Material Innovations for Long-Lasting Plate Heat Exchangers

JUL 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Material Evolution and Objectives

Plate heat exchangers have been a cornerstone of industrial thermal management for decades, with their efficiency and compact design making them indispensable in various sectors. The evolution of materials used in these exchangers has been driven by the need for improved performance, longevity, and cost-effectiveness. Initially, carbon steel was the primary material of choice due to its availability and low cost. However, its susceptibility to corrosion and fouling led to the adoption of stainless steel, which offered better resistance to harsh environments.

As industrial processes became more demanding, the focus shifted towards more advanced materials. Titanium emerged as a premium option for its exceptional corrosion resistance, particularly in seawater applications. Nickel alloys, such as Hastelloy and Inconel, found their niche in highly corrosive environments, especially in chemical processing industries. These materials significantly extended the operational life of plate heat exchangers but came with a substantial cost premium.

The pursuit of enhanced heat transfer efficiency led to innovations in plate design and material composition. The introduction of copper-brazed plates offered improved thermal conductivity, while the development of composite materials aimed to combine the benefits of different materials. Polymer-based plates, for instance, provided excellent chemical resistance at a lower cost, albeit with limitations in high-temperature applications.

Recent years have seen a surge in research focused on nanomaterials and surface modifications. Nanocoatings have shown promise in enhancing heat transfer rates and reducing fouling, potentially extending the operational life of exchangers. Additionally, the exploration of graphene and carbon nanotubes as additives or coatings has opened new avenues for material innovation, offering the potential for unprecedented thermal conductivity and corrosion resistance.

The primary objectives driving material innovations for long-lasting plate heat exchangers are multifaceted. Firstly, there is a continuous push for materials that can withstand increasingly aggressive operating conditions, including higher temperatures, pressures, and corrosive media. Secondly, the industry seeks materials that can maintain their performance over extended periods, reducing the frequency of maintenance and replacement. Thirdly, there is a growing emphasis on materials that can enhance energy efficiency, either through improved heat transfer characteristics or by reducing pumping power requirements.

Environmental considerations have also become a significant factor in material selection and development. The industry is moving towards materials that are more sustainable, both in terms of their production and end-of-life recyclability. This shift aligns with broader sustainability goals and regulatory pressures, driving research into bio-based and recyclable materials that can meet the demanding requirements of plate heat exchangers.

As industrial processes became more demanding, the focus shifted towards more advanced materials. Titanium emerged as a premium option for its exceptional corrosion resistance, particularly in seawater applications. Nickel alloys, such as Hastelloy and Inconel, found their niche in highly corrosive environments, especially in chemical processing industries. These materials significantly extended the operational life of plate heat exchangers but came with a substantial cost premium.

The pursuit of enhanced heat transfer efficiency led to innovations in plate design and material composition. The introduction of copper-brazed plates offered improved thermal conductivity, while the development of composite materials aimed to combine the benefits of different materials. Polymer-based plates, for instance, provided excellent chemical resistance at a lower cost, albeit with limitations in high-temperature applications.

Recent years have seen a surge in research focused on nanomaterials and surface modifications. Nanocoatings have shown promise in enhancing heat transfer rates and reducing fouling, potentially extending the operational life of exchangers. Additionally, the exploration of graphene and carbon nanotubes as additives or coatings has opened new avenues for material innovation, offering the potential for unprecedented thermal conductivity and corrosion resistance.

The primary objectives driving material innovations for long-lasting plate heat exchangers are multifaceted. Firstly, there is a continuous push for materials that can withstand increasingly aggressive operating conditions, including higher temperatures, pressures, and corrosive media. Secondly, the industry seeks materials that can maintain their performance over extended periods, reducing the frequency of maintenance and replacement. Thirdly, there is a growing emphasis on materials that can enhance energy efficiency, either through improved heat transfer characteristics or by reducing pumping power requirements.

