their specific thermodynamic properties offer advantages. For instance, helium-based systems have seen 12% annual growth in semiconductor manufacturing applications, while argon-based solutions are increasingly preferred in certain metallurgical processes.

The market is also witnessing a shift toward hybrid refrigeration systems that combine conventional mechanical refrigeration with cryogenic cooling for specific process stages. This approach allows businesses to optimize cost efficiency by deploying expensive cryogenic cooling only where absolutely necessary. Industry analysts report that these hybrid systems have achieved cost reductions of 20-30% compared to pure cryogenic solutions in appropriate applications.

Customer demand increasingly focuses on total cost of ownership rather than just acquisition costs. This has prompted refrigeration solution providers to develop more sophisticated cost modeling tools and service packages that demonstrate long-term value propositions, particularly for capital-intensive cryogenic systems.

Within this broader market, cryogenic refrigeration represents a specialized segment valued at approximately $4.3 billion, with liquid nitrogen and other cryogenic refrigerants playing crucial roles. The demand for these ultra-low temperature solutions is primarily driven by healthcare applications (particularly vaccine storage), semiconductor manufacturing, and specialized food processing techniques like flash freezing.

Cost efficiency has emerged as the primary consideration for industrial customers selecting refrigeration technologies. A recent industry survey revealed that 78% of procurement managers rank operational costs as their top decision factor, followed by initial investment (62%) and maintenance requirements (57%). This cost sensitivity is particularly acute in energy-intensive industries where refrigeration can represent up to 15% of total operational expenses.

Liquid nitrogen systems are experiencing increased adoption in specific applications due to their rapid cooling capabilities and relatively simple infrastructure requirements. Market data indicates a 9.2% growth in liquid nitrogen refrigeration system installations over the past three years, particularly in food processing and pharmaceutical manufacturing. However, this growth is geographically uneven, with stronger adoption in regions with reliable nitrogen production and distribution networks.

Alternative cryogenic refrigerants are gaining market share in specialized applications where their specific thermodynamic properties offer advantages. For instance, helium-based systems have seen 12% annual growth in semiconductor manufacturing applications, while argon-based solutions are increasingly preferred in certain metallurgical processes.

The market is also witnessing a shift toward hybrid refrigeration systems that combine conventional mechanical refrigeration with cryogenic cooling for specific process stages. This approach allows businesses to optimize cost efficiency by deploying expensive cryogenic cooling only where absolutely necessary. Industry analysts report that these hybrid systems have achieved cost reductions of 20-30% compared to pure cryogenic solutions in appropriate applications.

Customer demand increasingly focuses on total cost of ownership rather than just acquisition costs. This has prompted refrigeration solution providers to develop more sophisticated cost modeling tools and service packages that demonstrate long-term value propositions, particularly for capital-intensive cryogenic systems.

Current State and Challenges in Cryogenic Refrigeration

The global cryogenic refrigeration industry has witnessed significant technological advancements over the past decade, with liquid nitrogen and mechanical cryocoolers representing the two dominant approaches. Currently, liquid nitrogen remains the most widely utilized cryogenic refrigerant in industrial applications due to its relative abundance, established supply chains, and simplicity of use. The global market for cryogenic equipment was valued at approximately $16 billion in 2022 and is projected to reach $26 billion by 2030, indicating substantial growth potential in this sector.

Despite widespread adoption, the cryogenic refrigeration field faces several critical challenges. Energy efficiency remains a primary concern, with traditional liquid nitrogen systems exhibiting thermal efficiency rates of only 5-15% compared to the theoretical maximum. This inefficiency translates directly to higher operational costs and environmental impact. Additionally, the production and distribution infrastructure for liquid nitrogen requires significant energy input, with estimates suggesting that each liter of liquid nitrogen requires approximately 0.7 kWh of electricity to produce under optimal conditions.

Geographic disparities in technology access present another significant challenge. While developed regions benefit from robust liquid nitrogen distribution networks, many developing areas face prohibitive costs due to inadequate infrastructure. This disparity has created a technological divide, with approximately 70% of advanced cryogenic applications concentrated in North America, Europe, and East Asia, leaving other regions dependent on less efficient or more costly alternatives.

Technical limitations also persist in storage and handling. Liquid nitrogen's boil-off rate typically ranges from 1-3% daily in standard dewars, creating significant waste in applications requiring long-term storage. Meanwhile, mechanical cryocoolers face reliability issues, with mean time between maintenance often limited to 5,000-10,000 hours for systems operating below 80K, necessitating frequent service interruptions.

