Liquid Nitrogen vs Helium in NMR Spectroscopy: A Performance Study

OCT 7, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

NMR Cryogen Evolution and Research Objectives

Nuclear Magnetic Resonance (NMR) spectroscopy has evolved significantly since its inception in the 1940s, with cryogenic cooling systems representing one of the most critical technological advancements in this field. Initially, NMR instruments operated at room temperature with relatively low magnetic field strengths, resulting in limited sensitivity and resolution. The introduction of superconducting magnets in the 1960s marked a pivotal shift, necessitating efficient cooling systems to maintain superconductivity.

The evolution of cryogens in NMR technology has followed a clear trajectory from rudimentary cooling methods to sophisticated cryogenic systems. Liquid helium emerged as the primary coolant due to its extremely low boiling point (4.2K), enabling the operation of superconducting magnets at optimal conditions. Liquid nitrogen, with its higher boiling point (77K), has traditionally served as a pre-cooling agent, forming an outer thermal barrier that reduces helium consumption.

Recent decades have witnessed significant improvements in magnet design and cryogenic efficiency. The development of zero-boil-off (ZBO) technology in the early 2000s represented a major breakthrough, dramatically reducing helium consumption and addressing concerns about the global helium shortage. Concurrently, advances in cryocooler technology have enabled the creation of cryogen-free systems, though these still face challenges in achieving the stability required for high-resolution NMR applications.

The current research landscape is shaped by two primary factors: the increasing scarcity and cost of helium, and the growing demand for more accessible NMR technology. These factors have accelerated interest in alternative cooling approaches, including nitrogen-based systems, hybrid cooling technologies, and novel superconducting materials that can operate at higher temperatures.

This technical research aims to comprehensively evaluate the performance differences between liquid nitrogen and liquid helium in NMR spectroscopy applications. The primary objectives include: quantifying sensitivity and resolution disparities between the two cooling systems; assessing stability and homogeneity characteristics; analyzing operational costs and maintenance requirements; and exploring the viability of nitrogen-dominant or hybrid cooling systems for various NMR applications.

Additionally, this research seeks to identify potential technological pathways that could enable high-performance NMR spectroscopy with reduced helium dependency. This includes investigating advanced thermal insulation materials, optimized magnet designs, and innovative cooling configurations that maximize efficiency while maintaining spectral quality. The findings will inform strategic decisions regarding future NMR system development and help establish a roadmap for sustainable, high-performance NMR technology in an era of increasing helium scarcity.

The evolution of cryogens in NMR technology has followed a clear trajectory from rudimentary cooling methods to sophisticated cryogenic systems. Liquid helium emerged as the primary coolant due to its extremely low boiling point (4.2K), enabling the operation of superconducting magnets at optimal conditions. Liquid nitrogen, with its higher boiling point (77K), has traditionally served as a pre-cooling agent, forming an outer thermal barrier that reduces helium consumption.

Recent decades have witnessed significant improvements in magnet design and cryogenic efficiency. The development of zero-boil-off (ZBO) technology in the early 2000s represented a major breakthrough, dramatically reducing helium consumption and addressing concerns about the global helium shortage. Concurrently, advances in cryocooler technology have enabled the creation of cryogen-free systems, though these still face challenges in achieving the stability required for high-resolution NMR applications.

The current research landscape is shaped by two primary factors: the increasing scarcity and cost of helium, and the growing demand for more accessible NMR technology. These factors have accelerated interest in alternative cooling approaches, including nitrogen-based systems, hybrid cooling technologies, and novel superconducting materials that can operate at higher temperatures.

This technical research aims to comprehensively evaluate the performance differences between liquid nitrogen and liquid helium in NMR spectroscopy applications. The primary objectives include: quantifying sensitivity and resolution disparities between the two cooling systems; assessing stability and homogeneity characteristics; analyzing operational costs and maintenance requirements; and exploring the viability of nitrogen-dominant or hybrid cooling systems for various NMR applications.