Environmental considerations have also become a significant factor in material selection and development. The industry is moving towards materials that are more sustainable, both in terms of their production and end-of-life recyclability. This shift aligns with broader sustainability goals and regulatory pressures, driving research into bio-based and recyclable materials that can meet the demanding requirements of plate heat exchangers.

Market Analysis for Durable Heat Exchangers

The market for durable heat exchangers, particularly plate heat exchangers (PHEs), has been experiencing significant growth due to increasing demand across various industries. The global plate heat exchanger market is projected to reach a substantial value by 2028, driven by factors such as energy efficiency requirements, industrial expansion, and technological advancements in material science.

Key industries contributing to this market growth include chemical processing, food and beverage, HVAC, oil and gas, and power generation. These sectors are increasingly adopting plate heat exchangers due to their compact design, high thermal efficiency, and ease of maintenance. The food and beverage industry, in particular, has shown a strong preference for PHEs due to their ability to maintain strict hygiene standards and handle sensitive products.

Geographically, Asia-Pacific is emerging as the fastest-growing market for durable heat exchangers, fueled by rapid industrialization in countries like China and India. North America and Europe continue to be significant markets, driven by the need for energy-efficient solutions and stringent environmental regulations.

The demand for long-lasting plate heat exchangers is particularly strong in harsh operating environments, such as those found in the chemical and petrochemical industries. These sectors require heat exchangers that can withstand corrosive fluids, high temperatures, and high pressures over extended periods. This has led to a growing focus on material innovations that can enhance the durability and performance of PHEs.

Market trends indicate a shift towards more sustainable and energy-efficient solutions. Manufacturers are increasingly investing in research and development to create heat exchangers with improved heat transfer coefficients and reduced fouling tendencies. This not only extends the operational life of the equipment but also reduces maintenance costs and downtime for end-users.

The competitive landscape of the durable heat exchanger market is characterized by the presence of several large multinational corporations and numerous smaller, specialized manufacturers. Key players are focusing on product differentiation through material innovations and enhanced designs to gain a competitive edge.

Customer preferences are evolving, with a growing emphasis on total cost of ownership rather than initial purchase price. This shift is driving demand for heat exchangers that offer longer operational life, reduced maintenance requirements, and improved energy efficiency. As a result, manufacturers are increasingly offering comprehensive lifecycle services and performance guarantees to meet these customer expectations.

Key industries contributing to this market growth include chemical processing, food and beverage, HVAC, oil and gas, and power generation. These sectors are increasingly adopting plate heat exchangers due to their compact design, high thermal efficiency, and ease of maintenance. The food and beverage industry, in particular, has shown a strong preference for PHEs due to their ability to maintain strict hygiene standards and handle sensitive products.

Geographically, Asia-Pacific is emerging as the fastest-growing market for durable heat exchangers, fueled by rapid industrialization in countries like China and India. North America and Europe continue to be significant markets, driven by the need for energy-efficient solutions and stringent environmental regulations.

The demand for long-lasting plate heat exchangers is particularly strong in harsh operating environments, such as those found in the chemical and petrochemical industries. These sectors require heat exchangers that can withstand corrosive fluids, high temperatures, and high pressures over extended periods. This has led to a growing focus on material innovations that can enhance the durability and performance of PHEs.

Market trends indicate a shift towards more sustainable and energy-efficient solutions. Manufacturers are increasingly investing in research and development to create heat exchangers with improved heat transfer coefficients and reduced fouling tendencies. This not only extends the operational life of the equipment but also reduces maintenance costs and downtime for end-users.

The competitive landscape of the durable heat exchanger market is characterized by the presence of several large multinational corporations and numerous smaller, specialized manufacturers. Key players are focusing on product differentiation through material innovations and enhanced designs to gain a competitive edge.

Customer preferences are evolving, with a growing emphasis on total cost of ownership rather than initial purchase price. This shift is driving demand for heat exchangers that offer longer operational life, reduced maintenance requirements, and improved energy efficiency. As a result, manufacturers are increasingly offering comprehensive lifecycle services and performance guarantees to meet these customer expectations.