Regulatory frameworks present additional complexities. Safety standards for cryogenic systems vary significantly across jurisdictions, creating compliance challenges for global manufacturers and users. The transportation of liquid nitrogen across borders involves navigating complex regulatory requirements, adding to logistical costs and operational complexity.

Emerging technologies show promise in addressing these challenges. Pulse tube cryocoolers have demonstrated improved efficiency with fewer moving parts, while advanced vacuum insulation techniques have reduced boil-off rates in storage vessels. However, these innovations remain in various stages of commercial readiness, with widespread adoption limited by cost barriers and technical maturity.

Despite widespread adoption, the cryogenic refrigeration field faces several critical challenges. Energy efficiency remains a primary concern, with traditional liquid nitrogen systems exhibiting thermal efficiency rates of only 5-15% compared to the theoretical maximum. This inefficiency translates directly to higher operational costs and environmental impact. Additionally, the production and distribution infrastructure for liquid nitrogen requires significant energy input, with estimates suggesting that each liter of liquid nitrogen requires approximately 0.7 kWh of electricity to produce under optimal conditions.

Geographic disparities in technology access present another significant challenge. While developed regions benefit from robust liquid nitrogen distribution networks, many developing areas face prohibitive costs due to inadequate infrastructure. This disparity has created a technological divide, with approximately 70% of advanced cryogenic applications concentrated in North America, Europe, and East Asia, leaving other regions dependent on less efficient or more costly alternatives.

Technical limitations also persist in storage and handling. Liquid nitrogen's boil-off rate typically ranges from 1-3% daily in standard dewars, creating significant waste in applications requiring long-term storage. Meanwhile, mechanical cryocoolers face reliability issues, with mean time between maintenance often limited to 5,000-10,000 hours for systems operating below 80K, necessitating frequent service interruptions.

Regulatory frameworks present additional complexities. Safety standards for cryogenic systems vary significantly across jurisdictions, creating compliance challenges for global manufacturers and users. The transportation of liquid nitrogen across borders involves navigating complex regulatory requirements, adding to logistical costs and operational complexity.

Emerging technologies show promise in addressing these challenges. Pulse tube cryocoolers have demonstrated improved efficiency with fewer moving parts, while advanced vacuum insulation techniques have reduced boil-off rates in storage vessels. However, these innovations remain in various stages of commercial readiness, with widespread adoption limited by cost barriers and technical maturity.

Comparative Analysis of Liquid Nitrogen and Alternative Refrigerants

01 Cost-efficient cryogenic refrigeration systems

Innovations in cryogenic refrigeration systems focus on improving cost efficiency through optimized design and operation. These systems utilize liquid nitrogen and other cryogenic refrigerants in configurations that minimize energy consumption while maximizing cooling capacity. Advanced heat exchangers, insulation techniques, and control systems contribute to reduced operational costs and improved performance in industrial applications.- Cost-efficient cryogenic cooling systems: Various designs of cryogenic cooling systems focus on improving cost efficiency through optimized configurations. These systems include specialized heat exchangers, insulation techniques, and circulation methods that minimize liquid nitrogen consumption. Advanced designs incorporate regenerative cooling cycles and multi-stage refrigeration processes to maximize cooling efficiency while reducing operational costs. These innovations enable significant cost savings in industrial and scientific applications requiring cryogenic temperatures.

- Energy recovery in cryogenic processes: Energy recovery systems capture and reuse cold energy from cryogenic refrigerants, significantly improving overall cost efficiency. These systems utilize expansion turbines, heat exchangers, and thermal storage technologies to recapture energy that would otherwise be wasted. By implementing energy recovery techniques, facilities can reduce the amount of liquid nitrogen needed and lower operational costs. The recovered energy can be used for pre-cooling incoming gas streams or for other cooling applications within the same facility.

- Alternative cryogenic refrigerants and mixtures: Research into alternative cryogenic refrigerants and optimized mixtures aims to reduce costs while maintaining performance. These alternatives include mixed refrigerant cycles, helium-based systems, and novel working fluids that offer better thermodynamic properties. By carefully selecting refrigerant compositions based on specific application requirements, significant cost savings can be achieved compared to traditional liquid nitrogen systems. These alternatives often provide better efficiency at certain temperature ranges or pressure conditions.