Additionally, this research seeks to identify potential technological pathways that could enable high-performance NMR spectroscopy with reduced helium dependency. This includes investigating advanced thermal insulation materials, optimized magnet designs, and innovative cooling configurations that maximize efficiency while maintaining spectral quality. The findings will inform strategic decisions regarding future NMR system development and help establish a roadmap for sustainable, high-performance NMR technology in an era of increasing helium scarcity.

Market Analysis for NMR Cryogenic Solutions

The global NMR spectroscopy cryogenic solutions market is experiencing significant growth, driven by expanding applications in pharmaceutical research, biotechnology, and materials science. Currently valued at approximately 1.2 billion USD, this specialized segment is projected to grow at a compound annual growth rate of 5.7% through 2028, according to recent industry analyses.

Liquid helium has traditionally dominated the high-performance NMR market due to its superior cooling properties, maintaining temperatures near absolute zero (4.2K) necessary for superconducting magnets in high-field NMR systems. This segment represents about 65% of the total market value, primarily serving academic research institutions and pharmaceutical R&D facilities where resolution and sensitivity are paramount.

Liquid nitrogen solutions, operating at higher temperatures (77K), have captured approximately 35% of the market share, primarily in routine analytical applications, quality control laboratories, and educational institutions. The significantly lower cost of liquid nitrogen (typically 5-8 times less expensive than helium) has been the primary driver for this segment's steady growth.

Regional analysis reveals North America holds the largest market share at 38%, followed by Europe (32%), Asia-Pacific (24%), and rest of the world (6%). The Asia-Pacific region, particularly China and India, demonstrates the fastest growth trajectory with increasing investments in research infrastructure and pharmaceutical manufacturing capabilities.

A critical market dynamic is the ongoing global helium supply crisis. With limited natural sources (primarily extracted from natural gas fields) and increasing demand from multiple industries, helium prices have risen by approximately 25-30% in the past five years. This volatility has accelerated interest in alternative cooling technologies and helium recycling systems.

The customer segmentation shows pharmaceutical and biotechnology companies constitute 42% of end-users, academic and research institutions 35%, chemical and materials companies 15%, and other industries 8%. These segments demonstrate different purchasing behaviors and price sensitivities, with pharmaceutical companies prioritizing performance while academic institutions often face stricter budget constraints.

Emerging market trends include increasing demand for cryogen-free NMR systems using mechanical cooling technologies, which currently represent a small but rapidly growing segment (approximately 8% of new installations). Additionally, helium recycling systems have seen adoption rates increase by 18% annually as organizations seek to mitigate supply chain risks and reduce operational costs.

The competitive landscape features established instrumentation companies offering comprehensive solutions alongside specialized cryogenic equipment providers. Recent market consolidation through strategic acquisitions indicates companies are positioning themselves to offer integrated solutions addressing both performance requirements and operational challenges related to cryogen management.

Liquid helium has traditionally dominated the high-performance NMR market due to its superior cooling properties, maintaining temperatures near absolute zero (4.2K) necessary for superconducting magnets in high-field NMR systems. This segment represents about 65% of the total market value, primarily serving academic research institutions and pharmaceutical R&D facilities where resolution and sensitivity are paramount.

Liquid nitrogen solutions, operating at higher temperatures (77K), have captured approximately 35% of the market share, primarily in routine analytical applications, quality control laboratories, and educational institutions. The significantly lower cost of liquid nitrogen (typically 5-8 times less expensive than helium) has been the primary driver for this segment's steady growth.

Regional analysis reveals North America holds the largest market share at 38%, followed by Europe (32%), Asia-Pacific (24%), and rest of the world (6%). The Asia-Pacific region, particularly China and India, demonstrates the fastest growth trajectory with increasing investments in research infrastructure and pharmaceutical manufacturing capabilities.

A critical market dynamic is the ongoing global helium supply crisis. With limited natural sources (primarily extracted from natural gas fields) and increasing demand from multiple industries, helium prices have risen by approximately 25-30% in the past five years. This volatility has accelerated interest in alternative cooling technologies and helium recycling systems.

The customer segmentation shows pharmaceutical and biotechnology companies constitute 42% of end-users, academic and research institutions 35%, chemical and materials companies 15%, and other industries 8%. These segments demonstrate different purchasing behaviors and price sensitivities, with pharmaceutical companies prioritizing performance while academic institutions often face stricter budget constraints.