Current Challenges in Plate Heat Exchanger Materials

Plate heat exchangers (PHEs) have become integral components in various industries due to their efficiency and compact design. However, the materials used in their construction face several challenges that limit their longevity and performance. One of the primary issues is corrosion, which can significantly reduce the lifespan of PHEs. The aggressive environments in which these exchangers operate, often involving high temperatures and corrosive fluids, accelerate material degradation. This leads to reduced heat transfer efficiency and potential leaks, necessitating frequent maintenance or replacement.

Another critical challenge is fouling, which occurs when deposits accumulate on the heat transfer surfaces. These deposits act as an insulating layer, diminishing heat transfer effectiveness and increasing pressure drop across the exchanger. The materials currently used in PHEs are often susceptible to fouling, particularly in applications involving high-temperature fluids or those with suspended particles. This susceptibility not only reduces operational efficiency but also increases maintenance costs and downtime.

Thermal fatigue is a significant concern, especially in applications with frequent temperature fluctuations. The repeated expansion and contraction of materials can lead to cracking and eventual failure of the plates. Current materials struggle to maintain their structural integrity under these cyclic thermal stresses, limiting the operational lifespan of the heat exchangers.

Moreover, the demand for higher operating temperatures and pressures in various industrial processes poses a challenge to existing PHE materials. Many conventional materials exhibit reduced strength and creep resistance at elevated temperatures, restricting their use in high-temperature applications. This limitation hinders the expansion of PHE usage in emerging high-temperature processes, such as those in the chemical and petrochemical industries.

The need for lightweight yet durable materials presents another challenge. While reducing the weight of PHEs can lead to easier installation and reduced structural support requirements, it often comes at the cost of reduced durability or heat transfer efficiency. Striking the right balance between weight reduction and maintaining robust performance characteristics remains a significant material science challenge.

Lastly, the environmental impact and sustainability of PHE materials are becoming increasingly important considerations. There is a growing need for materials that are not only durable and efficient but also environmentally friendly in their production, use, and end-of-life disposal. This includes considerations for recyclability, reduced carbon footprint in manufacturing, and the elimination of hazardous substances in the material composition.

Another critical challenge is fouling, which occurs when deposits accumulate on the heat transfer surfaces. These deposits act as an insulating layer, diminishing heat transfer effectiveness and increasing pressure drop across the exchanger. The materials currently used in PHEs are often susceptible to fouling, particularly in applications involving high-temperature fluids or those with suspended particles. This susceptibility not only reduces operational efficiency but also increases maintenance costs and downtime.

Thermal fatigue is a significant concern, especially in applications with frequent temperature fluctuations. The repeated expansion and contraction of materials can lead to cracking and eventual failure of the plates. Current materials struggle to maintain their structural integrity under these cyclic thermal stresses, limiting the operational lifespan of the heat exchangers.

Moreover, the demand for higher operating temperatures and pressures in various industrial processes poses a challenge to existing PHE materials. Many conventional materials exhibit reduced strength and creep resistance at elevated temperatures, restricting their use in high-temperature applications. This limitation hinders the expansion of PHE usage in emerging high-temperature processes, such as those in the chemical and petrochemical industries.

The need for lightweight yet durable materials presents another challenge. While reducing the weight of PHEs can lead to easier installation and reduced structural support requirements, it often comes at the cost of reduced durability or heat transfer efficiency. Striking the right balance between weight reduction and maintaining robust performance characteristics remains a significant material science challenge.

Lastly, the environmental impact and sustainability of PHE materials are becoming increasingly important considerations. There is a growing need for materials that are not only durable and efficient but also environmentally friendly in their production, use, and end-of-life disposal. This includes considerations for recyclability, reduced carbon footprint in manufacturing, and the elimination of hazardous substances in the material composition.