- Automated control systems for cryogenic efficiency: Advanced control systems optimize the operation of cryogenic refrigeration equipment to maximize cost efficiency. These systems employ sensors, predictive algorithms, and automated flow control to maintain optimal operating conditions while minimizing refrigerant consumption. Real-time monitoring allows for dynamic adjustments based on cooling load requirements, ambient conditions, and system performance metrics. By preventing overcooling and optimizing refrigerant flow rates, these control systems can significantly reduce operational costs in cryogenic applications.

- Cryogenic storage and transportation efficiency: Innovations in cryogenic storage vessels and transportation systems focus on reducing boil-off rates and improving thermal insulation. These technologies include advanced vacuum insulation techniques, multi-layer insulation materials, and specialized pressure management systems. By minimizing heat transfer and evaporation losses during storage and transport, these innovations extend the usable life of liquid nitrogen and other cryogenic refrigerants. This results in lower consumption rates and reduced frequency of refilling, leading to significant cost savings in applications requiring cryogenic temperatures.

02 Liquid nitrogen production and storage optimization

Methods for optimizing the production, storage, and handling of liquid nitrogen to enhance cost efficiency. These innovations include improved liquefaction processes, advanced storage vessels with superior insulation properties, and systems for minimizing boil-off losses during storage and transport. By reducing production energy requirements and extending storage life, these technologies significantly improve the economic viability of liquid nitrogen as a cryogenic refrigerant.Expand Specific Solutions03 Energy recovery systems for cryogenic applications

Energy recovery technologies that capture and reuse cold energy from cryogenic refrigerants, particularly liquid nitrogen. These systems incorporate heat exchangers, expansion turbines, and thermal storage components to harness the cooling potential that would otherwise be wasted. By recycling cold energy, these innovations substantially reduce the overall energy consumption and operating costs of cryogenic cooling processes in industrial and commercial applications.Expand Specific Solutions04 Alternative cryogenic refrigerants and mixtures

Development of alternative cryogenic refrigerants and refrigerant mixtures that offer improved cost efficiency compared to conventional options. These alternatives include specially formulated gas mixtures, natural refrigerants, and recycled industrial gases that provide comparable cooling performance at lower costs. Research focuses on refrigerants with favorable thermodynamic properties, reduced environmental impact, and improved safety profiles for various industrial cooling applications.Expand Specific Solutions05 Cryogenic cooling system integration and automation

Integration of cryogenic cooling systems with automated control technologies to optimize refrigerant usage and enhance cost efficiency. These innovations include smart monitoring systems, predictive maintenance algorithms, and demand-responsive cooling controls that adjust refrigerant flow based on real-time requirements. By precisely matching cooling capacity to actual needs and minimizing waste, these integrated systems significantly reduce operational costs while maintaining performance standards.Expand Specific Solutions

Key Industry Players in Cryogenic Refrigerant Market

The liquid nitrogen versus cryogenic refrigerants market is in a mature growth phase, with an estimated global value exceeding $20 billion annually. The competitive landscape features established industrial gas giants like Praxair Technology, Air Liquide SA, and Messer Group dominating market share through extensive distribution networks and production capabilities. Chart Inc. and MVE Biological Solutions lead in specialized cryogenic equipment manufacturing, while CIMC Safeway Technologies has emerged as a significant tank container producer. Technical maturity varies by application, with medical and laboratory applications (supported by F. Hoffmann-La Roche and CooperSurgical) showing high standardization, while emerging applications in energy storage (Highview Enterprises) remain in development phases. Cost efficiency comparisons increasingly favor closed-cycle refrigeration systems over liquid nitrogen in high-volume applications despite higher initial capital investment.

Praxair Technology, Inc.

Technical Solution: Praxair has developed advanced cryogenic distillation technology that optimizes the production of liquid nitrogen with significantly reduced energy consumption. Their proprietary air separation units (ASUs) incorporate enhanced heat exchange systems that recover up to 85% of the energy typically lost in conventional systems. Their VPSA (Vacuum Pressure Swing Adsorption) technology combined with cryogenic rectification achieves production costs approximately 30-40% lower than traditional methods. Praxair's integrated supply chain management system further reduces operational costs by optimizing delivery logistics and minimizing boil-off losses during transport and storage. Their CryoEase® service model provides customized solutions that match supply precisely with demand patterns, eliminating waste and reducing overall refrigerant costs by an estimated 15-20% compared to conventional bulk delivery systems.

Strengths: Industry-leading energy efficiency in production; comprehensive supply chain optimization; scalable solutions for various industries. Weaknesses: Higher initial capital investment required; system complexity necessitates specialized maintenance personnel; performance advantages diminish at smaller scales of operation.

