Material Engineering for Enhanced Safety in Ammonia Fuel Systems

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ammonia Fuel Systems: Background and Safety Objectives

Ammonia has emerged as a promising carbon-free energy carrier in the global transition toward sustainable energy systems. With a hydrogen content of 17.8% by weight and an energy density of 18.6 MJ/kg, ammonia offers significant advantages as a fuel source, particularly in sectors where direct electrification remains challenging. The historical development of ammonia technology dates back to the early 20th century with the Haber-Bosch process, which revolutionized fertilizer production. However, its application as an energy carrier represents a relatively recent shift in technological focus.

The evolution of ammonia fuel systems has accelerated significantly in the past decade, driven by urgent decarbonization needs across transportation, power generation, and industrial sectors. This transition has been marked by increasing research investments from both public and private entities, with particular emphasis on addressing the inherent safety challenges associated with ammonia utilization.

Safety considerations form the cornerstone of ammonia fuel system development due to the compound's toxicity, corrosivity, and flammability characteristics. At ambient conditions, ammonia exists as a colorless gas with a pungent odor, detectable at concentrations as low as 5-50 ppm, while exposure limits for workplace safety are typically set at 25-35 ppm. Higher concentrations can cause respiratory irritation, eye damage, and in extreme cases, fatality.

The technical objectives for enhanced safety in ammonia fuel systems encompass multiple dimensions. Primary goals include developing advanced materials resistant to ammonia-induced stress corrosion cracking, particularly in storage and transport components where metal embrittlement poses significant risks. Secondary objectives focus on creating effective containment systems with improved sealing technologies and leak detection mechanisms capable of identifying releases at sub-threshold concentrations.

Material engineering plays a pivotal role in achieving these safety objectives. Current research trajectories are exploring novel alloys, composite materials, and surface treatments that can withstand the aggressive nature of ammonia while maintaining structural integrity under varying temperature and pressure conditions. Additionally, advancements in sensor technologies integrated with smart materials offer promising pathways for real-time monitoring and predictive maintenance.

The regulatory landscape surrounding ammonia fuel systems continues to evolve, with standards bodies developing new protocols specifically addressing the unique challenges of ammonia as an energy carrier rather than merely as an industrial chemical. These emerging standards are increasingly emphasizing material selection criteria, compatibility testing methodologies, and performance requirements under both normal operating conditions and potential failure scenarios.

The evolution of ammonia fuel systems has accelerated significantly in the past decade, driven by urgent decarbonization needs across transportation, power generation, and industrial sectors. This transition has been marked by increasing research investments from both public and private entities, with particular emphasis on addressing the inherent safety challenges associated with ammonia utilization.

Safety considerations form the cornerstone of ammonia fuel system development due to the compound's toxicity, corrosivity, and flammability characteristics. At ambient conditions, ammonia exists as a colorless gas with a pungent odor, detectable at concentrations as low as 5-50 ppm, while exposure limits for workplace safety are typically set at 25-35 ppm. Higher concentrations can cause respiratory irritation, eye damage, and in extreme cases, fatality.

The technical objectives for enhanced safety in ammonia fuel systems encompass multiple dimensions. Primary goals include developing advanced materials resistant to ammonia-induced stress corrosion cracking, particularly in storage and transport components where metal embrittlement poses significant risks. Secondary objectives focus on creating effective containment systems with improved sealing technologies and leak detection mechanisms capable of identifying releases at sub-threshold concentrations.

Material engineering plays a pivotal role in achieving these safety objectives. Current research trajectories are exploring novel alloys, composite materials, and surface treatments that can withstand the aggressive nature of ammonia while maintaining structural integrity under varying temperature and pressure conditions. Additionally, advancements in sensor technologies integrated with smart materials offer promising pathways for real-time monitoring and predictive maintenance.