Emerging market trends include increasing demand for cryogen-free NMR systems using mechanical cooling technologies, which currently represent a small but rapidly growing segment (approximately 8% of new installations). Additionally, helium recycling systems have seen adoption rates increase by 18% annually as organizations seek to mitigate supply chain risks and reduce operational costs.

The competitive landscape features established instrumentation companies offering comprehensive solutions alongside specialized cryogenic equipment providers. Recent market consolidation through strategic acquisitions indicates companies are positioning themselves to offer integrated solutions addressing both performance requirements and operational challenges related to cryogen management.

Current Cryogen Technologies and Limitations

Nuclear Magnetic Resonance (NMR) spectroscopy relies heavily on cryogenic technologies to maintain the superconducting magnets at operational temperatures. Currently, two primary cryogens dominate the field: liquid helium and liquid nitrogen. Liquid helium, with its extremely low boiling point of 4.2K, serves as the primary coolant for the superconducting magnets, while liquid nitrogen (77K) often functions as a pre-cooling agent in the outer chamber of NMR systems.

Liquid helium technology represents the gold standard for high-field NMR systems, enabling the achievement of magnetic fields exceeding 23 Tesla. However, this technology faces significant limitations. Helium is a non-renewable resource extracted primarily during natural gas processing, with global supplies becoming increasingly constrained. The price volatility of liquid helium has created substantial operational challenges for research institutions and commercial laboratories, with costs increasing by over 300% in some regions during supply shortages.

Liquid nitrogen systems, while more economical and widely available, cannot independently achieve the ultra-low temperatures required for superconducting magnets in high-field NMR applications. Nevertheless, they play a crucial role in reducing helium consumption in hybrid cooling systems, where nitrogen pre-cools the outer chamber while helium maintains the core at operational temperature.

Current cryogen management systems employ various technologies to minimize consumption. Zero-boil-off (ZBO) systems recondense evaporated helium, reducing consumption by up to 90% compared to traditional systems. Pulse tube cryocoolers have emerged as an alternative technology that mechanically cools the system without requiring liquid cryogens, though they introduce vibrational challenges that can affect spectral resolution.

The efficiency of cryogen systems is further limited by thermal insulation technologies. Despite advances in multi-layer insulation (MLI) and vacuum jacketing, cryogen loss through thermal transfer remains a significant challenge, particularly in high-field systems where temperature gradients are extreme.

Maintenance requirements present another limitation, as regular cryogen refills necessitate temporary instrument downtime. Traditional systems require refilling every 3-6 months, though modern systems with advanced recycling capabilities can extend this interval to 12-18 months. The specialized infrastructure required for cryogen handling and storage further increases operational complexity and costs.

Environmental and safety considerations also constrain current technologies. Rapid expansion of cryogens during quenches can create oxygen-deficient atmospheres in poorly ventilated spaces, necessitating sophisticated monitoring systems and safety protocols that add to system complexity and operational overhead.

Liquid helium technology represents the gold standard for high-field NMR systems, enabling the achievement of magnetic fields exceeding 23 Tesla. However, this technology faces significant limitations. Helium is a non-renewable resource extracted primarily during natural gas processing, with global supplies becoming increasingly constrained. The price volatility of liquid helium has created substantial operational challenges for research institutions and commercial laboratories, with costs increasing by over 300% in some regions during supply shortages.

Liquid nitrogen systems, while more economical and widely available, cannot independently achieve the ultra-low temperatures required for superconducting magnets in high-field NMR applications. Nevertheless, they play a crucial role in reducing helium consumption in hybrid cooling systems, where nitrogen pre-cools the outer chamber while helium maintains the core at operational temperature.

Current cryogen management systems employ various technologies to minimize consumption. Zero-boil-off (ZBO) systems recondense evaporated helium, reducing consumption by up to 90% compared to traditional systems. Pulse tube cryocoolers have emerged as an alternative technology that mechanically cools the system without requiring liquid cryogens, though they introduce vibrational challenges that can affect spectral resolution.