Air Liquide SA

Technical Solution: Air Liquide has pioneered a comprehensive approach to cryogenic efficiency through their Nexelia™ integrated solutions. Their technology combines optimized production facilities with advanced distribution networks and smart monitoring systems. For liquid nitrogen specifically, their latest generation of air separation units achieves energy consumption reductions of approximately 10-15% compared to industry standards. Air Liquide's proprietary turboexpander technology recovers expansion energy during the liquefaction process, further improving efficiency. Their Turbo-Brayton refrigeration systems provide reliable cooling with minimal maintenance requirements and can be precisely sized to application needs. The company has also developed specialized insulation technologies that reduce storage and transport losses by up to 25%, significantly improving the total cost of ownership for cryogenic refrigerant systems across their lifecycle.

Strengths: Global distribution network providing economies of scale; advanced energy recovery systems; comprehensive digital monitoring reducing operational costs. Weaknesses: Premium pricing model may result in higher initial costs; solutions often require long-term contracts; standardized offerings may not be optimal for unique applications.

Technical Innovations in Cost-Efficient Cryogenic Systems

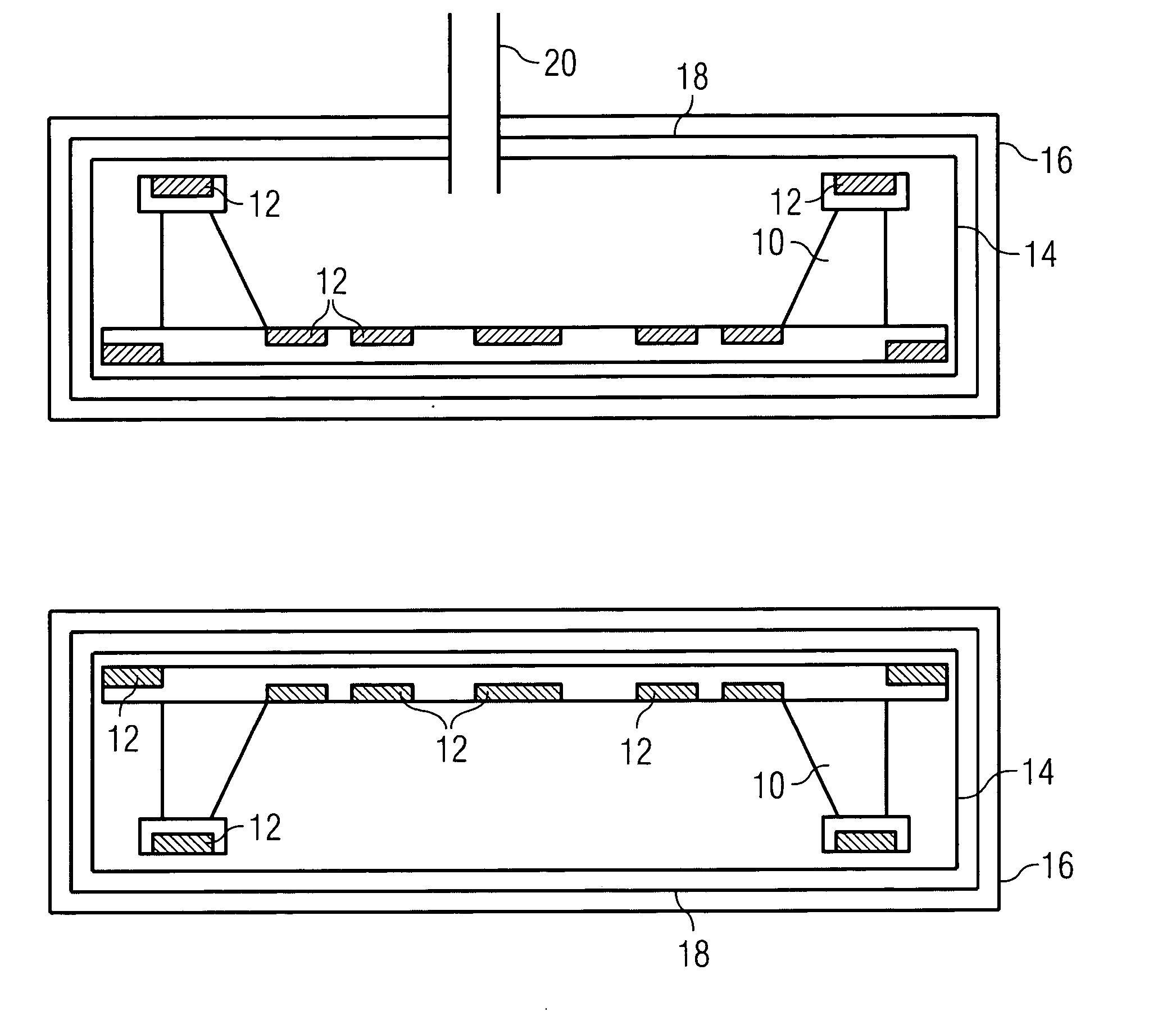

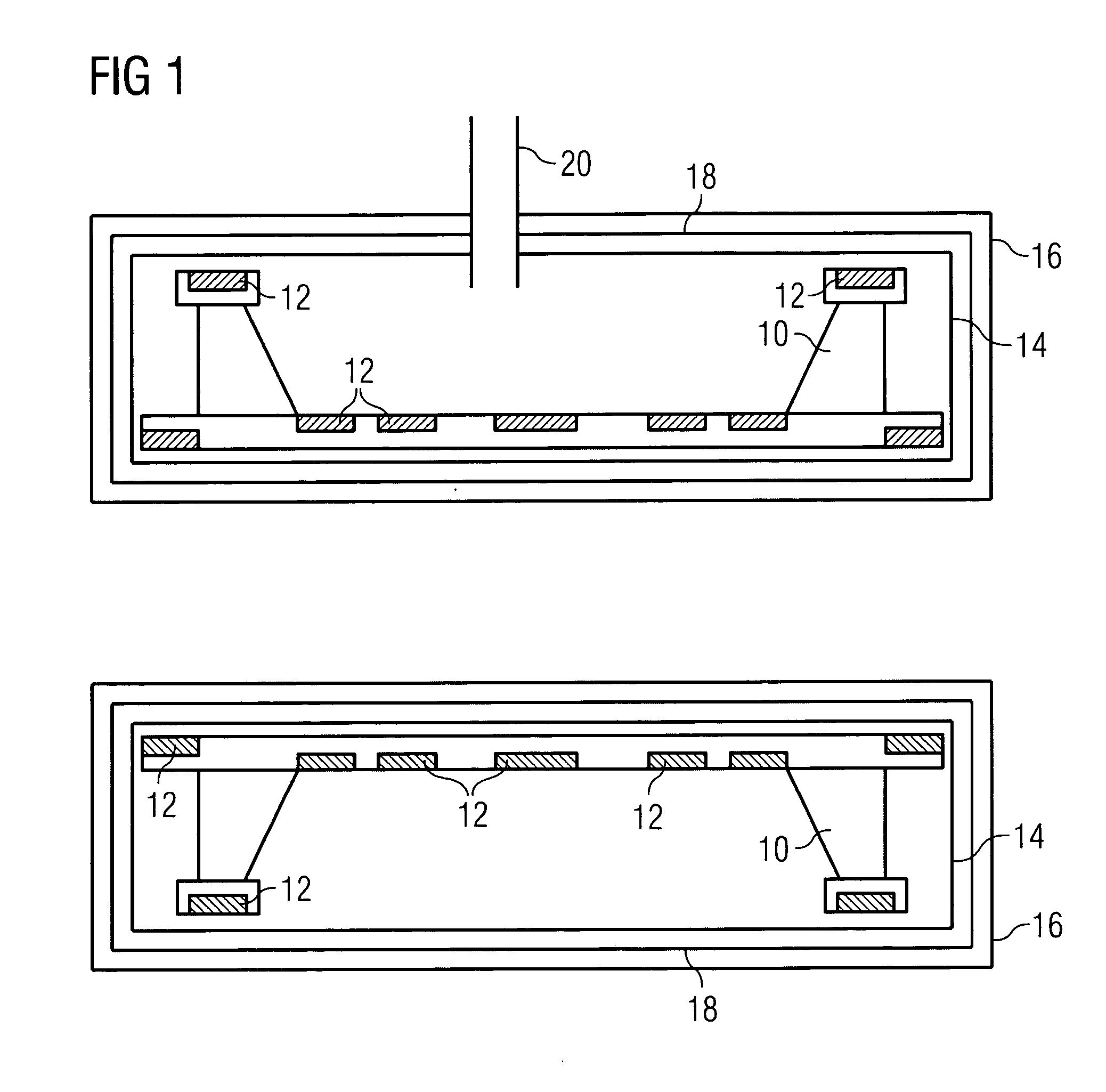

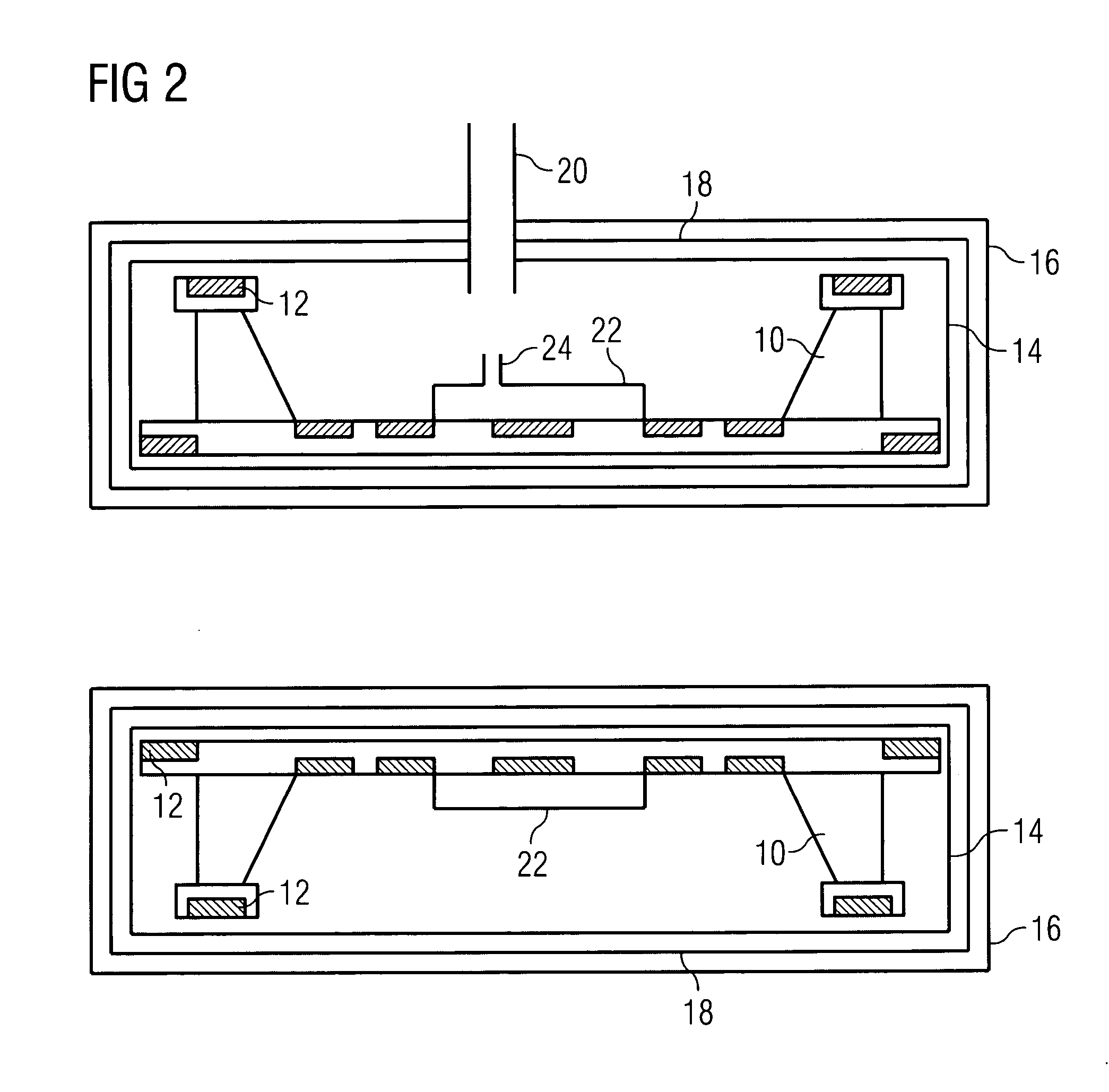

Method and apparatus for maintaining a system at cryogenic temperatures over an extended period without active refrigeration

PatentActiveUS20060288731A1

Innovation

- A secondary cryogen, such as solid nitrogen, is used in thermal connection with the system to act as a thermal battery, absorbing latent heat during phase changes and extending the cooling period without consuming excessive working cryogens, allowing for reduced cryogen volumes and costs.

