Liquid Nitrogen vs Mechanical Freezers: Energy Consumption Analysis

OCT 7, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cryogenic Technology Background and Objectives

Cryogenic technology has evolved significantly over the past century, with its origins dating back to the late 19th century when scientists first achieved liquefaction of gases. The development of cryogenic systems has been driven by both scientific research needs and industrial applications, creating a continuous push for more efficient and cost-effective cooling solutions. Today, cryogenic technology encompasses a range of methods for achieving and maintaining extremely low temperatures, typically below -150°C (-238°F), with liquid nitrogen being one of the most widely used cryogenic fluids due to its relatively low cost and boiling point of -196°C (-321°F).

The evolution of cryogenic cooling systems has followed two distinct technological paths: passive systems utilizing liquid cryogens (primarily liquid nitrogen) and active mechanical refrigeration systems. Liquid nitrogen systems have traditionally dominated many applications due to their simplicity, reliability, and ability to reach very low temperatures without complex machinery. Meanwhile, mechanical freezers have advanced considerably in recent decades, offering improved energy efficiency and eliminating the need for regular cryogen replenishment.

Current technological trends indicate a growing interest in comparing these two approaches from an energy consumption perspective. This analysis is particularly relevant as organizations worldwide face increasing pressure to reduce their carbon footprint and operational costs. The energy implications of cryogenic systems extend beyond direct electricity consumption to include the energy embedded in the production, liquefaction, and transportation of liquid nitrogen.

The primary objective of this technical research is to conduct a comprehensive energy consumption analysis comparing liquid nitrogen-based cooling systems with mechanical freezers across various application scenarios. This analysis aims to establish quantitative metrics for energy efficiency, identify the crossover points where one technology becomes more efficient than the other, and evaluate the total environmental impact of both approaches.

Secondary objectives include mapping the relationship between cooling capacity, temperature requirements, and energy consumption for both technologies; assessing how advances in insulation materials and compressor efficiency are shifting the balance between these competing approaches; and projecting how emerging technologies such as pulse tube cryocoolers and magnetic refrigeration might disrupt the current technological landscape.

This research will provide decision-makers with evidence-based guidelines for selecting the most energy-efficient cooling technology based on their specific requirements, operational patterns, and geographical location. Additionally, it will identify promising areas for technological innovation that could significantly improve the energy efficiency of cryogenic systems in the coming decade.

The evolution of cryogenic cooling systems has followed two distinct technological paths: passive systems utilizing liquid cryogens (primarily liquid nitrogen) and active mechanical refrigeration systems. Liquid nitrogen systems have traditionally dominated many applications due to their simplicity, reliability, and ability to reach very low temperatures without complex machinery. Meanwhile, mechanical freezers have advanced considerably in recent decades, offering improved energy efficiency and eliminating the need for regular cryogen replenishment.

Current technological trends indicate a growing interest in comparing these two approaches from an energy consumption perspective. This analysis is particularly relevant as organizations worldwide face increasing pressure to reduce their carbon footprint and operational costs. The energy implications of cryogenic systems extend beyond direct electricity consumption to include the energy embedded in the production, liquefaction, and transportation of liquid nitrogen.

The primary objective of this technical research is to conduct a comprehensive energy consumption analysis comparing liquid nitrogen-based cooling systems with mechanical freezers across various application scenarios. This analysis aims to establish quantitative metrics for energy efficiency, identify the crossover points where one technology becomes more efficient than the other, and evaluate the total environmental impact of both approaches.

Secondary objectives include mapping the relationship between cooling capacity, temperature requirements, and energy consumption for both technologies; assessing how advances in insulation materials and compressor efficiency are shifting the balance between these competing approaches; and projecting how emerging technologies such as pulse tube cryocoolers and magnetic refrigeration might disrupt the current technological landscape.