The regulatory landscape surrounding ammonia fuel systems continues to evolve, with standards bodies developing new protocols specifically addressing the unique challenges of ammonia as an energy carrier rather than merely as an industrial chemical. These emerging standards are increasingly emphasizing material selection criteria, compatibility testing methodologies, and performance requirements under both normal operating conditions and potential failure scenarios.

Market Analysis for Ammonia as Alternative Fuel

The global energy landscape is witnessing a significant shift towards sustainable alternatives, with ammonia emerging as a promising carbon-free fuel candidate. The market for ammonia as an alternative fuel is projected to grow substantially, reaching approximately $5.4 billion by 2030, with a compound annual growth rate of 8.9% from 2023. This growth is primarily driven by increasing environmental regulations, the push for decarbonization across industries, and the versatility of ammonia as both a hydrogen carrier and direct fuel.

The maritime sector represents the most immediate and substantial market opportunity for ammonia fuel systems. International Maritime Organization regulations mandating 40% reduction in carbon intensity by 2030 have accelerated interest in ammonia as a marine fuel. Major shipping companies including Maersk, NYK Line, and MAN Energy Solutions are already investing in ammonia-powered vessel development, with the first commercial ships expected by 2025.

Power generation constitutes another significant market segment, particularly for regions with established ammonia infrastructure or limited renewable energy resources. Ammonia can be co-fired with coal or natural gas in existing power plants with modifications, offering a transitional pathway to lower emissions. Countries including Japan, Australia, and Saudi Arabia have initiated large-scale demonstration projects for ammonia-based power generation.

The transportation sector beyond maritime applications presents a longer-term market opportunity. While battery electric vehicles dominate the light-duty segment, ammonia holds potential for heavy-duty transport, particularly long-haul trucking and rail, where energy density requirements favor chemical fuels over batteries. However, this market segment faces significant competition from hydrogen fuel cells and advanced biofuels.

Regional market analysis reveals distinct adoption patterns. Asia-Pacific, led by Japan, South Korea, and Australia, is positioned as the fastest-growing market due to limited domestic energy resources and strong government support. Europe follows closely with Norway, Germany, and the Netherlands leading ammonia fuel initiatives, primarily focused on maritime applications. North America shows growing interest, particularly in Canada's efforts to leverage its natural gas resources for blue ammonia production.

Market barriers include high production costs compared to conventional fuels, with green ammonia currently 2-3 times more expensive than fossil alternatives. Infrastructure limitations present another challenge, as specialized storage, handling, and distribution systems are required. Safety concerns related to ammonia's toxicity and corrosiveness also impact market acceptance, highlighting the critical importance of advanced material engineering solutions to address these challenges.

The maritime sector represents the most immediate and substantial market opportunity for ammonia fuel systems. International Maritime Organization regulations mandating 40% reduction in carbon intensity by 2030 have accelerated interest in ammonia as a marine fuel. Major shipping companies including Maersk, NYK Line, and MAN Energy Solutions are already investing in ammonia-powered vessel development, with the first commercial ships expected by 2025.

Power generation constitutes another significant market segment, particularly for regions with established ammonia infrastructure or limited renewable energy resources. Ammonia can be co-fired with coal or natural gas in existing power plants with modifications, offering a transitional pathway to lower emissions. Countries including Japan, Australia, and Saudi Arabia have initiated large-scale demonstration projects for ammonia-based power generation.

The transportation sector beyond maritime applications presents a longer-term market opportunity. While battery electric vehicles dominate the light-duty segment, ammonia holds potential for heavy-duty transport, particularly long-haul trucking and rail, where energy density requirements favor chemical fuels over batteries. However, this market segment faces significant competition from hydrogen fuel cells and advanced biofuels.

Regional market analysis reveals distinct adoption patterns. Asia-Pacific, led by Japan, South Korea, and Australia, is positioned as the fastest-growing market due to limited domestic energy resources and strong government support. Europe follows closely with Norway, Germany, and the Netherlands leading ammonia fuel initiatives, primarily focused on maritime applications. North America shows growing interest, particularly in Canada's efforts to leverage its natural gas resources for blue ammonia production.