Existing Material Solutions

01 Material selection for improved longevity

Choosing appropriate materials for plate heat exchangers can significantly enhance their lifespan. Corrosion-resistant alloys, such as stainless steel or titanium, are often used to withstand harsh operating conditions and prevent degradation over time. The selection of materials depends on factors like the fluids being processed, operating temperatures, and pressure requirements.- Material selection for improved longevity: Choosing appropriate materials for plate heat exchangers can significantly enhance their lifespan. Corrosion-resistant alloys and high-quality stainless steel are often used to withstand harsh operating conditions and prevent degradation over time. The selection of materials should consider factors such as the fluids being processed, operating temperatures, and pressure requirements.

- Design optimization for durability: Optimizing the design of plate heat exchangers can contribute to their longevity. This includes features such as improved plate geometry, enhanced flow distribution, and reinforced gasket designs. Advanced computational fluid dynamics (CFD) analysis can be used to optimize flow patterns and minimize areas of stagnation or high turbulence that may lead to premature wear.

- Maintenance and cleaning strategies: Regular maintenance and effective cleaning procedures are crucial for extending the lifespan of plate heat exchangers. This includes periodic inspections, proper chemical cleaning methods, and the implementation of preventive maintenance schedules. Automated cleaning systems and easy-to-disassemble designs can facilitate more frequent and thorough cleaning, reducing the risk of fouling and corrosion.

- Operational parameters and control: Careful control of operational parameters can significantly impact the longevity of plate heat exchangers. This includes monitoring and adjusting factors such as flow rates, temperatures, and pressure differentials. Implementing advanced control systems and sensors can help maintain optimal operating conditions, prevent thermal stress, and reduce the risk of mechanical damage.

- Innovative sealing and gasket technologies: Developing and implementing innovative sealing and gasket technologies can enhance the durability of plate heat exchangers. This includes the use of advanced elastomers, composite materials, and novel gasket designs that can withstand high temperatures and pressures. Improved sealing technologies can prevent leaks, reduce the need for frequent replacements, and extend the overall lifespan of the heat exchanger.

02 Design optimization for durability

Optimizing the design of plate heat exchangers can contribute to their longevity. This includes features such as improved plate geometry, enhanced flow distribution, and reinforced gasket designs. These design elements help reduce wear and tear, minimize fouling, and improve overall performance, thereby extending the operational life of the exchanger.Expand Specific Solutions03 Maintenance and cleaning techniques

Regular maintenance and effective cleaning procedures are crucial for prolonging the life of plate heat exchangers. This includes periodic inspections, proper cleaning methods to remove fouling and scale buildup, and timely replacement of worn components. Implementing these practices helps maintain optimal performance and prevents premature failure of the equipment.Expand Specific Solutions04 Advanced coatings and surface treatments

Applying specialized coatings or surface treatments to plate heat exchanger components can enhance their durability. These treatments can improve corrosion resistance, reduce fouling, and minimize wear. Examples include anti-fouling coatings, hydrophobic treatments, and hardening processes that extend the operational life of the exchanger plates and other critical components.Expand Specific Solutions05 Monitoring and control systems

Implementing advanced monitoring and control systems can contribute to the longevity of plate heat exchangers. These systems can detect early signs of performance degradation, monitor operating conditions, and optimize process parameters. By enabling proactive maintenance and preventing excessive stress on the equipment, these systems help extend the overall lifespan of the heat exchangers.Expand Specific Solutions

Key Players in Heat Exchanger Industry

The market for material innovations in long-lasting plate heat exchangers is in a growth phase, driven by increasing demand for energy-efficient heat transfer solutions across various industries. The global plate heat exchanger market is expected to reach significant size in the coming years, with a compound annual growth rate of around 6-8%. Technologically, the field is advancing rapidly, with companies like Alfa Laval, SWEP International, and Vahterus Oy leading innovation in materials and design. These firms are developing new alloys and surface treatments to enhance corrosion resistance and thermal efficiency. Emerging players such as Resonac Packaging and Mitsubishi Shindoh are also contributing to material advancements, particularly in specialized applications. The technology's maturity varies across different sectors, with some industries adopting cutting-edge solutions while others still rely on traditional materials.