This research will provide decision-makers with evidence-based guidelines for selecting the most energy-efficient cooling technology based on their specific requirements, operational patterns, and geographical location. Additionally, it will identify promising areas for technological innovation that could significantly improve the energy efficiency of cryogenic systems in the coming decade.

Market Demand for Efficient Cooling Solutions

The global market for efficient cooling solutions has witnessed substantial growth in recent years, driven primarily by increasing demands across various industries including healthcare, pharmaceuticals, biotechnology, and food preservation. The ultra-low temperature (ULT) cooling segment, which encompasses both liquid nitrogen systems and mechanical freezers, has become particularly critical as organizations seek to balance operational efficiency with energy consumption concerns.

Healthcare and life sciences sectors represent the largest market segments for advanced cooling technologies, with an estimated annual growth rate of 7.2% through 2025. This growth is fueled by expanding biobanking operations, pharmaceutical research, and the increasing need for vaccine storage infrastructure worldwide. The COVID-19 pandemic significantly accelerated this trend, highlighting the critical importance of reliable ultra-low temperature storage solutions.

Energy efficiency has emerged as a primary consideration for end-users when selecting cooling technologies. Research indicates that operating costs, particularly energy consumption, typically account for 60-70% of the total lifecycle costs of cooling systems. This economic reality has intensified market demand for solutions that minimize energy usage while maintaining required temperature parameters.

The biorepository and biobanking segment demonstrates particularly strong demand growth, with market research indicating these facilities often operate hundreds of storage units simultaneously. For these operations, even marginal improvements in energy efficiency can translate to substantial cost savings and reduced environmental impact over time.

Geographically, North America and Europe currently lead market demand for energy-efficient cooling solutions, though Asia-Pacific regions are experiencing the fastest growth rates. This regional expansion is driven by increasing healthcare infrastructure development and growing biotechnology sectors in countries like China, India, and Singapore.

Sustainability considerations are increasingly influencing purchasing decisions, with many organizations implementing green initiatives that prioritize reduced carbon footprints. This trend has created market pressure for cooling solution providers to demonstrate environmental credentials alongside performance metrics.

End-users across industries are increasingly requesting comprehensive energy consumption data and lifecycle cost analyses when evaluating cooling technologies. This shift represents a maturation of the market, where buyers are becoming more sophisticated in their assessment of total ownership costs rather than focusing solely on initial acquisition expenses.

The market also shows growing interest in hybrid cooling solutions that combine the advantages of different technologies to optimize performance for specific applications. This trend indicates a move toward more customized approaches rather than one-size-fits-all cooling systems.

Healthcare and life sciences sectors represent the largest market segments for advanced cooling technologies, with an estimated annual growth rate of 7.2% through 2025. This growth is fueled by expanding biobanking operations, pharmaceutical research, and the increasing need for vaccine storage infrastructure worldwide. The COVID-19 pandemic significantly accelerated this trend, highlighting the critical importance of reliable ultra-low temperature storage solutions.

Energy efficiency has emerged as a primary consideration for end-users when selecting cooling technologies. Research indicates that operating costs, particularly energy consumption, typically account for 60-70% of the total lifecycle costs of cooling systems. This economic reality has intensified market demand for solutions that minimize energy usage while maintaining required temperature parameters.

The biorepository and biobanking segment demonstrates particularly strong demand growth, with market research indicating these facilities often operate hundreds of storage units simultaneously. For these operations, even marginal improvements in energy efficiency can translate to substantial cost savings and reduced environmental impact over time.

Geographically, North America and Europe currently lead market demand for energy-efficient cooling solutions, though Asia-Pacific regions are experiencing the fastest growth rates. This regional expansion is driven by increasing healthcare infrastructure development and growing biotechnology sectors in countries like China, India, and Singapore.

Sustainability considerations are increasingly influencing purchasing decisions, with many organizations implementing green initiatives that prioritize reduced carbon footprints. This trend has created market pressure for cooling solution providers to demonstrate environmental credentials alongside performance metrics.