Market barriers include high production costs compared to conventional fuels, with green ammonia currently 2-3 times more expensive than fossil alternatives. Infrastructure limitations present another challenge, as specialized storage, handling, and distribution systems are required. Safety concerns related to ammonia's toxicity and corrosiveness also impact market acceptance, highlighting the critical importance of advanced material engineering solutions to address these challenges.

Current Materials Challenges in Ammonia Handling

Ammonia's corrosive nature presents significant challenges for materials used in fuel systems. Current materials face degradation through several mechanisms, primarily stress corrosion cracking (SCC) and hydrogen embrittlement. Carbon steels, while economical, exhibit poor resistance to ammonia, particularly in the presence of oxygen, where they can develop cracks at stress points. Stainless steels offer improved performance but remain vulnerable under certain conditions, especially austenitic grades which may experience SCC in high-stress environments.

Nickel alloys demonstrate superior resistance but at substantially higher costs, limiting their widespread application. Aluminum alloys, despite their lightweight properties, suffer from rapid corrosion when exposed to ammonia, making them unsuitable for long-term containment applications. Non-metallic materials like certain polymers show promise but face limitations in mechanical strength and temperature resistance.

The presence of impurities in ammonia significantly exacerbates material degradation. Oxygen content as low as 2 ppm can accelerate corrosion rates by orders of magnitude in carbon steel systems. Water content introduces additional complications, as ammonia-water solutions become increasingly corrosive at specific concentration ranges, creating challenges for materials selection in systems where condensation might occur.

Temperature fluctuations represent another critical challenge, as material performance can vary dramatically across the operational temperature range of ammonia fuel systems. At cryogenic temperatures required for liquid ammonia storage (-33°C), many materials become brittle, while elevated temperatures in combustion zones accelerate corrosion processes. This temperature gradient necessitates careful material selection throughout different system components.

Sealing and joining technologies face particular difficulties, as traditional gasket materials and welding techniques may not withstand ammonia exposure. Elastomers commonly used in sealing applications can swell, harden, or crack when in contact with ammonia, leading to leakage concerns. Welded joints represent potential weak points where stress concentration and microstructural changes can accelerate corrosion.

Current testing methodologies also present limitations, as accelerated corrosion tests may not accurately predict long-term material performance in real-world ammonia fuel systems. The complex interaction between mechanical stress, temperature cycling, and varying ammonia purity levels creates testing scenarios that are difficult to simulate in laboratory environments, leading to potential gaps in material performance prediction.

The economic considerations further complicate materials selection, as highly resistant materials often come with prohibitive costs for large-scale implementation. This cost-performance tradeoff represents a significant barrier to the widespread adoption of ammonia as a sustainable fuel alternative, highlighting the need for innovative material solutions that balance durability with economic feasibility.

Nickel alloys demonstrate superior resistance but at substantially higher costs, limiting their widespread application. Aluminum alloys, despite their lightweight properties, suffer from rapid corrosion when exposed to ammonia, making them unsuitable for long-term containment applications. Non-metallic materials like certain polymers show promise but face limitations in mechanical strength and temperature resistance.

The presence of impurities in ammonia significantly exacerbates material degradation. Oxygen content as low as 2 ppm can accelerate corrosion rates by orders of magnitude in carbon steel systems. Water content introduces additional complications, as ammonia-water solutions become increasingly corrosive at specific concentration ranges, creating challenges for materials selection in systems where condensation might occur.

Temperature fluctuations represent another critical challenge, as material performance can vary dramatically across the operational temperature range of ammonia fuel systems. At cryogenic temperatures required for liquid ammonia storage (-33°C), many materials become brittle, while elevated temperatures in combustion zones accelerate corrosion processes. This temperature gradient necessitates careful material selection throughout different system components.