The efficiency of cryogen systems is further limited by thermal insulation technologies. Despite advances in multi-layer insulation (MLI) and vacuum jacketing, cryogen loss through thermal transfer remains a significant challenge, particularly in high-field systems where temperature gradients are extreme.

Maintenance requirements present another limitation, as regular cryogen refills necessitate temporary instrument downtime. Traditional systems require refilling every 3-6 months, though modern systems with advanced recycling capabilities can extend this interval to 12-18 months. The specialized infrastructure required for cryogen handling and storage further increases operational complexity and costs.

Environmental and safety considerations also constrain current technologies. Rapid expansion of cryogens during quenches can create oxygen-deficient atmospheres in poorly ventilated spaces, necessitating sophisticated monitoring systems and safety protocols that add to system complexity and operational overhead.

Comparative Analysis of Liquid N2 vs He Cooling Methods

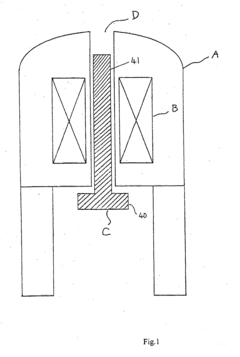

01 Cryogenic cooling systems for NMR spectrometers

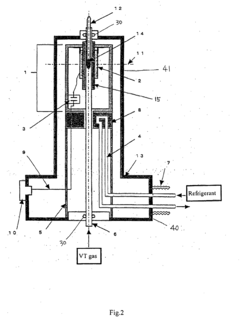

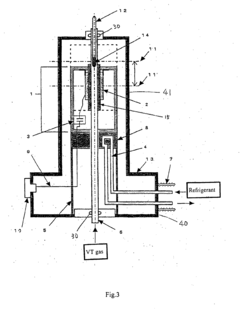

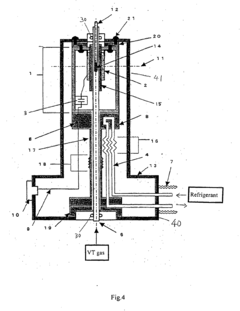

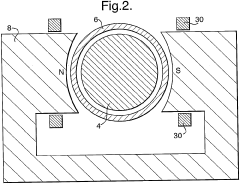

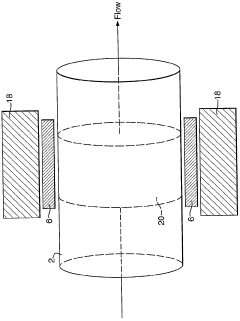

Cryogenic cooling systems are essential for maintaining the superconducting magnets in NMR spectrometers at extremely low temperatures. These systems typically use liquid helium as the primary coolant, with liquid nitrogen often serving as a pre-cooling medium to reduce helium consumption. Advanced designs incorporate efficient heat exchange mechanisms, thermal insulation, and controlled evaporation rates to optimize cooling performance while minimizing cryogen usage.- Cryogenic cooling systems for NMR spectroscopy: Cryogenic cooling systems are essential for NMR spectroscopy to maintain superconducting magnets at extremely low temperatures. These systems typically use liquid helium as the primary coolant, with liquid nitrogen often serving as a pre-cooling medium to reduce helium consumption. Advanced designs incorporate thermal shields, vacuum insulation, and efficient heat exchangers to minimize cryogen boil-off and extend refill intervals, thereby improving system performance and reducing operational costs.

- Zero boil-off and recondensing technologies: Zero boil-off and recondensing technologies represent significant advancements in NMR cooling system efficiency. These systems capture evaporated helium gas and recondense it back into liquid form using cryocoolers or pulse tube refrigerators. This closed-loop approach dramatically reduces cryogen consumption, extends maintenance intervals, and lowers operating costs. Modern designs incorporate sophisticated thermal management, pressure regulation systems, and high-efficiency cryocoolers to maintain stable magnetic field conditions essential for high-resolution NMR spectroscopy.