End-users across industries are increasingly requesting comprehensive energy consumption data and lifecycle cost analyses when evaluating cooling technologies. This shift represents a maturation of the market, where buyers are becoming more sophisticated in their assessment of total ownership costs rather than focusing solely on initial acquisition expenses.

The market also shows growing interest in hybrid cooling solutions that combine the advantages of different technologies to optimize performance for specific applications. This trend indicates a move toward more customized approaches rather than one-size-fits-all cooling systems.

Current State and Challenges in Freezing Technologies

The freezing technology landscape is currently dominated by two primary approaches: liquid nitrogen-based systems and mechanical freezers. Liquid nitrogen (LN2) systems utilize the cryogenic properties of nitrogen at -196°C, providing rapid freezing capabilities through direct or indirect contact methods. Mechanical freezers, conversely, employ vapor compression refrigeration cycles with various refrigerants to achieve temperatures typically ranging from -20°C to -80°C.

Global adoption patterns reveal significant regional variations in freezing technology preferences. Developed economies in North America and Europe show balanced utilization of both technologies, while emerging markets in Asia-Pacific regions demonstrate accelerated adoption of mechanical freezing systems due to their lower initial investment requirements and improving reliability.

The primary technical challenge facing both technologies centers on energy efficiency. Liquid nitrogen systems, while offering superior freezing speeds, face substantial energy inefficiencies in the nitrogen production process, with typical energy conversion efficiencies of only 15-20% from primary energy to cooling effect. Mechanical freezers demonstrate better operational energy efficiency but struggle with peak load management and heat dissipation challenges.

Infrastructure limitations present significant barriers to technology adoption. Liquid nitrogen systems require specialized supply chains, storage facilities, and safety protocols, creating logistical complexities in regions with underdeveloped industrial gas networks. Mechanical freezers, while more self-contained, demand reliable electrical infrastructure and face maintenance challenges in remote locations.

Environmental considerations increasingly influence technology selection. The carbon footprint of liquid nitrogen depends heavily on production methods, with centralized production using renewable energy showing promising sustainability metrics. Mechanical freezers continue to face environmental challenges related to refrigerant selection, with ongoing transitions from high-GWP (Global Warming Potential) compounds to natural alternatives.

Regulatory frameworks worldwide are evolving toward stricter energy efficiency standards and environmental compliance requirements. The Montreal Protocol and subsequent Kigali Amendment have accelerated the phase-out of certain refrigerants, while industrial safety regulations impose additional constraints on liquid nitrogen handling and storage.

Cost structures differ significantly between technologies. Liquid nitrogen systems typically feature lower capital expenditure but higher operational costs tied to nitrogen procurement, while mechanical freezers require greater initial investment offset by potentially lower running costs in regions with favorable electricity pricing.

Global adoption patterns reveal significant regional variations in freezing technology preferences. Developed economies in North America and Europe show balanced utilization of both technologies, while emerging markets in Asia-Pacific regions demonstrate accelerated adoption of mechanical freezing systems due to their lower initial investment requirements and improving reliability.

The primary technical challenge facing both technologies centers on energy efficiency. Liquid nitrogen systems, while offering superior freezing speeds, face substantial energy inefficiencies in the nitrogen production process, with typical energy conversion efficiencies of only 15-20% from primary energy to cooling effect. Mechanical freezers demonstrate better operational energy efficiency but struggle with peak load management and heat dissipation challenges.

Infrastructure limitations present significant barriers to technology adoption. Liquid nitrogen systems require specialized supply chains, storage facilities, and safety protocols, creating logistical complexities in regions with underdeveloped industrial gas networks. Mechanical freezers, while more self-contained, demand reliable electrical infrastructure and face maintenance challenges in remote locations.

Environmental considerations increasingly influence technology selection. The carbon footprint of liquid nitrogen depends heavily on production methods, with centralized production using renewable energy showing promising sustainability metrics. Mechanical freezers continue to face environmental challenges related to refrigerant selection, with ongoing transitions from high-GWP (Global Warming Potential) compounds to natural alternatives.