Sealing and joining technologies face particular difficulties, as traditional gasket materials and welding techniques may not withstand ammonia exposure. Elastomers commonly used in sealing applications can swell, harden, or crack when in contact with ammonia, leading to leakage concerns. Welded joints represent potential weak points where stress concentration and microstructural changes can accelerate corrosion.

Current testing methodologies also present limitations, as accelerated corrosion tests may not accurately predict long-term material performance in real-world ammonia fuel systems. The complex interaction between mechanical stress, temperature cycling, and varying ammonia purity levels creates testing scenarios that are difficult to simulate in laboratory environments, leading to potential gaps in material performance prediction.

The economic considerations further complicate materials selection, as highly resistant materials often come with prohibitive costs for large-scale implementation. This cost-performance tradeoff represents a significant barrier to the widespread adoption of ammonia as a sustainable fuel alternative, highlighting the need for innovative material solutions that balance durability with economic feasibility.

Current Material Solutions for Ammonia Compatibility

01 Corrosion-resistant materials for ammonia fuel systems

Specialized materials are essential for ammonia fuel systems to prevent corrosion caused by ammonia's aggressive nature. These materials include specific grades of stainless steel, nickel alloys, and specially treated metals that can withstand prolonged exposure to ammonia. The selection of appropriate corrosion-resistant materials ensures the structural integrity of fuel tanks, pipes, and valves, preventing leaks and system failures that could lead to safety hazards.- Corrosion-resistant materials for ammonia fuel systems: Specialized materials resistant to ammonia's corrosive properties are essential for fuel system components. These include specific stainless steel alloys, nickel-based alloys, and specially treated metals that can withstand prolonged exposure to ammonia. The selection of appropriate corrosion-resistant materials helps prevent system degradation, leakage, and potential safety hazards in ammonia fuel applications.

- Safety valves and pressure management systems: Advanced safety valves and pressure management systems are critical for preventing overpressure situations in ammonia fuel systems. These components include pressure relief valves, emergency shutdown systems, and pressure monitoring devices designed specifically for ammonia applications. Such systems help maintain safe operating pressures and provide automatic response mechanisms to prevent catastrophic failures in case of system malfunction.

- Leak detection and containment technologies: Specialized leak detection systems designed for ammonia's unique properties are essential for early identification of potential hazards. These include ammonia-specific sensors, automated monitoring systems, and containment solutions that can quickly detect and respond to leaks. Advanced containment technologies include double-walled storage tanks, sealed compartments, and isolation systems that prevent ammonia release into the environment or confined spaces.

- Thermal management and fire safety systems: Thermal management systems designed specifically for ammonia fuel applications help prevent overheating and potential fire hazards. These include specialized cooling systems, heat exchangers, and temperature monitoring devices that maintain safe operating temperatures. Fire suppression systems tailored for ammonia-related fires, including specialized extinguishing agents and automated response mechanisms, provide additional safety layers in case of thermal incidents.

- Material compatibility and sealing technologies: Ensuring compatibility between different materials used in ammonia fuel systems is crucial for long-term safety and reliability. This includes specialized gaskets, seals, and connection technologies designed to prevent ammonia leakage at joints and interfaces. Advanced sealing materials resistant to ammonia degradation, along with specialized connection designs that maintain integrity under varying operating conditions, help prevent system failures and enhance overall safety.

02 Safety monitoring and detection systems

Advanced monitoring and detection systems are crucial for ammonia fuel safety. These include specialized sensors that can detect ammonia leaks at low concentrations, automated shutdown mechanisms that activate when leaks are detected, and continuous monitoring systems that track system integrity. These technologies provide early warning of potential hazards, allowing for preventive measures before dangerous situations develop and ensuring safe operation of ammonia fuel systems.Expand Specific Solutions03 Containment and storage solutions