Alfa Laval Corporate AB

Technical Solution: Alfa Laval has developed innovative material solutions for long-lasting plate heat exchangers, focusing on corrosion resistance and thermal efficiency. Their AlfaNova fusion-bonded plate heat exchangers use 100% stainless steel construction, eliminating the need for gaskets and brazing materials[1]. This technology allows for operation in extreme temperature and pressure conditions. Additionally, Alfa Laval has introduced a new copper-based alloy, ALOneTM, specifically designed for seawater applications. This material offers superior resistance to crevice corrosion and stress corrosion cracking compared to traditional titanium plates[2]. The company has also implemented advanced surface treatments, such as their CurveFlowTM technology, which enhances heat transfer efficiency while reducing fouling[3].

Strengths: Superior corrosion resistance, high thermal efficiency, and ability to operate in extreme conditions. Weaknesses: Potentially higher initial costs compared to traditional materials and limited application in certain industries due to specialized designs.

Swep International AB

Technical Solution: Swep International AB has made significant advancements in material innovations for long-lasting plate heat exchangers. Their focus has been on developing high-performance, corrosion-resistant materials that can withstand demanding operating conditions. Swep has introduced a proprietary stainless steel alloy, SwepAlloyTM, which offers enhanced resistance to both general and localized corrosion[1]. This alloy is particularly effective in applications involving aggressive media and high temperatures. Additionally, Swep has developed a unique copper brazing process that creates stronger, more durable joints between plates, improving the overall lifespan of their heat exchangers[2]. The company has also implemented advanced surface treatments, such as their AsymetricFlowTM technology, which optimizes flow distribution and heat transfer while minimizing the risk of fouling and scaling[3].

Strengths: High corrosion resistance, improved durability, and optimized heat transfer efficiency. Weaknesses: Potentially higher production costs and limited compatibility with certain fluids due to specialized alloy composition.

Innovative Material Technologies

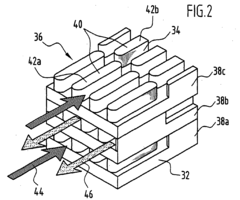

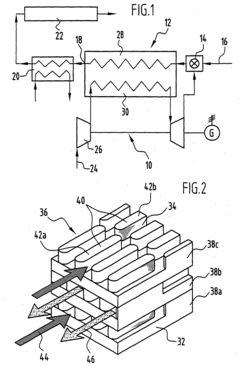

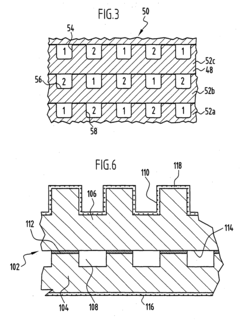

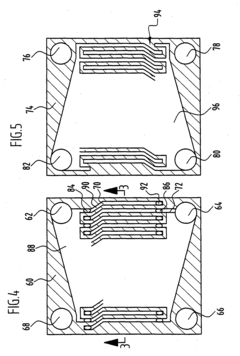

Heat exchanger plate, plate heat exchanger provided therewith, and method for manufacturing a plate heat exchanger

PatentInactiveEP2588827A2

Innovation

- The use of ceramic materials, specifically silicon carbide, for heat exchanger plates with channel webs that form channel walls to stabilize the flow channels and the plate substrate, allowing for thinner layers without mechanical destabilization, and enabling effective heat transfer through a stacked arrangement.

Plate heat exchanger, process for manufacturing a plate heat exchanger, and ceramic fibre reinforced composite material, more particularly for plate heat exchanger

PatentInactiveEP1544565A2

Innovation

- The use of short-fiber-reinforced ceramic composite materials, such as C/C-SiC, with channels formed in plates made of silicon carbide or silicon nitride, and an anti-corrosion layer like cordierite or yttrium silicate, which reduces brittleness and provides high-temperature resistance and corrosion protection.