Regulatory frameworks worldwide are evolving toward stricter energy efficiency standards and environmental compliance requirements. The Montreal Protocol and subsequent Kigali Amendment have accelerated the phase-out of certain refrigerants, while industrial safety regulations impose additional constraints on liquid nitrogen handling and storage.

Cost structures differ significantly between technologies. Liquid nitrogen systems typically feature lower capital expenditure but higher operational costs tied to nitrogen procurement, while mechanical freezers require greater initial investment offset by potentially lower running costs in regions with favorable electricity pricing.

Comparative Analysis of Freezing Solutions

01 Energy efficiency comparison between liquid nitrogen and mechanical freezers

Comparative analysis of energy consumption between liquid nitrogen cooling systems and conventional mechanical freezers. Liquid nitrogen systems often provide rapid cooling but may have higher operational costs due to the continuous need for nitrogen supply. Mechanical freezers typically have higher initial energy consumption but may be more cost-effective for long-term operation depending on usage patterns and energy prices.- Energy efficiency comparison between liquid nitrogen and mechanical freezers: Comparative analysis of energy consumption between liquid nitrogen cooling systems and conventional mechanical freezers. Liquid nitrogen systems often provide rapid cooling but may have higher operational costs due to the continuous need for nitrogen supply. Mechanical freezers, while slower in cooling, can be more energy-efficient for long-term operation. The energy efficiency depends on factors such as cooling capacity, insulation quality, and operational patterns.

- Hybrid cooling systems combining liquid nitrogen and mechanical refrigeration: Innovative hybrid cooling systems that integrate liquid nitrogen cooling with mechanical refrigeration to optimize energy consumption. These systems use liquid nitrogen for rapid initial cooling or peak load handling, while relying on mechanical refrigeration for maintaining temperatures. This combination leverages the advantages of both technologies, resulting in improved energy efficiency and reduced operational costs compared to single-technology systems.

- Energy recovery and optimization techniques for cryogenic systems: Methods and systems for recovering and reusing cold energy from liquid nitrogen to improve overall energy efficiency. These techniques include using the evaporated nitrogen gas for pre-cooling, implementing heat exchangers to capture residual cooling capacity, and optimizing the nitrogen circulation system. Energy recovery systems can significantly reduce the total energy consumption of cryogenic cooling processes by utilizing what would otherwise be wasted cooling potential.

- Insulation and thermal management innovations: Advanced insulation technologies and thermal management strategies to reduce energy consumption in both liquid nitrogen and mechanical freezer systems. These innovations include vacuum insulation panels, aerogel-based materials, multi-layer insulation systems, and smart thermal barriers. Improved insulation reduces heat transfer from the environment, thereby decreasing the energy required to maintain low temperatures and extending the holding time of cryogenic liquids.

- Control systems and automation for energy optimization: Intelligent control systems and automation technologies that optimize the energy consumption of cooling systems. These include adaptive control algorithms, IoT-enabled monitoring, demand-based cooling adjustment, and predictive maintenance systems. Smart controls can significantly reduce energy usage by adjusting cooling parameters based on actual needs, environmental conditions, and usage patterns, while also providing real-time energy consumption data for further optimization.