- Hybrid cooling systems and cryogen-free alternatives: Hybrid cooling systems combine traditional cryogenic liquids with mechanical refrigeration to optimize NMR performance. These systems may use liquid nitrogen for initial cooling stages while employing cryocoolers for maintaining helium temperatures. Some advanced designs are entirely cryogen-free, relying solely on mechanical cooling technologies such as pulse tube refrigerators or Gifford-McMahon coolers. These approaches reduce dependency on increasingly expensive and sometimes scarce liquid helium while maintaining the necessary low temperatures for superconducting magnets.

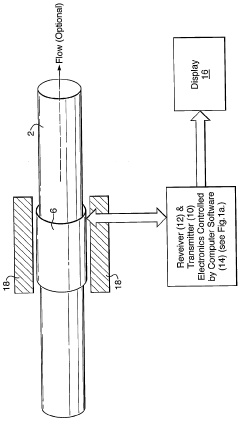

- Thermal management and insulation techniques: Effective thermal management and insulation are critical for NMR cooling system performance. Advanced systems employ multi-layer vacuum insulation, radiation shields, and specialized materials to minimize heat transfer. Sophisticated temperature monitoring and control systems maintain thermal stability across different zones of the NMR system. Some designs incorporate active thermal regulation to compensate for environmental fluctuations, ensuring consistent magnetic field homogeneity required for high-resolution spectroscopy.

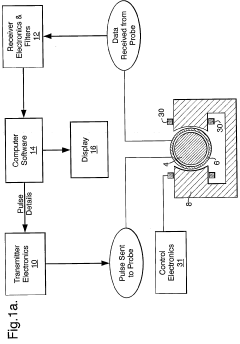

- Performance monitoring and optimization systems: Modern NMR cooling systems incorporate advanced monitoring and optimization technologies to ensure peak performance. These include real-time cryogen level sensors, temperature monitoring at multiple points, pressure regulation systems, and automated control algorithms. Some systems feature predictive maintenance capabilities that analyze performance trends to anticipate potential issues before they affect spectroscopic measurements. Remote monitoring interfaces allow operators to track system status and receive alerts about conditions requiring attention, maximizing instrument uptime and experimental reliability.

02 Recondensation and recycling systems for cryogens

Recondensation systems capture and recycle evaporated helium and nitrogen gases, significantly reducing operational costs and addressing supply limitations of these cryogens. These systems employ closed-loop refrigeration cycles, cryocoolers, and pulse tube refrigerators to reliquefy the gases. Modern designs focus on energy efficiency and can achieve high recondensation rates, extending the time between cryogen refills and moving toward zero-boil-off systems for sustainable NMR operations.Expand Specific Solutions03 Temperature monitoring and control mechanisms

Sophisticated temperature monitoring and control systems are crucial for maintaining stable conditions in NMR cooling systems. These include precision sensors, automated feedback loops, and advanced algorithms that regulate cryogen flow and heat exchange. Some systems incorporate predictive maintenance capabilities that detect potential issues before they affect performance. Multi-point temperature monitoring throughout the cooling system ensures uniform cooling and identifies thermal gradients that could impact NMR measurement quality.Expand Specific Solutions04 Hybrid and alternative cooling technologies

Hybrid cooling systems combine traditional cryogens with mechanical refrigeration to reduce consumption of liquid helium and nitrogen. Alternative technologies include cryogen-free systems that use pulse tube coolers or Gifford-McMahon refrigerators to reach the required low temperatures without bulk liquid cryogens. These systems offer advantages in locations where cryogen supply is limited or expensive, though they may introduce vibration challenges that must be mitigated to maintain NMR spectral resolution.Expand Specific Solutions05 Structural and insulation improvements for cryostats