Corrosion Resistance Strategies

Corrosion resistance is a critical factor in the longevity and efficiency of plate heat exchangers, particularly in harsh operating environments. To address this challenge, several innovative strategies have been developed and implemented in recent years.

One of the most effective approaches is the use of advanced materials with inherent corrosion-resistant properties. Titanium and its alloys have gained significant traction due to their exceptional resistance to various corrosive media. These materials offer excellent protection against both general and localized corrosion, making them ideal for applications in chemical processing and seawater environments.

Another promising strategy involves the application of protective coatings. Thin-film coatings, such as those based on titanium nitride (TiN) or diamond-like carbon (DLC), have shown remarkable success in enhancing the corrosion resistance of traditional materials like stainless steel. These coatings not only provide a barrier against corrosive agents but also improve the overall surface properties of the heat exchanger plates.

Surface modification techniques have also emerged as effective corrosion resistance strategies. Laser surface alloying and plasma electrolytic oxidation are two innovative methods that can significantly enhance the corrosion resistance of metallic surfaces. These processes create a modified surface layer with improved chemical stability and mechanical properties.

The development of self-healing materials represents a cutting-edge approach to corrosion resistance. These materials incorporate microcapsules or vascular networks filled with healing agents that are released upon damage, effectively sealing cracks and preventing corrosion progression. While still in the early stages of development for heat exchanger applications, self-healing materials show great promise for extending equipment lifespan.

Electrochemical protection methods, such as cathodic protection and anodic protection, continue to play a crucial role in corrosion prevention. Recent advancements in these techniques include the development of smart cathodic protection systems that can adjust their output based on real-time corrosion monitoring data, ensuring optimal protection under varying operating conditions.

Lastly, the integration of nanotechnology in material design has opened new avenues for corrosion resistance. Nanostructured materials and nanocomposites offer enhanced corrosion resistance due to their unique surface properties and ability to form stable passive layers. These materials are particularly promising for applications requiring both high corrosion resistance and excellent heat transfer characteristics.

One of the most effective approaches is the use of advanced materials with inherent corrosion-resistant properties. Titanium and its alloys have gained significant traction due to their exceptional resistance to various corrosive media. These materials offer excellent protection against both general and localized corrosion, making them ideal for applications in chemical processing and seawater environments.

Another promising strategy involves the application of protective coatings. Thin-film coatings, such as those based on titanium nitride (TiN) or diamond-like carbon (DLC), have shown remarkable success in enhancing the corrosion resistance of traditional materials like stainless steel. These coatings not only provide a barrier against corrosive agents but also improve the overall surface properties of the heat exchanger plates.

Surface modification techniques have also emerged as effective corrosion resistance strategies. Laser surface alloying and plasma electrolytic oxidation are two innovative methods that can significantly enhance the corrosion resistance of metallic surfaces. These processes create a modified surface layer with improved chemical stability and mechanical properties.

The development of self-healing materials represents a cutting-edge approach to corrosion resistance. These materials incorporate microcapsules or vascular networks filled with healing agents that are released upon damage, effectively sealing cracks and preventing corrosion progression. While still in the early stages of development for heat exchanger applications, self-healing materials show great promise for extending equipment lifespan.

Electrochemical protection methods, such as cathodic protection and anodic protection, continue to play a crucial role in corrosion prevention. Recent advancements in these techniques include the development of smart cathodic protection systems that can adjust their output based on real-time corrosion monitoring data, ensuring optimal protection under varying operating conditions.

Lastly, the integration of nanotechnology in material design has opened new avenues for corrosion resistance. Nanostructured materials and nanocomposites offer enhanced corrosion resistance due to their unique surface properties and ability to form stable passive layers. These materials are particularly promising for applications requiring both high corrosion resistance and excellent heat transfer characteristics.

Environmental Impact Assessment

The environmental impact of plate heat exchangers (PHEs) is a critical consideration in their design, manufacturing, and operation. Long-lasting PHEs contribute significantly to sustainability efforts by reducing the need for frequent replacements and minimizing waste generation. Material innovations play a crucial role in enhancing the longevity and environmental performance of these heat transfer devices.