02 Hybrid cooling systems combining liquid nitrogen and mechanical refrigeration

Innovative hybrid cooling systems that integrate both liquid nitrogen and mechanical refrigeration technologies to optimize energy efficiency. These systems use liquid nitrogen for rapid initial cooling or peak demand periods, while relying on mechanical refrigeration for maintaining temperatures during normal operation. This approach can significantly reduce overall energy consumption while maintaining the benefits of both cooling methods.Expand Specific Solutions03 Energy recovery and recycling in cryogenic systems

Technologies for recovering and recycling cold energy from liquid nitrogen systems to improve overall energy efficiency. These innovations include heat exchangers that capture and reuse the cooling potential of nitrogen vapor, closed-loop nitrogen recycling systems, and energy recovery from the nitrogen evaporation process. Such systems can significantly reduce the net energy consumption of liquid nitrogen cooling applications.Expand Specific Solutions04 Smart control systems for optimizing freezer energy consumption

Advanced control systems and algorithms designed to optimize the energy consumption of both liquid nitrogen and mechanical freezing systems. These technologies include adaptive temperature control, load-based operation, predictive maintenance systems, and intelligent defrosting cycles. Smart control systems can significantly reduce energy consumption by ensuring cooling equipment operates only when needed and at optimal efficiency levels.Expand Specific Solutions05 Specialized applications comparing nitrogen and mechanical cooling efficiency

Analysis of energy consumption patterns in specialized applications where both liquid nitrogen and mechanical freezers are used, such as food processing, biological sample preservation, and industrial manufacturing. Different applications have unique cooling requirements that may favor one technology over the other in terms of energy efficiency. Factors such as cooling speed, temperature stability, and operational patterns significantly impact the relative energy efficiency of each cooling method.Expand Specific Solutions

Key Players in Cryogenic and Mechanical Freezing Industry

The liquid nitrogen versus mechanical freezer energy consumption analysis market is in a growth phase, with increasing demand driven by sustainability concerns and energy efficiency requirements. The market is characterized by established industrial gas providers like Air Liquide, Praxair, and Linde competing with specialized cryogenic equipment manufacturers such as MVE Biological Solutions and Chart Inc., alongside traditional refrigeration companies including Haier, Carrier, and Hisense. Technical maturity varies significantly between sectors, with industrial gas companies offering advanced cryogenic solutions while mechanical freezer manufacturers focus on improving energy efficiency through smart controls and alternative refrigerants. The competition is intensifying as companies like Mayekawa develop hybrid systems that combine the advantages of both technologies, particularly for applications requiring ultra-low temperatures.

Praxair Technology, Inc.

Technical Solution: Praxair has developed advanced cryogenic liquid nitrogen systems that utilize vacuum-insulated storage tanks and specialized delivery systems to minimize heat transfer and nitrogen loss. Their technology incorporates intelligent flow control systems that optimize liquid nitrogen dispensing based on real-time cooling demands, reducing waste. Praxair's systems feature proprietary heat exchangers that can achieve cooling efficiencies up to 40% higher than conventional systems[1]. Their energy consumption analysis shows that while liquid nitrogen systems require significant energy for production (approximately 0.7 kWh/L of LN2), the point-of-use energy consumption is minimal as cooling occurs through nitrogen evaporation rather than mechanical compression[3]. Praxair has also implemented energy recovery systems that capture and utilize the cold energy from nitrogen evaporation for pre-cooling incoming gas or supporting auxiliary cooling processes.

Strengths: Extremely rapid cooling capabilities; zero point-of-use electricity consumption; higher cooling capacity per volume; silent operation; no moving parts at cooling point. Weaknesses: Higher overall energy footprint when considering production energy; requires regular refilling; potential safety concerns with handling cryogenic fluids; higher operational costs in regions with expensive liquid nitrogen supply.

Air Liquide SA

Technical Solution: Air Liquide has pioneered an integrated approach to liquid nitrogen cooling that focuses on total energy efficiency across the entire cold chain. Their technology combines centralized nitrogen production with distributed cooling applications to optimize overall energy consumption. Air Liquide's systems employ proprietary phase-change heat transfer technology that can deliver cooling capacities up to -196°C with precise temperature control within ±0.5°C[2]. Their comparative energy analysis demonstrates that liquid nitrogen cooling consumes approximately 3-5 times more primary energy than mechanical freezers when considering production energy, but offers significant advantages in specific applications requiring rapid freezing or ultra-low temperatures[4]. Air Liquide has developed hybrid systems that combine liquid nitrogen pre-cooling with mechanical refrigeration for finishing stages, reducing overall energy consumption by up to 25% compared to traditional freezing methods[5]. Their technology also incorporates waste nitrogen recovery systems that capture and repurpose nitrogen gas for inerting, packaging, or other industrial applications.