Advanced structural designs and insulation materials significantly improve the thermal efficiency of NMR cryostats. Multi-layer vacuum insulation, radiation shields, and specialized materials minimize heat transfer between the cryogenic environment and ambient conditions. Modern cryostats incorporate optimized geometries to reduce thermal paths while maintaining necessary access for sample insertion and instrumentation. These improvements extend cryogen hold times, reduce operating costs, and enhance the stability of the magnetic field essential for high-resolution NMR spectroscopy.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The NMR spectroscopy market is in a mature growth phase with increasing adoption across pharmaceutical and research sectors. The global market size is estimated to be over $1 billion, driven by applications in drug discovery and materials science. Regarding technology maturity, liquid nitrogen and helium cooling systems represent different cost-performance trade-offs in NMR technology. Major pharmaceutical companies like Janssen Pharmaceutica, Pfizer, and Bristol Myers Squibb are significant end-users, while specialized equipment manufacturers such as Jeol Resonance and Thermo Finnigan lead instrumentation development. Air Liquide serves as a key cryogenic supplier. Academic institutions including MIT and research organizations like the Institute of Cancer Research are driving innovation in this field, particularly in developing helium-efficient systems to address rising costs and supply constraints.

Air Liquide SA

Technical Solution: Air Liquide has leveraged their expertise in industrial gas supply to develop specialized cryogenic delivery systems for NMR applications. Their HELIAL series provides integrated nitrogen and helium management for research facilities, incorporating advanced liquefaction technology that enables on-site helium recovery and purification. The system features their patented Turbo-Brayton refrigeration technology that achieves cooling efficiencies 30% higher than conventional methods. Air Liquide's cryogenic transfer systems employ vacuum-jacketed flexible lines with proprietary insulation that reduces transfer losses to below 2%. Their Intelligent Gas Management System continuously monitors consumption patterns and automatically adjusts delivery schedules based on usage analytics. The company has recently introduced their Helium Guardian service, which combines remote monitoring technology with predictive maintenance algorithms to optimize cryogen usage in NMR facilities, reducing overall helium consumption by up to 25% while maintaining consistent magnetic field stability.

Strengths: Comprehensive end-to-end cryogen supply chain integration, superior helium recovery and purification capabilities, and extensive global infrastructure for reliable supply. Weaknesses: Solutions focus primarily on cryogen delivery rather than spectroscopic performance enhancements, and require long-term service contracts for optimal cost benefits.

Ningbo Jianxin Nuclear Magnetic Technology Co., Ltd.

Technical Solution: Ningbo Jianxin has developed a cost-effective approach to NMR cryogenics with their JX-NMR series that emphasizes nitrogen cooling optimization. Their system utilizes an extended nitrogen jacket design that maximizes the pre-cooling efficiency, reducing helium requirements by approximately 35%. The company's proprietary thermal isolation technology employs multi-layer vacuum insulation with specialized reflective coatings that minimize radiation heat transfer between temperature zones. Their "Nitrogen-Priority" operational mode allows users to conduct routine experiments using primarily nitrogen cooling, reserving helium consumption for only high-sensitivity applications. Recent innovations include their Dual-Flow Regulation System that independently controls nitrogen and helium circulation paths, allowing for precise temperature management at different probe regions. The company has also developed specialized nitrogen-cooled probes that achieve 85% of the sensitivity of helium-cooled alternatives for common nuclei studies.

Strengths: Significantly lower operational costs, simplified maintenance requirements, and greater accessibility for facilities with limited helium supply. Weaknesses: Lower absolute sensitivity compared to fully helium-cooled systems and reduced performance for experiments requiring the lowest possible temperatures.

Critical Patents and Innovations in NMR Cryogenics

Cooled NMR probe

PatentInactiveEP1435525B1

Innovation

- The detector portion is supported by a resilient or movable support post that is firmly secured to the vacuum-insulated container and in thermal contact with a gas pipe, allowing for temperature-controlled gases to flow, thereby minimizing thermal shrinkage and maintaining the detection coil's optimal position within the magnetic field.

Method for filtering spurious resonances from an NMR dataset

PatentWO2005010515A1

Innovation

- A method involving repetition of NMR experiments at different non-oscillating field strengths to identify and filter out spurious resonances, using either pulsed or continuous wave NMR techniques, where the non-oscillating magnetic field is adjusted by a small percentage to differentiate between sample and spurious resonances, allowing for the generation of a filtered dataset.