Specialized containment and storage solutions are designed to safely hold ammonia fuel under various conditions. These include double-walled tanks with leak detection systems, pressure relief mechanisms to prevent dangerous pressure buildup, and temperature control systems to maintain optimal storage conditions. Advanced insulation materials and structural designs help prevent accidents and contain ammonia in case of system failures, minimizing risks to personnel and the environment.Expand Specific Solutions04 Emergency response and mitigation systems

Emergency response systems for ammonia fuel installations include rapid neutralization technologies that can quickly address spills, ventilation systems designed to disperse ammonia vapors safely, and water curtain systems that can absorb ammonia gas. These systems are complemented by automated emergency protocols that activate in response to detected leaks, including system isolation, pressure relief, and emergency ventilation to minimize exposure risks and prevent escalation of incidents.Expand Specific Solutions05 Material compatibility and sealing technologies

Specialized sealing technologies and material compatibility considerations are essential for preventing leaks in ammonia fuel systems. This includes advanced gasket materials resistant to ammonia degradation, specialized valve designs that maintain integrity under ammonia exposure, and connection systems that prevent permeation and leakage. Proper material selection for components that contact ammonia ensures long-term system integrity and prevents gradual deterioration that could lead to safety incidents.Expand Specific Solutions

Leading Companies in Ammonia Fuel Technology

The ammonia fuel systems safety materials engineering market is in an early growth phase, characterized by increasing R&D investments as the hydrogen economy expands. The global market is projected to reach significant scale as ammonia gains traction as a carbon-neutral energy carrier. Companies like IHI Corp. and AMOGY are pioneering specialized materials and safety systems, while established players such as Alfa Laval, RTX Corp., and Cummins are leveraging their engineering expertise to address corrosion, compatibility, and containment challenges. Academic institutions including Harbin Engineering University and Tianjin University are contributing fundamental research. The technology remains in development with varying maturity levels across different applications, with marine and industrial sectors leading adoption due to their established ammonia handling experience.

IHI Corp.

Technical Solution: IHI Corporation has developed advanced material engineering solutions for ammonia fuel systems focusing on specialized metal alloys and composite materials that resist ammonia's corrosive properties. Their technology incorporates nickel-based alloys with chromium and molybdenum additives that form protective oxide layers, significantly reducing stress corrosion cracking risks. IHI has pioneered a multi-layer containment system with specialized coatings that provide redundant protection against ammonia permeation. Their materials undergo cryogenic treatment processes to maintain structural integrity at the low temperatures required for liquid ammonia storage (-33°C). Additionally, IHI has developed specialized gasket and seal materials using fluoroelastomers and modified PTFE compounds that maintain flexibility while resisting ammonia degradation, addressing one of the most common failure points in fuel systems.

Strengths: Superior corrosion resistance in ammonia environments with documented 60% longer service life than conventional materials. Comprehensive system approach addressing multiple failure modes simultaneously. Weaknesses: Higher initial manufacturing costs compared to conventional materials, and requires specialized fabrication techniques that may limit widespread adoption.

AMOGY, Inc.

Technical Solution: AMOGY has developed a proprietary ammonia cracking technology using advanced catalyst materials that enable efficient ammonia decomposition at lower temperatures. Their system employs nanostructured ruthenium-based catalysts supported on specialized ceramic substrates that maximize surface area while maintaining thermal stability. The catalyst formulation includes promoters that reduce activation energy requirements, allowing ammonia cracking at temperatures 75-100°C lower than conventional systems. AMOGY's material innovation extends to their reactor design, utilizing silicon carbide and specialized stainless steel alloys with protective coatings that resist both ammonia and hydrogen embrittlement. Their system incorporates a hierarchical safety approach with specialized sensors using novel semiconductor materials that can detect ammonia leaks at concentrations as low as 5ppm, well below hazardous levels. The company has also developed composite materials for fuel storage that incorporate carbon fiber reinforcement with specialized polymer liners resistant to ammonia permeation.