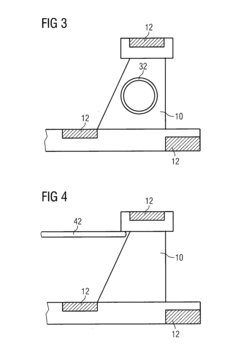

Cryogenic container

PatentActiveUS20110309086A1

Innovation

- A cryogenic container design featuring a flexible primary container within a secondary container with a heat exchanger space, using inexpensive heat exchange media like liquid nitrogen for freezing and thawing, and a disposable outer container for reduced logistical and environmental impact.

Environmental Impact and Sustainability Considerations

The environmental impact of cryogenic refrigerants represents a critical consideration in industrial applications, particularly when comparing liquid nitrogen with alternative refrigerants. Liquid nitrogen production primarily relies on air separation units (ASUs), which consume significant electrical energy. However, once produced, liquid nitrogen itself has zero global warming potential (GWP) and ozone depletion potential (ODP), as it simply returns to the atmosphere as nitrogen gas, which constitutes approximately 78% of Earth's atmosphere naturally.

In contrast, many traditional cryogenic refrigerants such as hydrofluorocarbons (HFCs) and chlorofluorocarbons (CFCs) exhibit substantial GWP values, sometimes thousands of times more potent than CO2 as greenhouse gases. Even newer alternatives like hydrofluoroolefins (HFOs) still maintain some environmental impact, albeit reduced. This fundamental difference positions liquid nitrogen favorably in environmental assessments when considering direct emissions.

The carbon footprint of liquid nitrogen is predominantly tied to its production and transportation phases. Modern ASUs have achieved significant efficiency improvements, reducing energy consumption by approximately 25-30% over the past two decades. Additionally, when liquid nitrogen production facilities utilize renewable energy sources, their environmental impact decreases substantially. Several manufacturers have begun implementing solar and wind power integration into their production facilities, potentially reducing carbon emissions by up to 60% compared to conventional grid-powered operations.

Transportation logistics also factor significantly into environmental considerations. Liquid nitrogen typically requires local or regional production due to boil-off concerns during long-distance transport, necessitating distributed production facilities. This decentralized model can reduce transportation emissions but may sacrifice economies of scale in production efficiency. Studies indicate that transportation typically accounts for 15-20% of liquid nitrogen's total carbon footprint in most applications.

End-of-life considerations present another environmental dimension. While liquid nitrogen simply evaporates without harmful residues, many alternative refrigerants require specialized recovery and disposal procedures to prevent atmospheric release. The infrastructure and energy required for these recovery systems add to the lifecycle environmental impact of traditional refrigerants, costs not incurred with liquid nitrogen systems.

Regulatory frameworks increasingly favor environmentally benign refrigeration solutions. The Kigali Amendment to the Montreal Protocol mandates the phase-down of high-GWP refrigerants, creating regulatory pressure that favors alternatives like liquid nitrogen. This shifting regulatory landscape may transform cost equations as carbon pricing mechanisms and environmental compliance costs continue to evolve globally.

In contrast, many traditional cryogenic refrigerants such as hydrofluorocarbons (HFCs) and chlorofluorocarbons (CFCs) exhibit substantial GWP values, sometimes thousands of times more potent than CO2 as greenhouse gases. Even newer alternatives like hydrofluoroolefins (HFOs) still maintain some environmental impact, albeit reduced. This fundamental difference positions liquid nitrogen favorably in environmental assessments when considering direct emissions.

The carbon footprint of liquid nitrogen is predominantly tied to its production and transportation phases. Modern ASUs have achieved significant efficiency improvements, reducing energy consumption by approximately 25-30% over the past two decades. Additionally, when liquid nitrogen production facilities utilize renewable energy sources, their environmental impact decreases substantially. Several manufacturers have begun implementing solar and wind power integration into their production facilities, potentially reducing carbon emissions by up to 60% compared to conventional grid-powered operations.

Transportation logistics also factor significantly into environmental considerations. Liquid nitrogen typically requires local or regional production due to boil-off concerns during long-distance transport, necessitating distributed production facilities. This decentralized model can reduce transportation emissions but may sacrifice economies of scale in production efficiency. Studies indicate that transportation typically accounts for 15-20% of liquid nitrogen's total carbon footprint in most applications.

End-of-life considerations present another environmental dimension. While liquid nitrogen simply evaporates without harmful residues, many alternative refrigerants require specialized recovery and disposal procedures to prevent atmospheric release. The infrastructure and energy required for these recovery systems add to the lifecycle environmental impact of traditional refrigerants, costs not incurred with liquid nitrogen systems.