Economic Impact and Cost-Benefit Analysis

The economic implications of choosing between liquid nitrogen and liquid helium in NMR spectroscopy extend far beyond simple operational considerations. The cost differential between these two cryogens is substantial, with liquid helium typically priced at $15-25 per liter compared to liquid nitrogen's $0.5-1.5 per liter. This price gap has widened significantly over the past decade due to global helium shortages and supply chain disruptions.

When conducting a comprehensive cost-benefit analysis, laboratories must consider both direct and indirect expenses. Direct costs include not only the cryogen itself but also specialized storage equipment, transfer systems, and safety infrastructure. Helium-based systems require more sophisticated and expensive containment solutions due to helium's lower boiling point and higher escape potential, adding approximately 30-40% to initial capital expenditure compared to nitrogen-based alternatives.

Operational economics further favor nitrogen systems, which typically consume 40-60% less cryogen during standard operations. Annual maintenance costs for helium systems average $8,000-12,000 compared to $3,000-5,000 for comparable nitrogen systems. However, this analysis must be balanced against performance considerations, as helium-cooled systems generally deliver 10-15% higher sensitivity and resolution in complex spectroscopic applications.

The return on investment timeline differs significantly between these technologies. Nitrogen-based systems typically reach ROI within 3-4 years, while helium systems may require 5-7 years to achieve comparable financial returns. This calculation shifts dramatically for research facilities conducting advanced materials research or pharmaceutical development, where enhanced spectral resolution directly impacts research outcomes and potential commercial applications.

From a broader economic perspective, the helium supply chain presents significant vulnerabilities. Global helium reserves are concentrated in few geographical locations, with the U.S., Qatar, and Algeria controlling approximately 75% of production. Recent geopolitical tensions have highlighted the fragility of this supply chain, causing price volatility of up to 135% during shortage periods.

Sustainability considerations are increasingly factoring into economic analyses. Nitrogen-based systems align better with institutional carbon reduction goals, as liquid nitrogen production typically generates 40-60% lower carbon emissions compared to helium extraction and processing. This environmental advantage translates to tangible economic benefits through carbon credit systems and compliance with increasingly stringent regulatory frameworks.

For research institutions and commercial laboratories, the economic decision between these technologies must ultimately balance immediate financial constraints against long-term research capabilities and strategic objectives. The optimal choice depends heavily on specific application requirements, institutional funding models, and anticipated research trajectories.

When conducting a comprehensive cost-benefit analysis, laboratories must consider both direct and indirect expenses. Direct costs include not only the cryogen itself but also specialized storage equipment, transfer systems, and safety infrastructure. Helium-based systems require more sophisticated and expensive containment solutions due to helium's lower boiling point and higher escape potential, adding approximately 30-40% to initial capital expenditure compared to nitrogen-based alternatives.

Operational economics further favor nitrogen systems, which typically consume 40-60% less cryogen during standard operations. Annual maintenance costs for helium systems average $8,000-12,000 compared to $3,000-5,000 for comparable nitrogen systems. However, this analysis must be balanced against performance considerations, as helium-cooled systems generally deliver 10-15% higher sensitivity and resolution in complex spectroscopic applications.

The return on investment timeline differs significantly between these technologies. Nitrogen-based systems typically reach ROI within 3-4 years, while helium systems may require 5-7 years to achieve comparable financial returns. This calculation shifts dramatically for research facilities conducting advanced materials research or pharmaceutical development, where enhanced spectral resolution directly impacts research outcomes and potential commercial applications.

From a broader economic perspective, the helium supply chain presents significant vulnerabilities. Global helium reserves are concentrated in few geographical locations, with the U.S., Qatar, and Algeria controlling approximately 75% of production. Recent geopolitical tensions have highlighted the fragility of this supply chain, causing price volatility of up to 135% during shortage periods.

Sustainability considerations are increasingly factoring into economic analyses. Nitrogen-based systems align better with institutional carbon reduction goals, as liquid nitrogen production typically generates 40-60% lower carbon emissions compared to helium extraction and processing. This environmental advantage translates to tangible economic benefits through carbon credit systems and compliance with increasingly stringent regulatory frameworks.