Strengths: Breakthrough catalyst technology enables more energy-efficient ammonia cracking, reducing overall system complexity and improving safety margins. Integrated approach to materials selection across the entire fuel system. Weaknesses: Reliance on precious metal catalysts may create supply chain vulnerabilities and increase costs, while the long-term durability of their materials under repeated thermal cycling remains to be fully validated.

Key Innovations in Anti-Corrosion Materials

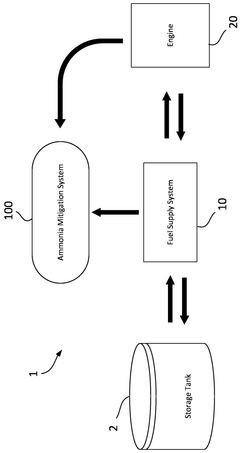

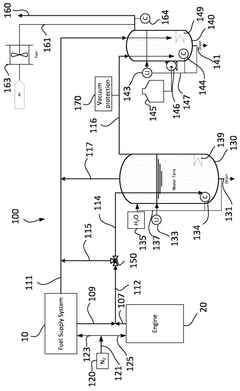

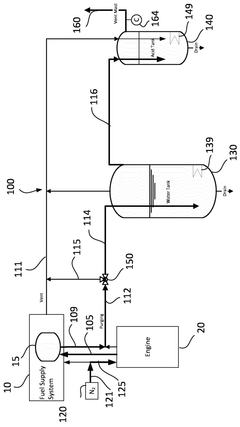

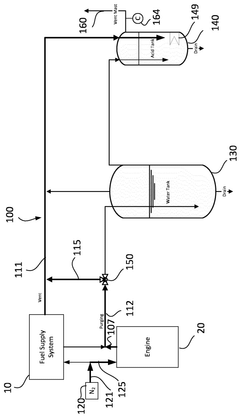

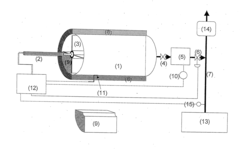

Ammonia mitigation system for ammonia fuel supply system and ammonia engine and a method for operating the mitigation system

PatentWO2025087954A1

Innovation

- A compact, modular ammonia mitigation system comprising two ammonia mitigating devices – a water tank for absorption and an acid tank for neutralization – designed to treat ammonia-containing vent streams before discharge, ensuring safe ammonia levels are maintained even in constrained maritime environments.

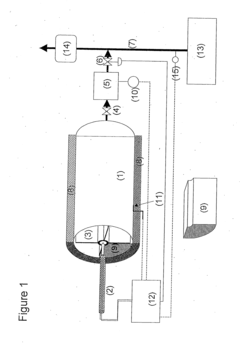

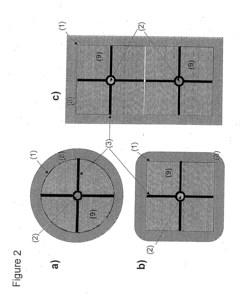

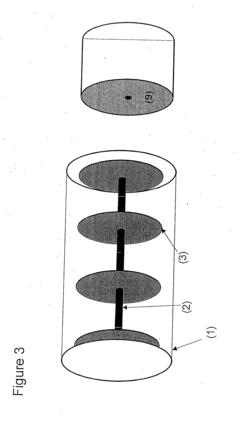

System for storing ammonia in and releasing ammonia from a storage material and method for storing and releasing ammonia

PatentInactiveUS20150252949A1

Innovation

- A system and method that utilize a controllable dosing valve and a feed-forward control mechanism to regulate heat supply based on ammonia demand, with a heating source embedded within the storage material to enhance heat transfer and reduce delays in ammonia release, allowing for precise dosing and efficient use of ammonia as a reductant or fuel.