One of the primary environmental benefits of durable PHEs is the reduction in raw material consumption. By extending the operational lifespan of these components, fewer resources are required for manufacturing replacement units. This decrease in material demand leads to lower energy consumption and reduced emissions associated with the extraction, processing, and transportation of raw materials.

The use of advanced, corrosion-resistant materials in PHE construction contributes to improved water quality and reduced chemical usage. Traditional materials often require frequent cleaning and treatment with harsh chemicals to prevent fouling and scaling. Innovative materials with enhanced surface properties can minimize these issues, reducing the need for chemical treatments and the subsequent release of potentially harmful substances into the environment.

Energy efficiency is another crucial aspect of the environmental impact of PHEs. Long-lasting, high-performance materials can maintain optimal heat transfer efficiency over extended periods, resulting in reduced energy consumption in various industrial processes. This improved energy efficiency translates to lower greenhouse gas emissions and a decreased carbon footprint for the facilities utilizing these heat exchangers.

The end-of-life considerations for PHEs are also influenced by material innovations. Advanced materials that are more easily recyclable or biodegradable can significantly reduce the environmental burden associated with disposal. Furthermore, the development of materials that enable easier disassembly and component separation facilitates more effective recycling processes, promoting a circular economy approach.

Water conservation is an additional environmental benefit of long-lasting PHEs. By maintaining their efficiency and reducing the frequency of cleaning and maintenance operations, these heat exchangers can contribute to decreased water consumption in industrial processes. This is particularly significant in water-stressed regions where conservation efforts are critical.

In conclusion, material innovations for long-lasting plate heat exchangers have far-reaching environmental implications. From reduced resource consumption and improved energy efficiency to enhanced recyclability and water conservation, these advancements play a vital role in minimizing the environmental footprint of industrial heat transfer operations. As research in this field progresses, it is expected that future PHEs will continue to offer increasingly sustainable solutions for various applications.

One of the primary environmental benefits of durable PHEs is the reduction in raw material consumption. By extending the operational lifespan of these components, fewer resources are required for manufacturing replacement units. This decrease in material demand leads to lower energy consumption and reduced emissions associated with the extraction, processing, and transportation of raw materials.

The use of advanced, corrosion-resistant materials in PHE construction contributes to improved water quality and reduced chemical usage. Traditional materials often require frequent cleaning and treatment with harsh chemicals to prevent fouling and scaling. Innovative materials with enhanced surface properties can minimize these issues, reducing the need for chemical treatments and the subsequent release of potentially harmful substances into the environment.

Energy efficiency is another crucial aspect of the environmental impact of PHEs. Long-lasting, high-performance materials can maintain optimal heat transfer efficiency over extended periods, resulting in reduced energy consumption in various industrial processes. This improved energy efficiency translates to lower greenhouse gas emissions and a decreased carbon footprint for the facilities utilizing these heat exchangers.

The end-of-life considerations for PHEs are also influenced by material innovations. Advanced materials that are more easily recyclable or biodegradable can significantly reduce the environmental burden associated with disposal. Furthermore, the development of materials that enable easier disassembly and component separation facilitates more effective recycling processes, promoting a circular economy approach.

Water conservation is an additional environmental benefit of long-lasting PHEs. By maintaining their efficiency and reducing the frequency of cleaning and maintenance operations, these heat exchangers can contribute to decreased water consumption in industrial processes. This is particularly significant in water-stressed regions where conservation efforts are critical.

In conclusion, material innovations for long-lasting plate heat exchangers have far-reaching environmental implications. From reduced resource consumption and improved energy efficiency to enhanced recyclability and water conservation, these advancements play a vital role in minimizing the environmental footprint of industrial heat transfer operations. As research in this field progresses, it is expected that future PHEs will continue to offer increasingly sustainable solutions for various applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!