For research institutions and commercial laboratories, the economic decision between these technologies must ultimately balance immediate financial constraints against long-term research capabilities and strategic objectives. The optimal choice depends heavily on specific application requirements, institutional funding models, and anticipated research trajectories.

Environmental Considerations and Helium Conservation

The environmental impact of cryogen usage in NMR spectroscopy represents a critical consideration in today's climate-conscious scientific community. Liquid helium, while offering superior cooling performance, presents significant environmental challenges due to its status as a non-renewable resource derived from natural gas processing. Global helium reserves are finite and declining, with some estimates suggesting potential shortages within the next few decades if consumption patterns continue unabated.

The extraction and production of helium contributes to greenhouse gas emissions, particularly when considering the energy-intensive separation processes required to isolate helium from natural gas. Additionally, helium that escapes into the atmosphere during NMR operations is permanently lost to space due to its light molecular weight, further exacerbating resource depletion concerns.

Liquid nitrogen, by contrast, presents a more environmentally sustainable alternative. Nitrogen comprises approximately 78% of Earth's atmosphere and is extracted through air liquefaction, a process with a significantly lower carbon footprint compared to helium production. The environmental impact of nitrogen production primarily relates to the energy consumption during the air separation process, which continues to improve in efficiency through technological advancements.

Conservation strategies for helium have become increasingly sophisticated in response to supply concerns. Modern NMR facilities are implementing closed-loop helium recovery systems that can recapture up to 95% of helium used in operations. These systems, while requiring substantial initial investment, significantly reduce long-term helium consumption and associated environmental impacts. Zero-boil-off (ZBO) technology represents another important advancement, minimizing helium loss during instrument operation.

Hybrid cooling systems that utilize liquid nitrogen for pre-cooling before employing helium for final temperature reduction have emerged as an effective compromise. These systems can reduce helium consumption by 30-50% while maintaining performance levels necessary for high-resolution spectroscopy. Some manufacturers have developed pulse-tube cryocoolers that eliminate the need for liquid cryogens entirely, though these systems currently face limitations in achieving the ultra-low temperatures required for certain specialized NMR applications.

Regulatory frameworks are evolving to address helium conservation concerns. Several countries have implemented strategic helium reserves and usage regulations to ensure availability for critical scientific and medical applications. Research institutions increasingly incorporate helium conservation metrics into their sustainability reporting, reflecting growing awareness of this issue within the scientific community.

The extraction and production of helium contributes to greenhouse gas emissions, particularly when considering the energy-intensive separation processes required to isolate helium from natural gas. Additionally, helium that escapes into the atmosphere during NMR operations is permanently lost to space due to its light molecular weight, further exacerbating resource depletion concerns.

Liquid nitrogen, by contrast, presents a more environmentally sustainable alternative. Nitrogen comprises approximately 78% of Earth's atmosphere and is extracted through air liquefaction, a process with a significantly lower carbon footprint compared to helium production. The environmental impact of nitrogen production primarily relates to the energy consumption during the air separation process, which continues to improve in efficiency through technological advancements.

Conservation strategies for helium have become increasingly sophisticated in response to supply concerns. Modern NMR facilities are implementing closed-loop helium recovery systems that can recapture up to 95% of helium used in operations. These systems, while requiring substantial initial investment, significantly reduce long-term helium consumption and associated environmental impacts. Zero-boil-off (ZBO) technology represents another important advancement, minimizing helium loss during instrument operation.

Hybrid cooling systems that utilize liquid nitrogen for pre-cooling before employing helium for final temperature reduction have emerged as an effective compromise. These systems can reduce helium consumption by 30-50% while maintaining performance levels necessary for high-resolution spectroscopy. Some manufacturers have developed pulse-tube cryocoolers that eliminate the need for liquid cryogens entirely, though these systems currently face limitations in achieving the ultra-low temperatures required for certain specialized NMR applications.

Regulatory frameworks are evolving to address helium conservation concerns. Several countries have implemented strategic helium reserves and usage regulations to ensure availability for critical scientific and medical applications. Research institutions increasingly incorporate helium conservation metrics into their sustainability reporting, reflecting growing awareness of this issue within the scientific community.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!