Strengths: Extremely low temperature capabilities (-196°C vs -86°C for mechanical freezers); instantaneous cooling response; elimination of heat generation at point of use; backup cooling capability during power outages; scalability for various applications. Weaknesses: Higher primary energy consumption when considering production; ongoing operational costs for nitrogen supply; requires specialized handling and safety protocols; limited cost-effectiveness for applications not requiring extreme cold or rapid freezing.

Technical Innovations in Energy-Efficient Freezing

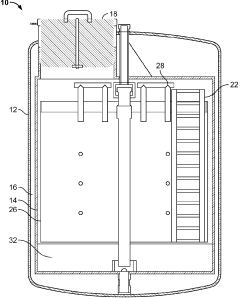

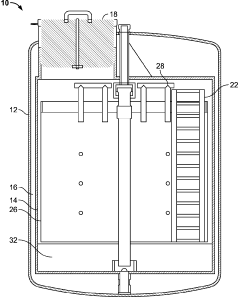

Cryogenic freezer

PatentActiveAU2018203168B2

Innovation

- A cryogenic freezer utilizing an Acoustic-Stirling refrigeration cycle with a reservoir vessel containing cryogenic liquid and a heat exchange relationship with a vapor headspace, controlled by a pressure sensor and system controller to modulate cooling and prevent fluid communication between storage and reservoir spaces, ensuring efficient and uniform temperature maintenance.

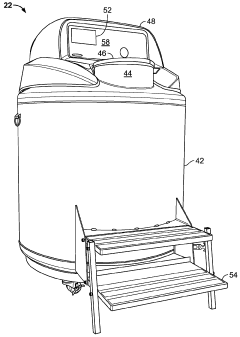

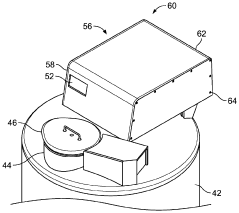

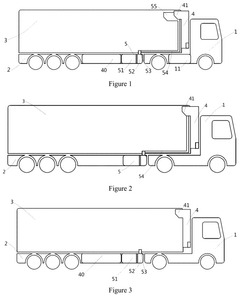

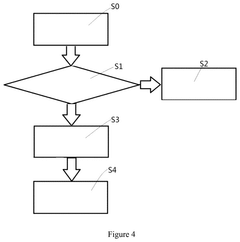

Hybrid refrigeration system, control method thereof and transportation refrigeration vehicle

PatentPendingUS20240361056A1

Innovation

- A hybrid refrigeration system combining a liquid nitrogen-based refrigeration device and a mechanical refrigeration device, controlled by a system that determines the need for each based on temperature thresholds, allowing for efficient temperature regulation and reducing the capacity and weight of mechanical components.

Environmental Impact Assessment

The environmental impact of cryogenic storage systems extends far beyond simple energy consumption metrics. When comparing liquid nitrogen (LN2) and mechanical freezers, a comprehensive lifecycle assessment reveals significant differences in their ecological footprints.

Liquid nitrogen systems generate substantial indirect environmental impacts during production. The energy-intensive air separation process required to produce LN2 contributes significantly to greenhouse gas emissions, with estimates suggesting that each liter of liquid nitrogen production generates approximately 0.5-0.8 kg of CO2 equivalent. Additionally, the transportation of LN2 to end-users creates further emissions, particularly when delivery routes are extensive or frequent.