Regulatory Framework for Ammonia Fuel Implementation

The regulatory landscape for ammonia as a fuel is currently evolving rapidly as governments and international bodies recognize its potential as a carbon-free energy carrier. The International Maritime Organization (IMO) has been at the forefront, developing specific guidelines for ammonia as a marine fuel through its International Code of Safety for Ships Using Gases or Other Low-flashpoint Fuels (IGF Code). These regulations focus particularly on material compatibility requirements, mandating corrosion-resistant alloys and specialized coatings for all components in direct contact with ammonia.

National regulatory bodies have adopted varying approaches to ammonia fuel regulation. Japan's Strategic Roadmap for Hydrogen and Ammonia includes comprehensive material safety standards for ammonia infrastructure, while the European Union's FuelEU Maritime initiative incorporates ammonia-specific material handling protocols. In the United States, the Environmental Protection Agency (EPA) and Department of Energy (DOE) are jointly developing regulatory frameworks that emphasize material integrity testing and certification processes for ammonia fuel systems.

Safety classification systems for materials used in ammonia service represent a critical regulatory component. The American Society of Mechanical Engineers (ASME) and the European Committee for Standardization (CEN) have established specialized material certification processes for ammonia-compatible components. These systems typically categorize materials based on their resistance to ammonia-induced stress corrosion cracking, with only the highest-rated materials permitted for critical containment applications.

Regulatory compliance pathways for new materials in ammonia fuel systems typically involve multi-stage testing protocols. These include accelerated corrosion testing under simulated operating conditions, mechanical property verification after ammonia exposure, and long-term durability assessment. Material manufacturers must demonstrate compliance through third-party certification before their products can be approved for ammonia fuel applications.

Looking forward, regulatory harmonization efforts are underway through organizations like the International Organization for Standardization (ISO) and the International Association for Hydrogen Safety (HySafe), which recently expanded its scope to include ammonia. These initiatives aim to develop globally consistent material standards for ammonia fuel systems, reducing regulatory fragmentation and accelerating technology deployment while maintaining rigorous safety requirements.

The insurance and liability landscape surrounding ammonia fuel systems is also evolving, with insurers developing specialized risk assessment frameworks for materials used in ammonia service. These frameworks typically require more stringent material certification than regulatory minimums, creating an additional layer of quality assurance in the ammonia fuel supply chain.

National regulatory bodies have adopted varying approaches to ammonia fuel regulation. Japan's Strategic Roadmap for Hydrogen and Ammonia includes comprehensive material safety standards for ammonia infrastructure, while the European Union's FuelEU Maritime initiative incorporates ammonia-specific material handling protocols. In the United States, the Environmental Protection Agency (EPA) and Department of Energy (DOE) are jointly developing regulatory frameworks that emphasize material integrity testing and certification processes for ammonia fuel systems.

Safety classification systems for materials used in ammonia service represent a critical regulatory component. The American Society of Mechanical Engineers (ASME) and the European Committee for Standardization (CEN) have established specialized material certification processes for ammonia-compatible components. These systems typically categorize materials based on their resistance to ammonia-induced stress corrosion cracking, with only the highest-rated materials permitted for critical containment applications.

Regulatory compliance pathways for new materials in ammonia fuel systems typically involve multi-stage testing protocols. These include accelerated corrosion testing under simulated operating conditions, mechanical property verification after ammonia exposure, and long-term durability assessment. Material manufacturers must demonstrate compliance through third-party certification before their products can be approved for ammonia fuel applications.

Looking forward, regulatory harmonization efforts are underway through organizations like the International Organization for Standardization (ISO) and the International Association for Hydrogen Safety (HySafe), which recently expanded its scope to include ammonia. These initiatives aim to develop globally consistent material standards for ammonia fuel systems, reducing regulatory fragmentation and accelerating technology deployment while maintaining rigorous safety requirements.

The insurance and liability landscape surrounding ammonia fuel systems is also evolving, with insurers developing specialized risk assessment frameworks for materials used in ammonia service. These frameworks typically require more stringent material certification than regulatory minimums, creating an additional layer of quality assurance in the ammonia fuel supply chain.