Regulatory frameworks increasingly favor environmentally benign refrigeration solutions. The Kigali Amendment to the Montreal Protocol mandates the phase-down of high-GWP refrigerants, creating regulatory pressure that favors alternatives like liquid nitrogen. This shifting regulatory landscape may transform cost equations as carbon pricing mechanisms and environmental compliance costs continue to evolve globally.

Supply Chain and Infrastructure Requirements

The supply chain and infrastructure requirements for liquid nitrogen and other cryogenic refrigerants represent critical factors in determining their overall cost efficiency. These requirements significantly impact the total cost of ownership and operational feasibility across different applications and geographical locations.

Liquid nitrogen supply chains typically involve production at air separation units (ASUs), where nitrogen is separated from atmospheric air through fractional distillation. These facilities require substantial capital investment and energy input, but benefit from economies of scale. The distribution network consists of specialized tanker trucks, railcars, and in some cases, pipeline systems for high-volume industrial consumers. Storage infrastructure necessitates vacuum-insulated vessels designed to minimize heat transfer and maintain cryogenic temperatures.

For other cryogenic refrigerants such as helium, hydrogen, and argon, the supply chain complexity increases substantially. Helium, for instance, is primarily extracted from natural gas wells with high helium content, creating geographical dependencies and supply vulnerabilities. The limited number of global helium sources results in more complex logistics and higher transportation costs compared to nitrogen.

Transportation infrastructure requirements vary significantly between refrigerants. While liquid nitrogen can be transported in relatively standardized cryogenic tankers, refrigerants like helium require specialized containers with enhanced insulation properties and pressure management systems. This specialization increases both capital and operational expenses throughout the distribution network.

Storage infrastructure at end-user facilities represents another significant cost factor. Liquid nitrogen systems typically require simpler storage solutions compared to other cryogenic refrigerants. The higher boil-off rates of alternatives like liquid hydrogen necessitate more sophisticated storage technologies with advanced insulation and pressure management capabilities, substantially increasing infrastructure costs.

Maintenance requirements also differ markedly. Liquid nitrogen systems generally demand less specialized maintenance expertise and less frequent service intervals. In contrast, systems using alternative refrigerants often require more specialized technical knowledge and more rigorous maintenance schedules, contributing to higher operational costs over the system lifecycle.

Regional availability presents another critical consideration. Liquid nitrogen production facilities are more widely distributed globally, reducing transportation distances and associated costs. Other refrigerants often face more constrained production geography, necessitating longer supply chains and increasing vulnerability to regional supply disruptions or geopolitical factors.

Liquid nitrogen supply chains typically involve production at air separation units (ASUs), where nitrogen is separated from atmospheric air through fractional distillation. These facilities require substantial capital investment and energy input, but benefit from economies of scale. The distribution network consists of specialized tanker trucks, railcars, and in some cases, pipeline systems for high-volume industrial consumers. Storage infrastructure necessitates vacuum-insulated vessels designed to minimize heat transfer and maintain cryogenic temperatures.

For other cryogenic refrigerants such as helium, hydrogen, and argon, the supply chain complexity increases substantially. Helium, for instance, is primarily extracted from natural gas wells with high helium content, creating geographical dependencies and supply vulnerabilities. The limited number of global helium sources results in more complex logistics and higher transportation costs compared to nitrogen.

Transportation infrastructure requirements vary significantly between refrigerants. While liquid nitrogen can be transported in relatively standardized cryogenic tankers, refrigerants like helium require specialized containers with enhanced insulation properties and pressure management systems. This specialization increases both capital and operational expenses throughout the distribution network.

Storage infrastructure at end-user facilities represents another significant cost factor. Liquid nitrogen systems typically require simpler storage solutions compared to other cryogenic refrigerants. The higher boil-off rates of alternatives like liquid hydrogen necessitate more sophisticated storage technologies with advanced insulation and pressure management capabilities, substantially increasing infrastructure costs.

Maintenance requirements also differ markedly. Liquid nitrogen systems generally demand less specialized maintenance expertise and less frequent service intervals. In contrast, systems using alternative refrigerants often require more specialized technical knowledge and more rigorous maintenance schedules, contributing to higher operational costs over the system lifecycle.

Regional availability presents another critical consideration. Liquid nitrogen production facilities are more widely distributed globally, reducing transportation distances and associated costs. Other refrigerants often face more constrained production geography, necessitating longer supply chains and increasing vulnerability to regional supply disruptions or geopolitical factors.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!