Mechanical freezers present different environmental challenges. While they avoid the production and transportation issues of LN2, they typically contain refrigerants with high global warming potential (GWP). Many older units utilize hydrofluorocarbons (HFCs) with GWP values thousands of times higher than CO2. Even small leakage rates of 5-10% annually can substantially impact climate change metrics. However, newer models increasingly employ natural refrigerants with significantly lower environmental impacts.

Waste generation represents another critical environmental consideration. LN2 systems produce minimal direct waste during operation but generate significant end-of-life waste from dewars and storage vessels. Mechanical freezers create more complex waste streams, including compressors, electronic components, and refrigerants requiring specialized disposal protocols to prevent environmental contamination.

Water consumption patterns also differ markedly between these technologies. The production of liquid nitrogen requires substantial cooling water, with estimates suggesting 10-15 liters of water per liter of LN2 produced. Mechanical freezers consume water indirectly through their electricity usage, particularly when powered by thermoelectric generation facilities that require cooling water.

Noise pollution presents an often-overlooked environmental impact. Mechanical freezers generate continuous operational noise ranging from 45-65 dB, potentially affecting workplace environments. LN2 systems produce intermittent noise during filling operations but are otherwise silent during storage periods, offering advantages in noise-sensitive settings.

Land use considerations reveal that centralized LN2 production facilities have concentrated environmental impacts at production sites but distributed impacts during transportation and use. Mechanical freezers distribute their environmental footprint more evenly across electricity generation sites and end-user locations, potentially offering advantages for regional environmental management strategies.

Liquid nitrogen systems generate substantial indirect environmental impacts during production. The energy-intensive air separation process required to produce LN2 contributes significantly to greenhouse gas emissions, with estimates suggesting that each liter of liquid nitrogen production generates approximately 0.5-0.8 kg of CO2 equivalent. Additionally, the transportation of LN2 to end-users creates further emissions, particularly when delivery routes are extensive or frequent.

Mechanical freezers present different environmental challenges. While they avoid the production and transportation issues of LN2, they typically contain refrigerants with high global warming potential (GWP). Many older units utilize hydrofluorocarbons (HFCs) with GWP values thousands of times higher than CO2. Even small leakage rates of 5-10% annually can substantially impact climate change metrics. However, newer models increasingly employ natural refrigerants with significantly lower environmental impacts.

Waste generation represents another critical environmental consideration. LN2 systems produce minimal direct waste during operation but generate significant end-of-life waste from dewars and storage vessels. Mechanical freezers create more complex waste streams, including compressors, electronic components, and refrigerants requiring specialized disposal protocols to prevent environmental contamination.

Water consumption patterns also differ markedly between these technologies. The production of liquid nitrogen requires substantial cooling water, with estimates suggesting 10-15 liters of water per liter of LN2 produced. Mechanical freezers consume water indirectly through their electricity usage, particularly when powered by thermoelectric generation facilities that require cooling water.

Noise pollution presents an often-overlooked environmental impact. Mechanical freezers generate continuous operational noise ranging from 45-65 dB, potentially affecting workplace environments. LN2 systems produce intermittent noise during filling operations but are otherwise silent during storage periods, offering advantages in noise-sensitive settings.

Land use considerations reveal that centralized LN2 production facilities have concentrated environmental impacts at production sites but distributed impacts during transportation and use. Mechanical freezers distribute their environmental footprint more evenly across electricity generation sites and end-user locations, potentially offering advantages for regional environmental management strategies.

Total Cost of Ownership Analysis

When evaluating the economic viability of cryogenic storage solutions, Total Cost of Ownership (TCO) analysis provides a comprehensive framework that extends beyond initial purchase costs. For liquid nitrogen (LN2) systems versus mechanical freezers, TCO encompasses acquisition expenses, operational costs, maintenance requirements, and end-of-life considerations over the equipment's lifespan.

Initial investment for LN2 storage systems typically ranges from $10,000 to $30,000, depending on capacity and features. These systems require minimal electrical infrastructure but necessitate specialized LN2 supply arrangements. Conversely, mechanical ultra-low temperature freezers demand higher upfront capital, generally between $15,000 and $50,000, with additional costs for electrical infrastructure modifications to support their significant power requirements.