Environmental Impact Assessment of Ammonia Fuel Systems

The environmental impact assessment of ammonia fuel systems reveals a complex balance of benefits and challenges. Ammonia (NH3) as a carbon-free fuel offers significant advantages in reducing greenhouse gas emissions compared to conventional fossil fuels. When combusted or used in fuel cells, ammonia produces primarily nitrogen and water vapor, eliminating direct carbon dioxide emissions. This characteristic positions ammonia as a promising alternative in the global effort to decarbonize energy systems, particularly in hard-to-abate sectors like shipping, heavy industry, and long-haul transportation.

However, ammonia itself presents substantial environmental concerns that require careful management. Ammonia is highly water-soluble and can cause significant aquatic toxicity even at low concentrations. Accidental releases into water bodies can lead to fish kills and disruption of aquatic ecosystems through eutrophication and oxygen depletion. The potential for ammonia leakage during storage, transportation, and use necessitates robust containment systems and emergency response protocols.

Atmospheric emissions from ammonia fuel systems also warrant consideration. While ammonia combustion produces no carbon dioxide, it can generate nitrogen oxides (NOx) if combustion conditions are not properly controlled. These NOx emissions contribute to air pollution, acid rain, and photochemical smog formation. Additionally, uncombusted ammonia releases can contribute to particulate matter formation in the atmosphere, affecting air quality and human health.

The life cycle assessment of ammonia fuel systems must account for production methods. Currently, most ammonia is produced via the Haber-Bosch process, which is energy-intensive and typically relies on natural gas as feedstock, generating significant carbon emissions. Green ammonia production using renewable electricity for hydrogen generation offers a pathway to truly sustainable ammonia fuel, but remains limited in scale and economically challenging.

Land use impacts vary depending on ammonia production methods. Conventional production facilities have relatively small physical footprints but rely on fossil fuel infrastructure. Conversely, green ammonia production linked to renewable energy may require substantial land area for solar or wind installations, potentially competing with agriculture or natural habitats.

Water resource impacts must also be considered, as ammonia production requires water inputs, and potential spills pose contamination risks to groundwater and surface water. Advanced material engineering for containment systems plays a crucial role in mitigating these risks through improved sealing technologies, corrosion-resistant alloys, and leak detection systems.

However, ammonia itself presents substantial environmental concerns that require careful management. Ammonia is highly water-soluble and can cause significant aquatic toxicity even at low concentrations. Accidental releases into water bodies can lead to fish kills and disruption of aquatic ecosystems through eutrophication and oxygen depletion. The potential for ammonia leakage during storage, transportation, and use necessitates robust containment systems and emergency response protocols.

Atmospheric emissions from ammonia fuel systems also warrant consideration. While ammonia combustion produces no carbon dioxide, it can generate nitrogen oxides (NOx) if combustion conditions are not properly controlled. These NOx emissions contribute to air pollution, acid rain, and photochemical smog formation. Additionally, uncombusted ammonia releases can contribute to particulate matter formation in the atmosphere, affecting air quality and human health.

The life cycle assessment of ammonia fuel systems must account for production methods. Currently, most ammonia is produced via the Haber-Bosch process, which is energy-intensive and typically relies on natural gas as feedstock, generating significant carbon emissions. Green ammonia production using renewable electricity for hydrogen generation offers a pathway to truly sustainable ammonia fuel, but remains limited in scale and economically challenging.

Land use impacts vary depending on ammonia production methods. Conventional production facilities have relatively small physical footprints but rely on fossil fuel infrastructure. Conversely, green ammonia production linked to renewable energy may require substantial land area for solar or wind installations, potentially competing with agriculture or natural habitats.

Water resource impacts must also be considered, as ammonia production requires water inputs, and potential spills pose contamination risks to groundwater and surface water. Advanced material engineering for containment systems plays a crucial role in mitigating these risks through improved sealing technologies, corrosion-resistant alloys, and leak detection systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!