Operational expenditure presents striking differences between the technologies. LN2 systems incur recurring costs for nitrogen supply, typically $0.50-$1.50 per liter, with consumption rates varying by storage volume and facility insulation quality. Annual LN2 costs can range from $5,000 to $20,000 for standard research applications. Mechanical freezers eliminate this consumable expense but generate substantial electricity costs, consuming 16-30 kWh daily, translating to $1,400-$2,600 annually at average commercial electricity rates.

Maintenance considerations further differentiate these technologies. LN2 systems feature simpler mechanical designs with fewer failure points, requiring maintenance primarily for monitoring systems and insulation integrity, averaging $500-$1,000 annually. Mechanical freezers demand more intensive maintenance regimens for compressors, refrigeration circuits, and electronic control systems, with annual service contracts typically ranging from $1,200 to $3,000, plus potential emergency repair costs.

Lifespan economics also favor different scenarios. LN2 systems generally operate reliably for 15-20 years with proper maintenance, while mechanical freezers typically require replacement after 8-12 years. This difference significantly impacts long-term capital planning and depreciation calculations.

Risk mitigation costs represent another critical TCO component. LN2 systems require oxygen monitoring systems ($2,000-$5,000) and staff safety training to manage asphyxiation risks. Mechanical freezers necessitate backup power systems ($5,000-$20,000) to protect samples during power outages, plus ongoing testing and maintenance of these backup systems.

Space utilization efficiency must also be monetized in TCO calculations. LN2 systems typically require dedicated, ventilated areas with specific safety features, while mechanical freezers generate significant heat that may necessitate additional HVAC capacity, potentially adding $3,000-$8,000 in infrastructure costs depending on facility design.

Initial investment for LN2 storage systems typically ranges from $10,000 to $30,000, depending on capacity and features. These systems require minimal electrical infrastructure but necessitate specialized LN2 supply arrangements. Conversely, mechanical ultra-low temperature freezers demand higher upfront capital, generally between $15,000 and $50,000, with additional costs for electrical infrastructure modifications to support their significant power requirements.

Operational expenditure presents striking differences between the technologies. LN2 systems incur recurring costs for nitrogen supply, typically $0.50-$1.50 per liter, with consumption rates varying by storage volume and facility insulation quality. Annual LN2 costs can range from $5,000 to $20,000 for standard research applications. Mechanical freezers eliminate this consumable expense but generate substantial electricity costs, consuming 16-30 kWh daily, translating to $1,400-$2,600 annually at average commercial electricity rates.

Maintenance considerations further differentiate these technologies. LN2 systems feature simpler mechanical designs with fewer failure points, requiring maintenance primarily for monitoring systems and insulation integrity, averaging $500-$1,000 annually. Mechanical freezers demand more intensive maintenance regimens for compressors, refrigeration circuits, and electronic control systems, with annual service contracts typically ranging from $1,200 to $3,000, plus potential emergency repair costs.

Lifespan economics also favor different scenarios. LN2 systems generally operate reliably for 15-20 years with proper maintenance, while mechanical freezers typically require replacement after 8-12 years. This difference significantly impacts long-term capital planning and depreciation calculations.

Risk mitigation costs represent another critical TCO component. LN2 systems require oxygen monitoring systems ($2,000-$5,000) and staff safety training to manage asphyxiation risks. Mechanical freezers necessitate backup power systems ($5,000-$20,000) to protect samples during power outages, plus ongoing testing and maintenance of these backup systems.

Space utilization efficiency must also be monetized in TCO calculations. LN2 systems typically require dedicated, ventilated areas with specific safety features, while mechanical freezers generate significant heat that may necessitate additional HVAC capacity, potentially adding $3,000-$8,000 in infrastructure costs depending on facility design.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!